MARKET OVERVIEW

The global split case pumps market has been greatly influential in past and continues to influence water and fluid handling across most sectors. Split-case pumps are rugged and efficient; therefore, they find applications in a variety of sectors like water industry, fire protection, and industrial processes. Huge bulk-handling fluid equipment creates the demand across municipal and industrial applications for these pumps.

As technologies and industries grow, so will the Global Split Case Pumps market concerning design and functionality. What distinguishes this split-case design and makes it easier to handle and maintain out of so many other pumps is the actual feature that allows for disassembly and reassembly of the split casing without disturbing the pipework, which has strongly influenced their use in difficult applications in which reliability and serviceability come first.

Advanced technology and materials could be expected to lead in the market in the foreseeable future. High on the list will be the initiatives by manufacturers to come up with corrosion- and wear-resistant materials that improve efficiency. The positive influences would be vast on the one hand regarding split-case pumps' efficiency enhancement, and this very aspect will keep strategic importance for all pump systems in industries hungry for reliability.

In the energy industry, the driving forces behind demand for split case pumps will be the efficient transfer of fluids within Machines utilized for energy generation and distribution. In that aspect, these pumps will be fundamental to handling flow rates and subsequently to controlling processes in power and oil-and-gas companies. As demand for energy continues to grow and infrastructure development reaches its peak, the global demand for split case pumps will be varied, with some emphasis placed on extreme conditions and variable flow operation considerations.

The municipal water sector will also remain a very lucrative market for split case pumps especially because of water treatment and distribution applications. Pumps will therefore be needed that guarantee constant performance to ensure dependable water supply systems. Split case pumps shall answer the call with their strength and ability to handle large flow rates of water effectively.

The trends of automation and smart technologies in industrial sectors will be another factor pushing the Global Split Case Pumps market. Future developments on the digital monitoring and control systems will bring further improvement in pump operational efficiency. Such advanced control system will deploy extensive meaningful features, such as sensors and data analytics, thereby real-time monitoring and maintenance, reducing unplanned downtime and increasing performance.

Global Split Case Pumps market is estimated to reach $14101.4 Million by 2032; growing at a CAGR of 6.5% from 2025 to 2032.

GROWTH FACTORS

The Global Split Case Pumps market seems to be on a ramp. Within the pumping industry, this segment may see a continuum because of certain major factors: One of the chief factors driving the demand for split case pumps is the increased infrastructure development in the world. These pumps are preferred for large water supply schemes and wastewater treatment projects due to their efficiency and sturdiness. Thus, with the increase in urbanization and new infrastructure projects, the demand for reliable pumping solutions will increase too.

The other market driver is technological advancement. Novel design and manufacturing technologies of pumps will enable more efficiency and better performance of split case pumps. For instance, practically all new split-case pumps being engineered these days come under the umbrella of energy-efficient pumps, and this is something rather pertinent in our low energy-use-and-carbon-footprint world. The smartness of these pumps has made even a potential augmentation for flexible work under a different operation environment, thereby becoming even much more critical for industries aspiring for process optimization.

On the contrary, there are a few factors that will either support or throw a spanner in the works when it comes to the Global Split Case Pumps market. Firstly, the advanced split case pumps come with a very high upfront price tag. Although it shall propel the savings and efficiency over a life cycle, its upfront price tag is still enormous, making it rather difficult for smaller companies or small projects with limited budgets to afford. Secondly, raw material prices could influence the production cost of split case pumps, making sales prices to the end-user even higher.

But with that in mind, some lucrative opportunities are also on the way for this market going by the horizon. Increasing emphasis on water conservation and management opens opportunities for split-case pumps. With stricter regulations coming in on water, industries and municipalities would be on the lookout for better, efficient, and reliable pumping solutions. As developing economies revive industrial activities, the demand for split-case pumps will be increasing since these economies invest in infrastructure and industrial development.

The net effect is that the Split Case Pumps Market is expected to grow on an account of infrastructural development and technological advancement, but there are lots of hurdles it has to cross and sustain through, of which some are related to high initial costs and fluctuating prices of raw materials. Another side will be for water management and industrial expansion, which will provide mammoth growth opportunities in the coming years.

