MARKET OVERVIEW

The global polyphenylene ether market is an important segment of high-performance polymers that combines performance properties of heat resistance, dimensional stability, and mechanical strength. Although there are several applications that have established precedence in automotive, electrical, and industrial sectors, the scope of polymerization with respect to new applications extends far beyond these traditional application areas. In the future, this market will be transformed into an innovative approach, altering its scope in line with industry movement towards green, advanced material alternatives.

Undoubtedly, the most exciting possibility is space exploration. With rising investments in aerospace technology and interplanetary missions, there will be a growing requirement for materials that can withstand extreme temperatures and radiation exposure. The Global Polyphenylene Ether market stands to benefit in this field due to thermal stability and resistance to very harsh environmental conditions. The fact that the polymer is lightweight and capable of maintaining structural integrity may lead to its future applications, such as spacecraft components, satellite structures, and protective coatings in missions outside the terrestrial environment.

This avenue that holds great promise is known as biomedical engineering. It is the only field where ongoing developments in materials science are redefining the healthcare future. This is partly because of the biocompatibility and chemical degradation resistance of the polymer, which makes it a preferred candidate for medical implants and surgical tools for drug delivery. With the demands for non-toxic and long-lasting materials required for the well-being of humankind, innovative processing techniques can in the future place the Global Polyphenylene Ether market firmly into next-generation medical devices.

Renewable energy- This polymer can also result in advanced breakthroughs in solar-panel technologies as well as wind turbine manufacturing. As the energy demand increases further and becomes critical at a global level, a need arises for tough, efficient materials. The Global Polyphenylene Ether market may require expanded use in photovoltaic modules and turbine blade components due to its ability to endure prolonged exposure to UV radiation and high temperatures. Research efforts directed toward improved conductivity and resistance to weather will further enhance its role in sustainable energy solutions.

Advanced manufacturing is also a unique opportunity for artificial intelligence. With industries rapidly going to automation, especially with visionary ideas of getting artificial intelligence in it, there is a need for high-performance polymers to support very complex robotic systems, electronic sensors, and smart materials. The Global Polyphenylene Ether market would gain from these advances through lightweight but strong solutions for next-generation industrial automation and precision-driven technologies.

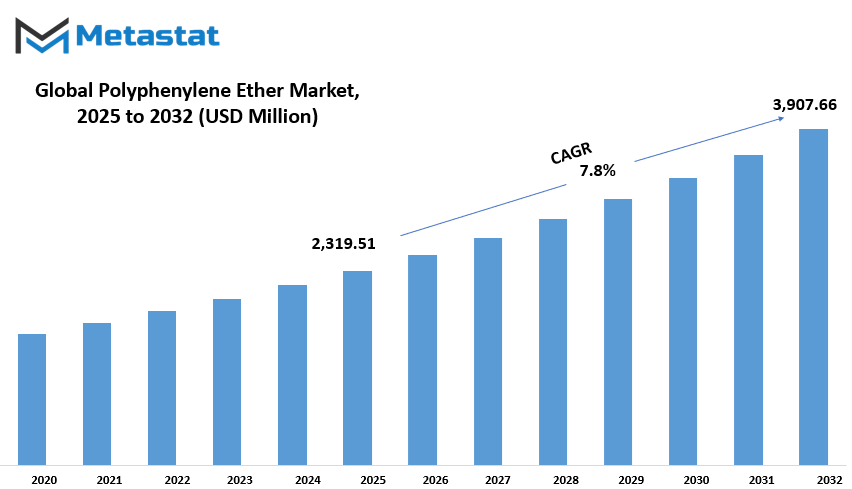

Global Polyphenylene Ether market is estimated to reach $3,907.66 Million by 2032; growing at a CAGR of 7.8% from 2025 to 2032.

GROWTH FACTORS

Polyphenylene ether has really become a ubiquitous and fast-growing material in the industries around the globe, as a material that is tough and efficient. One of the key drivers of increased demand around the use of this material is the deep-rooted application of lightweight, high-performance plastics in the automotive and electronics industries.

These considerations make polyphenylene ether a material of choice for automobile manufacturers who wish to reduce weight in vehicles for enhanced fuel economy against lay-down regulations; besides, the properties of this polymer include excellent thermal and mechanical specifications. The electronics sector equally seeks materials that endure not-so-high temperatures yet are able to give electrical insulation; hence, the increasing acceptance of polyphenylene ether investments. The companies are thus continuously working towards integrating polyphenylene ether in their products to get more of the balance between durability and productivity with cost.

