MARKET OVERVIEW

Global PBT resin will be dominated by the high-performance thermoplastics, namely PBT (polybutylene terephthalate) resin, as a major sector of the larger materials industry. Applications include automotive, electronics, and consumer goods. Due to superior mechanical properties, chemical resistance, and thermal stability, manufacturers are now searching for PBT resin as part of their selection of materials for applications under demanding conditions.

The automotive markets will necessitate the production of PBT resin as this demand for light materials grows in the automobile world. The upcoming production of more fuel-efficient designs for vehicles will be enabled through the usage of lighter parts. PBT resin will therefore become the material to produce extremely light yet so strong components to enable electrical connectors, housings, and internal components. They will not only make the cars more fuel efficient but also reduce emissions as a step closer to some of the world's sustainability goals.

It will also witness significant evolution into the electronics segment in this regard. As consumer electronics have grown increasingly compact and multi-functional, the need to develop materials holding integrity under both heat and pressure will rise very rapidly. The high thermal stability and excellent electrical insulating property of PBT make it an ideal material for components such as circuit boards, connectors, and insulators. The improved performance and reliability of the electronic devices will pave the way for more and more manufacturers to opt for PBT resin as against the conventionally used material.

The versatility of PBT resin would also benefit the consumer goods industry. It would be found in household items, appliances, and packaging. PBT has a longer lifespan and more resistance to wear, and thus, the products would last for years. Additionally, because PBT can be molded into complex shapes, the designs could significantly be innovative and aesthetically functional.

With environmental concerns growing in importance, the Global PBT Resin market would respond to that demand through the search for sustainable practices. The industry would move toward developing bio-based PBT resins that do not only outperform but also generate the least carbon footprint. These novelties would rather appeal to those customers who, with gradual maturity, have become increasingly concerned about the environment imposed by purchases made from their vendor and expand the market's appeal further.

PBT Resin Formulations - Developments in Research and Development Further Improvements in Properties Will Result Research and development of PBT resins have led to significant improvements in properties, and special grades for specific applications are developed from them. It is a part of a natural process of aging in the growth and change of industries, thereby increasing the demand for custom arrangements, which would continue to generate new opportunities in the Global PBT Resin market.

The Global PBT Resin market will be competitive with major and big established players, along with the new entrants. The companies will try to establish a niche through innovative products and green practices. Joint venture and partnership will be done among players to help the companies utilize each other's strengths and help hasten the development.

The Global PBT Resin market will be characterized by significant contributions in various industries, which will mainly be driven by the demand for high-performance materials. Industrially, value-added products will characterize it, where the necessity for material usage is proving to be the base of PBT's importance. As more and more industries try to upgrade themselves according to changing consumer preferences and regulatory standards, PBT resin usage will certainly attract pivotal importance. Such a market will lead to material innovation at the top, and the future holds great possibilities.

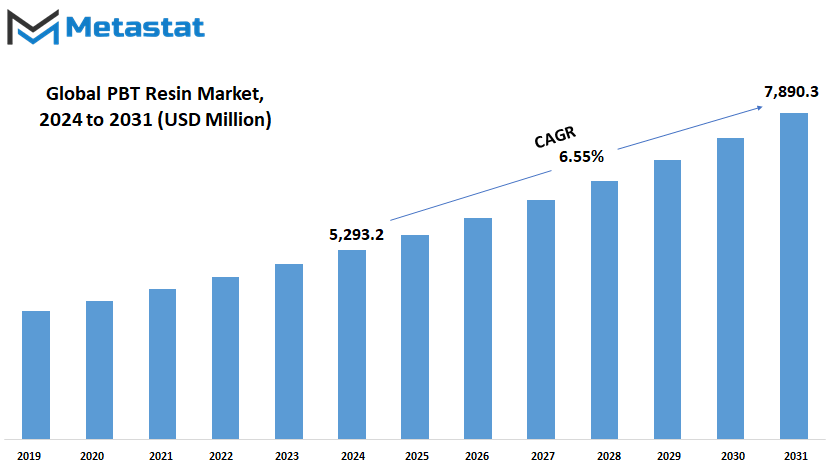

Global PBT Resin market is estimated to reach $7,890.3 Million by 2031; growing at a CAGR of 6.55% from 2024 to 2031.