MARKET SEGMENTATION

By Type

It is important to accentuate the particular sub-markets that would create surety and have already influenced the Global Split Case Pumps market and will continue to do so going forward. In this regard, the split case pumps are having high capacity, low relative cost and highly durable, making by definition attractive for application in a variety of fields: water supply, irrigation and industrial processes. The way forward is obviously putting itself on technology advancement and efficiency enhancement within the market.

There are primarily two types of Global Split Case Pumps, which are horizontal and vertical split-case pumps. The defining case of horizontal split-case pumps is that the pump shaft is aligned horizontally. It gives easy access to the internal components; therefore, installation and maintenance become easy such that repairs and service are facilitated. This type is mainly suitable in applications where space does not matter much especially where the pump has to handle high flow rates. To keep pace with these demands, the horizontal split-case pumps will continue to be in demand as industries strive for enhanced operational efficiency, reduced downtime, and minimized manifold losses.

Apart from having vertical shaft pumps, such pumps are also referred to as vertical split casing pumps and are thus more favorable to installations in which space is limited. Their designs tend to be space-saving and often help towards a more compact design of the whole system. This is to say that vertical pumps are preferred in places where installation space is small, or height restrictions on the installment are few. This design also possesses features that are good for applications needing a lot of pressure and are placed above the water source.

The reason is that both pumps will take advantage of the techno innovations through their quest for a greater degree of energy efficiency. The direction that manufacturers will most likely follow regarding that trend will be to enhance the performance and reliability of these pumps in order to meet the always increasing and varying needs of industries. In the future, as the Global Split Case Pumps market evolves, differentiation between horizontal and vertical types will base itself on their respective areas of applications and later changing needs of end-users.

By Material

In a very intrinsic way, the Global Split Case Case Pumps market is a segment of pumps because there are lots of applications one could think of from a different viewpoints, whether it is with respect to materials or otherwise. It is classified broadly into four main material types: Cast Iron, Stainless Steel, Alloy, and Others. Each of the materials has its pros and cons and are generally selected for specific needs.

The highest consumption in the Global Split Case Pumps market has come from Cast Iron. This material is characterized by its superior strength and well suited in applications of heavy-duty in which a pump will have to put up with a lot of wear and tear. Most users in an industry segment regarding water and wastewater management prefer it because of cost-effectiveness and reliability.

Another major material is stainless steel, which will also be used because it is resistant to corrosion and high temperatures, making it applicable in any application in which a pump might be exposed to severe chemicals or extreme temperatures. Stainless Steel pumps are now used in pharmaceutical and food processing industries where cleanliness and endurance are the controlling factors.

Combining different metals into alloys creates special metals with some unique qualities absent in either Cast Iron or Stainless Steel. Alloys are primarily designed to improve pump performance and life under specific applications. They have a unique utility for certain conditions: chemical or temperature, requiring special resistance and strength.

Thus, the remaining portion of materials not falling under the categories defined above is embodied in the "Others" section. This would include advanced composites and specialty materials tailored for rather specific, narrow applications. These, however, could still be on the pipeline to advanced technology development so that even newer materials could be made available in such high performance and efficiency.

Of course, the prospects with regard to the Global Split Case Pumps market are very bright, not to mention innovations and growth. Most likely, advances in materials science would bring developments in new and better pump materials with some improved properties, making these vital components last even longer. Of course, it would continuously manage challenging demands as they change along with more specialized solutions such that the Split Case Pumps market would always have increasingly sophisticated options with respect to that.

The Global Split Case Pumps market is an industry in dynamism, ready for its next steps into the future with respect to materials such as Cast Iron, Stainless Steel, Alloy, and Others. Each material category will thus play an important role in the quest to cater to such diversified application areas through technological developments and industry demands.

By Application

The global split-case pumps market creates itself as a necessary component of the international industrial scene. These pumps feature a split casing which makes it easy to service and repair them. These pumps find various applications due to all the above aspects. The new technologies developed by the requirements of several sectors have driven this particular market.

As mentioned above, the Global Split Case Pumps market will grow with the passage of time because there will be many applications. Primarily, municipalities will continue being prominent sectors. The increasing size of cities and the increase in their people obviously necessitate proper efficient distribution systems for water to drive demand for split case pumps. These works are especially suited with large volumes of water being treated and thereby reliable supply of such water.