The other element that has set a new trend in the market is the increased competitiveness among engineering plastics towards sustainability and recyclability. Environment and waste-related stringent regulations raised challenges to manufacturers in seeking alternatives in reducing waste generation and enhancing recycling. Polyphenylene ether fits well in those industries looking out for a balancing act or performance with sustainability. It can be mixed with other polymers to make composites that are suitable not only for industrial performances but also for global sustainability goals. Firms that invest in such eco-conscious plastics feel that their growth opportunities would be enhanced by serving these socially savvy consumers and industries.

However, challenges such as high manufacturing costs impede further polyphenylene ether adoption. One major concern is the high cost of manufacturing it. Increased expenses are borne by complex processing requirements and sophisticated technology, which axiomatically reduce availability to some manufacturers. In addition, any significant fluctuation in the rates of raw materials becomes another hurdle affecting profitability in such a manner that uncertainty prevails as to the likely path any business render itself in future. Accordingly, a pressing concern for players engaged in the industry, therefore, remains in finding cost-efficient ways of production.

On the contrary, the emerging opportunities point out new directions for market growth. Fast-growing adoption of polyphenylene ether associated with electric vehicles and renewable energy applications holds the essential trend that is expected to give stimulation for growth in the predicted period. As globally activities toward clean energies progress, materials that ensure performance and reliability are countertops. Technological advancements are also making material properties better and allow new applications across a range of industries.

MARKET SEGMENTATION

By Type

The Global Polyphenylene Ether market is on the rise as industries understand its multifunctional usage and advantages across different segments within such types as PPO Resin, which is valued at $686.00 million, and Modified Polyphenylene Oxide (MPPO), each serving different industrial applications. The increasing demand for these materials comes from excellent properties such as high thermal resistance, lightness, and impressive mechanical resistance. Therefore, automotive, electrical, and healthcare industries rely on these materials for their economic values and durability in harsh environments.

PPO Resin presents an enormous capacity to boost the performance of countless products for this reason. It is used commonly in automobiles, where the companies look for lightweight and heat-resistant materials to improve fuel efficiency and durability for use in vehicles. Additionally, the electrical and electronics sectors enjoy the insulating qualities of the resin for safer, more reliable electric components. As technology evolves over the years, PPO Resin is set to remain a core material for high-performance solutions across multiple industries.

Modified Polyphenylene Oxide (MPPO) adds versatility, allowing its use in those applications that require enhanced resistance to chemicals and enhanced structural integrity. It is a variant which therefore grants industries an opportunity to tailor material properties according to their demands, thus broadening the role of MPPO within specialized manufacturing processes. Because MPPO is stable in extreme conditions under which performance and longevity may matter a lot, it becomes the material of choice in such fields.

As industries seek alternative means to innovate within material solutions, it further projects growth in the Global Polyphenylene Ether market in up coming years. Corporations invest in research and development to better refine the technology for production and performance output of products to meet standards which keep changing in industries. The environment focus and energy efficiency are also further contributors to this growth.

With continued development and advancements, therefore, the Polyphenylene Ether market is likely to turn on with more applications and higher technology. Materials' adaptability would enable them into relevance in contemporary manufacturing, shaping the fate of different industries that rely on polymers of improved quality in terms of performance and durability.

By Application

Global Polyphenylene Ether market is on the road to steady growth with all kinds of industries realizing the usefulness of this product in varied applications across the globe. Manufacturers appreciate the material for its properties of being harder than nails, heatproof, and light in weight. This material is therefore very widely used across different industries. In terms of application areas, the market is divided into air separation membranes, medical machinery, automotive components, electronic parts, and fluid handling systems. Demand for Polyphenylene Ether therefore increases in each of these segments, making them prime candidates for use by industries that want real performance and efficiency enhancements from their materials.

Air separation membranes are of considerable importance for industrial gas production that Polyphenylene Ether could contribute to stability and longevity. Polyphenylene Ether can withstand severe temperature variations while maintaining structural integrity; hence, it has the rightful place in this field. In the same sense, safety and durability in medical instruments will be assured by the inertness and hygiene properties of Polyphenylene Ether.

An important area of Polyphenylene ether application arises from the automotive industry, which heavily relies on this material to manufacture lightweight, heat-resistant components capable of improving fuel efficiency and overall performance of vehicles.

Polyphenylene Ether ably meets the requirements for endurance of heat and electrical stress in electronic components. Circuit boards, connectors, and insulation materials are made out of the material, which improves the reliability and safety of electronic equipment. Fluid handling is enabled using this material by corrosion resistance and its ability to work well in tough conditions. Polyphenylene Ether-based components are installed by industries in chemical handling, water treatment, and fuel distribution to achieve long life and operational efficiency.

