MARKET OVERVIEW

The Global Injection Molded Plastic market is characterized not only by traditional applications but also by changes in material composition and molding throughout the industry. Hostile research aimed at biodegradable and recyclable polymers indicates a likely shift in what this industry offers. Given that manufacturers will also be looking in this direction, alternative materials with an environmental benefit could be sourced with the required mechanical properties for performance and durability as an ongoing challenge. The introduction of bio-resins and composites reinforced could actually make eco-friendly injection molded plastics more readily accepted across industry applications.

Injection Molded Plastics being sold in the world market have come to be accepted as a significant division of the plastics industry, one that offers wide applications in several areas. Continuous changes in materials science, manufacturing processes, and technological developments redefine notions of productivity and product quality in this market. Manufacturers seek cheaper and durable solutions in numerous ways, with injection-molded plastics being, perhaps, the prime choice for a variety of industries, including automotive, health care, packaging, electronics, and consumer products. The ability to produce complex shapes with great precision has made mass production a most desirable approach, specifically to explore popular lightweight, high-strength, and environmentally friendly materials.

The Global Injection Molded Plastic industry will be further technologically advanced in molding machinery. The introduction of automation and artificial intelligence will cut cycle times, decrease waste, and ensure product uniformity on the production line. Smart technology will allow real-time monitoring of the injection process, where materials will include consistent precision in distribution as well as structural integrity. Production efficiencies together with reduced costs will make even small- and medium-sized firms able to afford this technology.

Apart from material and process advancement, changing factors will be expected to change supply chain dynamics within the industry. The increasing digitalization of procurement and distribution channels will ease operations for manufacturers, suppliers, and end-users. The integration of digital twins and predictive maintenance tools within molding operations can help decrease machine downtime and support a continuous workflow. This may also encourage the establishment of local manufacturing hubs with shifting global trade policies to support steady shipping while alleviating logistics uncertainties.

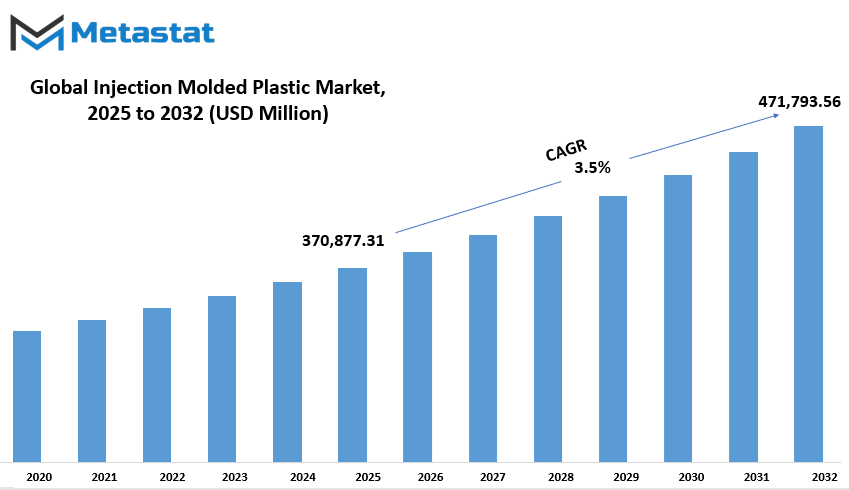

Global Injection Molded Plastic market is estimated to reach $471,793.56 Million by 2032; growing at a CAGR of 3.5% from 2025 to 2032.

GROWTH FACTORS

The Global Injection Molded Plastic market is going through major changes where industries are searching for materials that would be light and durable for numerous applications. This is mainly due to the demands of the automotive and packaging sectors because of the fact that these industries rely upon injection-molded plastics for their efficiency, cost gains, and design flexibility. It shows that this processing method is most likely to be used in industry's applications because of the ability to produce complex shapes in high precision. As the trend in popular products changes toward lightness and sustainability, manufacturers are continuously coming up with several new formulations to increase the performance and sustainability attributes of any plastic component.

Thus, advancement in injection molding technology has been quite vital in improving production efficiency. Innovations concerning automation, real time monitoring, and better material blends have reduced production time and waste in a fantastic manner, thereby increasing output while consuming still less resources. This, which is significant for every field, has not only reduced costs but also improved quality and longevity of plastic components. The more industries travel toward producing and consuming mass products of high quality, the more technology improvement ads rely on direct market expansion in the areas of improvement.

However, existing challenges are there; environmental sustainability is a typical concern to be addressed. The strict regulations on plastic waste management and pollution have forced several governments worldwide to create policies that limit the uses of plastic. The market now has an increasing demand for eco-friendly alternatives, leading manufacturers to invest in biodegradable and recycled plastics. Though these solutions show good possibilities for reducing environmental impacts, they considerably also need large-scale investments in research and development. Apart from that, price fluctuation in raw materials causes uncertainty in the production cost and profit margins. These conditions create a lot of price volatility, as the entire petrochemical raw material front determines the entire price volatility.

