MARKET OVERVIEW

The global heavy duty apron feeder market is an utmost important part in industries requiring efficient and heavy-duty management of bulk material handling. Mining, construction, cement manufacturing, etc., industries strongly rely on the application of apron feeders. With considerable capacity of material transportation being its priority, apron feeder is a cost-saving and heavy-duty conveyance of coal to ore, rocks, and other bulk material over distant distances. The equipment is made to endure for a long time to work effectively under adverse conditions and operate effectively under stressful conditions, with a steady flow of materials from one point to another in the production process. As firms aim to reduce the cost of material handling and increase efficiency, the value of the global heavy duty apron feeder market will also increase.

The best feature of apron feeders is to withstand heavy loads but consume minimal maintenance. With steel or alloy pans welded together by a series of rollers, these feeders are designed to withstand maximum stress, reduce downtime, and increase throughput. Their robust build guarantees long-term performance, and they are an essential machine when processing material that demands precision and consistency. Within the mining sector, for instance, apron feeders play a vital role in the conveying of large, irregular material. The device offers the necessary strength for raw material handling of large quantities, important in the development of a smooth and uninterrupted process.

Apron feeders help in the feeding of raw material like limestone and clay to the manufacturing line in cement plants. The ability of feeders to transport difficult-to-move material without stoppage or breakdown makes them inevitable in ensuring continuity of the process. Technology employed in the global heavy duty apron feeder market will also improve, with firms considering the improvement of design and materials applied in the fabrication of feeders. Improvements will most likely lead to improved systems with greater capacities and lower operating costs.

Automation will also be the dominant characteristic of the apron feeder systems. Future growth can include the incorporation of intelligent sensors and monitoring systems that check the state of the equipment and provide feedback in real time that can be used to detect issues before they become full-blown problems. The global heavy duty apron feeder market's future will also be influenced by an increased demand for more energy-efficient and environmentally friendly solutions. There will be the possibility of organizations developing new systems that use less energy without reducing equipment performance.

With business needing to tackle environmental needs and manage operating expenditures, green technology will be a significant driving factor for apron feeder technology advancement. Apron feeders involving other material handling machinery, i.e., conveyor or crushers, will also happen more often. As production processes are streamlined by companies, having around-the-clock operations at various stages of the material handling chain will be a critical competitive edge. With these technologies, the industry will experience more multi-functional, automated, and power-saving solutions that can serve a broader range of industries.

The global heavy duty apron feeder market will be a key player in material movement across industries to allow companies to continue operating with reliability and efficiency. As new technologies emerge and the requirements of an industry change, the design and application of apron feeders will evolve to meet the heavy-duty material handling requirements of the day.

Global heavy duty apron feeder market is estimated to reach $1,562.99 Million by 2032; growing at a CAGR of 6.9% from 2025 to 2032.

GROWTH FACTORS

The global heavy duty apron feeder market will experience continuous growth in the coming years due to several reasons pertaining to increasing industrial activity and infrastructure development. The feeders are extensively used to handle large and heavy material in industries such as mining, construction, and cement. With industries expanding and requiring more efficiency and longer lifespan for products in their machinery, the demand for reliable feeding systems like apron feeders will also increase. Their ability to transfer bulk material without jamming or breaking makes them indispensable for large operations. Increasing demand for automation and precision in material handling is one of the key growth drivers.

Because companies are attempting to reduce labor and increase production, they are sure to invest in advanced and durable systems. The need for increased productivity and decreased downtime also leads to the move to machines that can withstand harsh environments and have lower maintenance needs. Technological advancements, such as improved materials and smart control systems, also support the global heavy duty apron feeder market. These innovations make apron feeders more energy-efficient as well as have a longer life, thus appealing in cost-conscious markets. Another important driver is the growth of mining and infrastructure projects, mainly in areas of high mineral contents. As the government and private sector remain committed to pouring money into road construction, tunnels, and other megaprojects, there will be demand for equipment with the capability of moving raw material efficiently.

