MARKET OVERVIEW

The Global Sheet Molding Compound (SMC) market is expected to witness heavy growth in the coming years mainly due to its increased adoption in various sectors, including automotive, electrical, and construction. Being a material, SMC is prepared as a combination of polyester resin and reinforcing fibers, which has become an integral part in the manufacturing of lightweight yet strong parts. Since this material is easily molded to take complex shapes while offering enhanced mechanical properties, it is better suited for applications requiring both strength and flexibility. As industries seek more efficient and sustainable ways of production, the Global Sheet Molding Compound (SMC) market is expected to expand further as companies look to include SMC in their offerings.

The market for SMC is very big, cutting across a myriad of application ranges. In the automotive industry, for example, it shall be crucial in the design of lighter vehicles since weight reduction is still a key factor in improving fuel efficiency. The versatility of SMC will allow manufacturers to produce a very lightweight yet stress-resistant component such as body panels, hoods, and bumpers in vehicles. A significant advantage in the electrical industry is that there will be higher usage of SMC because it provides excellent insulation properties in the form of electrical enclosures, circuit breakers, and other high-voltage equipment. It also offers resistance to severe environmental conditions, hence applicable in many outdoor applications.

The construction industry will also experience an increased rate of utilization in SMC because of the newly discovered uses including structural parts such as door panels, roofing materials, and facades. This molding complexity makes possible the maximum of creative freedom in architectural design, and the durability of the material will ensure great and long-lived constructions in different climates. To add more, the already growing requirement for sustainability and energy efficiency in construction materials makes SMC a more environmentally friendly choice when compared to metals and plastics used in the industry.

