MARKET OVERVIEW

The Global Metal Bonding Adhesives market is poised to become a powerful factor in industries worldwide due to the unique properties they have and areas of application. While manufacturers look for innovative solutions for joining metal components, these adhesives can turn out to be a prospective variant of traditional mechanical fastening methods. They are to be widely used in the creation of automotive, aerospace, construction, and electronic products where lightweight, yet strong materials are demanded. These adhesives will offer strong bonding and lightweight properties that are very important to industries seeking to strive for efficiency by reducing production costs. With advances in technology, these adhesives will be called upon to better enhance the performance of metal joints by providing the best possible resistance against temperature, chemicals, and environmental conditions. The diversity of the products will include epoxy, acrylic, polyurethane, among other specially developed formulations that best meet particular industrial requirements.

The metal bonding adhesives will open a chance for manufacturers to venture into new designs and simplify their production processes. These adhesives will eliminate drilling or welding and offer the possibility of constructing more complex structures without substrate damage. The environmental sustainability will further be enhanced by this innovation since the reduction in the use of traditional mechanical fasteners will reduce the amount of energy and gases needed for their manufacture. One outstanding characteristic is the flexibility of the adhesives, in that they can be applied on many metals, such as aluminum, steel, and titanium, which make them amply applicable.

In particular, metal bonding adhesives will largely be needed in the automotive industry. Already, the trend is toward lightweight, fuel-efficient vehicles; hence, the need for strong and, at the same time, lightweight bonding solutions will be highly relevant. Such adhesives will help the auto manufacturers join dissimilar materials and at the same time not compromise on the structural integrity of the vehicle. Secondly, they enhance vehicle safety with better crash performance than the traditional fastening techniques. These adhesives will also find applications in enhancing the aesthetic value of the vehicle, for they make it possible to have smooth surfaces and a finish without seams.

It is especially metal bonding adhesives that will meet the regulatory standards and stringent performance requirements in the aerospace industry. The growing requirement of using lightweight materials in the design of aircraft will be the main driver for these adhesives, as they help the manufacturers decrease the overall weight of the aircraft without compromising on safety and durability. These adhesives will also offer advanced resistance to fatigue, which is very important in the aerospace industry where continuous stress and vibration are experienced.

The Global Metal Bonding Adhesives market will benefit the construction industry by providing strong bonding solutions to metal structures, hence improving their durability and lifespan. They will come in handy in applications where conventional methods are not feasible, or aesthetics happens to be an important criterion. These adhesives will provide an efficient and trustworthy solution for the bonding of metal components of infrastructure and architectural applications.

As the global metal bonding adhesives market grows further, companies would invest in R&D for the establishment of newer products that would help meet the changing requirements of industries. Adhesives with improved performance characteristics, especially in curing time, flexibility, and climatic resistance, would be anticipated. The other area that manufacturers would attach importance to would be the development of eco-friendly adhesives in line with global sustainability initiatives. These adhesives will minimize the ecological footprint of the bonding processes and thus aid industries in their quest to reduce their carbon footprint.

The other key growth driver of the Global Metal Bonding Adhesives market will be the electronics industry. With electronic devices becoming miniaturized and more complex, there will arise a huge demand for bonding solutions that are accurate and reliable. Such adhesives will have the advantage of binding fragile parts without generating excessive heat or pressure that may damage sensitive electronics. Industry players in this sector will reap benefits in terms of creation of strong bonds with minimal substrate preparation, where efficiency and reliability are of essence.

The Global Metal Bonding Adhesives market will play a key role in shaping the future of manufacturing and design across many industries. Reduction in weight, flexibility of design, and their being environmentally friendly are some of the advantages of these adhesives that will spur adoption and drive further innovation. As industries seek solutions that assure better performance with low environmental impact, metal bonding adhesives are at the forefront of this transformation. Their performance in providing durable and effective bonding solutions will make these adhesives still relevant and important many years from now; therefore, they will become a part of any modern manufacturing or construction technique.

