MARKET OVERVIEW

The global screw compressor market is ready to break free from traditional boundaries, entering a new era where sustainability and innovation will reign supreme within its industry. With industries' desires to increase efficiency and conserve energy, the use of screw compressors will no longer be limited to factory floors but will extend across sectors promoted by automation and green technology. This market will not only be a niche for compressed air; it will become a part of processes that require consistency, reliability, and flexibility in changing conditions.

The future advances in this sector will not be confined to incremental change but will possibly redefine performance criteria. Oil-injected and oil-free versions will see substantial improvements to address more stringent regulatory standards and customer demands in terms of purity and ecological footprint. The market will slowly trend toward smart compressors that can self-monitor and predictive maintain, saving downtime and improving operational effectiveness. These changes will not be in a vacuum but will be facilitated by an infrastructure more designed to handle connected and automated systems.

The evolution of the global screw compressor market will also cross into digital transformation initiatives within industrial industries. Integration with IoT and AI platforms will remodel compressors into intelligent belongings in place of mere static machines. Such a transformation will permit real-time facts processing and analysis, making it viable for industries to take nicely-informed decisions that maximize power use and minimize operating charges. The shift to integrated solutions shall now not best cope with large-scale industries however additionally small and medium organizations, establishing doors to customized structures that concentrate on wonderful operational requirements.

Environmental factors will play a key role in determining the path of this market. Designs down the road will focus on energy recovery systems, sound-reducing features, and environmentally friendly lubricants, all in line with planetary efforts toward decreasing carbon prints. These developments will make screw compressors key components in making businesses sustainable across various industries. Beyond the usual uses in manufacturing and energy, the technology will increasingly become applicable in new sectors, such as renewable energy ventures, the health industry, and advanced manufacturing.

Yet another dimension that will define this business is customization. Blanket models will increasingly make way for solutions developed for specialized applications with performance parameters tailored exactly to match end-user needs. Such a transformation will require intense cooperation between producers and users, driving innovation well beyond run-of-the-mill product types. As markets matured, competition is expected to depend upon the capability to provide compressors that are both durable and digital-smart as well as eco-sensitive.

In the end, the future of the global screw compressor market will transcend its existing role as a mechanical fix, but rather become a seamless part of sustainable industrial infrastructure. Through the marriage of technological advancement with environmental responsibility, the industry will evolve into a place where efficiency, intelligence, and responsiveness meet, guaranteeing its pertinence for decades to come.

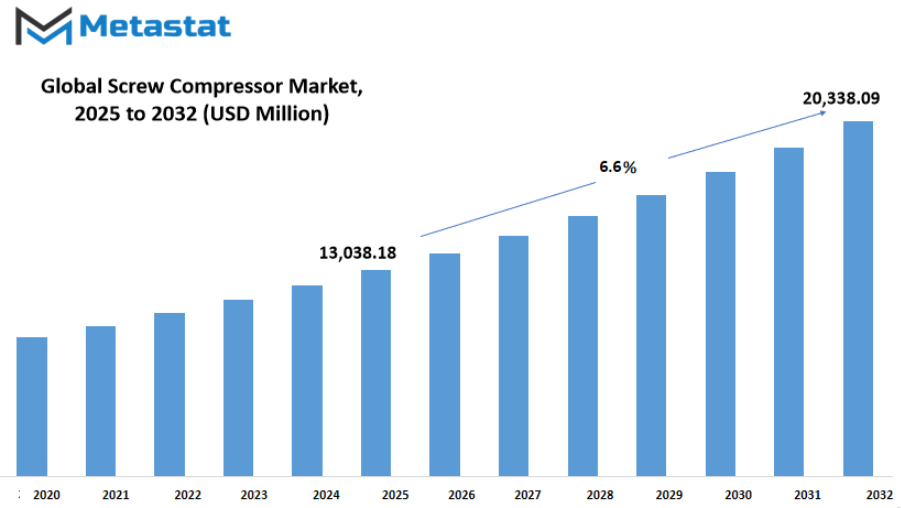

Global screw compressor market is estimated to reach $20,338.09 Million by 2032; growing at a CAGR of 6.6% from 2025 to 2032.