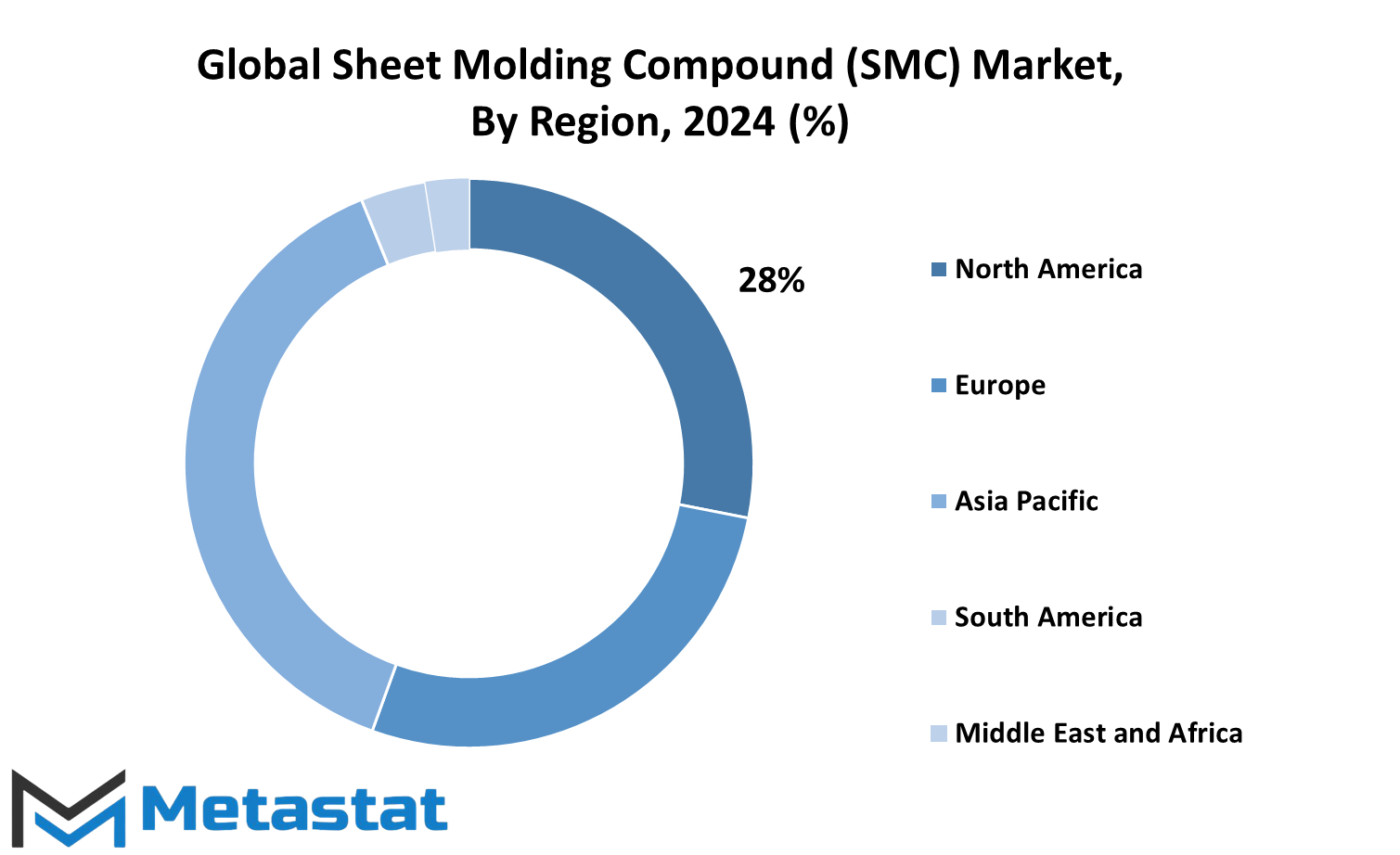

The Global Sheet Molding Compound (SMC) market geographically is expected to witness high action across key regions. North America and Europe would maintain their strength in the market primarily because of their well-developed manufacturing activities and large-scale auto and electrical industries. Asia-Pacific would be the home ground for booming industrial activities and rapid investment in manufacturing technology, increasingly becoming a base for SMC production and consumption. Other regions that will see emerging opportunities include Latin America and the Middle East, due to increased demand for modern solutions in construction and automotive applications, among which will be demands for stronger yet efficient materials like SMC.

The Global Sheet Molding Compound (SMC) market shall be influenced by innovation and technological advancement in the future. As the industries continue to demand performance materials offering excellent properties such as heat, moisture, and chemical resistance, SMC will most likely be at the center of the point in material engineering. Manufacturers will work on improving methods in producing SMC at a lower cost to enhance the material’s performance and beat competition from high demand arising in different sectors. Grow with the demand of sustainability, where the market will slowly change toward such sustainability alternatives without compromising on quality and performance. With more SMC prove itself to be reliable, versatile, and cost-effective material, market presence is sure to increase in the coming years.

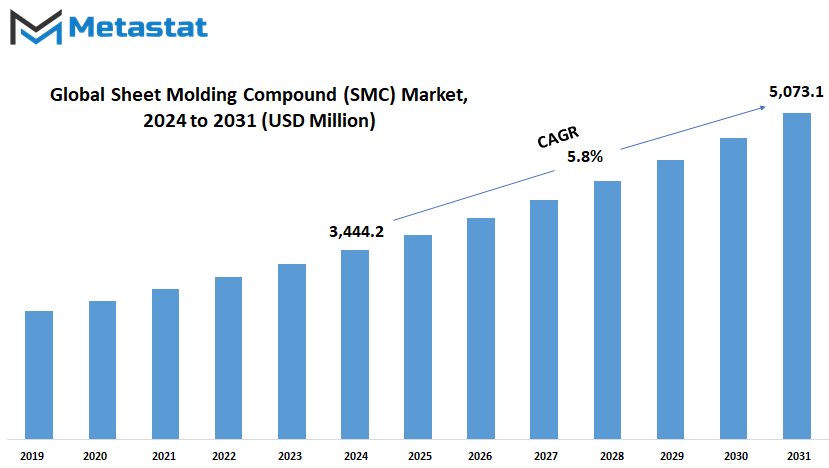

Global Sheet Molding Compound (SMC) market is estimated to reach $5,073.1 Million by 2031; growing at a CAGR of 5.8% from 2024 to 2031.

GROWTH FACTORS

The Global Sheet Molding Compound (SMC) market is expected to grow steadily over the coming years. One of the most important reasons for this trend is the increasing demand for lighter but stiffer parts, especially within the automotive sector. In their pursuit of greater environment-friendliness, automotive companies are increasingly being pushed to look for alternatives that cut down on fuel consumption and carbon emissions. The need for these kinds of demands indeed creates a requirement for materials that are not only strong and robust but, above all, very light in weight. SMC materials have bridged this requirement very nicely. They offer an outstanding ratio of strength-to-weight, which makes the material excellent for automotive parts, such as body panels, bumpers, and components of interior applications. As the pressure for greener, more efficient vehicles continues, the demand for SMC over time will continue to increase.