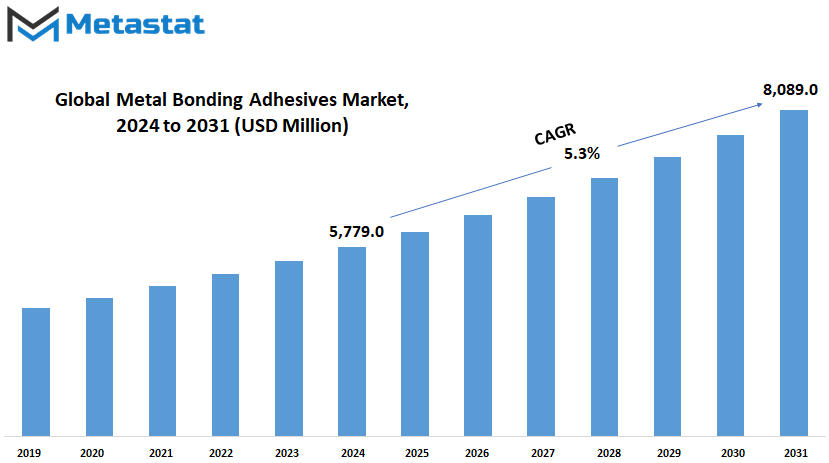

Global Metal Bonding Adhesives market is estimated to reach $8,089.0 Million by 2031; growing at a CAGR of 5.3% from 2024 to 2031.

GROWTH FACTORS

The Global Metal Bonding Adhesives market is likely to register exponential growth in the coming years with several of these drivers opening up an exciting opportunity for industries that are involved. Demand for lightweight yet high-strength materials arising from the automotive and aerospace industries is one of the prime reasons behind this growth. As efficiency and performance begin taking precedence over other factors in these industries, the contribution of metal bonding adhesives becomes highly important. These adhesives thus provide the possibility of bonding different metals without excessive weight and increasing the performance of all types of vehicles and aircraft, reducing fuel costs.

Besides, metal bonding adhesives increasingly find an application in structural purposes. Such adhesives provide strong solutions for bonding metals in constructions where traditional methods like welding or mechanical fastening are unfeasible or even undesirable in some situations. Such adhesives are quite an interesting solution for engineers and designers when the need is to achieve maximum structural strength in a product due to their flexibility and strength.

Although growth prospects are very promising, there are a few challenges that can still be seen in this market. One of the major reasons preventing these very advanced adhesive formulations from reaching numerous prospective users in different industries has been their high process cost. Advanced formulations require advanced chemical processes, raising production cost. These higher costs may hence deter, especially smaller manufacturers or those in cost-sensitive markets. In addition, complexity in application and associated surface preparation requirements for such adhesives also present problems. The effectiveness of metal bonding adhesives depends on proper surface preparation, but this is time-consuming and labor-intensive. If it is not done right, it will yield suboptimal bonding and reduce the reliability of the adhesives.

In the future, continuous innovation in adhesive technologies is likely to drive further growth for the Global Metal Bonding Adhesives market. There is a growing opportunity in developing high-performance adhesives designed specially to work in very extreme environments, including high-temperature and chemical-exposure, high-stress conditions, where adhesives with improved durability and resistance properties are required. Developing special adhesives will open up new avenues in the market by offering their applications in those sectors that operate under difficult conditions, particularly so in the defense, oil and gas, and renewable energy industries.

Materials science and technology advances will also be among the factors that would shape the future of the industry. Innovations that help cut the cost of production and simplify application processes are likely to attract more users and cause market expansion. Companies investing in research and development to create adhesives that have both performance and cost-effectiveness will also better manage to capture a larger market share. Another key driver of innovation and growth will be the push toward sustainable, environmentally friendly adhesives as industries work to lessen their impact on the environment.

The Global Metal Bonding Adhesives market is primed for exponential growth with a rise in demand for light, yet strong, materials and improvements in adhesive technologies. Needless to say, some challenges will have to be met in the course of developing high-performance adhesives and innovations targeting cost reduction and application efficiency. With all that said, prospects envision a very active future for the market with industries continuing to evolve in search of effective solutions to their bonding needs.

MARKET SEGMENTATION

By Type

The Global Metal Bonding Adhesives market is going to go through immense change and expansion in years to come. Adhesives are material capable of holding materials together in a strong, durable manner. The ability of these adhesives to stick to metal surfaces and bond them together is definitely important for the integrity of a structure and, without it, in several industries, the structure can easily turn very brittle. Advances in technology will drive the demand for such adhesives because they are efficient in cutting down manufacturing costs while substantially improving the performances of products. The increased rate in the market will be witnessed in other regions, with high industrialization and increasing technological advancement, demanding good adhesive solutions.