GROWTH FACTORS

The global screw compressor market is finding traction as industries become an increasing number of automated and there's a developing demand for green compressed air answers. Screw compressors find mass use due to their efficiency and capacity for non-stop operation, making them ideal for huge-scale manufacturing and processing facilities. As industries turn out to be greater automation-focused and comprise automation of their operations, demand for constant and excessive-overall performance air compression systems will preserve growing. This circulate in the direction of automation serves as a compelling force for the market, with companies on the lookout for reliable answers that could in shape evolving manufacturing needs.

The other key contributor to the size of the global screw compressor market is the heightened focus on energy efficiency. Companies are being compelled to lower energy consumption as well as operational expenses, with the result being higher demand for energy-efficient screw compressors. These compressors not only maximize power consumption but are also stable performers in the long run, and hence are a desirable choice for organizations looking to achieve sustainability objectives without sacrificing productivity. This trend is likely to influence purchasing as organizations seek solutions that can produce both performance and cost reduction.

Albeit with high growth possibilities, the market also has some issues to face. One of the most important challenges is having excessive up-the front expenses in the set up of screw compressors, which typically deters small and medium-scale businesses from the usage of them. Also, problems concerning noise and heat emanation for the duration of utilization may additionally avert their utilization in regions in which quiet or controlled conditions are required. Such aspects can also obstruct market penetration, specially in industries that are not tolerant of such hazards.

On the opposite hand, the growing demand for screw compressors inside the oil and gasoline industry, as well as in HVAC systems, will generate giant opportunities throughout the next few years. These industries need efficient and dependable air answers for essential approaches, and screw compressors are best for such requirements. As there is an ongoing upward thrust in infrastructure improvement and commercial tasks globally, the usage of these compressors is destined to witness a constant increase. The growing need for business automation and the fashion in the direction of energy-efficient answers guarantees that the global screw compressor market will remain imperative to the commercial surroundings inside the close to destiny.

MARKET SEGMENTATION

By Type

The global screw compressor market has improved to turn out to be a extensive factor of a number of industries attributable to its capacity to provide reliable and electricity-saving air compression solutions. The compressors are being utilized significantly across manufacturing, oil and gas, car, and strength sectors because of their reliability in operation and persistence. Contrary to standard compressors, screw compressors function the use of a rotary mechanism that minimizes the loss of electricity and promotes smooth operation, making them a favorite amongst organizations that need airflow to be non-stop. Not only does this efficiency useful resource operational methods, however it additionally assists industries in decreasing their power fees in the long run, which is a key motive force behind their increasing popularity.

The industry is divided into two large categories: oil-loose and oil-injected screw compressors. Oil-free compressors are a must in industries wherein air cleanliness is paramount, including pharmaceuticals, food and beverage, and electronics. They provide a guarantee that no oil ends up in the final product, which qualifies them for packages stressful the first-class degrees of hygiene and excellent. Based on current projections, the oil-free section has attained a market fee of $4,373.04 million, reflecting its predominant contributions to pleasurable enterprise-unique requirements. Demand for oil-loose structures will maintain growing as corporations attention an increasing number of on protection, regulatory compliance, and environmental sustainability.

However, oil-injected screw compressors are still heavily used in heavy-responsibility programs together with mining, production, and preferred production. Oil is utilized by these compressors for lubrication and cooling purposes, accordingly enabling them to assist large loads and perform underneath worrying situations. They are cheaper than oil-loose devices and tend to be utilized in industries wherein smooth air isn't a top priority. Oil-injected compressors' flexibility and lengthy lifespan lead them to a viable desire for corporations that price efficiency and reliability for a low priced fee.