GROWTH FACTORS

The global PBT resin market is expected to increase considerably in the coming years, mainly on account of such significant factors as increasing demand within the automotive sector and higher usage in electrical and electronic components. Amongst other attributes, it boasts of unique light weight and durability, making PBT resins one of the most sought-after varieties by manufacturers looking for improvement in the efficiency and performance of products in the industry. For instance, the automotive industry has embraced lighter material in order to achieve fuel efficiency and overall reduction in vehicle weight, thereby making PBT resin a critical element to achieve this objective.

Another aspect which is showing considerable growth is the application of PBT resin in the electrical and electronics sector due to the upsurge requirement for materials that possess excellent insulation properties. As more electronics are miniaturized to smaller and increasingly complex designs, PBT's reliability in insulating and resisting heat will be vital for manufacturers of these products. In pursuit of miniaturization, especially with regard to electronics, seems to hold much promise for the demand for high-performance materials such as PBT resins.

Challenges abound in the market, with fluctuating raw material prices. These price fluctuations will spill over to the cost of production, which, in turn, will have an impact on the cost and availability of the PBT resin in the market. This competition from other similar varieties of engineering plastics such as polycarbonate and nylon may also impact the growth of PBT resin. The manufacturers will seek alternatives that can present similar results at a minimal cost; this will, in turn, slow the progress of the PBT resin market.

Still, despite all of these problems, the global PBT resin market appears to be bright and promising in the future. The trend towards miniaturization in electronics and demand for higher-performance materials create opportunities in many markets. As advanced technology keeps evolving, more efficient and durable industries may have a need for better performance, and thus PBT resin can act as a strong candidate in the near future. The future relevance of the material will depend more on its flexibilities towards a multitude of applications, as it appears to adapt to the wide range of industry applications and is a good sign that this is being well supported by the market forces, which is also fuelling the momentum for this market.

Though the global PBT resin market does not have a rosy future free of problems, its prospects in its current form are bright, especially in segments like automotive and electronics. This market will indeed be driven by innovation and performance in the years ahead.

MARKET SEGMENTATION

By Type

Global PBT Resin market has shown immense growth and is facing many changes because of increased demands by various sectors. This material has high thermal stability along with chemical resistance and mechanical strength, which make it preferable for application in such automotive, electrical, and consumer goods. The evolution of market innovation is highly increasing in the formulation by the manufacturers to enhance performance as well as satisfy specific customer demands.

By type, the Global PBT Resin market is further categorized into reinforced and unreinforced PBT resin. Reinforced PBT resin adds additives such as glass fibers or any other material for increasing its strength and durability. The kind of resin is highly in demand where high performance is required for mechanical actions. For instance, in the automotive industry, reinforced PBT resin is being increasingly used for components that require higher strength and offer resistance to impact, heat, and chemicals. There is pressure from government regulation and consumer demand upon vehicle manufacturers to reduce weight without compromising on safety and performance, hence increasing the requirement for reinforced PBT resin.

Unreinforced PBT resin is another important segment of the Global PBT Resin market. This type of resin is excellent in its flow properties, and therefore it is resorted to intricate molding procedures. It is highly used in applications that do not necessarily demand high mechanical strength. Such applications include domestic appliances, connectors, and all other electronic parts. The enlarged growth of the electronics industry, mainly consumer electronics and telecommunications, will also demand much of unreinforced PBT resin. Newer formulations that would exhibit improved processing characteristics and final application performance offer an opportunity for manufacturers in the unreinforced PBT resin.

Advancements in production technologies alongside material formulations are to take center stage in the coming years for the global PBT resin. Such innovations will enable producers to provide options which come with reduced environmental impacts, resins bio-based notwithstanding. While industries worldwide continue to advance toward sustainability, these trends will also shape the PBT resin market and create opportunities for solutions that fulfill both performance requirements and environmental standards. Increasing usage of electric vehicles and renewable energy technologies will also pave the way for an upward curve in demand for specialized PBT resin products designed to face very particular challenges posed by such applications.

By Processing Method

This sector is an important division in the materials industry, thereby showing high potential and innovation in the worldwide PBT Resin market. With performance-related requirements in the high-performance materials, this market will change in many ways. PBT, or Polybutylene Terephthalate, is a thermoplastic engineering polymer that shows excellent mechanical properties, chemical resistance, and thermal stability. These properties allow the material to be suitable for an extensive range of applications from auto parts to electrical and electronic devices.