Split-case pumps are most important when it comes to the handling and treatment of wastewater in the area of industrial wastewater. Industrialization is increasing and there is an increasing concern for the environment; hence, effective wastewater management is surely going to create good prospects for these pumps. Their robust design therefore enables them to work well under tough condition hence very suitable for such operations.

The oil and gas industry is the second largest market for split-case pumps. These pumps are getting more and more important in this segment in the oil and gas extraction process. They are used to pump very different types of fluids under very high pressure and very high temperatures. And with energy demands still soaring and new areas opening up for exploration, the need for even more reliable pumping solutions is bound to increase.

The production of electricity is another essential area for which very special pumps are used. These are called split case pumps and they have been used in the power plants within their cooling systems because they are able to move really large amounts of water. Since the world keeps moving towards most renewable sources of energy and is also setting up new power plants, the demand for these kinds of super high end pumping solutions will rise even further.

In addition, a lot of these will probably turn to split-case pumps, especially the chemical sector for the movement of corrosive and abrasive fluids, as well as the pulp and paper industries and steel plants. As these sectors grow and mature, the demand for strong, efficient, well- sized pump systems will also grow.

Some other niche applications will be district heating and cooling systems soaking areas. In this, split case pumps are utilized for thermal energy distribution management in district heating and cooling and in mining, serve water and slurry duties under exceptionally tough environmental conditions.

The current Global Split Case Pumps market has a bright outlook, spurred on by the municipal water, industrial wastewater, oil and gas, power generation, and chemicals sectors. Such fast-growing industries with expansion needs will require a continuous stream of reliable and effective pumping solutions.

By End-User

The Global Split Case Pumps market is a very vibrant and vital area of pumping technology in view of its rapid evolution and forecasted key changes in coming years. Primarily, there are four basic end-user categories: industrial, commercial, municipal, and residential, all having a crucial role in forming its total structure.

Within industrial applications, split case pumps are one of the main components for any plant due to their robust construction that allows them to handle large volumes of fluid. They are applied in manufacturing, mining, and energy industries. With industrial growth and the emergence of new technologies for manufacturing, the demand for industrial split case pumps will be on the rise, therefore increasing the demand for reliable and high-performance pumping solutions.

Split case pumps are used mainly for commercial purposes in the likes of shopping malls, office buildings, and hotels. Due to rapid urbanization, commercial buildings are becoming a necessity, being in most cases structurally complex, which calls for more efficient water and HVAC systems. Split case pumps will greatly help achieve this with their longevity and energy efficiency. Future enhancements will see even more smart technologies embedded into pumps for maximized performance and lowered energy usage.

Municipal applications of the split case pump are into importance for functioning water supply and sewage systems for many cities and towns. The future uninterrupted global population increase coupled with urbanization will exert greater strains on municipal water and waste systems. The importance of split case pumps will be found with ensuring that such municipal systems run into minimal hitches and problems. In conjunction with better technology and infrastructure, more complex pumps could be designed, such that they handle bigger volumes and service.

The residential ones are not too different, although they are rare. Primarily, these pumps find their usage in residential applications in large buildings or complexes that require effective water distribution systems. As residential areas and building technology evolve, so will demand for split case pumps within such environments. Any future advancement in this regard is likely to be driven by the design and the efficiencies of the pump.

The overall outlook for the global split case pumps market will change with technological advancements and different demands for its various user categories. Growth and change in this market are defined by industrial, commercial, municipal, and residential segments. Split-case pumps thus will remain an integral part of the continued growth and change across these industries providing efficient and balanced fluid handling solutions worldwide.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$9100.0 million |