In the destiny, the global screw compressor market will maintain growing as industries search for equipment that is energy-green, high-appearing, and environmentally pleasant. With advancements in generation, oil-loose as well as oil-injected models may be greater state-of-the-art, offering smarter functionality and superior manage options for consumers. Increased emphasis on environmentally friendly manufacturing and lower strength utilization can even improve the call for for screw compressors globally. As greater industries see their blessings, these systems will remain a crucial part of industrial operations, facilitating productivity and development for years yet to come.

By Technology

The global screw compressor market has extended to turn out to be an important phase of different industries because it gives green and dependable compressed air solutions. Screw compressors have a considerable application in manufacturing, construction, oil and gas, and different industries due to the fact they produce non-stop airflow without principal pulsations This is the reason that they are ideal for applications requiring high demand where consistency and energy efficiency are primarily sought after. With time, these compressors have been developed into a business favorite of long-lasting performance with little maintenance in contrast to conventional piston-based machinery. With industries growing and becoming more modernized by the day, the demand for advanced screw compressors is bound to increase, with a constant need for productivity and lower operation costs.

Speaking of the global screw compressor market by technology, the market is classified into two broad categories: portable and stationary screw compressors. Portable screw compressors are constructed for portability and are thus a terrific choice for companies like creation and mining, where compressed air is needed in a couple of places. They are lightweight, easy to move and supply, and might characteristic in harsh situations. Their portability allows agencies to work successfully in distant or transient running locations without sacrificing the nice of air deliver. These compressors have a tendency to be provided with onboard gasoline options, contributing to their versatility in out of doors operations wherein electricity might not be effortlessly to be had.

Stationary screw compressors, on the other hand, are designed for fixed situations and consistent operation and are ideal to be used in big-scale production vegetation. They are traditional in manufacturing facilities, strength technology vegetation, and processing industries wherein compressed air in extremely good quantities is needed twenty-four hours an afternoon. Stationary systems are characterized with the aid of their efficiency in terms of power use, toughness, and capability for integration with automated processes. As compressors which might be supposed for everlasting installations, they have a tendency to have better capacity and refined controls, ensuring clean operation in spite of harsh conditions. Their capacity for sustaining large operations without being hampered places them as key additives of commercial infrastructure.

Portable and desk bound screw compressors each own unique advantages, with their implementation based totally on an appropriate needs of an industry. Portable units permit for comfort and ease of transportation, while desk bound machines provide remarkable efficiency and dependability to massive manufacturing operations. As improvements in generation keep advancing compressor layout, the marketplace will witness improvements tied to power performance, noise suppression, and intelligent tracking structures. This mix of overall performance, adaptability, and sustainability will preserve screw compressors at the leading edge of industrial development for the foreseeable future, allowing agencies to achieve their running targets in an efficient way.

By End User

The global screw compressor market is emerging as a significant feature of various industrial applications due to its reliability and efficiency in processing varied operations. The screw compressors are extensively used for delivering compressed air or gas for operations, thus becoming a valuable asset in varied sectors. Companies are more interested in increasing productivity without increasing energy expenses, and screw compressors contribute significantly towards attaining that balance. Their capacity to operate around the clock under tough conditions without significant breakdowns renders them extremely useful in industries requiring unfettered performance.

Of the large users, the oil and gas industry has recorded high uptake of screw compressors. This enterprise requires a machine that may sustain high-stress conditions and supply dependable performance at some point of key operations which includes transportation and processing of fuel. Screw compressors are used due to their power and capability to function below harsh environments. Likewise, the energy and electricity enterprise relies upon on these compressors to make sure a consistent supply of compressed air for turbines, mills, and different power elements. Their contribution closer to power technology positions them as a fundamental element in reaching world energy demands.