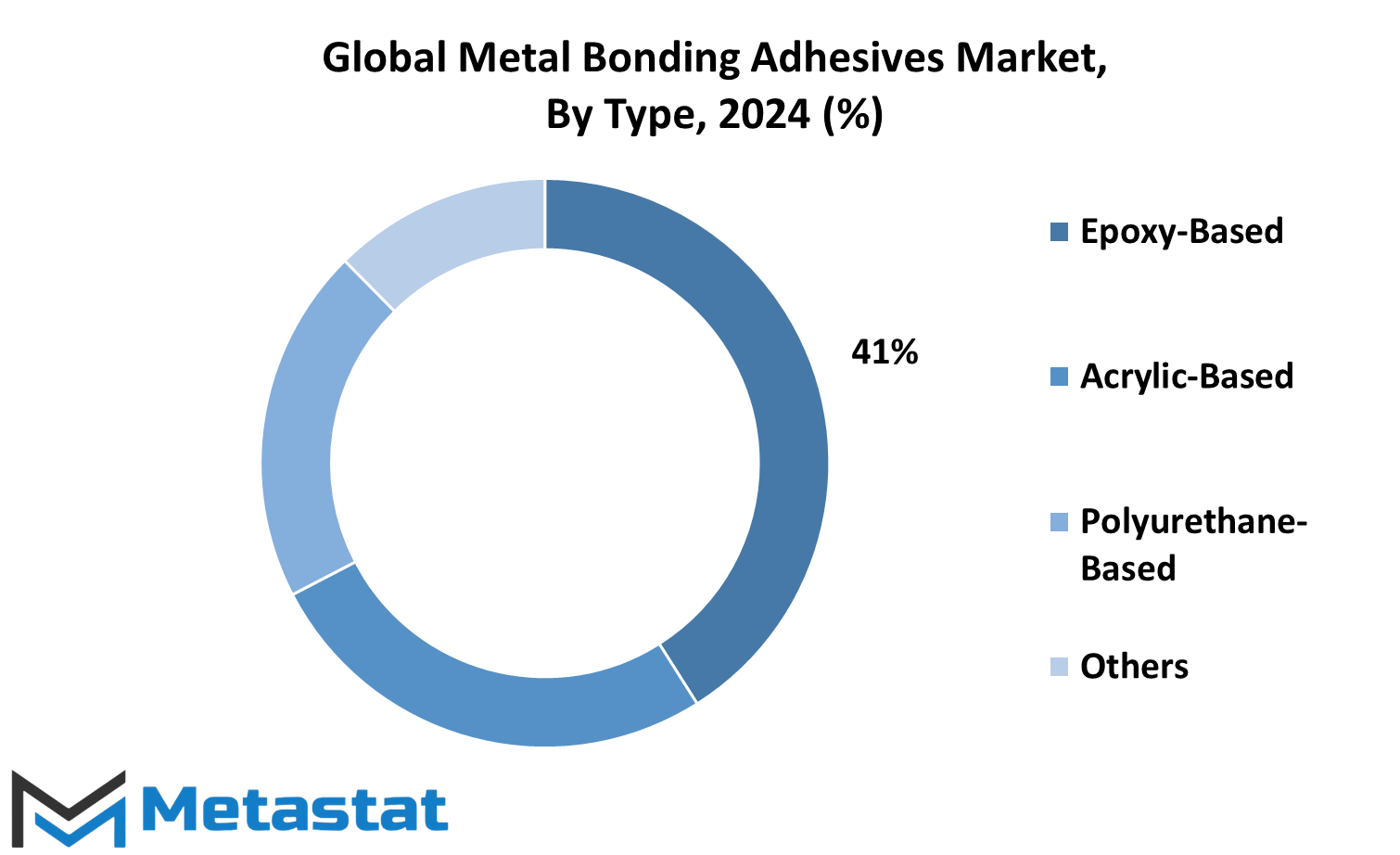

Epoxy-based adhesives will continue to hold the largest share in the overall metal bonding adhesives. It is a common application fact that epoxy-based adhesives have very good strength and resistance to many environmental factors, and they find applications in the aerospace, automotive, and electronics industry. The growing industries will increasingly demand reliable bonding solutions as new products are innovated and developed; hence, epoxy-based adhesives. Improvements in epoxy formulations in the future will bring about performance advancements, extending their domain of application to even more demanding markets, such as renewable energy technologies.