The different processing techniques followed in the Global PBT Resin industry decide upon the performance of the end products. Among these injection molding is widely followed. The process is efficient in producing complex pieces that need accurate length and shapes, making it suitable for automotive and consumer products. Since manufacturers desire efficiency and reliability, injection-molded PBT components might continue to enjoy demand.

Extrusion is another very critical processing technique in this industry. In this process, the PBT resin is forced through a die to obtain shapes of considerable length, such as sheets, films, or pipes. The versatility of this technique makes it highly popular in construction and packaging industries among others. Upcoming sustainability requirements are likely to propel future advancements in extrusion technology to ensure a better material utilization with less waste.

Presently, it is widely applied to produce hollow plastic parts, the largest of which are containers and bottles, gaining popularity due to its peculiar advantages at creating lightweight but strong products, regarding the trend toward lowering material consumption without compromising performance. Technology evolution in blow molding will further drive PBT capabilities in achieving packaging solutions for sustainable consumer demands.

Other processing methods that don’t easily fit into categories above also present necessary diversification of the applications of PBT. For instance, with 3D printing, and thermoforming, newer or more innovative possibilities are brought open in custom work and rapid prototyping. All these will help more companies test PBT in new ways and bring new possibilities for its use in many different industries as science advances.

By End-User

The Global PBT resin market is expanding dramatically and is driven by quickly increasing demand in all sectors. PBT or polybutylene terephthalate is a thermoplastic engineering polymer, which happens to possess outstanding strength and durability properties. This material has become very important in many applications: automotive, electrical and electronics, consumer appliances, industrial machinery, medical devices, and packaging. Further advancements in various industries will significantly enhance reliance on PBT resin, thus the future map of this market will be changed.

PBT resin is used in the automobile industry because it is relatively lightweight with good performance properties. Manufacturers seek ways to improve fuel efficiency and reduce emissions. When they come up with components such as interior and exterior parts, connectors, and housing for electrical systems for the automobile industry, they are most likely going to look for PBT resin. Electric automobiles will create a larger share of demand in the PBT market since more than a few advanced materials that offer better thermal and chemical resistance are required for such vehicles.

Electrical and electronics is another market segment from which the growth of the global PBT resin market registers significant contributions. The demand for lightweight and durable materials, especially for connectors, switches, and housings, has, in recent times gained momentum. With rapid technological advancements, further adoption of PBT resin will be prompted as the need arises for improved materials capable of withstanding difficult environments without suffering a degradation in performance. Moreover, there is a great trend toward more smart home applications and automation, which will increase the demand for materials that meet the needs of even more complex and compact systems from the electrical and electronics industries.

Consumer appliances are also using PBT resin due to its flexibility in meeting both the aesthetic and functional requirements. While consumers opt for environment-friendly and reliable appliances, the manufacturers would look for PBT to strengthen the performance of the product for a longer time. In the field of medical devices, the demand for PBT resin will increase in respect of healthcare gadgets that are getting more sophisticated and require more rugged materials that are also biocompatible.

Packaging, being part of product protection as well as marketing, is shifting towards being more sustainable. PBT’s toughness and recyclability will be imperative in response to the rising market for environmentally friendly packaging solutions. Other industries, such as industrial machinery, are also growing using PBT extensively because of its mechanical properties and chemical resistivity.

Overall, the Global PBT resin market will experience growth in several of the world’s sectors as demand for superior and durable materials continues to increase. Individual industries will harness PBT’s special properties for application-specific performance capabilities in products to meet the emerging demands of the marketplace. Therefore, the various stakeholders in the PBT resin market ought to expect tremendous opportunities for growth as well as innovation ahead.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$5,293.2 million |

