MARKET OVERVIEW

The global anchoring fasteners market is a special part in manufacturing and construction sector, providing critical mechanical parts which will have behind-the-scenes functions but also help in structural support. Anchoring fasteners, designed to anchor primarily things into concrete, masonry, or another material, are a vital component in industrial buildings and business construction. Since the demand for strength and building stability will persist to influence engineering design, the market for these fasteners will develop not in melodramatic leaps, but in incremental leaps forward of material science and application quality.

It is not a market built on broad consumer trends or fleeting alterations in popular taste. Instead, it indicates more industry requirements like precision engineering, seismic safety requirements, and ongoing focus on enduring performance under unexpected stress conditions. The market players in the global anchoring fasteners market are mechanical anchor producers, adhesive systems, and expansion bolts, engineers, and contractors who rely upon them for dependable performance in applications involving loads. Every application, from bridge reinforcement to offshore rig installation, requires a particular combination of mechanical strength, corrosion resistance, and environmental durability.

Instead of using seasons or style, this market will be driven by changing building codes, changes in civil engineering practice, and scientific progress in the science of materials. It will also be more segmented according to anchor type, base material compatibility, and installation method. Although anchoring fasteners can look the same in construction to the inexperienced eye, the difference is with regard to performance characteristics like pull-out capacity, load transfer efficiency, and fatigue and environmental degradation resistance over extended durations.

The global anchoring fasteners market will not be limited to new build only. Much of future demand will be for retrofitting and rehabilitation of old infrastructure in high-income economies. Old bridges, tunnels, and public buildings, many of them decades old, will require their anchoring systems renewed in order to meet new safety standards. The constant requirement for structural reinforcements will create a consistent pipeline for market activity, unaffected by cyclical economic forces.

Another force that will determine this market will be geographic demand diversity. Developing economies will concentrate on technical upgrades and compliance, while advanced economies will keep investing in basic infrastructure where anchor fasteners have rudimentary but essential functions. However, there will not be a global standard owing to dissimilarities in climate, construction methods, and available material across geographical areas.

In coming years, businesses in the global anchoring fasteners market will be investing in testing capability, production precision, and application-specific innovation. This investment will be low in building new demand and high in guaranteeing performance in a broader spectrum of structural uses. With building increasingly crossing ecological considerations and durability goals, demand for durable anchoring systems will be consistent and increasingly technologically demanding.

In the end, the global anchoring fasteners market will be guided neither by hype nor by shallow surface-level technology. Its path will be rather a slow, deliberate reaction to the engineering need of a world that still erects, renews, and reinforces the buildings on which contemporary life rests.

