MARKET OVERVIEW

The Global Rotomolding Market and the Industrial Rotomolding are rapidly becoming the prime movers for hollow plastic products in the very advanced production techniques of rotational molding. Such processes, in fact, provide completely durable, seamless, and complexly shaped components, which elementary do not entail high pressure molded tooling. With this technique, industries can be referred to as automotive, construction, agriculture, healthcare, which have light-weighted and cost-efficient products for specific application purposes.

Rotational molding is unlike the earlier methods of making any plastic articles which allow materials to be distributed uniformly on the products and consequently have uniform wall thickness with greater structural strength. The resin is placed powdered into a hollow mold, afterwards it is heated and rotated around multiple axes. As it melts, it catches on the interior surfaces and cools into solid form. This kind of process eliminates the secondary assembly processes, and also waste and costs of production involved.

As a result, there is a growing demand in several industries which finds in innovation sources possible advanced materials and automation technology to enhance efficiency. Rotational molding is testimony to diversity and makes it the most preferred option for large, complex, very strong and durable components-resistant to high and low temperature, UV rays and many chemicals present in the nature.

This manufacturing process is really beyond its ordinary application and will allow the use of bespoke options in niche markets. Water storage tanks, fuel containers, playground equipment, as well as medical enclosures all serve as points of application for this technique. Here, the adaptability of the manufacturing process ensures that all industries are catered for without compromising on quality. With all this and many happenings towards sustainability, l hold strong views that recycled and biodegradable materials will get to form a more prominent part in process application, as the “greening” efforts across countries around the world are being taken further.

Mold-making technology advances and digital design tools will also be critical in producing new production modes. To deliver improved product durability and performance, composite materials and enhanced polymers will be explored by manufacturers. Also, smart manufacturing technologies like “live” monitoring and data analytics will operate to reduce the cycle time of production and materials waste, realizing more sustainable practices.

This will also result in the future development of this industry depending upon changing consumer demands, regulations, and technology advancement related to polymers. Rotomolding will hold its ground in being critical because it’s cost-effective and long-life manufacturing technique, which have the best advantages regarding flexibility in design, structural soundness, and endurance over time, as markets have become more focused on economic and strong forms of manufacturing.

The complexity of producing geometries without large investment costs of tooling supplies makes this method a practical one for wide applications. Global Rotomolding Market will now continue to grow and make holds better potential by bringing cutting-edge innovations by which companies would change the entire market dynamics and then sustain in this competitive landscape.

In this era, major changes in the market environment are accepted by every company and stakeholder through the implementation of sustainable solutions, automation, and creating product efficiency through the advancement of materials science.

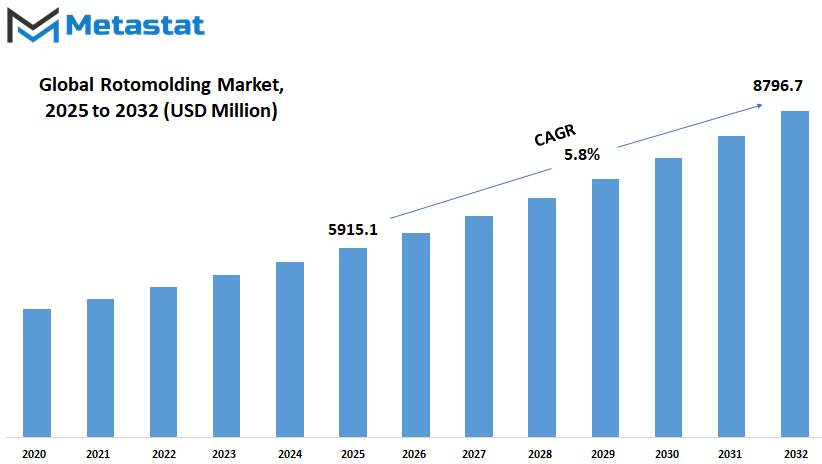

Global Rotomolding market is estimated to reach $8796.7 Million by 2032; growing at a CAGR of 5.8% from 2025 to 2032.