Advances in 3D printing technologies also offer new grounds to SMC market. Due to the added complexity and structural contours that are achievable with these technologies, 3D printing has made possible to produce SMC components in a manner which can be relatively cheaper and efficient. Such development might become important in industries where precision and customization are cardinal. An even more significant demand for SMC materials can be seen because the ability to quickly produce intricate parts meeting specific performance criteria is possible.

However, challenges abound for Global Sheet Molding Compound (SMC) market to harness its true potential. The unavailability of some grades of SMC is likely to seriously hamper sourcing of components in small quantities or for niche applications. Since these specific demands cannot always be imposed by the manufacturing process, this might slightly delay production and discourage flexibility. Uniform properties may sometimes be tough to obtain in different batches of SMC material. This variation in performance might compromise the material’s possibility of upholding high standards, where precision and reliability are strictly called upon by demanding industries like aerospace and automobiles.

Despite these challenges, the market still offers significant opportunities, especially as advancements in SMC materials and manufacturing processes continue. One place of promising applications is the development of advanced thermal management systems. In aerospace, automotive, and energy storage industries, it is extremely critical to effectively manage the heat, as it keeps the components operating within a safe and efficient regime. As newer developments are being seen in SMC materials with increasing thermal solutions, the demand is expected to gain higher prospects through subsequent years, henceforth; the market will experience more growth in the future years. As such changes remain under the limelight, the Global Sheet Molding Compound (SMC) market should also regain growth amidst such challenges.

MARKET SEGMENTATION

By Resin Type

Demand for Global Sheet Molding Compound (SMC) market is going to grow significantly in the coming years, as its scope across many various industries increases. As such, this material, mainly used for manufacturing automotive and electrical parts and parts for construction, possesses some particular benefits, such as high strength, light, and easy to mold. Among the various resins available for SMC production, Polyester and Vinyl Ester are the most significant segments. In terms of value, the Polyester Resin only accounted for 1942.8 million USD in 2021, which speaks to the huge popularity and level of demand for the same within the industries.

Polyester resin is the most widely used in SMC market for its excellent properties, such as low cost, durability, good resistance to chemicals and environmental factors. In addition, it is quite widely used for lightweight and high-strength components in the automotive industry, which is gaining attention for weight reduction to maintain good fuel efficiency by the automobile industries around the world. These recent trends are consistent with the trend towards electric vehicles, which necessitates materials that allow weight reduction without compromising on safety. The Vinyl Ester resin, although niche, has a wider demand because of its excellent performance in corrosion and heat resistance and is one of the raw materials with promising potential for application in the electrical industry, marine, wind energy, and others demanding industries with high-performance requirements. As more and more industries realize and adopt strategies to encourage sustainable practices, there will be huge growth in the use of Vinyl Ester in SMC production as this endures better and has better performance.

In addition to these, Epoxy and other resin types like Phenolic and Polyurethane also account for some percentage of the market. These resins provide some exclusive advantages; good bonding properties with extreme temperature resistance qualify them for specific aeronautic and construction applications. The Global Sheet Molding Compound (SMC) market will go further with companies looking at ways to make other resins work even better.

As the world shifts towards more sustainable solutions, properties of SMC will continue to be upgraded to make it more versatile and cost-effective. The quest for high-performance materials like SMC is bound to gain momentum, especially as more industries prefer innovation that produces efficiency, cuts costs, and improves overall product performance. Continued innovation and diversification of resin types in the SMC market will ensure it remains an integral aspect of the manufacturing sector worldwide for a fairly long period of time.

By Fiber Type

The global sheet molding compound (SMC) market, going forward, is envisaged to witness a tremendous increase, supported by the evolution in the material technology and demand for the product in all segments. Mainly, the reasons for growth are contributed to SMC’s wide application area, especially in industries such as automobiles, construction, and consumer goods. This industry has experienced huge growth due to the increase in demand for strong, light, and durable material, and SMC has managed to gain immense usage as an alternative to conventional materials such as metal and plastic. The SMC market can be divided into different types based on the type of fiber used; all of them have an important role in deciding the overall market.