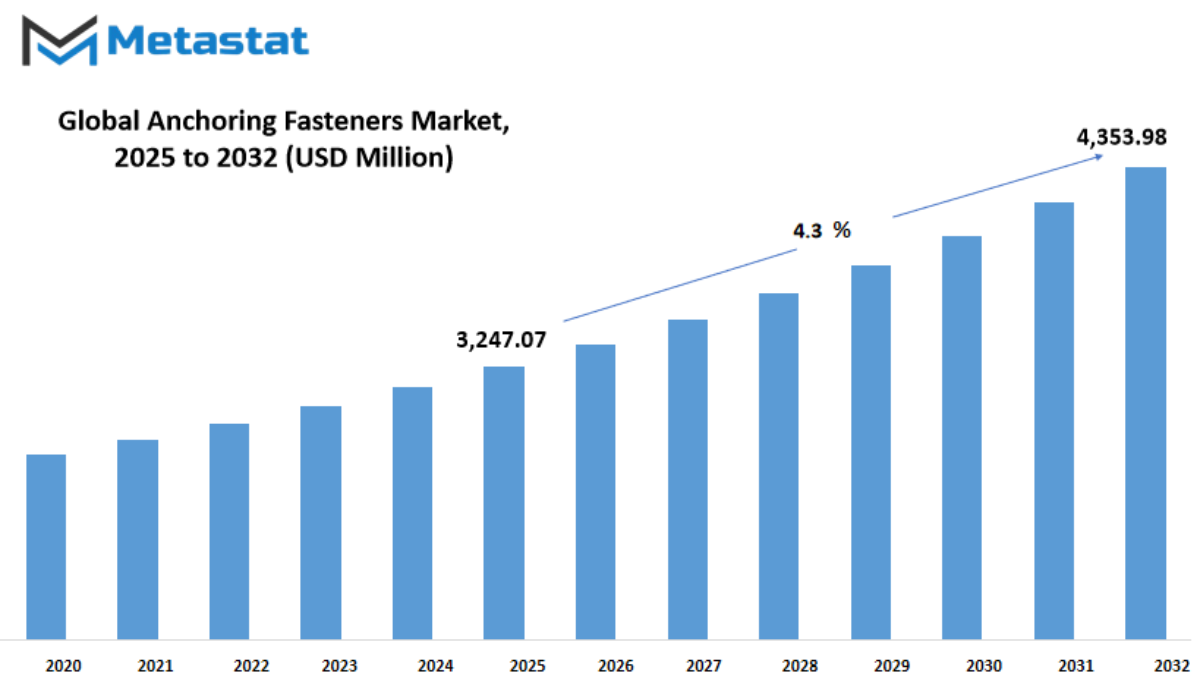

Global anchoring fasteners market is estimated to reach $4,353.98 Million by 2032; growing at a CAGR of 4.3% from 2025 to 2032.

GROWTH FACTORS

The global anchoring fasteners market is expected to grow steadily due to the rising need for stronger, longer-lasting fastening systems in both infrastructure and commercial construction. As cities expand and the need for reliable support structures becomes more critical, anchoring fasteners play a key role in ensuring safety and stability. They are especially important in large projects where secure connections between building materials are essential. This demand will continue to rise as governments and private sectors invest in better transportation networks, public buildings, and energy facilities that all require dependable anchoring solutions.

Another important factor contributing to market growth is the increase in renovation and retrofit projects. Many older buildings, bridges, and roads are being updated to meet current safety standards, and this creates a strong need for fastening products that can be installed securely in existing structures. These kinds of projects often require anchoring systems that are not only reliable but also easy to use in a variety of materials such as concrete, brick, or stone. As more attention is given to making older infrastructure safer and more energy efficient, the demand for such products will only go up.

However, the market does face some challenges. One major issue is the fluctuating cost of raw materials used in manufacturing. Metals like steel and other alloys, which are essential for making fasteners, often see price swings that affect production costs. When these costs rise sharply, it becomes harder for manufacturers to maintain consistent pricing, which can slow down market growth. Another concern is the strict standards that companies must follow during the installation process. Fasteners need to meet specific codes and testing requirements, which can make the process more complex and time-consuming for installers and builders alike.

Looking ahead, there are strong opportunities for innovation in this area. The development of corrosion-resistant and high-performance anchoring fasteners designed for use in tough conditions will likely boost demand. These advanced fasteners will be especially useful in projects located in coastal or industrial areas, where exposure to harsh elements can quickly damage standard materials. Companies that focus on making their products more durable and easier to install will have a better chance of leading the market in the future. As technology improves and construction needs become more specific, anchoring fasteners will need to keep up by offering smarter and more resilient solutions that builders can rely on.

MARKET SEGMENTATION

By Type

The global anchoring fasteners market is expected to grow steadily as construction practices, infrastructure projects, and industrial activities continue to expand across the world. This market, by type, is further segmented into mechanical anchors, chemical anchors, and plastic anchors. Each of these types plays a unique role in securing materials to concrete, masonry, or other surfaces. As modern building designs evolve to include more complex structures and materials, the need for reliable fasteners will become even more essential. Builders and engineers will keep looking for strong, easy-to-install, and cost-effective options, and this is where anchoring fasteners will remain key.

Mechanical anchors, for example, are popular due to their ability to hold high loads immediately after installation. These fasteners are commonly used in heavy-duty applications such as bridges, tunnels, and multi-story buildings. As urban areas become denser and construction projects demand faster timelines, mechanical anchors will likely be used more often because they reduce downtime and speed up project delivery. Their ability to perform under pressure in harsh conditions makes them a go-to choice for large-scale developments.

Chemical anchors, on the other hand, offer more flexibility in terms of load distribution and placement. These fasteners are useful when working with older or damaged concrete because they do not cause expansion stress. They bond directly to the base material, creating a strong hold that is ideal for structural upgrades or retrofitting. In the future, as sustainability becomes a larger part of construction planning, chemical anchors may see more use in renovation work where existing materials are preserved rather than replaced.

