MARKET OVERVIEW

The global pressure vessels market falls under the larger industrial equipment and manufacturing sector, which will remain the backbone of large-scale process and storage systems. These vessels will be designed to hold gases or liquids at pressures dramatically different from ambient pressures, requiring accurate material composition, superior welding processes, and stringent safety standards. Globally, demand for such vessels will emerge from growing specialized requirements in oil and gas, energy generation, chemical processing, and water treatment segments.

In the coming years, the global pressure vessels market will be characterized by manufacturers and fabricators' capability to accommodate growingly stringent regulatory regimes and multiform application conditions. Each ship will have to be designed not just for operating pressure, but also for temperature variation, corrosion resistance, and lifecycle cost-effectiveness. Local codes like ASME in North America or PED in Europe will inform design and fabrication practices, providing an international manufacturing environment demanding technical adjustment and local expertise.

Product differentiation in the global pressure vessels market will presumably come about through structural shape, internal design, and orientation of use. Vertical or horizontal, cylindrical or spherical, these design configurations will be tailored to end-users' required flow and containment requirements. Individualized customization will play a pivotal role in ensuring material compatibility and pressure retention safety. Additionally, automation and non-destructive testing will play larger roles, enhancing manufacturing consistency and inspection reliability at fabrication facilities worldwide.

While power generation and petrochemical industries will continue to need large-sized vessels for operational reliability, modular and smaller pressure vessels will be increasingly significant as compact industrial processes and decentralized energy systems gain popularity. The range of application scenarios will require design and deployment flexibility, along with transportation and installation modes that enable mobility without compromising integrity.

The reach of the global pressure vessels market will move beyond the standard industrial application to incorporate such areas as renewable energy storage and cutting-edge manufacturing procedures. As hydrogen fuel systems and carbon capture technologies grow in importance, the capability of pressure vessels to fit gaseous compositions and pressure ratios with untapped innovation will gain increasing clarity. Materials like carbon fiber composites and high-strength stainless steels will find greater use, led by the demand for lightweight and high-strength applications.

In addition, digital solutions will be incorporated into the vessel lifecycle, allowing operators to track internal pressure, structural fatigue, and corrosion in real time. Predictive maintenance platforms will minimize downtime and enhance safety by identifying plant managers with failure risks before they lead to disastrous consequences. This model will not only redefine how vessels are maintained but how they are originally designed.

The global pressure vessels market will remain to change with the effects of engineering innovation, regulatory requirements, and changing industrial strategies. While applications multiply, and technology remakes conventional processes, the function of pressure vessels will continue to be a cornerstone of industries that depend on controlled pressure conditions for essential operations.

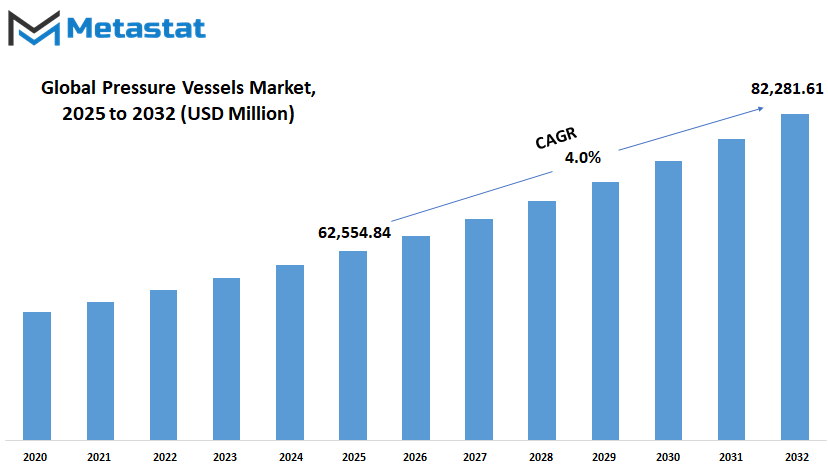

Global pressure vessels market is estimated to reach $82,281.61 Million by 2032; growing at a CAGR of 4.0% from 2025 to 2032.