Global SMC market The Glass Fiber Reinforced SMC segment is the largest in the Global SMC market. In 2021, the glass fiber segment accounted for around 2331.4 USD million and remains one of the largest shares in the market’s growth. High strength/weight ratios are produced by the glass fiber reinforced SMC. Strength without heavy weights is therefore recommended in industries such as automotive and construction. Being one of the cheap SMC, the mechanical properties of this type of SMC are also excellent with good heat and corrosion resistance. With an increasingly greater need to withstand extreme conditions, demand for glass fiber reinforced SMC would go up further in the future.

The Carbon Fiber Reinforced SMC segment is relatively much smaller compared to the glass fiber segment but is gaining with superior strength and lesser weight. Carbon fiber reinforced SMC offers opportunities for some unique advantages that are not achievable with conventional materials, especially in weight-critical applications. Carbon fibers are highly prized by the automotive, aerospace, and sports equipment industries, among others, where maximum performance and weight optimization is at a premium. Therefore, as manufacturing technologies advance and cost of this new composite goes down, carbon fiber reinforced SMC is likely to become ever more significant to sectors within those industries. The potential applications of these materials will propel the market growth in the quest to achieve improved fuel efficiency and performance in vehicles, as well as the pursuit of sustainability initiatives.

Hybrid SMC is another fast-emerging trend: mixing together different types of fibers to maximize the properties of the material. Hybrid SMC has been gaining ground in the market due to the flexibility it offers in tailoring the properties of SMC to suit any specific application. Hybrid SMC currently offers unique advantages such as high strength, low weight, and cost-effectiveness by combining fibers made of glass and carbon. In an effort to meet the demands of customized solutions from industry, hybrid SMC is going to drive innovation for new opportunities in the global market. Conclusion Global Sheet Molding Compound SMC market is intended to grow as industries continue to target more advanced materials with a promise of strength, durability, and being lightweight. The advancement in glass fiber, carbon fiber, and hybrid SMC will cater to the varied requirements of different sectors, and such material is bound to come out on top in the future.

By Application

The global market for Sheet Molding Compound (SMC) will really boom in the future. Sheet Molding Compound is a material with not fragile, however light weight properties. More applications are discovered for this material across various industries and technologies. It will mainly be anticipated as technology advances and pushes for more efficient and sustainable alternatives that the demand for SMC will increase. Specifically, these are automotive, electrical and electronics, construction, aerospace and defense, consumer goods, and industrial equipment, and will dominate the future market.

Global Sheet Molding Compound (SMC) market will grow within automotive with significant focus on reduced weight of the vehicle to improve fuel efficiency and reduce emissions over time. Car makers are always wanting material innovation, and SMC fits the bill as being lightweight, strong, and durable. SMC use is widely found in automotive components such as bumpers, hoods, and door panels. The product will certainly see more significant adoption rates in electric vehicles within the near future since it can contribute to energy efficiency and performance, as sustainability continues to trend upward.

The electrical and electronics industry will also benefit from the SMC market. The demand in electronic devices for high-performance goods necessitates insulating and strong materials. There is a continued quest for such materials, and the need for dielectric materials makes SMC an ideal material to be used for this purpose. The material's versatility means it is used within many electrical components, such as circuit breakers and electrical housings, and these will continue to be required as technology advances.

The construction industry is also going to play a very significant part in growing the Global Sheet Molding Compound (SMC) market. With the looming need to reduce and reuse lightweight, long-lasting cost-effective materials, SMC is used in a number of construction products. It shows good resistance to corrosion and impact that makes it a good material for use in the building panels, doors, and window frames. Further, demand from the construction industry for sustainable and energy-saving building materials would continue propelling adoption of SMC.

An immediate need of aerospace and defense is the formulation of lightweight materials that can be used under severe conditions. SMC's strength-to-weight ratio can thus be used as a possible alternative to manufacture parts for aircraft as well as defense equipment. The increasing demand for efficient and rugged material in this sector will undoubtedly increase usage in the manufacturing of parts like aircraft panels and structural components.

The consumer goods and industrial equipment industries also are expected to see increased demand for SMC. It will remain in demand as manufacturers seek long-lasting yet cost-effective materials. SMC properties make it suitable for applications related to appliances, machines, and any other consumer or industrial product that warrants different attributes.

Some of the greatest growth is noted in the coming years for the Global Sheet Molding Compound (SMC) market. This is because the material is expected to play a strong role in meeting the requirements driven by sustainability, with an even greater spread of applications in multiple industries.