Another key segment, Polyurethane-based adhesives, valued for its flexibility and resistance to impact and vibrations. These properties make them suitable for use in the automotive and construction sectors, where dynamic stress is what materials are exposed to. The global shift towards lightweight and energy-efficient vehicles is going to increase the use of polyurethane adhesives, as manufacturers will turn to such materials in their attempt to bring down vehicle weight without compromising on safety or performance. This trend will be of greater importance in the future demand for polyurethane-based adhesives, particularly when the automotive companies are driven into compliance with very strict environmental regulations.

The fast curing and various resistance capabilities make this class proper for applications in electronics and transport. With increasing production efficiency and minimization of idle time being the priorities of industries, acrylic-based adhesives will be more in demand due to their potential to increase the speed of manufacturing processes. Besides, new acrylic formulations with enhanced properties will further broaden their spectrum of applications in growing markets where industrialization is taking place at a faster pace.

Other forms of adhesives meant for niche applications are equally set to grow in the Global Metal-to-Metal Bonding Adhesives market. These include adhesives designed for high-temperature environments or specialized uses in medical devices. With research and development ongoing, such niche products will bring diversity and adaptability in a changing industry to meet the market’s needs.

The metal bonding adhesives market is largely driven by technological advancement, growing demand for such adhesives from the industry to find efficient and reliable bonding solutions, and an increased focus on sustainability and innovativeness from the manufacturers. This is one market that will continue to grow, offering more opportunities in growth and development as manufacturers put more emphasis on sustainability and innovativeness. The future will come along with more specialized adhesives tailored to meet the unique challenges of modern industries, hence ensuring that the market remains dynamic and responsive to global trends.

By Application

In the near future, the global metal bonding adhesives market will experience considerable growth. The reason is that there has been extensive progress or development in different industries. With the continuous advancement in technology, the requirement for high-performance bonding solutions is also growing in sectors such as automotive, electronics, and industrial equipment. Such adhesives have many benefits, which include high strength and durability, hence their demand for applications requiring dependable and long-lasting bonds. This is an indication of a bright future as the market inches toward sustainability and efficiency.

The need for better fuel efficiency and lower emissions has led to the increasing demand for lightweight materials in the automotive and transportation industries. The move will be greatly contributed to by metal bonding adhesives through their capacity to bond dissimilar materials, such as aluminum and composites, in vehicle body structures. It will help manufacturers create lighter, more fuel-efficient vehicles without compromising safety and performance. As electric and autonomous vehicles continue to gain in number, sophisticated adhesives designed to undertake a wide temperature range and vibration resilience are even more important.

In the electronic and consumer appliances industries, miniaturization and improved performance will raise demand for new bonding solutions. As devices grow in miniature and complexity, traditional mechanical fasteners shall be unsuitable in some applications. Then, the metal bonding adhesives shall be at hand to give strong bonds without adding bulk and weight to the final product. In addition, they will improve heat dissipation and electrical conductivity, hence assuring efficient and reliable electronic gadgets.

Another area of growth for the Global Metal Bonding Adhesives market will be industrial equipment. With increasing sophistication of machinery and equipment, adhesives that bear such harsh environments and heavy loads will be much in demand. Metal bonding adhesives will provide the strength and durability needed in demanding applications such as mining, construction, and manufacturing. In addition, these adhesives will enable the use of lighter materials, hence reducing overall equipment weight and providing increased energy efficiency.

Besides these major applications, metal bonding adhesives will find uses in other industries such as aerospace, defense, and renewable energy. Whereas the aerospace sector is going to make a use of those adhesives which can sustain ultra-high temperatures and pressures, the renewable energy sector will utilize resilient bonding solutions for wind turbines and solar panels. As these industries continue to grow, demands for metal bonding adhesives will also increase.

By End-User

In the future also, the Global Metal Bonding Adhesives market will surely surge as its demand multiplies through every possible industry. The adhesives, known to have high bonding strength, are crucial in many industries due to their durability, resistance in difficult environments, and excellent metal bonding properties. With industry development, efficient and reliable bonding solutions would be required and hence drive the demand for metal bonding adhesives.

