MARKET OVERVIEW

The Global High Performance Polymers Market would take up the shape of diverse sectors in terms of providing advanced high performance, highly phenomenally prepared materials that meet the specific stringent requirements of modern manufacturing and engineering technology. As industries diversify, specializing in delivering solutions for extreme conditions such as high-temperature, chemical, and mechanical exposure, high performance polymers will soon be the most commonly developed polymers across aerospace, automotive, electronics, and healthcare applications. Most of them would be made of very sophisticated polymers but would prove unmatched battling benefits to give new levels of efficiency and reliability to any industry.

The Global High Performance Polymers Market will evolve through characteristics that mainly focus on performance improvements of materials and increasing costs of environmental regulations. Such materials will develop applications beyond conventional polymer limitations in demanding environments. Switching from conventional plastics to high performance types will allow firms to produce lighter, more durable products reliably demonstrating use under extreme operating conditions. Whether it's thus high-temperature operation for aerospace components or outstanding mechanical strength for automotive parts, high performance polymers are clearly going to be instrumental in achieving industry goals.

Moving forward, the high performance polymers are expected to be very widely used in that particular segment in the electronics industry. Increasing demands for smaller, faster, and more efficient devices will trigger even better high performance materials. High performance polymers will gain a wider range of applications in connectors, insulators, and semiconductor portions, thanks to their outstanding qualities: high thermal stability and excellent insulating properties. High performance polymers will allow manufacturers to create high-quality products capable of withstanding the increased technological challenges posed by rapidly evolving smartphones, computers, wearable devices, etc.

Moreover, the market itself will go green with increasing environmental concern. This will include many innovations in designing and producing high performance polymers with reduced environmental effects. Manufacturers will also start using green technologies, ensuring that the entire production process of these advanced materials will be within sustainability standards. The industry will also witness polymers based on renewable resources procurement, rendering them more eco-friendly and reducing reliance on fossil fuel dependency. This trend within the industry will meet the increasing demand for sustainable alternatives across industries while ensuring the high performance qualities required in high-stress environments.

Global High Performance Polymers market is estimated to reach $44,127.27 Million by 2032; growing at a CAGR of 3.6% from 2025 to 2032.

GROWTH FACTORS

The global high performance polymers market is firmly on the rise, moving up with the requirements of the various industries for strong yet lightweight workable materials. The driving forces of the growing demand for stronger yet lighter materials are the automotive and aerospace industries, where better fuel efficiency, performance, and overall sustainability depend upon such materials. As these industries work towards reaching higher environmental standards and improving their offerings, high performance polymers will be very much needed in the game. These materials are also now becoming adopted in electronics, where the advantages of enhanced efficiency and relatively high miniaturization allow the development of tiny yet powerful gadgets capable of meeting the ever-growing needs of consumers.

Despite this robust growth scenario, the world of high performance polymers are constantly challenged by many factors that are limiting their large-scale use. The most important constraint has been the high production cost of these advanced materials. The manufacturing techniques for high performance polymers are so complex that they become economically unfeasible to many industries that are price sensitive. Therefore, some sectors, particularly those in the lower-margin or otherwise cost-sensitive quadrant find it more difficult to embrace these materials. Besides this, stringent environmental regulations regarding polymer disposal and recycling constitute another major barrier. The more these regulations tighten, the more industries will have to discover the sustainability of the life cycle of these materials. This will, unfortunately, come at the cost of higher production costs and lower market adoption rates.

Yet opportunities for the market also exist in good numbers. One of the key areas of opportunity is the renewable energy sector. High performance polymers are increasingly being applied in the manufacture of solar panels and wind turbines, which requires them to endure very harsh environments while being lightweight and efficient. Thus, as the quest for cleaner energy gains momentum, the demand for these materials will increase even further, creating an enormous window for innovation and growth. Another good prospect for high performance polymers lies in medical devices. These, by their very nature, promise to engender innovations in healthcare since they meet the exact standards for medical applications including biocompatibility, strength, and flexibility. Countering to demands created by medical solutions available in the market, high performance polymers will have even more to address in terms of the transforming potential of medical devices and technology into the future.