GROWTH FACTORS

The Global Rotomolding market is on the edge of thumbs-up growth in the years to come and will be influenced by multiple factors impacting the path ahead. Rotomolding or rotational molding is an industrial processing method to create hollow plastic products by heating and rotating the molds. This technique can be versatile and economically beneficial, and so finds itself highly employed in numerous industries including automotive, construction, and consumer goods.

Some of the primary drivers that the Global Rotomolding market could use are rising demand for lightweight and durable plastic products. Industries are still looking for materials that would, among other factors, reduce weight without sacrificing strength, and among these rotomolded plastics fit in well. For example, in the automotive industry, rotomolded components are used to secure the rail. That means decreased weight for the overall automobile, hence better fuel efficiency. For instance, the construction sector could also gain from rotomolded tanks and containers which are rugged yet easy to install.

Another factor contributing to market growth is the customizability linked to the rotomolding technology. With very few increases in costs, manufacturers can produce quite complicated shapes and sizes that cater to the tailored solutions' needs for specific client requisites. This flexibility is rather advantageous in the manufacturing setup of specialized equipment and custom-designed consumer products.

However, some challenges may inhibit the growth of the market from other directions. For instance, the availability of some raw materials-for example, polyethylene-may disturb the production costs and pricing strategy. Environmental issues pertaining to plastic use and disposal are becoming causes of strict restrictions and regulations, thus posing a challenge to the industry in its growth and activity.

Though there are challenges, advancements in material science and technology shore up promises for the Global Rotomolding market. Issues relating to the environment are being tackled through the creation of biodegradable and recyclable polymers forming part of the worldwide shift toward sustainable practices. Furthermore, automation and digitalization of the rotomolding process must be used for greater efficiency and to reduce wastage and cost.

Thus, finding solutions leaned toward lighter and more durable, customized plastic products should therefore lead to growth in the Global Rotomolding market. Raw material pricing, along with environmental regulations, is proving to be crucial toward the market growth. Advances in sustainable materials will lead to sustainable production methods that will be seen as an innovative application. The market is going to flourish with the application of such solutions into the industries joining needs of the consumers worldwide.

MARKET SEGMENTATION

By Material Type

In the years to come, the Global Rotomolding market will witness a lot of growth due to the advancement of material science and manufacturing techniques. Rotational molding i.e., rotomolding itself is a process that forms with the help of heating along with the rotation of molds hollow plastic products. This has provided designers with flexibility and cost-effectiveness features that made it fully participative in every industry.

Main raw source rotomolded materials are Polyethylene (PE). It is durable, easily moldable, and inexpensive. As the industries are always looking for greener facilities, development in the ways of creating bio-based and recyclable PE types will continue to grow, responding to worldwide environmental initiatives.

Polyvinyl Chloride (PVC) is another material used in rotomolding. PVC has property advantages such as strength and environmental degradation resistance. At the same time, PVC is used for products needing durability and strength. Research into new formulations of PVC is focusing on reducing environmental impacts at different stages of its lifecycle and recyclability.

Low-density Polypropylene (PP): An intermediate between strength and weight for applications that require durability and lightness: in the future, further advances on PP composites will provide enhanced properties leading to larger applications within many industries -for example, in automotive and aerospace where performance and efficiency will be paramount.

Known for toughness along with resistance to wear, Nylon is used in articles of which heavy mechanical performance is required. Soon, new improvements in nylon blends and processes may open up applications in high-stress environments like industrial machinery and high-stress structural parts.

Other basic materials like polycarbonate and polyurethane serve in the rotomolding setup. Polycarbonate is used for impact resistance and transparency in products that would stipulate both, whereas the flexibility and abrasion resistance of polyurethane are important for items subject to constant movement or friction. Work continues in relation to properties of those materials so that a larger selection may be available with manufacturers.