Nevertheless, such challenges also create new spaces in the industry. They provide great momentum to the adoption of biodegradable and recycled plastics as a measure for aligning themselves with global sustainability goals. Many companies are creating more economically sustainable production processes, reducing use of virgin plastics, and bringing circular economy principles into their operations. The medical sector is another experiencing a now wild increase in demand for precision-molded plastic components. From syringes and surgical instruments to specialized medical devices, the requirement for good-quality, sterile, and precisely made plastic increases. Expansion of healthcare infrastructure and the advent of medical equipment technologies are both supposed to supplement this area more.

MARKET SEGMENTATION

By Raw Material

Injection-molded plastic products are an important form of market for many durable and low-cost measures of production for many different types of products. The injected molded plastic markets are very much affected by advancements in technology, lightweight materials, and large-scale production with precision and efficiency. Injection molded plastics can be put into various sectors like automotive, packaging, construction, electronics, and health. As injection molding is the process that generates parts of superior quality and with reproducibility and low wastage, it becomes unsurpassed in present-day manufacturing.

Raw materials for injection molding play a very important role in the properties as well as the performance of the end product. Polypropylene (PP) is anyhow consumed in huge amounts for which it holds a market of $63,747.92 million. Its flexible, tough, and chemical resistant nature warrants that it is most suitable for packaging, automotive and consumer goods segments. Another candidate of injection molding is Acrylonitrile Butadiene Styrene, which is well established in the market because of its properties like high strength, good impact resistance, and temperature resistance in fine and very high and low range.

HDPE and LDPE have gained extensive importance and utility in industries with weight limits, moisture resistance, and general application in containers, pipes, and industrial applications. PS finds applications in packaging and disposable products, while PE derives its popularity from versatileness and processability. PVC is popular because of its great strength and resistance to environmental damages, making it highly used for construction and medical applications. Other specialty polymers are also utilized to meet specifications for certain industries whereby they possess unique properties suitable for advanced manufacturing.

The major force behind the growth of the injection-molded plastic market is the increasing demand for sustainable and recyclable plastics. The industry is moving towards eco-friendly solutions and developing research programs on biodegradable polymers and other high-performance polymers. Additionally, newly developed automations and designs for injection molding technology are helping push the limits in both efficiency for production and product quality. The acceptance of lightweight, durable plastics for automotive manufacturing in support of fuel efficiency and reduction of carbon emanation is also accounted for by the trend towards electric and hybrid vehicles. Injection molded plastics in the medical domain are further expanding in applications to manufacture vital components like syringes, medical devices, and packaging materials that are guaranteed safe and hygienic.

By Application

The global plastic injection mold market is undoubtedly an important industry sector for industries seeking durable and cost-efficient production technologies. Injection molding is a manufacturing process known for producing precision-finished plastic parts efficiently; it assures uniform design appearance for the mass production run. Nowadays, lightweight, durable, recyclable plastics are ideals among the industries utilizing advanced materials.

Injection-molded plastics are chiefly used in packaging light-and-powerful material coming in handy in the storing and transporting of goods. The search for sustainable packaging directed innovation toward the development and application of biodegradable and recyclable plastics. Companies have invested in research focusing on sustainable packaging with the aim of reducing negative environmental impacts while maintaining an adequate strength-flexibility ratio. The food-and-beverage product packaging industry is very reliant on injection-molded plastics for containers, bottles and caps to safeguard the quality and extend the shelf life of products.

Injection-molded plastics help reduce vehicle weight, improving fuel consumption and performance. Dashes, bumpers, and interior panels are plastic to cut costs and increase design and functional attributes. The ever-growing demand for lightweight materials in electric vehicles has pushed further advances in plastic molding technology. The strength and impact resistance of injection-molded plastics will further increase vehicle safety, durability, and longevity.

Injectable plastics offer construction strength, weather resistance, and ease of installation. These materials go into piping systems, insulation and window frames, and other structural works requiring durability yet at affordable pricing. The ability to manufacture components with complex shapes and sizes makes injection molding an excellent choice for building jobs with stringent requirements for precision and reliability. Besides, an increase in energy-efficient buildings has posed a demand for further application of polystyrene or plastic-based insulation materials that would enhance the thermal performance.