GROWTH FACTORS

The global pressure vessels market is attracting interest because of increased demands within a number of major industries. As industrial processes continue to grow, the requirement for heavy-duty equipment to cope with high-pressure operations becomes increasingly essential. One of the primary forces propelling this market is increasing demand from energy and petrochemical industries. These sectors are dependent upon pressure vessels in order to hold liquids and gases under high pressure, and thus they play a critical role in day-to-day operations. With the increase in global demand for energy, the demand for sophisticated pressure systems that can efficiently and safely store and transport vital materials will grow.

Meanwhile, increasing industrialization and a continued increase in power generation activities also contribute to the growth of this market. With additional factories and power plants being constructed to supply increasing populations, the application of pressure vessels will become more prevalent. This greater application will not only solidify the market but also stimulate producers to invest in improved and more efficient designs.

But the global pressure vessels market is far from perfect. The materials chosen for the fabrication of pressure vessels are usually costly, thereby increasing the cost of production. These materials need to be of high quality in order to support pressures that go to extreme levels, increasing the expense. In addition to this, the firms have to abide by strict safety standards, since the collapse of a pressure vessel can cause drastic effects. This entails frequent checking and servicing, which may hinder operations and hike overall costs.

Notwithstanding such challenges, there are bright prospects in the future of the global pressure vessels market. One of the major sources of expansion is the evolution of new materials and better production methods. Lightweight but stronger composite materials, as opposed to conventional metals, are becoming increasingly prevalent. These products can reduce production cost, weight, and enhance performance, and make pressure vessels more efficient and secure. New fabrication techniques will also assist in producing vessels with higher accuracy, minimizing the potential of failure and extending their life.

Over the coming years, as industries seek more safe, cost-effective, and efficient means of controlling high-pressure surroundings, demand for contemporary pressure vessels will increase. The urge for cleaner energy and enhanced industrial concern for safety will only intensify this trend. With progress taking the lead, the market will experience consistent growth, despite current challenges.

MARKET SEGMENTATION

By Material Type

The global pressure vessels market continues to increase steadily as a result of industrial requirements and need for more advanced storage technologies. As industries expand and look for improved ways of dealing with high-pressure conditions, pressure vessel utilization becomes more critical. Pressure vessels play an essential role in holding liquids or gases at various pressures and are an essential part of chemical processing, energy, and manufacturing processes. Their importance will only increase as technologies advance and more secure regulations are implemented in different industries around the world. One of the drivers of the future of this market is material choice to construct such ships.

Different materials have different benefits, based on what use and pressure requirement. Among them, titanium stands out for its resistance to corrosion, with an above-average strength-to-weight ratio. It is especially useful in companies that work with coarse chemicals or where cleanliness is a prime concern. As industrial applications keep demanding greater strength and performance under stress, use of titanium will become increasingly common. Nickel and nickel alloys are also finding increasing use for their resistance to high temperatures and corrosive atmospheres. This makes them of importance of the first order for chemical and heat applications in which performance is necessary over the long term.

Their future use is certain to expand as business wants more dependable and more extended-running equipment. Tantalum, although less commonly utilized, has unmatched corrosion and heat resistance. It will likely be utilized more and more within specialist fields where safety and dependability cannot be compromised. Steel is yet a material with widespread application due to the fact that it is both economical and strong. With the advancement of manufacturing processes and further enhancement of steel quality, steel will remain competitive in the global pressure vessels market. It is expected that newer types of steel with better properties will be developed to meet future industrial needs.