The meals and beverage marketplace also employs screw compressors to offer clean and oil-loose air for bottling, packaging, and different production methods. As the products ought to meet stringent safety and hygiene conditions, the compressors utilized on this industry are made to save you infection even as ensuring performance. However, the chemicals and petrochemicals enterprise needs heavy-responsibility systems for procedures along with chemical reactions, garage, and transportation. Screw compressors are commonly used here because of their capability in accommodating gases and vapors under strain, with easy and secure operations.

Other sectors, including manufacturing and building, additionally depend on screw compressors for several packages. Whether strolling pneumatic equipment or backing up material dealing with structures, those compressors offer reliability and versatility in diverse applications. Their versatility in serving various industrial purposes remains a solid reason why they remain a popular option. With advancing technology and the need for industries to adopt better systems, their application of screw compressors will continue to expand across industries, further solidifying their grip on the international market.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$13,038.18 million |

|

Market Size by 2032 |

$20,338.09 Million |

|

Growth Rate from 2025 to 2032 |

6.6% |

|

Base Year |

2024 |

|

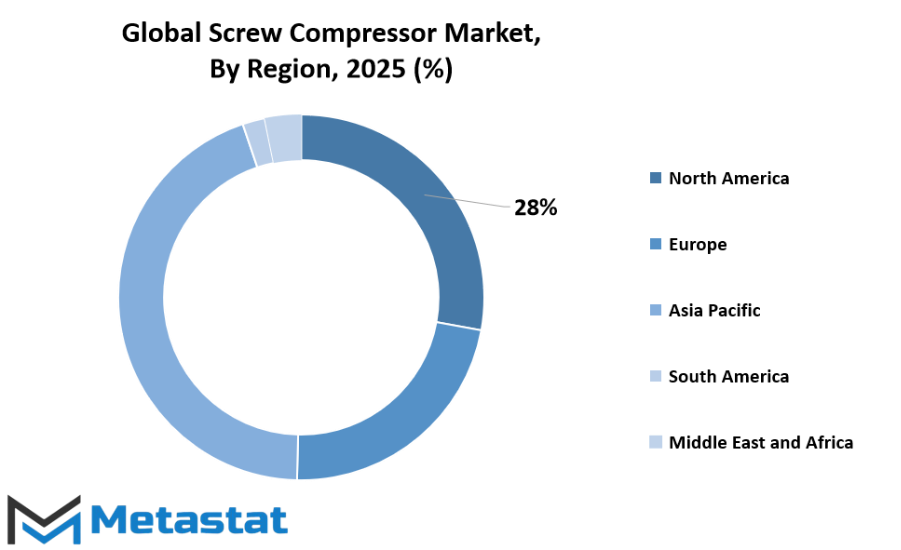

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global screw compressor market is also receiving massive attention as industries keep efficiency and reliability at the top of their agendas. Screw compressors are without difficulty hired in various sectors, including production, power, and automotive, due to the fact they can provide consistent overall performance at low electricity loss. Their efficiency in lowering strolling expenses without affecting productiveness has made them a source of interest in various areas. With growing business operations globally, the call for sophisticated and energy-saving screw compressors will remain strong, influencing patterns of demand throughout key geographical regions.

Geographically, the screw compressor market is segmented into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. North America incorporates the United States, Canada, and Mexico, wherein strong production and oil and gas industries gas using screw compressors. The availability of trendy industrial base inside the U.S. Is a key component in maintaining this location aggressive. Canada and Mexico also are making contributions through their increasing commercial bases, aided by way of non-stop investments in superior technologies.

The marketplace in Europe is represented through the UK, Germany, France, Italy, and the Rest of Europe. This region enjoys stringent environmental policies and a excessive focus on strength performance, compelling industries to include upgraded compressor answers. Germany, as an engineering and automobile manufacturing hub, is a key driver, at the same time as Italy and France exhibit constant demand due to numerous business uses. The overall European interest in green practices will be expected to support market growth in future years.