As technology develops, the Global Rotomolding market will have an opportunity with the innovations of materials making this promising. Sustainable and high-performance efficiency will drive the advanced material and processes usage to meet industry-specific needs across the world. By making them available worldwide, the advancement observes not only the current conditions boring but the future challenges as well in position for the rotomolding sector to dominate globally in manufacturing demands.

By Application

The Global Rotomolding market will witness high growth in the forthcoming years, as it has many applications across different industries. Rotomolding, also referred to as rotational molding, is the manufacturing process to produce hollow plastic products by heating and rotating the molds. This technique is versatile and economical and finds application across different sectors.

Many industrial applications of rotomolding exist for building storage tanks and containers. As more and more industries expand and look for storage options, the demand for rotomolded products will also increase. The agriculture industry is another application of rotomolding. Rotomolding is used for the manufacture of machines such as water tanks and feeding troughs. Now, in the global context of sustainable farming, the need for reliable agricultural equipment will further augment the growth of the rotomolding market.

The automotive sector is another area contributing to the growth of the rotomolding market. Manufacturers use this technique to produce lightweight and durable parts like fuel tanks and fenders. The increased demand for lightweight parts towards the EVs and for improving fuel efficiency will therefore increase the attractiveness of rotomolding.

Sculptures and home decorations are associated with rotomolding for producing innovative designs to manufacture in unique shapes and textures. The designers here appreciate the firm’s flexibility to synthesize a combination of beauty and functionality. As more personalized, stylish home furniture will be demanded by consumers, the rotomolding market is set to grow in this area.

The building and construction sector also benefits from rotomolding for the manufacture of pipes and ducts and roofing materials. The durability and weather resistance of rotomolded products suit them for construction applications. Globally, with increasing urbanization and infrastructure development, the region is anticipated to flourish.

Toy and playground equipment manufacturers leverage rotomolding to provide safe and sturdy products. Parents and teachers are focused on safety and quality features, thus maintaining the steady demand for rotomolded toys and playground structures. As increased awareness develops in the area of child safety, this segment of the rotomolding market is predicted to boom.

The marines benefit from rotomolding in making items like buoys, kayaks, and other components for boats. Corrosion resistance and buoyancy tend to be properties of rotomolded products, thus making them excellent for marine application. Recreational water activity becomes more popular, thus boosting the need for rotomolding at that market.

The Global Rotomolding market is set to undergo tremendous growth across various applications. Industries appreciate the versatility, durability, and cost-effectiveness of rotomolded products. As new technologies and consumer demands evolve, so will the rotomolding market: it will adapt and grow to meet those emergent needs.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$5915.1 million |