Plastic anchors, while generally used for lighter tasks, will also remain important. Their cost-effectiveness and ease of use make them suitable for residential and light commercial projects. As do-it-yourself (DIY) culture and small-scale construction become more popular, plastic anchors may see a rise in demand, especially in emerging markets where affordability is a key factor.

Overall, the global anchoring fasteners market will continue to be shaped by innovations in material science, changing building codes, and the push for faster, safer, and more durable construction methods. With smart cities and green buildings becoming more common, anchoring systems will have to meet higher expectations. This steady transformation in how buildings are designed and built ensures that anchoring fasteners will remain an essential part of modern infrastructure.

By Substrate

The global anchoring fasteners market is expected to grow steadily in the coming years due to rising construction needs and infrastructure improvements across both developed and developing regions. As cities expand and older buildings require maintenance, fasteners play a key role in keeping structures secure and reliable. They are used to attach one material to another, especially where strong and lasting bonds are needed, like in bridges, tunnels, commercial buildings, or residential developments. Their importance will increase as safety regulations and engineering standards become more strict.

Looking at how the global anchoring fasteners market is divided by substrate, several materials stand out. Concrete remains the most common material for anchoring fasteners. This is because it is widely used in construction and provides a strong base. As construction companies aim for greater strength and durability, fasteners that are compatible with concrete will remain in high demand. Solid masonry is another important substrate. These are stones or bricks without holes, often used in older buildings or specific architectural styles. Fasteners used here must be durable and resistant to wear, especially as more attention is being given to preserving historic structures.

Hollow or perforated masonry is different. These materials have gaps or holes, which means the fasteners need to be designed to grip securely without causing cracks or damage. As lightweight construction methods gain popularity, this type of masonry will likely be seen more often, and the market will need to adapt with better fasteners. Autoclaved aerated concrete (AAC) is also a growing segment. It is lighter and offers better insulation than regular concrete, making it useful in energy-efficient building designs. However, AAC is more fragile, so fasteners for this material have to be specially made to avoid breaking or weakening the structure.

Other substrates include unique or newer materials that may not yet be widely adopted. As innovations in construction materials continue, especially those that focus on reducing environmental impact, the market will need to adjust. Manufacturers will develop fasteners that are lighter, stronger, and more resistant to temperature changes or moisture. In the future, we will likely see smarter fastening systems as well possibly with built-in sensors to detect wear or stress over time. The global anchoring fasteners market will not only expand in size but also shift toward more advanced, safer, and efficient solutions to meet the growing demands of modern construction.

By End Use

The global anchoring fasteners market is expected to see steady growth in the coming years, shaped by both rising infrastructure demands and ongoing industrial development. These fasteners play a key role in connecting structural components securely to concrete or masonry surfaces, making them essential in a wide range of building and repair activities. As more countries invest in stronger infrastructure, smart cities, and greener energy solutions, the demand for reliable anchoring systems will only grow stronger.

In the construction and real estate sector, the use of anchoring fasteners will continue to rise. As buildings become taller and more complex, the need for sturdy fastening systems increases. Whether in residential towers or commercial spaces, safety standards are pushing for higher-quality materials and better installation methods. Contractors and developers are now more aware of the long-term value of reliable anchoring solutions, especially as building codes become stricter across many regions.

The energy and utilities sector is also driving change in the global anchoring fasteners market, particularly with the growing use of solar panels and green roofs. Anchoring fasteners are vital for installing these systems safely on rooftops and open land. As governments across the globe continue to support renewable energy projects, the market will benefit from increased investment. Fasteners used in these projects must hold up against weather changes and carry heavy loads for long periods, making quality and durability major factors in product choice.

In industrial and manufacturing facilities, anchoring fasteners help secure heavy machinery and structural components. As automation and robotics increase in factories, there will be a greater need for fastening solutions that can handle vibration and constant use. These facilities are also moving toward more flexible and modular setups, which means fasteners that are easy to install and remove will become more popular.

Government and public sector projects also add to the growing demand. Roads, bridges, airports, and rail systems all rely on dependable anchoring methods. With many countries focusing on public safety and resilience in construction, especially in areas prone to natural disasters, the demand for high-performance anchoring fasteners will likely continue to expand.