The "Others" category includes newer composites and metals that are continually emerging. These products are likely to take a more prominent role as industries experiment and implement alternative solutions that suit specific requirements without negatively affecting safety or longevity. As the world keeps developing, the global pressure vessels market will be driven more towards highly optimized and specialized material selection. Each material type will be chosen with more consideration towards specific functions and performance needs. The market will see a steady growth in demand over the next few years, driven by requests for more secure, durable, and flexible pressure solutions in most industries.

By Product

The global pressure vessels market is expected to experience steady growth over the coming years on the back of growing industrial demands and shifting energy policies. Pressure vessels are containers which have the capability to hold gases or fluids at high pressure, and they are a critical part of many industries. As more industrial activities are being executed globally, especially in the emerging world, the need for reliable and safe pressure vessels will continue to grow. The need is not only driven by traditional industries like oil and gas but also emerging energy industries and innovative manufacturing processes.

On the basis of product, the market has been divided into boilers, nuclear reactors, separators, and others. Boilers have been in common usage for many decades in power houses and factories. They are set to continue being in vogue since they are core to the generation of steam and heat. As industries transition to cleaner, more efficient solutions, newer boiler designs will focus on enhanced safety, higher heat recovery, and lower emissions. These advancements will propel manufacturers to produce better materials and processes, adding to the overall value of this market sector. Nuclear reactors for power also play a significant role within this sector. With countries looking for answers to being less reliant upon fossil fuels, nuclear power can be viewed as a safe solution.

This will create demand for advanced pressure vessels that are capable of sustaining extreme environments while ensuring safety measures. Safety comes first, pressure vessels used in nuclear power facilities will be required to meet tougher standards and utilize superior materials that can withstand long-term stress and radiation. Even though opinions of individuals towards nuclear energy can vary, the technological advancement may make it a more sought-after choice to make in the coming years. Separators used by the oil, gas, and chemical industries to split different fluids or gases will remain important in the global pressure vessels market as companies look for improved efficiency and safety of operation. Advances in sensor technologies and automation systems will drive this segment's growth by allowing for more precise control and reduction of wastage.

Other pressure vessels, used in all sorts of industrial plants, will also see steady demand. As new technologies and more intricate industries emerge, especially crafted vessels will be needed to meet specialized requirements. The fate of the global pressure vessels market in the future will be contingent upon how quickly manufacturers are able to respond to emerging needs, safety standards, and energy goals without rising costs and environmental effects.

By Heat Source

The global pressure vessels market is expected to demonstrate constant growth as industries seek stronger and more secure equipment to manage high-pressure activities. Pressure vessels are employed in numerous industries such as energy, chemicals, and manufacturing, and contribute significantly to maintaining systems secure and efficient. One significant way of viewing this market is by heat source, with the vessels categorized into two: fired and unfired pressure vessels. Both have their function and set of benefits based on the operation's needs.

Fired pressure vessels employ a direct heat source, for example, a flame or furnace, to bring heat into the contents inside. These are typically used in power plants and chemical processing plants. They are heat and pressure-resistant vessels, and their purpose is directly related to the generation of energy. As power demand increases and more efficient technologies are sought, these vessels will continue to be of value. In parallel, there is a greater emphasis on cleaner and more secure fuel sources. This can affect the production and application of fired vessels in the future, encouraging companies to produce designs that are adaptable with various sources of energy.

Alternatively, unfired pressure vessels do not employ direct heating. They utilize other means like steam or electricity to warm or transfer fluids and gases. These vessels are prevalent in industries that prioritize safety and energy conservation. As more businesses embrace renewable energy and seek to reduce carbon emissions, unfired vessels will be increasingly essential. Their pressure-handling capabilities without open flames make them particularly useful for operations where safety and environmental sensitivity are chief concerns.

In the future, both pressure vessel types will be required to evolve as the world adjusts to changing standards and growing expectations for safety, longevity, and performance. Firms will spend more on research and development to create vessels that are longer-lived and function in more challenging environments. New materials and intelligent monitoring systems could also determine the manner in which vessels are constructed and serviced. As markets increasingly integrate and attention turns toward more environmentally friendly operations, the global pressure vessels market will evolve to address these issues.