|

Market Size by 2032 |

$8796.7 Million |

|

Growth Rate from 2025 to 2032 |

5.8% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

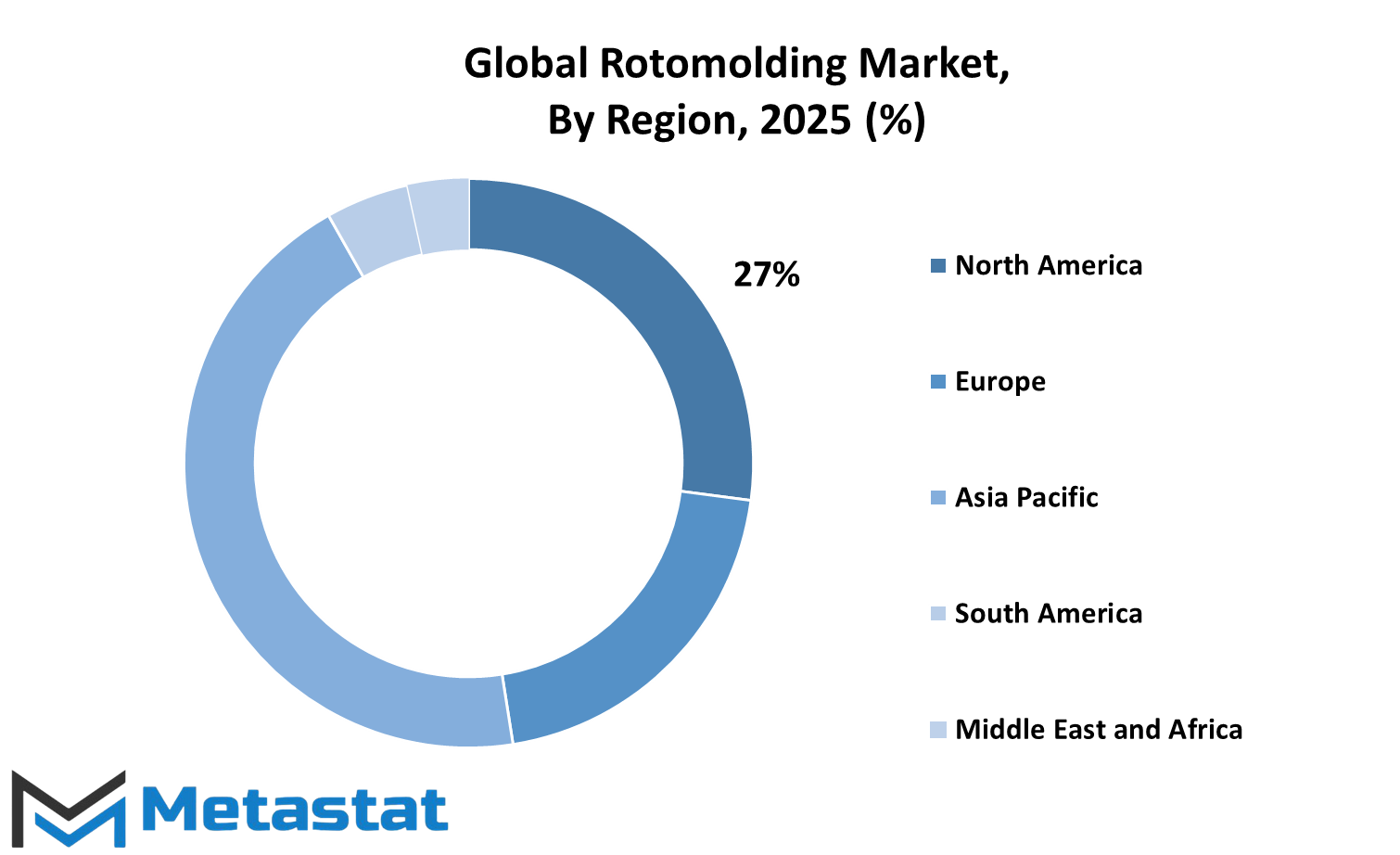

Over the next few years, some countries are going to create strong synergies for growth and enable the global rotomolding industry to achieve such massive growth in all periods. Automotive, agriculture, and construction industries in North America, especially in the USA, Canada, and Mexico, are going to demand rotomolded products, which will boost the growth of the North American market. Additionally, changing technology and a higher demand for durable and lightweight materials are going to change things favorably for the market.

Then europe has become another major contributor to rotomolding, along with the United Kingdom, Germany, France, Italy, and the other countries bordering them, which, most of these nations say, will continue on a steady growth path. The increasing demand for rotomolded products is because of sustainability knowing that the market moves toward greener processes for production which would better promote rotomolding in packaging as well as consumer goods.

Among all the regions that are anticipated to claim territory in the rotomolding marketplace, the countries of the Asia Pacific-India, China, Japan, South Korea, and other surrounding countries-there is a great possibility that these will take the fastest strides in growth. Urbanization and industrialization facilitate market advancement while increased disposable income is vital. Automotive and electronics are expected to drive demand for rotomolded components, given its low-cost designs and flexibility.

With the slowing pace of growth, most of the increase in South America will derive from Brazil and Argentina. The agricultural picture is positive with the associated large areas of demand, and demand for rotomolded tanks and containers will be supported in some measure by a developing need for efficiency in terms of creating solutions for water storage.