The Global Polyphenylene Ether market is set to grow as industries continue to explore its advantages. Businesses are investing in refining production techniques to enhance quality and flexibility. Research and development programs are aimed at the improvement of material properties for use in newly emerging sectors. With increasing awareness of sustainable and high-performance materials, this market is expected to remain important for industrial applications. The adoption of Polyphenylene Ether will continue by businesses seeking to optimize performance, reduce costs, and meet changing industry standards.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$2,319.51 million |

|

Market Size by 2032 |

$3,907.66 Million |

|

Growth Rate from 2025 to 2032 |

7.8% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

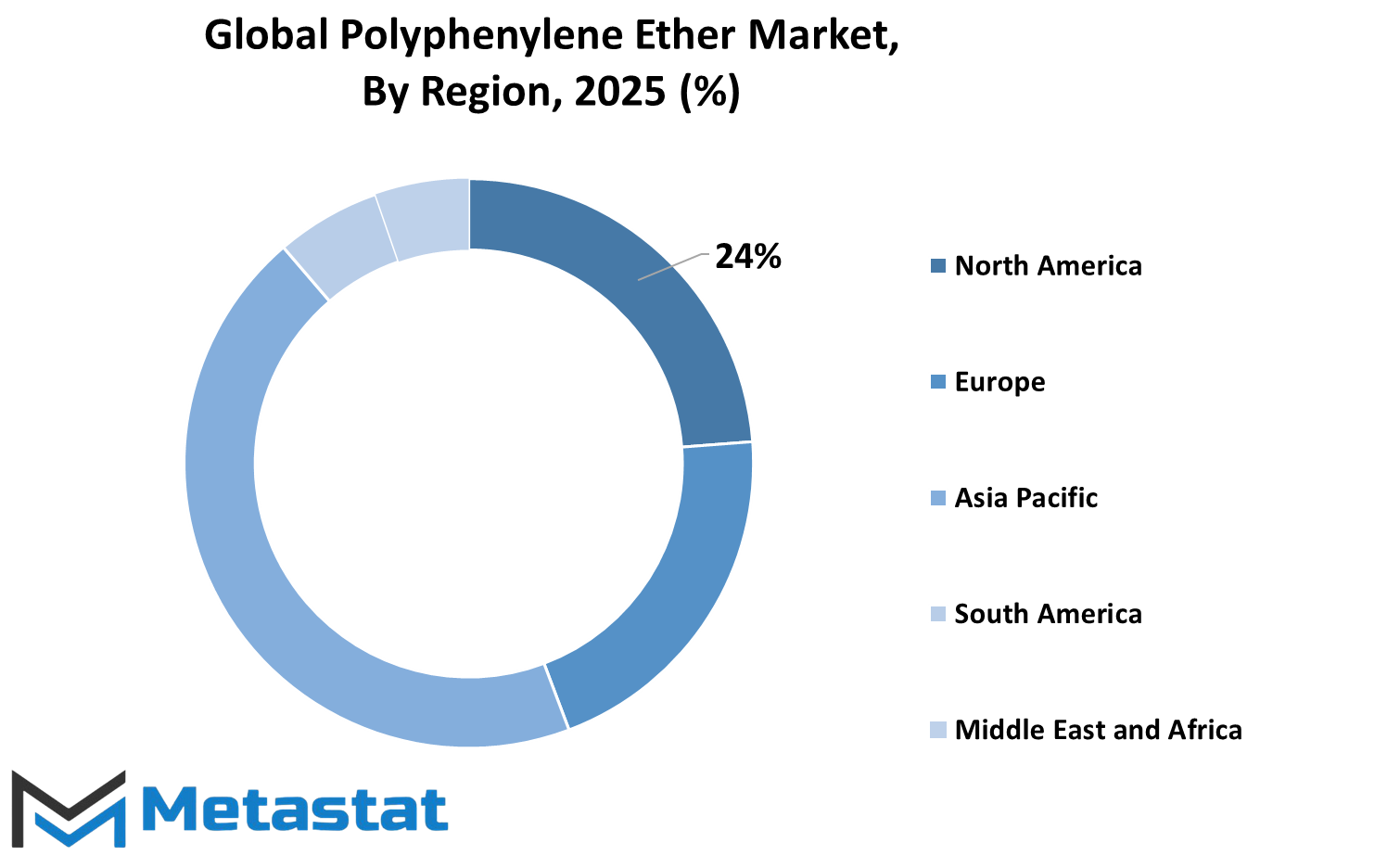

Ethylene is an indispensable Polyphenylene material in the market diversified into different regions, reflective of the growing demand for high-performance polymers across a variety of industries. Geography-wise, that is categorized in North America, Europe, Asia-Pacific, South America, and the Middle East & Africa; this will have an influence on growth in terms of its overall economics and industrial dynamics.