MARKET SEGMENTATION

By Product Type

The High Performance Polymers held a great market on account of their demand from sectors like automotive, electronics and aerospace. High temperature or chemicals are environmental conditions under which these polymers have retained their strength and stability. Being lightweight, it again wins against metals to cut down weight not affecting performance. Hence, this optimal strength with respect to heat and durability makes the material important for advanced engineering applications where more conventional materials fail in comparison.

Among many of the segmentations of product type impacting the market, Polyphenylene Sulfide (PPS) is one of the prime segments worth an estimated $5,155.68 million. The first-class properties of PPS such as chemical resistance and thermal stability render it perfect for use in electrical and mechanical parts of automobiles. Another versatile polymer, known as Polyphthalamide (PPA), is used mostly in applications where toughness and resistance to high temperatures are necessary, making it useful for components found in automotive engine compartments. Likewise, there is Polyamide (PA), among them PA46 and PA4T. Applicable where there is a requirement for mechanical strength and high heat resistance, usually put to automotive and industrial equipment.

As with Liquid Crystal Polymers (LCPs), they take it right in maintaining high dimensional stability combined with very high heat resistivity and applied extensively in electronics such as connectors and micro components. They maintain their strength and performance even when fabricated into extremely thin parts, an added advantage for compact devices. Polyether Ether Ketone (PEEK)-that is strength, chemo resistance and biocompatibility. All these very useful properties make it high in demand in the aerospace and medical device community. Closely related to PEEK is Polyaryletherketone (PAEK), which also holds credibility with respect to its mechanical strength and heat resistance, thereby leading it as a front-runner in industries like oil and gas where load requirements are tremendous.

The term "Others" includes a number of high performance materials that are not frequently used but form each part of the specialized need. Each product type in this segment is designed for only one specific technical function that no other standard plastic can address. Considering the problems that these industries are experiencing demanding better and more efficient functioning, it is only reasonable to think that polymers like these will become even more important by providing solutions where strength, durability, and deliverability just cannot be negotiated.

By Application

The steady growth of the high performance polymers market is because more sectors are now exploiting the opportunities these materials present in various applications. These polymers are characterized by their endurance and performance in moderately extreme conditions. They resist fairly high temperatures, resist chemicals, and resist strength and durability, thus making a useful application in different sectors. With respect to the applications of the market, it is divided into Automotive, Medical, Aerospace & Defense, Electrical & Electronics, Building & Construction, and Others. These are of different significance in each sector and thus have very much contributed to their growth in the market.

In automobile works, these high performance polymers are meant to assist car manufacturers in developing lightweight versions of cars without compromising on strength and safety. A further shot at such objectives is fuel-friendliness as these lighter vehicles will be consumed less. Furthermore, it has been proven to withstand the temperatures and pressures produced by engines and other moving systems. In the medical field, these materials gain value for their safekeeping and strength enough to last for a long duration. These probably found application in surgical tools, implants, and tubing. Their endurance in wear and sterilization makes them ideal for the healthcare sector.

That is an aerospace and defense sector in which high performance polymers are used in mass. Aircraft and defense related equipment require materials that are lightweight and have exceptional resistance against extreme hot-tempered conditions and stress. These polymers improve fuel efficiency and performance without compromising safety standards. They are of great importance in the electrical and electronics industries as they can provide insulation against heat and electricity. As electronic appliances keep becoming smaller and much more efficient, the materials that can withstand the highest intense heat without getting degraded become significant.

High performance polymers have insulation, piping, and coatings applications in the building and construction sector. They resist wear, weathering, and chemicals, which ensures a long service life of buildings with little maintenance. Other applications include those found in industrial machinery, textiles, and consumer products, where durability and performance are vital.