Injection-molded plastics are also utilized in consumables and electronics to manufacture lighter and durable products, from mobile phone casings to applications around the house. These plastics display a combination of strength, flexibility, and design freedom. Electronics companies utilize materials that withstand heat and resist current, which makes advanced plastic composites necessary for the production of components. Stylish designs that have become the order of the day in the market ushered even more innovations into the world of injection-molded plastics.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$370,877.31 million |

|

Market Size by 2032 |

$471,793.56 Million |

|

Growth Rate from 2025 to 2032 |

3.5% |

|

Base Year |

2025 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

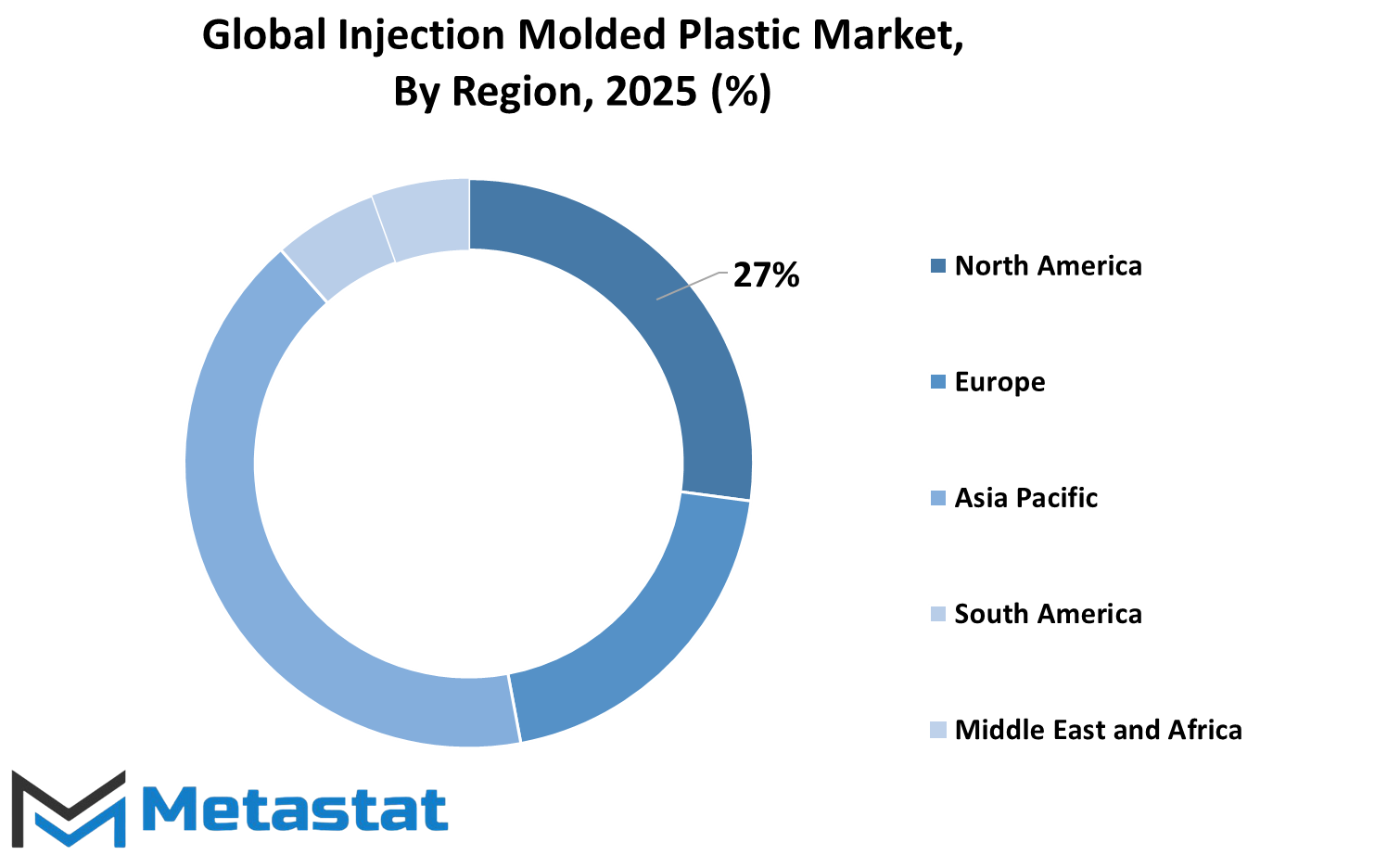

The Global Injection Molding Plastic Market is something that is largely defined and influenced by several factors, including geographical distribution. Aside from this, the market is streamlined for a considerable number of areas through which it can carve its differences and hence complement itself from the very growth and expansion at its geographical earmarks such as North America, bearing some eminent market players like USA, Canada, and Mexico. North America can boast of excellent manufacturing technologies, a strong industrial base, and a steady rise in the demand for plastic components in automotive, packaging, and consumer goods applications putting established market players within the region.