In the automotive and transport industry, metal bonding adhesives will become prominent in the vehicle manufacturing and assembly process. The need and desire to have lighter vehicles for improved fuel efficiency will be a factor that will force manufacturers to turn to these adhesives other than traditional welding and mechanical fasteners. This change will bring stronger, lighter, cleaner, and greener vehicles in step with the global drive toward sustainable transportation solutions.

Advancements in the Global Metal Bonding Adhesives market will come very handy in the aerospace and defense sector. The adhesives will play a key role in constructing aircraft and spacecraft, where power and durability are extremely important. Going ahead, while aspiring toward better fuel efficiency in air travel, the aerospace industry will need metal bonding adhesives at its core to create lightweight yet efficient aircraft designs that lower carbon emissions.

With the trend of making electronic devices smaller and more sophisticated, the use of metal bonding adhesives in electronics and electrical applications is expected to keep on rising. The adhesives provide manufacturers with reliable bonding solutions to meet the demand for small size and efficiency; they ensure integrity and performance. Further, miniaturization and functionality trends in electronics will be the basis upon which additional advancements in adhesive technology are evolved.

One can, therefore, see the broad application of metal bonding adhesives in the building and construction industry. With changing construction practices, the trend is toward using materials that can provide adequate strength and durability with less construction time and lower costs. The metal bonding adhesives will provide such a solution to enable the construction of resilient and sustainable structures.

These adhesives will be required in the marine and shipbuilding industries to guarantee the structural integrity of vessels and their performance. The metal bonding adhesives will contribute solutions to enhance ship durability and lessen maintenance needs as the focus in the industry shifts to more fuel-efficient and environmentally friendly ships.

The precision and reliability that metal bonding adhesives provide will benefit the medical devices industry. As demand for advanced medical devices continues to increase, so will manufacturers’ reliance on these adhesives to produce high-performance, safety-oriented devices that meet strict regulatory standards.

The Global Metal Bonding Adhesives market will grow concurrently with industrial demand for more efficient, sustainable, and innovative solutions. In the wake of technological evolutions tracking various sectors, metal bonding adhesives will be an important constituent of the process. Industrial continuous development will again open up newer opportunities and challenges for the metal bonding adhesives market to create much more evolved adhesive technologies for the future.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$5,779.0 million |

|

Market Size by 2031 |

$8,089.0 Million |

|

Growth Rate from 2024 to 2031 |

5.3% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global metal bonding adhesives market is likely to experience substantial growth in the coming years across all key regions, fueled by technological innovation and demand for successful adhesion in a wide range of industries. A regional analysis of this market reveals various trends and opportunities that show how these areas will offer future growth.

Growth for the North American region in the metal adhesives market is forecast due to strong industrial activity and technological innovation. The United States, Canada, and Mexico will continue to lead in industries related to aerospace, automotive, and electronics applications. In such fields, metal bonding adhesives are of quite importance since the components have to be lightweight with adequate durability. Their evolution into products that provide superior performance, are environmentally sustainable, and economical will assume a prominent position. The growing interest in weight reduction of vehicles to save fuels will further boost the demand for metal bonding adhesives in this region.

Europe is the other key market, and it comprises countries such as the UK, Germany, France, and Italy, which are mainly involved in developing innovative technologies related to the automotive and aerospace industries. Tight regulations regarding emissions and sustainability will increase the speed of growth of eco-friendly metal bonding adhesives. Probably, the investment in research and development by European manufacturers will go into developing innovative adhesives with high performance but low environmental impact. The demand for such adhesives will be further boosted by the interest of this region in renewable energy, especially wind energy, for the construction of wind turbines and other infrastructure.

The fastest growth in the metal bonding adhesives market is projected to take place in the Asia-Pacific region. This surge can be attributed to rapid industrialization and urbanization in countries such as India, China, Japan, and South Korea. As these nations are further increasing the manufacturing abilities, the requirement for efficient bonding solutions will rise in the near future, especially in sectors like automotive, electronics, and construction. The huge industrial base and the fast-growing automotive industry of China will largely contribute to the market growth. Japan and South Korea, high up in the league of technology, will take the lead in innovation in the area of high-performance adhesives.

In South America, the metal bonding adhesives market will benefit from increasing activity in the sectors of automobile and construction, notably in Brazil and Argentina. Improving infrastructure also will increase the demand for strong and reliable bonding solutions in the region. The regional focus on building industrial capacity and improving product quality will further drive demand for the market as local manufacturers seek the latest adhesive technologies.