As the world turns its attention towards renewable energy infrastructure, that will also contribute to the demand because such projects entail the transport of heavy quantities of heavy material. Although there may be certain restraining factors which may check the growth of the market. High initial and installation setup price is one such issue that can be challenge for small-sized companies. Secondly, ignorance regarding the application and benefit of heavy-duty feeders in certain areas can develop reluctance towards adoption, which in turn can decelerate adoption. Market pace can be affected by volatility in raw material prices and project delays in construction. Despite all such concerns, there is significant future scope in the market.

Growing focus on sustainability and the need for effective handling equipment in waste management and recycling can offer new opportunities for growth. New markets with emerging markets with developing industries and increasing investments in construction can offer promising opportunities. Overall, with the development of technology and increasing industrial needs, the global heavy duty apron feeder market will play a pivotal role in the future of material handling.

MARKET SEGMENTATION

By Installation Type

The global heavy duty apron feeder market gradually finds itself in the spotlight as companies look for more heavy-duty and efficient material handling equipment. As more industries call for systems capable of withstanding heavy loads and harsh conditions, the demand for apron feeders will grow steadily in the long term. These machines are mainly used to move heavy and bulky materials, especially in cement plants, construction, and mines. Their nature allows them to handle raw and bulky materials that other types of equipment would struggle with. As such, they will usually be the preferred choice where reliability and longevity are a factor. In the future, the future of the global heavy duty apron feeder market shows the possibility of change, especially in terms of how the machines are installed.

Depending on the type of installation, the market is also segmented further into horizontal and inclined configurations. Both designs have some advantages based on the site planning and material flow requirements. Horizontal arrangements are typically preferred in applications where space is limited or where material has to be transported directly across without changing elevation. Inclined setups, on the other hand, are handy where material needs to be moved at an angle, typically to supply another device or to level out uneven terrain. Such choices are guiding the way industries design their operations, especially with a view to maximizing efficiency at minimum cost addition. The future may hold more customized apron feeders adapted to specific industrial projects' requirements. With technology advances fueling manufacturing more and more, the way these feeders are designed can only continue to grow and include smart additions such as autonomous load control or even remote monitoring.

These developments won't just save on manpower, but also keep breakdowns away and improve safety. There might also be environmentally driven factors playing a role here, forcing makers to make machines not only potent but energy-effective. Developing economies are also ready to play an important role in driving demand upward. As such economies build up infrastructure and grow mining activity, they will demand equipment that is able to match. These businesses will likely focus on offering solid support and multi-purpose products that address various regional concerns.

The global heavy duty apron feeder market also has the potential to grow with companies looking to replace older systems with newer, more efficient models. As markets change, the demand for reliable and affordable material handling solutions will keep this market thriving and progressing.

By Type

The global heavy duty apron feeder market is essential for the handling and transportation of materials in heavy-duty and dependable industries. The feeders are very important in industries like mining, construction, and cement, where heavy-duty equipment is necessary to efficiently handle a lot of raw materials. With increasing numbers of industries demanding longer and more efficient solutions, the market's future looks good with technological innovation and an increased demand for heavy machinery. On the basis of segmentation type-wise, it is divided into three segments on the basis of plate width: Plate Width 1500 Below, Plate Width 1500-2500, and Plate Width 2500 Above.

All these models are appropriate for different industry requirements, based on the capacity of size and material to be transferred. Plate Width 1500 Below is appropriate for low-volume businesses, where there is minimal material to be conveyed and less space to work within. This model will have constant demand from industries requiring medium to light material transfer. Conversely, Plate Width 1500-2500 and Plate Width 2500 Above are intended for heavy-duty handling of material.

These feeders are for enterprises that deal with huge amounts of raw material, such as mining and heavy construction. As technology evolves, the bigger feeders in these ranges are better suited to take care of even more heterogeneous materials at even greater capacities. Over the next few years, the global heavy duty apron feeder market will continue to grow due to increasing demand for machinery capable of meeting the escalating demand for raw material by industries. Spreading plates are an indicator of sustained demand for heavier, heavy-duty feeders that can load more.

With technology moving forward, future technologies will continue enhancing these feeders in that they will be efficient and cost-saving. The feeders will continue to be more energy-efficient with features that reduce the wear and tear on the equipment in order to make them last long.