The future of the market is not only about providing tough equipment but also about enabling advancement in cleaner energy and safer manufacturing. The balance between toughness, safety, and innovation will drive the way the market develops and in which direction it will proceed in the next few years.

By Application

The global pressure vessels market will keep rising steadily because the demand from a number of industries continues to grow. The vessels are utilized for various crucial purposes, two of the most important being storage vessels and processing vessels. Both play specific purposes and are required in a different set of industrial operations. Storage tanks are employed to store liquids or gases, whereas processing vessels are employed to facilitate chemical reactions, heat transfer, or other processes involving controlled pressure. As industries grow, demand for both vessels will grow. The globe is headed towards more sophisticated manufacturing, energy generation, and chemical processing systems. These developments will have a direct bearing on pressure vessel design, construction, and application.

Safety, reliability, and efficiency will be even greater concerns in the near future. Numerous companies will concentrate on designing ships that can withstand more pressure without failing. There could be new materials employed, those that are lighter, stronger, and capable of weathering harsh conditions. Vessels will probably be designed to last longer and be easier to maintain. Technology will be a large player, with sensors being installed inside the vessels to track temperature and pressure in real-time. Accidents will be avoided, and downtime will be minimized. Pressure vessels will not merely be containers anymore but will be intelligent tools that provide useful feedback.

Increased emphasis on clean energy will also mold this market. As nations transition to alternatives such as hydrogen, pressure vessels will be required to handle and process these gases in a safe manner. Hydrogen, for instance, must be stored at high pressure, so traditional designs may have to change. This transition will introduce new challenges but also create new opportunities. Businesses that evolve and provide sure and new solutions will be highlighted. The pressure vessel sector will experience new collaborations between material providers, manufacturers, and technology developers to address future needs.

Due to these developments, research and development investment will increase. Companies will seek means to make vessels safer, less expensive, and more convenient. Governments can also introduce new regulations to guarantee security and environment conservation, further promoting innovation. The future of the global pressure vessels market will be determined by the success these systems have in satisfying new industrial and environmental requirements. Storage and processing vessels will both continue to be vital, and their design will continue to change to serve an increasingly safe and efficient industrial world.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$62,554.84 million |