|

Market Size by 2032 |

$14101.4 Million |

|

Growth Rate from 2025 to 2032 |

6.5% |

|

Base Year |

2025 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

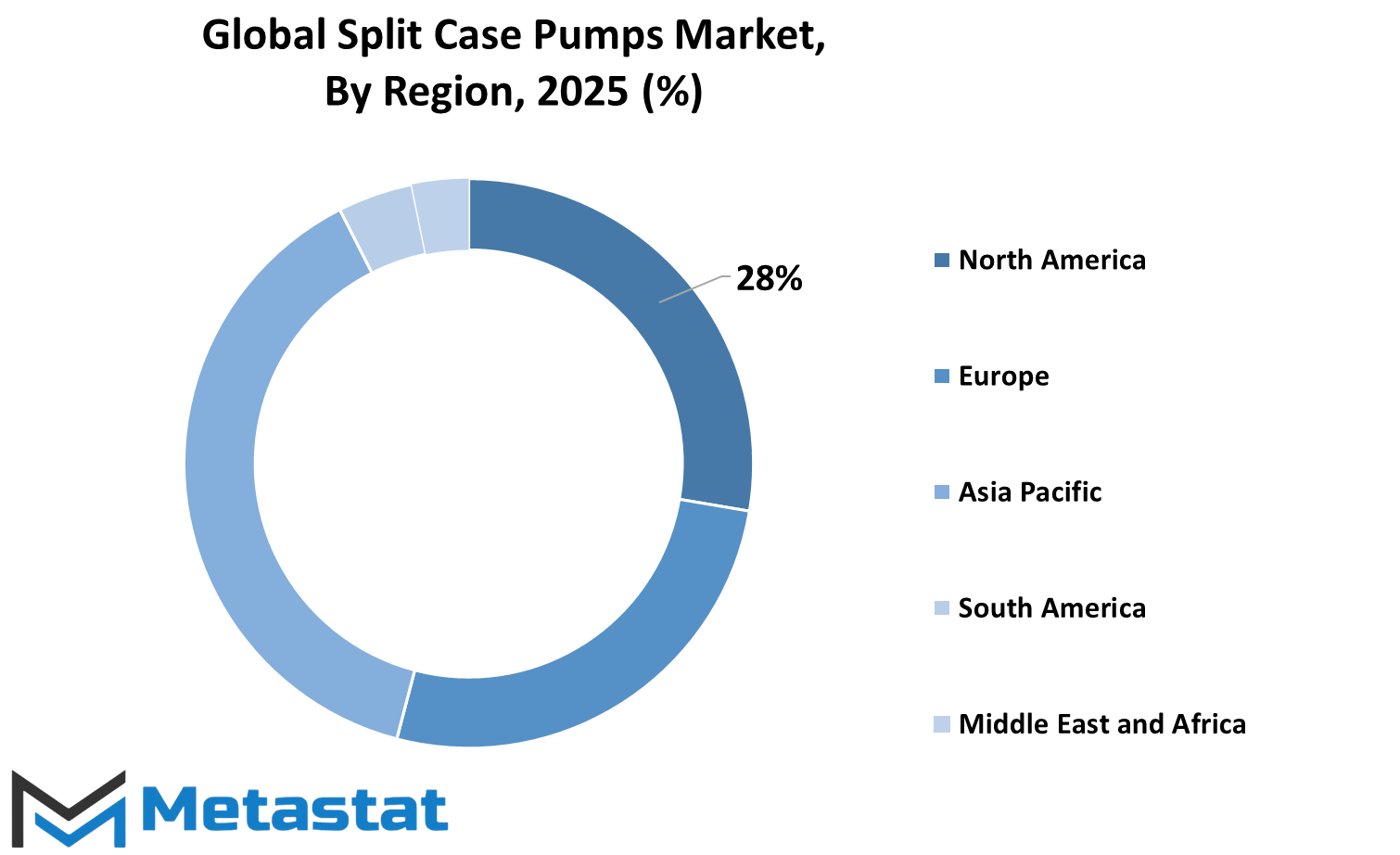

REGIONAL ANALYSIS

Geographical diversity stands as a significant characteristic of the regional segmentation in the global split case pumps market impacting its dynamics. In its turn, each of these regions confers special features and growth patterns that could define future development of the market.

The North American region, including the U.S., Canada, and Mexico, has also significantly contributed to the global market due to the fact that infrastructural development and technological advancement are already in the region, with considerable contribution continuing from thereon. Demand for split case pumps in North America will see further growth due to several industrial and municipal projects as well as enhanced developments in energy-efficient technologies.

Europe, with the largest markets in the region being the UK, Germany, France, Italy, and the rest of Europe, is expected to pose strength in the global split-case pumps market. The European market is characterized by high-quality standards and modern technologies. The sustainability and energy-efficiency trend in Europe will further propel the growth of advanced split-case pump systems in the region, keeping in line with environmental regulations and energy-saving targets.