Overall, the global heavy duty apron feeder market will continue to grow at a consistent rate since there will be a greater need for such feeders as industries will require heavier-duty versions to transport heavy material. Plate width segmentation of the market will offer a vast array of applications, each tailor-made to meet the unique requirements of different industries. With technological advancements, the feeders will improve such that they will be able to cope better with the requirements of the industrial world as it exists now.

By Application

The global heavy duty apron feeder industry is an important segment of industries that relies on safe handling and transport of heavy loads. Apron feeders are heavy-duty equipment used to transport bulk materials, and they serve a proper fit for industries that handle enormous quantities of raw or processed material. Over the years, the feeders have evolved and been applied in various industries. The heavy-duty apron feeder market is forecasted to grow due to technological advancements and an increased demand for effective handling systems for material. The global heavy duty apron feeder market is divided into several main application fields, each one of which plays a significant role in industrial growth and development all over the world.

Apron feeders have extensive applications in the metallurgy sector to convey raw materials such as ores, metals, and coal. These need a robust and reliable mode of transport, and apron feeders are the perfect fit for the job by ensuring smooth and continuous material flow without damaging the material at all. Metallurgical activities require heavy and constant feeding of furnaces, kilns, and other equipment for processing purposes, and so apron feeders are a very important element in such operations. Mining industry is another domain that depends entirely on the global heavy duty apron feeder market. Operations in the mining industry have extensive quantities of ore and other substance that must be moved from point to point.

Apron feeders make this possible by accepting materials of varying size and weight, ensuring that the supply is continuous and steady. The mining industry needs strongly resistant and reliable equipment, and for this reason, apron feeders are applied extensively in such surroundings. In the cement and building materials industry, apron feeders also play the same function. Heavy aggregates, cement, and other building materials have to be transported using equipment capable of withstanding constant wear and tear without a loss in efficiency in transporting the materials. Their heavy-duty function makes them fit for such hostile conditions found in cement and building environments.

Their ability to perform under severe conditions allows these firms to maintain a steady production level. Some of the other industries that use apron feeders include power generation facilities, waste disposal plants, and a whole host of other industrial processes for bulk material transfer. As technology advances and further improves, there will be an increased need for these improved, stable, and efficient pieces of equipment, resulting in a wider market for heavy-duty apron feeders. Glancing into the future, it can be seen that the global heavy duty apron feeder market will continue to be on the growth trajectory and develop further as more industries seek reliable material handling solutions. The future of the market will also see new technologies that will enhance the capacity of apron feeders, further making them efficient and responsive to the various needs of the industries. As industries change, so will the application of heavy-duty apron feeders in ensuring smooth operations across a range of applications.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$996.86 million |