Asia-Pacific is among the most rapidly growing areas, comprising India, China, Japan, South Korea, and the Rest of Asia-Pacific. Industrialization, urbanization, and infrastructure activities are primary drivers for the demand here. China and India are leading due to their growing manufacturing hubs, while Japan and South Korea concentrate on technological upgradation and accuracy engineering. The demand for new equipment in developing economies will maintain Asia-Pacific as one of the top contributors to world markets.

South America, dominated through Brazil and Argentina, and the Rest of South America, experiences strong boom led by way of the mining and electricity sectors. Concurrently, the Middle East & Africa vicinity that incorporates GCC Countries, Egypt, South Africa, and others is experiencing demand with oil and fuel projects and elevated investments in industrial flowers. These markets may revel in slower adoption in assessment to Asia-Pacific and North America, however enterprise diversification will continue to maintain the market developing. All in all, every area has wonderful increase drivers on the way to keep defining the future of the global screw compressor market.

COMPETITIVE PLAYERS

The global screw compressor market is consistently picking up momentum with its critical contribution to several industrial applications. Screw compressors are used extensively to supply compressed air reliably, and their popularity can be traced to the fact that they can support huge capacities of air with high dependability. Manufacturing, construction, food processing, and energy industries count heavily on these systems to ensure smooth functioning. In contrast to some other compression technologies, screw compressors are preferred for their constant running and capability to operate in demanding conditions, and as such, they form an integral part of a wide variety of industries globally. This constant demand will keep growing as companies seek energy-efficient and cost-effective means to facilitate industrial development.

Among the key drivers for increased uptake of screw compressors is their flexibility and minimal maintenance requirements. These compressors are built to withstand wear and tear, offering a longer lifespan than their conventional counterparts. As businesses become more focused on saving operational costs, the longevity and energy-saving properties of screw compressors render them a valuable investment. Coupled with advancing design and technology, their efficiency and noise levels are improving, adding an additional value for businesses that are concerned with safety and work environment comfort. The market will witness a steady drive for innovations that are aligned with tighter environmental standards and sustainability targets.

A number of companies are at the forefront in defining this market, with cutting-edge solutions to address varied industrial requirements. Some of the major players are Atlas Copco, Ingersoll Rand, Kaeser Kompressoren, ELGi Equipments, and Sullair. These companies have become established on the back of robust product portfolios as well as ongoing investment in research and development. Others, including Kobelco, Howden (Chart Industries), Aerzener Maschinenfabrik GmbH, BOGE Kompressoren, FS-Curtis, Quincy Compressor, Kaishan Group, ALMiG Kompressoren, and Sullivan-Palatek, are also major players. Their effort continues to be on bringing compressors that are more efficient, reliable, and compatible with newer systems, so they can continue to be competitive in a market that is performance-oriented and energy-efficient.

As businesses grow and become more advanced, the demand for high-reliability compressed air systems will only continue to grow. This opens doors for producers to bring products custom-made for particular industrial applications, from small business operations to massive production plants. The increased demand for oil-free compressors, particularly for food, pharmacy, and electronic industries, indicates a growing trend towards cleaner and greener technologies. Businesses that match their products with such demands will be in a prime position in the market. Eventually, the global screw compressor market will keep growing as efficiency, durability, and sustainability are always top of mind for companies across the globe.

Screw Compressor Market Key Segments:

By Type

- Oil Free

- Oil Injected

By Technology

- Portable

- Stationary

By End User

- Oil and Gas

- Food and Beverages

- Energy and Power

- Chemicals and Petrochemicals

- Others

Key Global Screw Compressor Industry Players

- Atlas Copco

- Ingersoll Rand

- Kaeser Kompressoren

- ELGi Equipments

- Sullair

- Kobelco

- Howden (Chart Industries)

- Aerzener Maschinenfabrik GmbH

- BOGE Kompressoren

- FS-Curtis

- Quincy Compressor

- Kaishan Group

- ALMiG Kompressoren

- Sullivan-Palatek

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252