|

Market Size by 2032 |

$82,281.61 Million |

|

Growth Rate from 2025 to 2032 |

4.0% |

|

Base Year |

2024 |

|

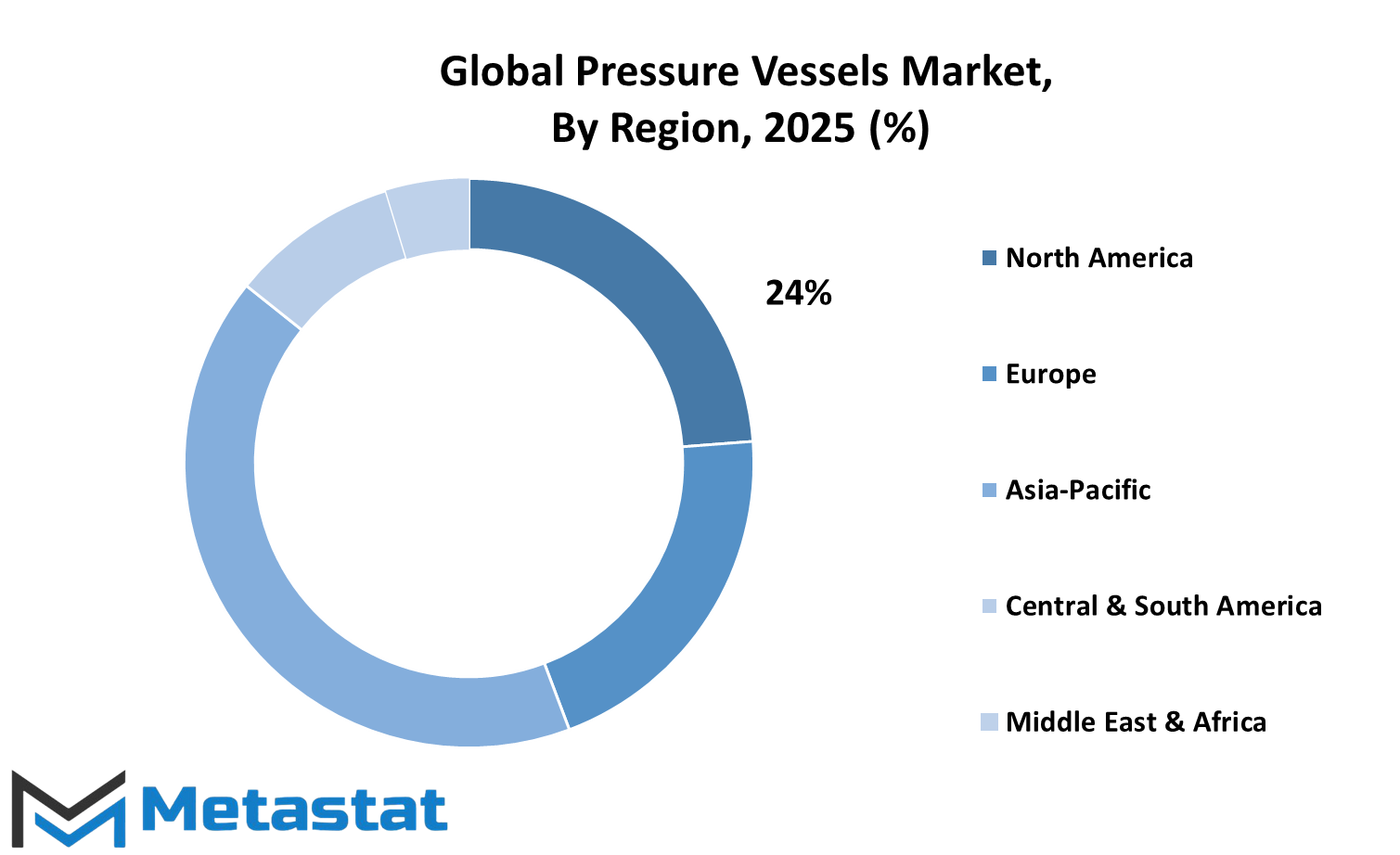

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global pressure vessels market is influenced by numerous global trends across many regions that will still drive its growth in the forthcoming years. Considering every region separately explains how various regions are gearing up for future needs, industrial transformations, and energy production changes. North America, for example, is consistently emphasizing modernization and enhancing safety in its infrastructure. The United States, Mexico, and Canada are all investing in chemical and energy manufacturing industries, which will be the drivers of future demand for pressure vessels. As sustainability becomes a common objective, industries throughout this region will increasingly look to cleaner energy sources, opening opportunities for pressure vessel use in newer technologies like hydrogen and carbon capture.

Europe, however, is likely to lead further into clean energy use. Countries like the UK, Germany, France, and Italy are moving away from fossil fuel dependency and leaning towards advanced energy storage systems. These developments will require strong, high-performance equipment, and pressure vessels will play a vital role. The market here is likely to see long-term growth as governments continue to support green technology initiatives and industrial safety regulations tighten. Throughout the remainder of Europe, parallel investments and policy reforms will increasingly underpin demand for advanced pressure vessels.

Asia-Pacific possesses some of the most promising potential for long-term market development. As China, India, Japan, and South Korea grow their industrial production, pressure vessel usage will increase steadily. Population growth and increasing energy requirements will stimulate additional investment in chemical processing, power production, and oil and gas infrastructure. Concurrently, innovation and cost-effective production within this market will position Asia-Pacific as a leading player in global Pressure Vessels production and consumption. Over the next several years, this region will likely remain at the forefront of volume and rate of development.