This brings Rotomolding in the Middle East and Africa, covering the GCC countries, Egypt, South Africa, and so on, into play as a developing market for rotomolding. While constructing infrastructure, the saving of water will also lead to the rising demand for rotomolded products in the construction and water management fields.

Thus, in general, the global rotomolding market continues on a path of growth, with every region contributing its specific opportunities and challenges. At the same time as industries are changing in order to meet the demand and need for innovation and sustainable solutions, that is when the demand for rotomolded products is anticipated to take center stage in future manufacturing worldwide.

COMPETITIVE PLAYERS

The global Rotomolding market has great potential to be transformed completely because it is increasingly demanding cost-effective, durable, and environment-friendly plastics by various industries. This industry is steadily growing with increasing demand for lightweight and corrosion-resistant products, especially in the automotive sector, agriculture, and water storage.

The competition among the major players is getting tougher as all companies want to become industry champions in meeting the evolving consumer demand and expectations from regulations, which pushes them to innovate and refine their manufacturing processes.

There are several strong companies established in the sector. Centro Incorporated, Sherman Roto Tank, and Ovun are some example organizations that have built reputation by availing quality products for various industries. In the same vein, Myers Industries Inc., Granger Industries Inc., and Assmann Corporation of America have made efforts to expand their product lines and operations towards improving efficiency for a competitive advantage. Roto Dynamics Inc. and RotoTank are adopting innovative practices through which they can redefine production processes; meanwhile, Koenders Mfg., Polyworld, and Dutchland Plastics invest in sustainable solutions for the environmental demands.

More interesting to look into the tomorrow of the industry is the ongoing trend of automating and integrating intelligent process technologies. Manufacturing shall consider robotics and data-driven processes to a larger extent, as all the efforts are aimed towards making production efficient. This new wave will reduce waste, improve accuracy, and save energy, giving rise to better-quality products at a lesser cost. Companies like Rotadyne Pty Ltd., Fixopan, and Rotoplast Inc. would embrace such advancements to keep their edges over others in the area of their concerns.

The other driving force shaping this industry is sustainability. With increasing awareness of plastic waste and environmental damage, companies are now conducting research to find alternative raw materials and eco-friendly production technologies. Recycled resins and even biodegradable plastics are becoming increasingly popular and viable to businesses as avenues for achieving globalization on sustainability. Industry leaders such as Ocean Plastic Intertrade Co. Ltd. are also expected to be active in this transformation while coming up with other less environmental harming approaches but without sacrificing durability or functionality.

Increasing competition will mean more strategic partnerships and market expansions. For instance, such partnerships will be made between companies that will complement one another with respect to research and development activities to stay ahead in a highly rewarding industry as regards innovation. With a lot of time spent on research, talk will now come of going into new geographical markets, which are chiefly emerging since the new requirements of consumers' demand are quite credible for durable and affordable plastic products.

Technology advancement, sustainability activities, and strategic growth will define the future of the global Rotomolding market. Continuous evolution in the industry by the main players places this market in the future dynamic and competitive arena, where the determinants of success will be innovations and adaptability.

Rotomolding Market Key Segments:

By Material Type

- Polyethylene (PE)

- Polyvinyl Chloride (PVC)

- Polypropylene (PP)

- Nylon

- Others (Polycarbonate, Polyurethane)

By Application

- Industrial

- Agriculture

- Automotive

- Furniture & Home Decor

- Building & Construction

- Toys & Playground Equipment

- Marine

- Others

Key Global Rotomolding Industry Players

- Centro Incorporated

- Sherman Roto Tank

- Ovun

- Myers Industries Inc.

- Granger Industries Inc.

- Assmann Corporation of America

- Roto Dynamics Inc.

- RotoTank

- Koenders Mfg.

- Polyworld

- Dutchland Plastics

- Rotadyne Pty Ltd.

- Fixopan

- Rotoplast Inc.

- Ocean Plastic Intertrade Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252