Other sectors like sports complexes, warehouses, and educational institutions will also contribute to market growth. As more of these facilities are built or upgraded, anchoring fasteners will remain a basic yet critical part of their design and structure. Looking ahead, as materials and technologies improve, the global anchoring fasteners market will keep evolving to meet both current and future building challenges.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$3,247.07 million |

|

Market Size by 2032 |

$4,353.98 Million |

|

Growth Rate from 2025 to 2032 |

4.3% |

|

Base Year |

2024 |

|

Regions Covered |

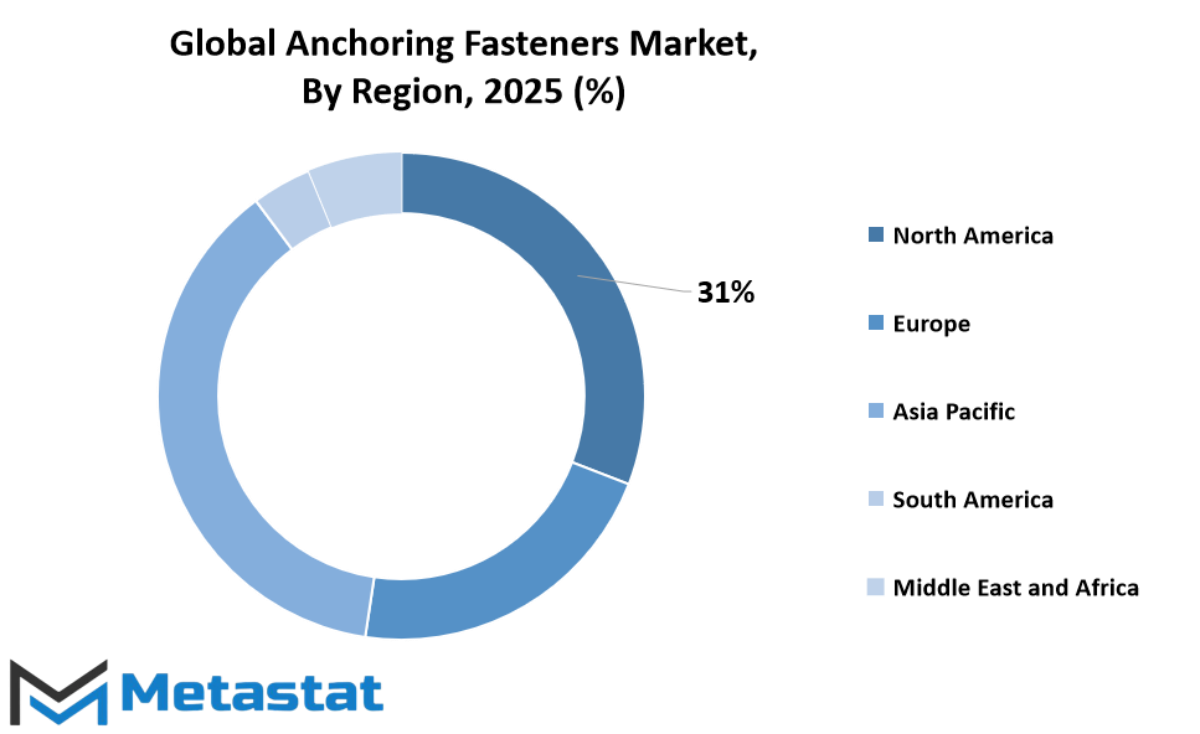

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global anchoring fasteners market is shaping the future of how construction and infrastructure projects will be handled across the world. As the need for durable, reliable, and cost-effective building solutions increases, anchoring fasteners are becoming a core part of how structures are secured and stabilized. With rising investments in commercial and residential construction, transportation networks, and industrial developments, the demand for these fasteners will only grow in the coming years. The push for urbanization, especially in emerging regions, is expected to fuel innovation and expansion across several sectors that rely on strong and secure fittings.

Looking at the geographical division, each region contributes in its own way to the growth and direction of the global anchoring fasteners market. North America, including the U.S., Canada, and Mexico, continues to lead with its advanced engineering techniques and large-scale infrastructure projects. The U.S., in particular, will remain a major consumer due to its ongoing upgrades in bridges, highways, and public buildings. Canada and Mexico will also see steady growth due to their investments in housing and energy sectors.