|

Market Size by 2032 |

$1,562.99 Million |

|

Growth Rate from 2025 to 2032 |

6.9% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

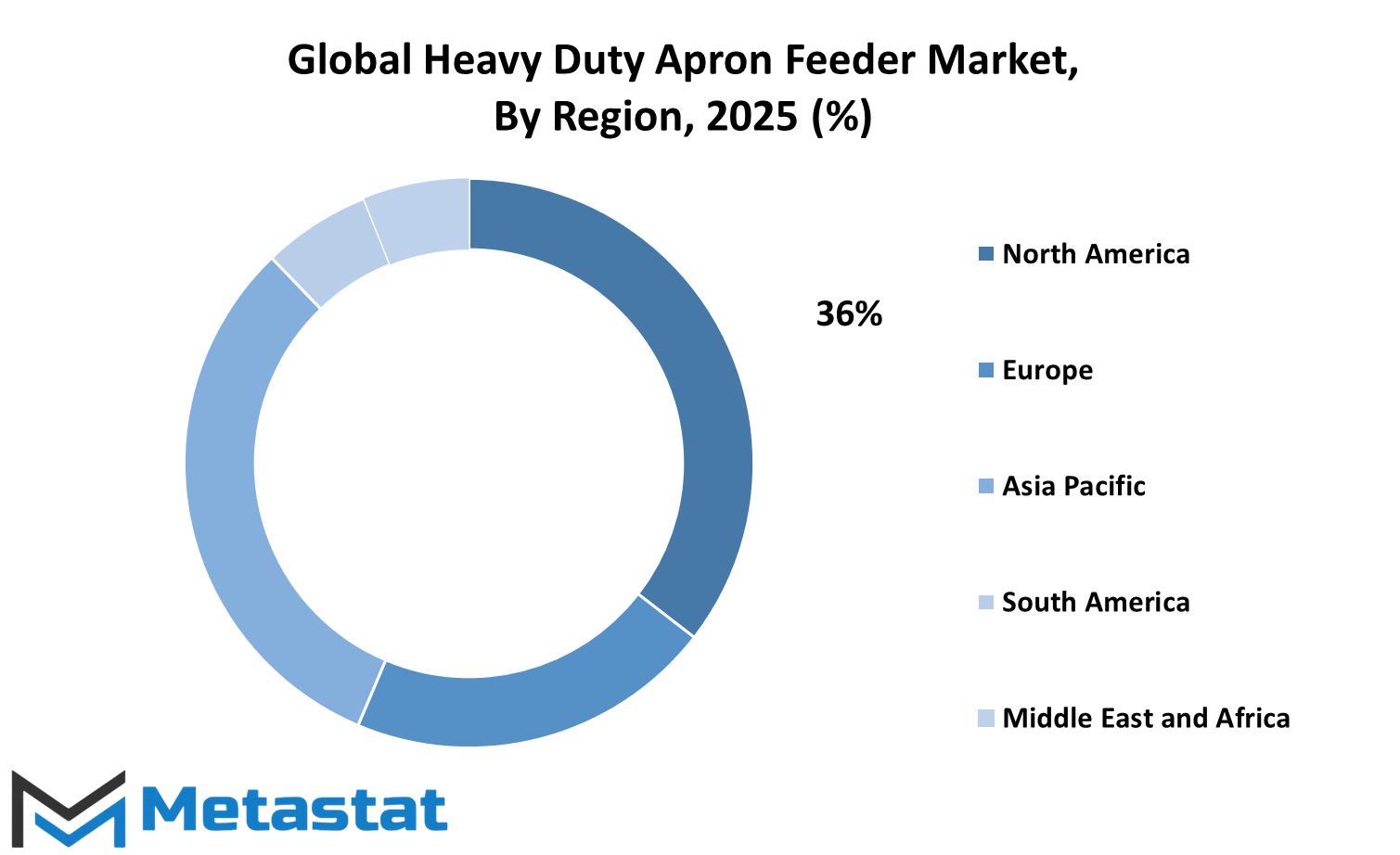

The global heavy duty apron feeder market is going through an enormous shift in how different regions are adopting and benefiting from this equipment. This market is spread across several geographical locations, and each of them has a set of characteristics, requirements, and growth opportunities of their own. With businesses worldwide continuing to grow, such feeders, vital for processing heavy material, will be increasingly vital to optimize efficiency and productivity in a high percentage of industries. Regional analyses of the global heavy duty apron feeder market reveal a definite trend in the development of this technology across different regions of the world. In North America, there is rising demand for heavy equipment, and industries such as mining, construction, and manufacturing are growing.

The United States, Canada, and Mexico are investing heavily in the redevelopment of their infrastructure, thereby significantly contributing to demand for robust and reliable material handling equipment like apron feeders. The sustainability and technology drive of the region also pushes manufacturers to be more innovative and come up with energy-saving, more durable solutions. The United States, in particular, will remain dominant in the North American region because of its gigantic-scale industries and continued requirement for heavy-duty equipment. Europe, being the region with many well-established industrial hubs, also illustrates a forthcoming requirement for advanced apron feeders. The UK, Germany, France, and Italy, on their part, are major players in this industry supported by their robust manufacturing and mining sectors.

The ambition for digitalization and automation of European industries will also shape the future of the global heavy duty apron feeder market in Europe. European manufacturers, seeking to meet stricter environmental standards, will increasingly look for energy-saving and green solutions. Asia-Pacific, driven by the fast-growing industrialization of countries like India, China, Japan, and South Korea, is likely to be among the fastest-growing markets for apron feeders. Mega-infrastructure projects in the pipeline coupled with increasing industrial output in these countries mean they are demanding ever more high-duty and efficient machinery to sustain their industries. China and India, in particular, are going to witness the biggest growth as they possess mass-level industrial activities and constant demand for new technologies.