By End-Use Industry

The SMC market has extensive growth opportunities in several industries since it offers many advantages, including flexibility and performance. SMC is a composite material made up of resin glass fibres mixed with fillers intended for high strength usage. Every one of these industries has its specific niche demands and challenges. This is going to be the century of immense growth in how these industries will welcome and in-gratiate SMC into their activities.

SMC continues to take over the automotive and transportation sectors as the market for light-weight, fuel-efficient yet safe, and strong materials is in ever-increasing need of more and more.

SMC has had a long journey since its invention, and the trend is only bound to grow with time. When automakers shift even more to reducing emissions and increasing energy efficiency, the future will depend more on SMC’s ability to replace metal components without ever sacrificing performance. The increased adoption of electric vehicles going forward will continue to fuel demand for such robust, sturdy, and lightweight materials as SMC.

The building and construction sector will not be left out. While construction techniques may change over time, there is an increased need for materials that are not only durable with low maintenance but also can be easily molded and shaped. Evidently, SMC satisfies such needs because it is highly resistant to environmental stresses such as moisture and extreme temperatures, which makes it suitable for roofing, wall panels, and any other application. With the growth of urbanization, the need for affordable and sustainable materials in construction is going to take the use of SMC further.

SMC will increasingly play an important role in the electrical and electronics industry, as there are increasing demands for high-performance, lightweight, and heat-resistant materials due to the further miniaturization and stronger demands of smaller yet much powerful devices. The best electrical insulation properties and appropriate material composition for applications like connectors, circuit breakers, and electrical enclosures make SMC a favorite choice, and with the integration of technology and advancing complexity of consumer electronic appliances, demand for such materials is likely to augment in the coming years.

Consumer goods and appliances will also be enhanced by the characteristics of SMC. More robust, affordable, and more aesthetically pleasing products trend seems to suggest manufacturers will use SMC quite often. SMC can be molded in complex shapes, and along with its strength in making up items like appliance panels and housings, this could be perfect.

The aerospace and defense industries highly value SMC due to its high strength-to-weight ratio and extreme resistance to temperature. More energy-efficient designs are definitely in the cards for the near future of the aerospace industry, so there is good likelihood of increasing the use of SMC in structural parts and other critical parts. Weight without compromise on durability will make SMC a key material in aerospace and defense technology for the future.

With the Global Sheet Molding Compound advancing, the increasing dominance of this material in these industries will define how products are manufactured, promising a future where components are lighter, stronger, and more resilient.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$3,444.2 Million |

|

Market Size by 2031 |

$5,073.1 Million |

|

Growth Rate from 2024 to 2031 |

5.8% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

Global Sheet Molding Compound market will continue rising due to the growing needs for advanced materials in automotive, construction, and electronics. Markets will be spread over different regions; each region will experience its trends and challenges ahead. Understanding the distribution of this geographical distribution can help companies and investors identify key opportunities and change shifts in the markets being analyzed.

North America, comprising the U.S., Canada, and Mexico, is a very promising market for SMC. The region's huge automotive industry is expected to grow with the companies' continued investments in lightweight materials for fuel-efficient and electric vehicles. The US and Canada are known leaders in technological innovations and this may further increase demand for advanced composite materials such as SMC. The region's exigency for sustainable solutions will further enhance the development of this market, as SMC provides great durability and weight-saving benefits.

Germany, France, Italy, and the UK will always be the major markets in the development of the global SMC market in Europe. The automotive and construction industries in Europe continue to be among the largest consumers of SMC, and this is only set to increase as governments and industries seek more sustainable and greener approaches. Growing interest in renewable energy and the importance of composites for building products will cause the market to grow. With a strong automotive and industrial manufacturing base, Germany will follow the larger trend toward increased adoption of SMC in the manufacture of light vehicles.

The Asia-Pacific region, including India, China, Japan, and South Korea, will be the major regional players in the global SMC market moving forward. One of the world's largest manufacturers, China, will drive SMC demand. Continuous investments in infrastructures and construction as well as the upcoming electric vehicle markets will continue to push the demand for SMC usage in these markets. The country's focus on technology and innovation along with Japan and South Korean technology will result in high-performance products, which means continued growth within the region will continue.

Advanced composite materials, the main players in the SMC market are Brazil and Argentina, with great demand by industries into automotive, construction, and electronics. This market is supposed to grow steadily and increasingly with increasing industrialization and a growing need for more durable and lightweight materials.