The Asia-Pacific region, which includes the growing economies of India, China, Japan, South Korea, and the rest of the region, is anticipated to show considerable growth in the split case pumps market in the near future. Rapid industrialization, urbanization, and infrastructure development in these countries will most likely propel demand. Another factor inducing growth in the region is the booming manufacturing industry in addition to the ongoing modernization trend of water supply and sewage systems in these respective countries.

In South America, including Brazil, Argentina, and the rest of South America, the split case pumps market is likely to witness gradual growth. Growth will be driven mainly by investments related to infrastructure and industrial projects. Also, the demand for efficient and reliable pumping solutions for water management and other applications will turf the development of the market in the region.

The Middle East & Africa, comprising GCC countries, Egypt, South Africa, and the rest of the region, will also bolster the worldwide split case pumps market. Infrastructure and industrial developments will be the driving force for demand in the Middle East. In Africa, improvements in water supply systems and development projects are expected to lend support toward market growth.

The Global Split Case Pumps market, in general, will be conditioned by regional demands and developments. The scenario will be different for every region based on the individual requirements and opportunities for growth, consequently creating their own possibilities and problems for the stakeholders.

COMPETITIVE PLAYERS

The increase in technological innovations along with the growing industrial needs is going to reinforce the market for global split case pumps. This is how the market is expected to perform in the future due to these innovations in the designs of the efficient pumps. Split-case pumps among the robust and most versatile pumps find increasing applications in water treatment, agriculture, and construction. This growth is driven by the reliability and efficiency in fluid handling required for high demand operational conditions.

These are the areas that the key players in the Global Split Case Pumps market such as KSB SE & Co. KGaA and ITT Goulds Pumps, Sulzer Ltd and Flowserve Corporation have focused on. Companies have been investing heavily in research and development to achieve better pump performances and enhance the service life of pumps. They are also implementing advanced materials and technologies in making the efficiency improvement include reduced maintenance requirements.

Undoubtedly, there is more that companies like Grundfos, Xylem Inc., and WILO SE add by innovating solutions to meet the sublime growth demand of the sectors. From energy-efficient designs to highly smart pump systems that feature advanced control and monitoring capability, the innovations keep coming from such firms and are expected to continue during future pump technology innovation.

Among these, Peerless Pump Company, EBARA Corporation, and Ruhrpumpen Group dominate the market because of their global presence and diverse split case pumps, manufactured to fit any of the major applications. Their existence in the market, along with having large diversified product lines, assists them in achieving very different requirements from their customer base over the geography. Other important players include Kirloskar Brothers Limited and Torishima Pump Mfg. Co., Ltd. Their contributions have increased the growth of the entire market as these companies deliver reliable quality pump solutions.

All that makes the fore runners for the Global Split Case Pumps market includes ANDRITZ Pumps, Pentair plc, as well as Patterson Pump Company, who come up with the most innovative pump technologies for the problems in the industries at hand. Well this is all regarding them being innovative as well as going towards the healthy customer satisfaction. Other players such as SPP PUMPS and Crane Pumps & Systems go on perfecting their pump performance and efficiency making sure that the market grows.

Thus, almost the entire future of the Global Split Case Pumps market shall be determined by these leading participants. Their innovation commitment and growing industrial needs will drive the continuous evolution of split case pump technologies. This would continue to make more sure, all that more efficient, more reliable, and cost-effective solutions shall emerge to meet the demands of the rapidly changing world.

Split Case Pumps Market Key Segments:

By Type

- Horizontal

- Vertical

By Material

- Cast Iron

- Stainless Steel

- Alloy

- Others

By Application

- Municipal Water

- Industrial Waste Water

- Oil, Gas, and Power Generation

- Chemical

- Pulp and Paper

- Steel Plant

- District Heating

- District Cooling

- Mining

- Others

By End-User

- Industrial

- Commercial

- Municipal

- Residential

Key Global Split Case Pumps Industry Players

- KSB SE & Co. KGaA

- ITT Goulds Pumps

- Sulzer Ltd

- Flowserve Corporation

- Grundfos

- Xylem Inc.

- WILO SE

- Peerless Pump Company

- EBARA Corporation

- Ruhrpumpen Group

- Kirloskar Brothers Limited

- Torishima Pump Mfg. Co., Ltd.

- ANDRITZ Pumps

- Pentair plc

- Patterson Pump Company

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252