In South America, Brazil and Argentina are also going to increase in this market. The rising mining and farming industries of this region will be the key drivers of heavy-duty apron feeder demand as these industries increase their operations to fulfill international markets. Though in a growth phase, the South American market should keep rising as infrastructure operations gain momentum and industries get mechanized. Last but not least, in the Middle East and Africa, apron feeder demand is on the rise, driven by mining operations, construction projects, and other heavy industries. The GCC countries, Egypt, and South Africa are most likely to see heavy-duty equipment uptake increase as these countries focus on diversifying their economies and investing in industrial growth and infrastructure development. As the prices of oil stabilize and the other industries thrive, demand for apron feeders globally in those sectors is likely to rise steadily in the next few years.

In summary, the Heavy Duty Apron Feeder market globally is shaping up in every region, and every region will have its specific requirements and challenges. With these industries evolving further and getting larger, there will be increased demand for such equipment, and it will drive innovation and market growth.

COMPETITIVE PLAYERS

The global heavy duty apron feeder market is continuously expanding because the industries around the world continue to rely on durable gear to move material under harsh conditions. The feeders are an indispensable component in the construction, mining, and cement industries where there is heavy and bulk material that needs to be transported efficiently and in a stable manner. In the coming years, the market of heavy-duty apron feeders will likely witness growth due to technological progress, the rise in demands for rugged material handling tools, and the spread of automation in manufacturing activities. Demand for the feeders will rise not just due to their mechanical productivity but also due to their ability to operate under rough conditions, a focus that is increasingly important in big business operations. Key players such as Metso Outotec, FLSmidth, and thyssenkrupp Industrial Solutions are at the forefront of innovations in the heavy-duty apron feeder industry.

These companies have developed sophisticated technologies to enhance the performance and lifespan of apron feeders. For example, new materials are now used to develop more wear-resistant and durable feeders, while the application of smart sensors is helping to improve maintenance processes through the provision of real-time data about performance and potential issues. As the globe keeps turning its focus on maximizing uptime and keeping costs of operations low, the role of technology will also grow even larger. Also, companies like Takraf, McLanahan Corporation, and Williams Patent Crusher and Pulverizer Co., Inc. are also driving the growth of this market by designing feeders that are tailored to meet the specific needs of specific industries and applications. The future of the market is characterized by a growing emphasis on providing custom solutions to meet the unique needs of different industries, from mining to power generation.

Apart from that, businesses also desire to minimize their carbon footprint, and energy-efficient and performance-optimized high-capacity apron feeders will be in higher demand. In the next few years, businesses will be emphasizing reliability, efficiency, and sustainability, and key market players like the Weir Group, Terex Corporation, and Astec Industries will have a significant role to play in offering products that can keep up with the demands. With the evolving market, these companies will likely explore new materials, designs, and smart technologies to expand product lines. The future of the heavy duty apron feeder market will be determined by innovation, and the industry leaders will keep pushing boundaries in material handling solutions so that companies can maintain efficient and sustainable operations in the long term.

Heavy Duty Apron Feeder Market Key Segments:

By Installation Type

- Horizontal

- Tilted

By Type

- Plate Width 1500 Below

- Plate Width 1500-2500

- Plate Width 2500 Above

By Application

- Metallurgy

- Mining

- Cement

- Construction Materials Industry

- Others

Key Global Heavy Duty Apron Feeder Industry Players

- Metso Outotec

- FLSmidth

- thyssenkrupp Industrial Solutions

- Takraf

- McLanahan Corporation

- Williams Patent Crusher and Pulverizer Co., Inc.

- Weir Group

- Terex Corporation

- Astec Industries, Inc.

- Aumund Fördertechnik

- LARSEN & TOUBRO LIMITED.

- Sandvik

- SHANGHAI ZENITH MINERAL CO., LTD.

- McCourt Equipment Inc.

- NEPEAN Conveyors

- CDE Global

- NM Heilig

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252