|

Market Size by 2031 |

$7,890.3 Million |

|

Growth Rate from 2024 to 2031 |

6.55% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

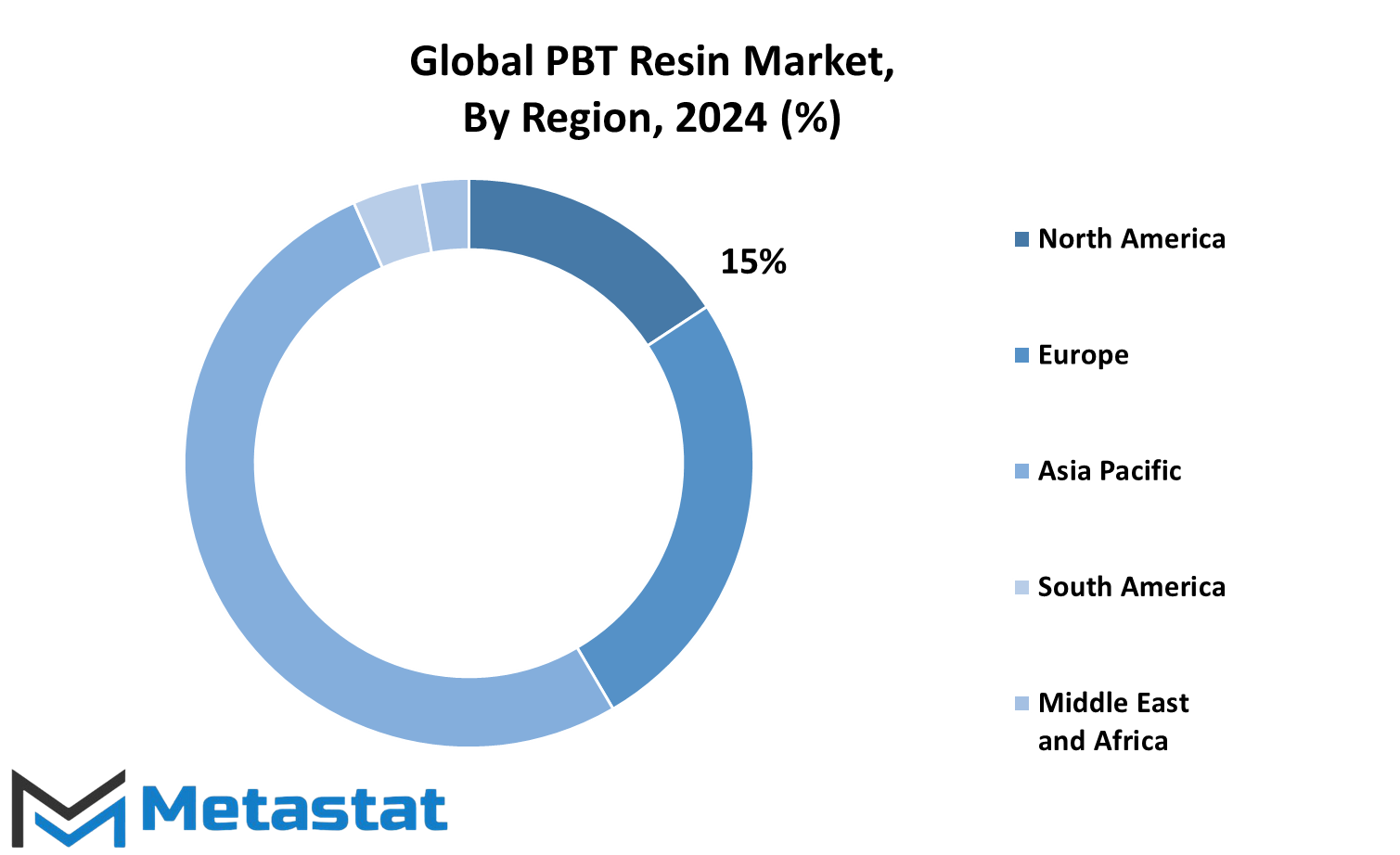

The PBT resin market is promising across the globe with the contribution of various characteristics and growth opportunities of all the regions. Among all such regions, the region of North America holds importance as the U.S., Canada, and Mexico encompass this market. North America has its demand for PBT resin with applications in automotive, electronics, and consumer goods. As the automobile industry continues to focus on developing a lightweight materials set for enhanced fuel efficiency, demand for high-performance resins like PBT will only increase. Additionally, the focus of this region towards innovation and technology, where conditions appear to be almost perfect to design advanced PBT materials, will continue to improve their performance and application scope.

Countries such as the UK, Germany, France, and Italy share the top list of countries that dominate the market for European PBT resin. Environmental regulations are strict in the European market while there is an enormous drive for sustainable practices. Manufacturers are at this moment investigating bio-based and recycled materials which would change the complexion of PBT resin production forever. Industry-wide focus on energy efficiency and emissions reduction will only go on to give momentum to demand for quality lightweight material like PBT. Therefore, in this region sustainability would be supported while market growth is enhanced.