This market among the European countries is driven by the likes of the United Kingdom, Germany, France, and Italy, amongst other European countries defining consistent growth trends for the entire region. This goes hand in hand with the nature of value-based European sustainability and environmental regulations, which stimulates innovation and pervades new techniques on green injection molding. The demand itself is significantly driven by the automotive and healthcare sectors as they tend to run after lightweight, durable, and high-performance plastic components.

Asia-Pacific stands tall in its clear arena by the market-major players-{India, China, Japan, and South Korea}. The rapidly industrializing region is enhancing its growth from increased consumer needs for plastic products. China has plus points as a global manufacturing hub and an injection-molded plastics production center for a wide range of applications. India and Japan also contribute significantly; the development in the areas of packaging, electronics, and construction thus plays a vital role in market growth. The rest of Asia-Pacific further adds to this region's highly dynamical growth.

Injection molded plastics are finding most developing countries in South America. In particular, Brazil and Argentina stand among the leading countries with potential markets for molded plastics. The steady demand for these products is coming from such industries as automotive, packaging, and construction. Economic situations that present challenges notwithstanding, the way into expansion is being opened by increased foreign investment and industrial growth. South America is still much part of the overall market structure as it contributes demand and supply dynamics.

Emerging markets within the Middle East & Africa include the GCC countries, Egypt, and South Africa. Such regions are in line with popular developmental investments directed toward construction, infrastructure, and consumer goods. This increases the demand for injection-molded plastics, particularly in the durable and cost-effective materials such as packaging and healthcare. The rest of the area also accommodates growth on a general scale and for itself makes the entire region potentially good for future expansion.

COMPETITIVE PLAYERS

This market is the place Injection Molded Plastics can be used in a critical role for fast, efficient, economical processing in industries for manufacturing plastic components. Growth is huge for the industry because with modern technology being available, there is now an ever-increasing demand for lightweight, strong, and flexible alternatives in numerous application areas, including automotive, packaging, electrical, medical, and consumer products. Injection molding manufacturers can develop very fine and complicated plastic parts in great bulk with highly reliable quality.

Injection-molded plastics have seen constant uptake in the automotive sector, thus benefiting this overall steady growth of the market. There are manufacturers who strive for lightweight materials that improve performance and reduce emissions when it comes to fuel efficiency and electric vehicles. The solution of plastics is very apt for replacing traditional stronger but heavier metal components with no sacrifice in strength or durability. The application of these plastics in packaging will witness an explosive demand as they are used to manufacture strong flexible boxes, up to the quality retention of products, and lengthy shelf life.

There is indeed a great insulating-protective-shielding injection molded plastics for fragile components and parts in electronics. Injection molded plastics have demands and applications in medical devices, surgical instruments, and pharmaceuticals packaging to ensure safety and compliance with the rigorous standards in the industry. Households, toys, and appliances inside and outside are popular consumer items made by manufacturers with the help of injection molding.

At the same time, aside from all its advantages, the market suffers from unstable prices of raw materials and environmental concerns on plastic wastes. However, biodegradable plastics and technological advancements in recycling opportunities nourish sustainable development. Companies are putting efforts into R&D for green processes that will meet the sustainability target of the international community.

Some of the prominent players in Injection Molded Plastic market include BASF SE, HTI Plastics Inc., ExxonMobil Corporation, NAN YA PLASTICS CORPORATION, LyondellBasell Industries N.V., INEOS Group Holdings S.A., SABIC, Covestro AG, Eastman Chemical Company, Huntsman Corporation, Mitsui Chemicals, Inc., Solvay S.A., Rutland Plastics, Sumitomo Chemical Co., Ltd., The Rodon Group, Heppner Molds, Berry Global, Inc., Celanese Corporation, Toray Industries, Inc., Evonik Industries AG, and Asahi Kasei Corporation. These companies give a lot of importance to innovation, product development, and sustainability in their businesses so as to have a competitive advantage.

Injection Molded Plastic Market Key Segments:

By Raw Material

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- High-density Polyethylene (HDPE)

- Low-density Polyethylene (LDPE)

- Polystyrene (PS)

- Polyethylene (PE)

- Polyvinyl Chloride (PVC)

- Others

By Application

- Packaging

- Automotive & Transportation

- Building & Construction

- Consumables & Electronics

- Medical

- Others

Key Global Injection Molded Plastic Industry Players

- BASF SE

- HTI Plastics Inc.

- ExxonMobil Corporation

- NAN YA PLASTICS CORPORATION

- LyondellBasell Industries N.V.

- INEOS Group Holdings S.A.

- SABIC

- Covestro AG

- Eastman Chemical Company

- Huntsman Corporation

- Mitsui Chemicals, Inc.

- Solvay S.A.

- Rutland Plastics

- Sumitomo Chemical Co., Ltd.

- The Rodon Group

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252