South America, too, is set to become more engaged in the future of the market. Brazil and Argentina are slowly opening up their energy and manufacturing industries. With increasing emphasis on production at home and overseas capacity, there will be a growing demand for pressure vessels that are trustworthy. In the Middle East and Africa, diversification of the economy is set to open new industry opportunities. As nations like Egypt, South Africa, and those in the GCC strive to develop away from oil, the need for safe and effective industrial equipment will become increasingly significant, making the global pressure vessels market even stronger.

COMPETITIVE PLAYERS

The global pressure vessels market is slowly forming itself into a progressively more advanced and competitive arena, propelled by continuous technological advancements and increasing industrial requirements. With most industries aiming to optimize efficiency, safety, and sustainability, the demand for pressure vessels is anticipated to maintain the same upward direction. These containers, which play a critical role in gas and liquid handling and storage under pressure, are gaining prominence in industries such as oil and gas, power generation, chemicals, and manufacturing. What is interesting about this market is not only the demand itself, but also the firms at the forefront of creating newer and more efficient products.

There are a number of key players driving innovation and reliability in this market. Firms like Larsen & Toubro Limited and Mitsubishi Heavy Industries, Ltd. enjoy long histories of reputation based on engineering prowess and steady performance. Their capacity to evolve toward shifting customer requirements and regulatory expectations has served to keep them grounded in the market. Ergil and Doosan Heavy Industries & Construction are also known for providing customized pressure vessel solutions that cater to demanding industrial needs. These companies are demonstrating how an eye for detail and research investment can define the future demand.

Other significant contributors are Gladwin Tank, IHI Corporation, and Bharat Heavy Electricals Limited (BHEL). They have all created special niches, employing cutting-edge manufacturing processes and superior-quality materials to provide reliable solutions. Their long-term dedication to client satisfaction and operational security shows the path the market will follow, where reliability is a matter of course rather than a choice. While Samuel Pressure Vessel Group and Abbott & Co (Newark) Ltd are versatile and global in reach, further assisting in serving local and global needs in effective measure.

Smaller but significant names such as Robinson Pipe & Vessel, Alloy Custom Products, and Ross Engineering, Inc. are driving innovation by providing customized solutions that are capable of fitting into various kinds of industrial operations. Springs Fabrication, Inc., Manchester Tank & Equipment Co., VPE, HOLLOWAY AMERICA, and TITAN Metal Fabricators are similarly active players that will drive the future course. These firms will be concerned with quality, compliance, and design flexibility, all issues that will become increasingly important as industries mature and global requirements change.

The global pressure vessels market will increase in size and sophistication, driven by the strategies and choices of these dominant players. What they do now is establishing the foundation for what the market will be like in the future.

Pressure Vessels Market Key Segments:

By Material Type

- Titanium

- Nickel & Nickel Alloys

- Tantalum

- Steel

- Others

By Product

- Boiler

- Nuclear Reactor

- Separator

- Others

By Heat Source

- Fired Pressure Vessels

- Unfired Pressure Vessels

By Application

- Storage Vessels

- Processing Vessels

Key Global Pressure Vessels Industry Players

- Larsen & Toubro Limited

- Mitsubishi Heavy Industries, Ltd.

- Ergil

- Doosan Heavy Industries & Construction

- Gladwin Tank

- IHI Corporation

- Bharat Heavy Electricals Limited (BHEL)

- Samuel Pressure Vessel Group

- Abbott & Co (Newark) Ltd

- Robinson Pipe & Vessel

- Alloy Custom Products

- Ross Engineering, Inc.

- Springs Fabrication, Inc.

- Manchester Tank & Equipment Co.

- VPE

- HOLLOWAY AMERICA

- TITAN Metal Fabricators

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383