Middle East & Africa is expected to perform at a moderating rate, and the principal markets here would be the GCC countries, Egypt, and South Africa. Demand for SMC will come from the construction sector, and the sector should continue to drive demand in various markets such as the UAE and Saudi Arabia. Renewable energy infrastructure development, which is now getting more momentum within this region, too should increase composite material usage.

As these regions continue to develop and evolve to meet changing market demands, the global SMC market will see different patterns and growth trends. The future looks bright, however, as SMC becomes more prevalent in industries seeking sustainable, high-performance materials.

COMPETITIVE PLAYERS

Competition in the Global Sheet Molding Compound (SMC) Market In this global sheet molding compound market, continued competition will be an important aspect that this sector will witness looking into the future with key players striving to advance and take on a more pivotal role in dictating the direction of this market. Among these big companies are IDI Composites International, Polynt S.p.A., Menzolit, Astar S.A., and Core Molding Technologies which all help in the continued development of the SMC industry. All the companies above not only excel in the development of SMC material properties but also through their global expansion and adjustment to the latest trends that come into the market.

As one of the leading companies in the SMC industry worldwide, IDI Composites International distinguishes itself via highly advanced products and its continuous efforts at innovation. It has positioned itself well to take on the rising demands of the automotive and construction sectors through its forte in improving the performance and versatility of its SMC products. Similar to this, Polynt S.p.A. is also quite strong, emphasizing the manufacturing of high-quality SMC materials for a range of applications, but primarily in automotive, where lightness and strength are a major concern in the manufacture of components. Menzolit is also a key player, having a long history and regarded for half a century as a precursor of SMC technology.

Men claims strong expertise in making customized solutions for all types of industries. So, this is expected to play an important role in steering the growth of the market. Other companies, including Astar S.A. and Core Molding Technologies, will continue to innovate and enhance their positions in the market. Core Molding Technologies has earned a reputation by offering cost-effective SMC solutions that match the stringest standards of the automotive and other high-performance industries, among others. Other major competitors that are molding the Global Sheet Molding Compound (SMC) market include Continental Structural Plastics (Teijin), Magna International, and DIEFFENBACHER GMBH. These firms have developed several composite materials for industries that seek more durable, lighter, and sustainable alternatives to conventional materials. The demand in the market for Sheet Molding Compound is expected to grow as sustainability and reducing carbon footprint gain momentum.

Other major market participants include AOC Aliancys, Zoltek Corporation, and Changzhou Tianma Group Co., Ltd., which have invested significantly in research and development in order to supply some of the advanced SMC products for the automotive, aerospace, and other markets. With innovation as their core focus, they remain competitive as they are harvesting the benefits generated by increasing global demand for high-performance composite material.

Hence, the prospects for the Global SMC market seem very bright as such competitive companies keep innovating and improving on their current offerings. With novel developments in material technology allied to a growing consideration for sustainability, it can be presupposed that the market will grow with much speed as it addresses the needs of industries globally. In this regard, the firms will significantly determine the future of the SMC market by addressing the increasing demand for lightweight, durable, and affordable materials.

Sheet Molding Compound (SMC) Market Key Segments:

By Resin Type

- Polyester

- Vinyl Ester

- Epoxy

- Others (e.g., Phenolic, Polyurethane)

By Fiber Type

- Glass Fiber Reinforced SMC

- Carbon Fiber Reinforced SMC

- Hybrid SMC (combination of different fibers)

By Application

- Automotive

- Electrical and Electronics

- Construction

- Aerospace and Defense

- Consumer Goods

- Industrial Equipment

By End-Use Industry

- Automotive and Transportation

- Building and Construction

- Electrical and Electronics

- Consumer Goods and Appliances

- Aerospace and Defense

Key Global Sheet Molding Compound (SMC) Industry Players

- IDI Composites International

- Polynt S.p.A.

- Menzolit

- Astar S.A.

- Core Molding Technologies

- Continental Structural Plastics (Teijin)

- Magna International

- DIEFFENBACHER GMBH

- AOC Aliancys

- Zoltek Corporation

- Changzhou Tianma Group Co., Ltd.

- Zhejiang Sida New Materials Co., Ltd.

- Devi Polymers Private Limited

- Zhejiang Yueqing SMC & BMC Manufacture Factory

- Huayuan Advanced Materials Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252