The Middle East & Africa offers massive potential for metal bonding adhesives, driven by the success of its construction and automobile industries. In a way, GCC countries, Egypt, and South Africa are making their forays into infrastructure development and auto manufacturing, thereby opening up opportunities for adhesive suppliers. As these economies diversify and industrialize, demand will begin to rise for effective bonding solutions that focus on products with the ability to offer durable performance under extreme environmental conditions.

Overall, the global metal bonding adhesives market will continue to grow, with each region uniquely contributing to its development. This emphasis on sustainability, technology innovation, and lean and efficient manufacturing processes is going to be a mark of the future for the metal bonding adhesives market and its persistence in several industries worldwide.

COMPETITIVE PLAYERS

The Global Metal Bonding Adhesives market will come along with demanding development and changes. The companies engaged in the production of adhesives developed especially to bond metal, which finds a niche in many industries like Automotive, Aerospace, Construction, and Electronics. The key companies operational in this market alone are DELO Industrie Klebstoffe, 3M, Arkema Group, Evonik Industries, H.B. Fuller, LORD Corporation, BASF, Permabond, DowDuPont, Sika, Henkel AG, Ashland, Huntsman Corporation, Solvay, and Parson Adhesives.

In this so-competitive landscape, these major companies in the Global Metal Bonding Adhesives market strive to bring out high performance in the product and cater to the changing needs of industries. DELO Industrie Klebstoffe specializes in offering solutions for adhesives and applications for high-tech bonding uses of industry. Similarly, 3M will most probably continue developing products that have higher strength and durability, specifically toward the automotive and aerospace industries. The Arkema Group's strong interest in sustainable development and high-performance materials puts it at the forefront in the production of eco-friendly adhesives that conform to global standards on the environment.

With improving technology, other companies such as Evonik Industries and H.B. Fuller will, therefore, have to invest in research and development to come up with adhesives that improve in thermal resistance and electrical conductivity. These improvements will be especially useful in electronics and electrical applications where reliability and efficiency are crucial. LORD Corporation, being an innovative solution provider in adhesives, will most probably diversify its product line to include adhesives that can withstand extreme conditions such as high temperatures and hostile chemicals.

In the near future, BASF, one of the largest chemical manufacturers, will focus on increasing the use of new chemical formulations in their metal bonding adhesives to deliver higher performance and multifunctionality. Permabond and DowDuPont will continue manufacturing faster-curing adhesives with strong bonding that is expected to withstand or perform well under high-speed manufacturing environments. Sika, Henkel AG, and Ashland will also be very instrumental in such a way that they would work on adhesives that would answer the demand of the construction sector in terms of bonding metal infrastructure components, ensuring long-lasting and reliable bonds.

The main players in the global metal bonding adhesives market would become more collaborative because of the evolving industrial requirements. Companies such as Huntsman Corporation and Solvay will continue to develop adhesives that are not only effective but also friendly to the environment. This trend of sustainability will be an identifying feature in the market as consumers and industries alike 'greenify' their product use. Parson Adhesives, being oriented toward customization and innovation, is likely to give the market a niche application-tailored product line, further diversifying its landscape.

Overall, technological innovation, sustainability pursuits, and cooperative initiatives shape the future of the Global Metal Bonding Adhesives market. Companies will keep innovating and evolving with the changing needs of the industry, thus ensuring the market remains dynamic and responsive in its entirety. As industries grow and develop in the future, this ever-mounting demand for high-performance metal bonding adhesives will also provide opportunities for further innovation and market growth.

Metal Bonding Adhesives Market Key Segments:

By Type

- Epoxy-Based

- Polyurethane-Based

- Acrylic-Based

- Others

By Application

- Automotive and Transportation

- Electronics and Consumer Appliances

- Industrial Equipment

- Others

By End-User

- Automotive and Transportation

- Aerospace and Defense

- Electronics and Electrical

- Building and Construction

- Marine and Shipbuilding

- Medical Devices

- Others

Key Global Metal Bonding Adhesives Industry Players

- DELO Industrie Klebstoffe

- 3M

- Arkema Group

- Evonik Industries

- H.B. Fuller

- LORD Corporation

- BASF

- Permabond

- DowDuPont

- Sika

- Henkel AG

- Ashland

- Huntsman Corporation

- Solvay

- Parson Adhesives

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252