North America's special position in this market has been largely contributed to by the important roles played by the U.S., Canada, and Mexico as key routes for production and consumption within the region. This area benefits from advanced manufacturing technologies coupled with an extensive industrial presence relying on Polyphenylene Ether, including segments such as automotive, electronics, and healthcare. An ever-increasing demand for lightweight and heat-resistant materials has fueled the innovation-nurturing development of polymer solutions.

Such countries as the UK, Germany, France, and Italy drive the European market again by technological advancement and a trend towards sustainability. This is reflected in well-encapsulated industries and in research that continues in polymer science, which further drives the steady uptake of Polyphenylene Ether products. Increased usage of energy-efficient and durable materials by industries will further foster growing demand in this area.

Asia-Pacific has one of the leading growth markets in the world. India, China, Japan, and South Korea are the top producers and consumers within the continent. High-performance polymers are being used ever increasingly in various applications in electronics, automotive, and construction and, thus, account for the rising demand attributable to industrialization. These initiatives have made data more politically cost-effective while improving mechanisms for innovation and investments in manufacturing.

Brazil and Argentina mainly occupy this portion of South America, using Polyphenylene Ether for a wide array of industrial applications. Awareness on advantages of advanced polymer materials is gradually uplifting the markets in this particular region. In terms of development, it is still behind other regions; however, increasing adoption of high-quality engineering plastics is there to ensure steady progress.

Over the gradual growth of the Middle East and Africa, including GCC Countries, Egypt, and South Africa, industries now look forward to building more advanced materials for construction, automotive, and electrical applications. Economic diversification efforts and infrastructure projects continue to add to the accumulating usage of Polyphenylene Ether-based products in these regions as they modernize industries. Therefore, most of the development on the part of the market in terms of further growth will depend on the high-performance polymers needed in modernizing industries.

COMPETITIVE PLAYERS

Global Polyphenylene Ether market importance increased with industries recognizing its innumerable applications. This material is highly valued for high-temperature resistance, chemical resistance, and structural durability; hence, it finds varied applications in automotive, electronics, and healthcare sectors. Manufacturers are encouraged to bring Polyphenylene Ether into their processes because of its lightweight and durable characteristics that lead to the manufacture of efficient and long-lasting products.

The companies involved in the Polyphenylene Ether industry are leveraging for better production while enhancing their portfolios. The key players in this market include Hitemp Polymers Pvt. Ltd., Ensigner, Entec Polymers, LLC, Julier (Xiamen) Technology Co., Ltd., Asahi Kasei Corporation, Mitsubishi Chemical Corporation, SABIC, Nagase America LLC, ROMIRA GmbH, and Xiamen Keyuan Plastic Co., Ltd. These companies are now conducting R&D activities to modify Polyphenylene Ether properties to conform to the latest demand from modern applications.

It is in the automotive industry that this material has found its major applications in conjunction with vehicle parts for improving fuel efficiency and lightness. And in the electronics domain, the insulating properties of Polyphenylene Ether are utilized for the manufacturing of high-performance devices. Applications in medicine are also increasing demand as Polyphenylene Ether is being utilized for producing sterilizable and biocompatible equipment. Eco-friendly variations of the polymer will pick up pace since industries are looking for sustainable solutions.

Technological advances and industrial needs will further push the growth of the global Polyphenylene Ether market. Companies will continually optimize their formulations to ensure higher performance, cost-effectiveness, and environmental sustainability. As demand rises across a variety of sectors, manufacturers may have to start adjusting to new requirements and consider innovative applications for this flexible material.

Polyphenylene Ether Market Key Segments:

By Type

- PPO Resin

- Modified Polyphenylene Oxide (MPPO)

By Application

- Air Separation Membranes

- Medical Instruments

- Automotive Parts

- Electronic Components

- Fluid Handling

Key Global Polyphenylene Ether Industry Players

- Hitemp Polymers Pvt. Ltd.

- Ensigner

- Entec Polymers, LLC

- Julier(Xiamen) Technology Co.,Ltd

- Asahi Kasei Corporation

- Mitsubishi Chemical Corporation

- SABIC

- Nagase America LLC

- ROMIRA GmbH

- Xiamen Keyuan Plastic Co.,Ltd

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383