Market growth derives from modernization in the techniques of the manufacture process and increased awareness regarding these polymers' benefits. The demand for high performance polymers is expected to rise as the industries keep turning toward efficiency, performance, and safety. This gradual swing towards better materials indicates the significance these polymers hold in the modern shapes of industries.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$34,456.91 million |

|

Market Size by 2032 |

$44,127.27 Million |

|

Growth Rate from 2025 to 2032 |

3.6% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

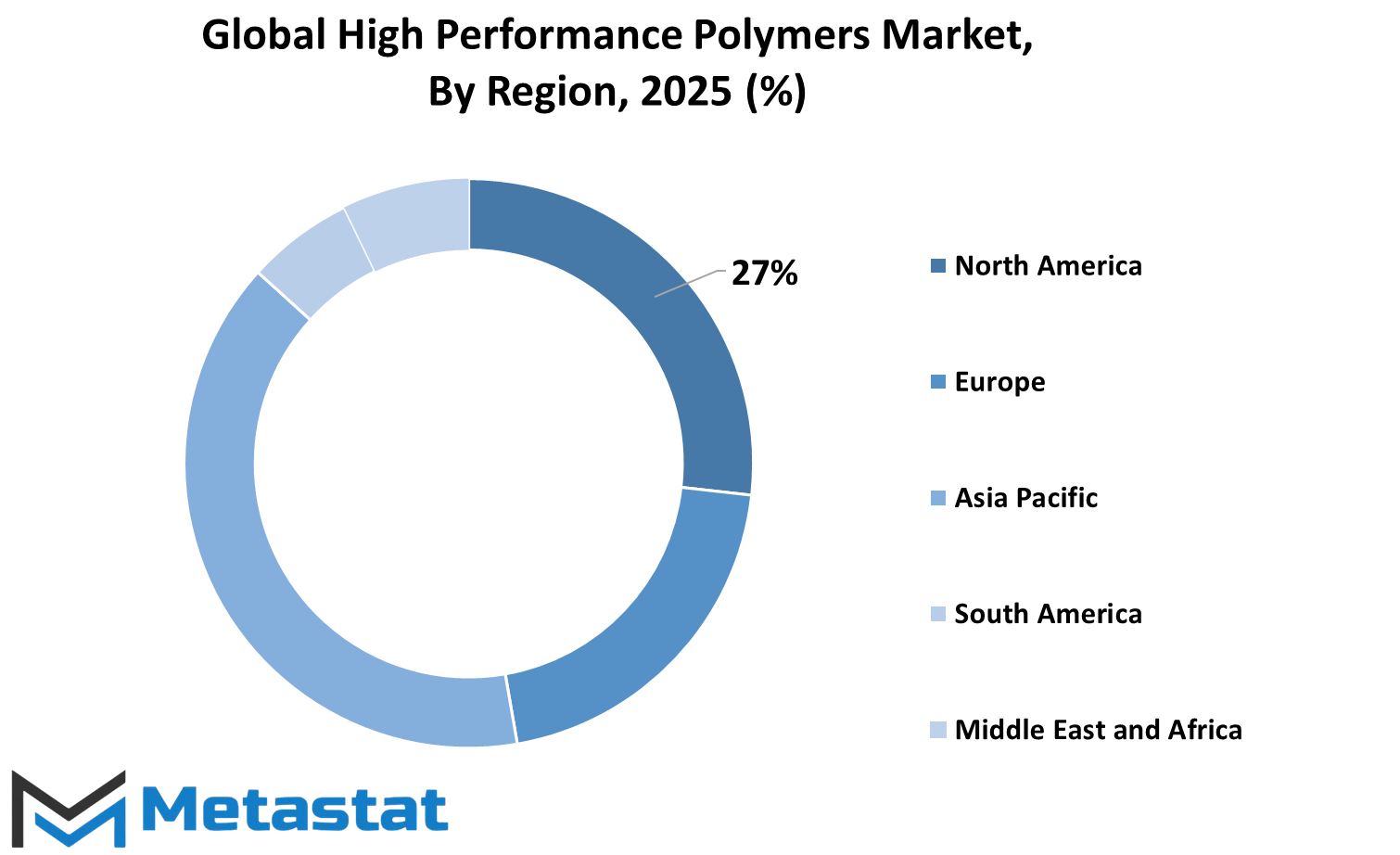

REGIONAL ANALYSIS

These all together create a world market in High Performance Polymers. Some may be very advanced and grow faster, while others still grow steadily, creating opportunities and markets on a global scale. Regions defined in the study carry different names around the world as North America, Europe, Asia-Pacific, South America, and Middle East & Africa: they comprise different households with key regional areas contributing much to market building. Thus, for North America, the big countries are the United States, Canada, and Mexico. Industrial development and broad-spectrum advanced technologies are encouraged in these countries, which drive demand for high performance polymers applications in automotive, electronics, and aerospace. The European market covers much of the UK, Germany, France, Italy, and the remaining part of Europe. In the region, the key players are interested in very set manufacturing industries that can demand lightweight and durable materials with very strong environmental and performance specifications.