Europe, covering the UK, Germany, France, Italy, and other countries, is focusing on sustainability and energy efficiency. Germany and the UK will likely increase their use of high-strength fasteners in renewable energy installations and transportation upgrades. The region’s focus on reducing environmental impact will encourage the adoption of products that are both long-lasting and environmentally friendly.

In the Asia-Pacific region, including India, China, Japan, South Korea, and others, the future is especially promising. As the population continues to grow and cities expand, the need for new infrastructure will drive demand. China and India will play a significant role as they keep building highways, railways, and large commercial spaces. Japan and South Korea, known for their technological advancements, will likely adopt more smart construction methods that depend on reliable anchoring systems.

South America, including Brazil and Argentina, is seeing renewed interest in construction as governments focus on improving public infrastructure. Projects in transportation and urban housing will keep the market active. In the Middle East and Africa, with GCC countries, Egypt, and South Africa at the forefront, development projects related to oil, gas, and tourism will keep the need for anchoring fasteners alive. These countries are working on ambitious city planning and industrial development, which means the market will continue to grow. Over time, the global anchoring fasteners market will be shaped by innovation, regional growth trends, and the global push for more stable and efficient construction practices.

COMPETITIVE PLAYERS

The global anchoring fasteners market is expected to see steady growth in the coming years, shaped by the demand for durable construction materials and advanced fastening solutions. Anchoring fasteners are widely used in both residential and commercial construction projects, infrastructure development, and industrial equipment installations. As building designs grow more complex and safety requirements become stricter, the need for reliable fastening systems will become even more important. These products play a key role in ensuring structural stability and long-term performance across a range of applications.

Several major companies are working to stay ahead of this growth by offering innovative and cost-effective fastening options. Companies like Hilti Group and the Würth Group are investing in smarter technologies and tools that support faster installation and improved load resistance. Their focus is on reducing labor time without compromising safety. Simpson Strong-Tie Company Inc. and Sika AG are also bringing forward products that support sustainable construction practices, using materials that are both strong and environmentally responsible.

Competition in the global anchoring fasteners market is not only about quality but also about how quickly companies can respond to project-specific needs. UNIQUE Fastners and Pacific Bolt Manufacturing Ltd. are known for their ability to produce customized solutions for unique environments. Meanwhile, Powers Fasteners, Inc. (DEWALT) and Rawlplug S.A. are enhancing their product lines by offering versatile options that can perform well under a range of conditions, from seismic zones to high-humidity areas. This flexibility will be crucial in the years ahead as climate conditions continue to shift and buildings must be adapted to new stressors.

Companies like Structural Bolt and Manufacturing, Fischer Group, and Mungo Befestigungstechnik AG are focusing on improving supply chains to make delivery times shorter and products more accessible across global markets. Their aim is to meet growing demand without raising costs significantly. On the other hand, BTM Manufacturing and Classic Metallic Sheets Factory LLC. are leaning into automation and precision engineering to create fasteners that meet tighter tolerances and work well in advanced construction systems.

Looking forward, the global anchoring fasteners market will not only be defined by product performance but also by how well companies align with evolving construction trends. The strongest players will likely be those who can blend technology, adaptability, and sustainability into their manufacturing and design processes. As urban spaces expand and infrastructure projects become more ambitious, the need for strong and efficient fastening solutions will only grow.

Anchoring Fasteners Market Key Segments:

By Type

- Mechanical Anchors

- Chemical Anchors

- Plastic Anchors

By Substrate

- Concrete

- Solid Masonry

- Hollow or Perforated Masonry

- Autoclaved Aerated Concrete

- Others

By End Use

- Construction & Real Estate

- Energy & Utilities (Solar and Green Roofs)

- Industrial & Manufacturing

- Government & Public Sector

- Others

Key Global Anchoring Fasteners Industry Players

- Hilti Group

- Structural Bolt and Manufacturing

- UNIQUE Fastners

- Powers Fasteners, Inc. (DEWALT)

- Pacific Bolt Manufacturing Ltd.

- Classic Metallic Sheets Factory LLC.

- BTM Manufacturing

- Würth Group

- Fischer Group

- Simpson Strong-Tie Company Inc.

- Mungo Befestigungstechnik AG

- Rawlplug S.A.

- Sika AG

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252