Asia-Pacific is likely to be one of the faster-growing regions across the world with countries such as China, India, Japan, and South Korea. These countries are expected to experience large-scale industrial growth in their automotive and electronics segments. With improving urbanization and increased disposable income, consumers are going to demand more high-performance durable products, thereby fueling the requirements for PBT resins. Greater innovations in the Asia-Pacific market for PBT resin are expected as more advanced manufacturing processes are being introduced, which improves the material application and property further.

The next opportunities will arise in South America, where Brazil and Argentina are the major players. Economic growth in the region and its industrial development would propel the consumption of PBT in many applications. Its local automotive industry and an increasing number of electronics manufacturing would contribute to the rise in PBT resins consumption.

The Middle East and Africa is expected to play a strong role in the PBT resin market in the future-into which region it is divided into countries of the Gulf Cooperation Council, Egypt, South Africa, and the rest of the region. These regions are currently pursuing infrastructural development and industrialization, thereby opening new avenues of applications for PBT, especially in the construction and automotive sectors. Overall, the global PBT resin market is still in its growth phase with every region exploiting its strength and market dynamics for increasing demand and application.

COMPETITIVE PLAYERS

The PBT resin market in the global scenario is highly dynamic, with significant inroads made by various players as they look to strengthen their market presence and offer newer solutions to cater to the changing needs of customers. This includes key players in the Saudi Basic Industries Corporation (SABIC), BASF SE, and Celanese Corporation. Their continued R&D efforts allow them to maintain pace with new trends in the market and to act more correctly in relation to such trends. For example, SABIC has highly invested in new technologies that enhance the performance of PBT resins, corresponding mostly to applications in automotive and electronics where durability and thermal resistance become significant.

Another important company in the global PBT resins market is BASF SE, known for its portfolio diversity and sustainability. The company focuses on developing PBT resins with less environmental impact. This is where the ever-growing demand comes into play: natural materials. This supports their market presence while speaking to the needs of consumers who are ever increasingly concerned with the imperatives of sustainability. Similar to the Celanese Corporation, the firm leverages its expertise in advanced materials to develop high-performance PBT resins suitable for applications where high strength and heat resistance are critical.

Competition was also driving the growth of the market by innovation and strategic partnership between companies such as Clariant AG and Daicel Corporation. In this regard, Clariant AG held that the development of specialty PBT resins in specific applications is better than other traditional resins. Daicel Corporation, on the other hand, would increase its production based on the increasing demand for the product in the world.

The key players in the PBT resin market include DuPont de Nemours Inc. and Evonik Industries AG, who possess considerable research capacities and can create new-generation materials. The latest innovation from DuPont in PBT resin is with higher thermal stability properties that can be used in demanding applications. Evonik specialized in high-performance materials has further extended its portfolio with better coverage in automobile and consumer products.

Of course, other major market players include LG Chem Ltd., Mitsubishi Chemical Corporation, and Lanxess AG, which are also doing great. For example, LG Chem invests more in the production of PBT resin as the demand increases from emerging markets. Mitsubishi Chemical Corporation focuses on making PBT resins with better product performance and excellent environmental sustainability.

The global PBT resin market is expected to continue to grow through the key players entering the scene and bringing innovations and strategic initiatives that will shape the future of the industry. With the combined contributions of such end users, both performance and applications of the resins are going to be improved and meet the demands of an increasingly sustainability-focused world.

PBT Resin Market Key Segments:

By Type

- Reinforced PBT Resin

- Unreinforced PBT Resin

By Processing Method

- Injection Molding

- Extrusion

- Blow Molding

- Others

By End-User

- Automotive

- Electrical & Electronics

- Consumer Appliances

- Industrial Machinery

- Medical Devices

- Packaging

- Others

Key Global PBT Resin Industry Players

- Saudi Basic Industries Corporation (SABIC)

- BASF SE

- Celanese Corporation

- Clariant AG

- Daicel Corporation

- DuPont de Nemours Inc.

- Evonik Industries AG

- Envalior

- Lanxess AG

- LG Chem Ltd.

- Mitsubishi Chemical Corporation

- Chang Chun Group

- Nan Ya Plastics Corporation

- Saudi International Petrochemical Company (Sipchem)

- Toray Industries Inc.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383