Asia-Pacific covers some of the most active countries in this market, including India, China, Japan, South Korea, and the rest of the countries in the Asia-Pacific region. These countries' ever-increasing population, intensifying industrial activities, along with booming automotive and electronics industries are fostering advanced polymer solutions demand. Such massive scales of investments in infrastructure and manufacturing are especially stimulated in China and India, while the larger functional markets from Japan and South Korea are the electronics industries.

The South American market includes Brazil, Argentina, and the rest of South America. The region is still developing compared to others, albeit demand for high performance polymers is slowly on the rise as industries begin to adopt these materials. Brazil stands out for its size and domination in industrial areas.

The region Middle East & Africa include GCC Countries, Egypt, South Africa, and the rest of the Middle East & Africa, thus the growing interests in high performance polymers in this region will also cut across construction, oil and gas, and transport applications. It is also known that countries like UAE and Saudi Arabia will always have huge investments in technology and innovation, hence constant creating demands for durable and efficient materials.

Each of these regions contributes to the High Performance Polymers world market. Some may be very advanced and grow faster while others grow steadily creating opportunities and markets on a global scale.

COMPETITIVE PLAYERS

High performance polymers market is steadily growing due to the increase in fairs and events over several industries in its use. The polymers are strong, resistant to heat and chemicals, and chemically stable. They are used in areas like automotive, aerospace, electronics, medical devices, and industrial equipment. Industries require materials that can maximize performance when put to hard conditions yet remain lightweight and efficient; high performance polymers thus remain a preferred choice. The polymers excel under stress and harsh environmental conditions, providing clear advantages over metals or conventional plastics.

Another reason fueling the increasing demand is that vehicle high performance polymers are beneficial to have in producing fuel-efficient and lightweight designs. In the automotive and aerospace sectors, manufacturers are constantly searching for ways to reduce weight without compromising strength. High performance polymer materials are used in parts like engine components, fuel systems, and interior panels since anything lightweight will, level, raise improved fuel economy. This applies to the electronics sector as well, connectors, circuit boards, and insulation material where durability and heat resistance really count. In medicine, implants, surgical instruments, and diagnostic equipment use these materials because they are safe and biocompatible.

The need for innovation and competition are driving the market. Companies have invested heavily in research to improve existing materials and invent new ones of even better performance. Meanwhile, as industries mature and new applications occur, the demand for customized solutions is increasing. Key players operating in the high performance polymers market are Solvay, Arkema, Evonik Industries, SABIC, Victrex plc, Daikin Industries Ltd., DuPont, BASF SE, Sumitomo Chemical, DIC Corporation, Mitsubishi Chemical Group, Toray Industries, Inc., Syensqo, Hardie Polymers, and Biesterfeld SE. These companies focus on expanding their global reach, advancing production processes, and meeting the increasing demand through innovation and collaboration.

In general, as far-high performance polymers are concerned, the market will continue to expand as industries search for better materials to respond to contemporary challenges. These materials are designed to be efficient, durable, and sustainable. In the next century, with stiff competition and a wide application spectrum, these materials will maintain their importance across various fronts.

High Performance Polymers Market Key Segments:

By Product Type

- Polyphenylene Sulfide (PPS)

- Polyphthalamide (PPA)

- Polyamide (PA) PA46 & PA4T

- Liquid Crystal Polymers (LCPs)

- Polyether Ether Ketone (PEEK)

- Polyaryletherketone (PAEK)

- Others

By Application

- Automotive

- Medical

- Aerospace & Defense

- Electrical & Electronics

- Building & Construction

- Others

Key Global High Performance Polymers Industry Players

- Solvay

- Arkema

- Evonik Industries

- SABIC

- Victrex plc

- Daikin Industries, Ltd.

- DuPont

- BASF SE

- Sumitomo Chemical

- DIC Corporation

- Mitsubishi Chemical Group

- Toray Industries, Inc.

- Syensqo

- Hardie Polymers

- Biesterfeld SE

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383