MARKET OVERVIEW

The global hard CMP pad market is a very important subset of the semiconductor industry. With increasing the pace of improvements in technology, the more demand for this highly professional pad will increase as its role in making semiconductor devices remains irreplaceable. Hard CMP pads are used fundamentally to produce the sort of planarity and smoothness on wafer surfaces that guarantees high performance and reliability in semiconductor parts. Their application goes beyond just polishing, in that they largely determine the efficiency and effectivity of a semiconductor manufacturing process. In the near future also, the evolution of semiconductor technology will further drive innovations within the Global Hard Chemical-Mechanical Polishing (CMP) Pad market.

As semiconductor devices are getting smaller in size and increasing in complexity, the requirement for more accurate and reliable CMP processes will get stronger. Such hard CMP pads, with a robust structure and high durability, will be of cardinal importance in these demands. They will support production of the next generation of semiconductor devices, including even smaller nodes and more intricate designs. Moreover, regional expansions and technological integrations are going to alter the global market of hard CMP pads drastically in the near future.

As countries invest in scaling up their national semiconductor manufacturing, demand for high-quality CMP pads will increase accordingly. This surge in demand will attract manufacturers to innovate and improve performance characteristics to suit specific advanced semiconductor processes. In the future, new materials and composite structures will come into the market, further optimizing the grinding process to ensure superior surface quality and reduced defect rates. The competitive landscape itself of the Global Hard Chemical-Mechanical Polishing (CMP) Pad market is going to undergo considerable transformations. With the new entrants in the market and existing ones consolidating, market dynamics will hasten greater collaboration and competitiveness. Enterprises would strongly move to research and development to remain ahead of technology trends and respond to ever-rising performance demands.

The innovative activity is linked with strategic partnerships or mergers that enable pooling resources and expertise toward keeping up with market demand and hereby widening outreach. In addition, environmental factors are going to be key players in the hard CMP pad market in the future. Green technology in terms of sustainability is certainly going to gain more traction across all industries, and hence manufacturers will have to come up with eco-friendly CMP pads. Such pads will be engineered to minimize their effect on the environment while improving or at best maintaining their performance baselines. Effective integration of sustainability into the production process will not only address the regulatory requirement element; it will also meet rapidly growing demands for green technologies from environmentally conscious consumers and businesses.

Further, the market will benefit from automation and artificial intelligence developments. AI-driven processes will rationalize the consumption of Hard CMP pads and bring in more precision to marsh down waste. The polishing process will be continuously tracked and regulated by automated systems to provide uniform quality and improved efficiency. This technological integration will become imperative in adhering to stringent specifications of today's semiconductor manufacturing and accomplish the goals of reducing costs and increasing productivity.

As the Global Hard Chemical-Mechanical Polishing (CMP) Pad market continues to evolve, it will play an indispensable role in the semiconductor industry's growth and innovation. The development of more advanced, durable, and sustainable CMP pads will be essential in supporting the production of cutting-edge semiconductor devices. Feeling the pulse of technology trends and market demand, they will ensure that the industry makes a sustainable contribution to the further development of semiconductor technology and thus shapes the future of electronics and software.

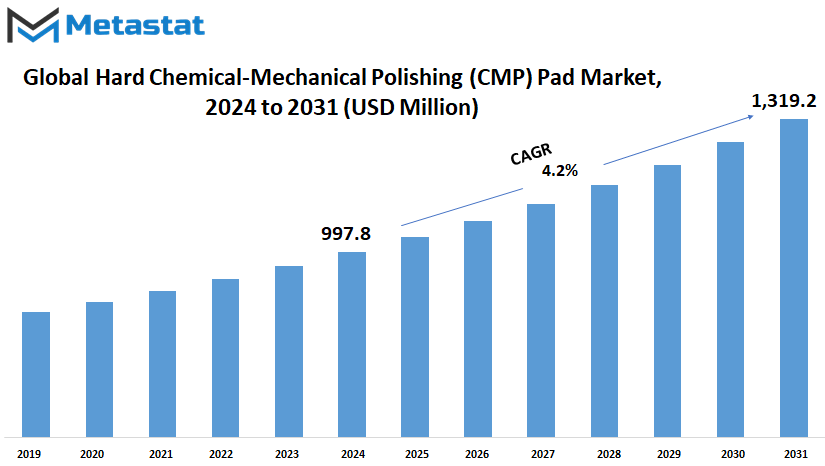

Global Hard Chemical-Mechanical Polishing (CMP) Pad market is estimated to reach $1,319.2 Million by 2031; growing at a CAGR of 4.2% from 2024 to 2031.

GROWTH FACTORS

The Global Hard Chemical-Mechanical Polishing (CMP) Pad market is bound to witness astoundingly rapid growth in the years to come. Increased demand for better precision and efficiency in semiconductor manufacturing processes acts as the primary driver. As this persecuted technology sector is delving deeper into changes and up-gradations, requirements for finer and more efficient modes of production are becoming all the more important. Hard CMP pads, in this context, can provide modern semiconductor fabrication techniques with much-needed precision and efficiency.

Material and design improvements raise the performance and durability of hard CMP pads. The innovations in this area make these pads more resistant, efficient, and meet the stringent demands of the semiconductor industry. These advancements not only improve the quality of the ultimate products but also increase the life of CMP pads, thereby giving better value for money.

ymaxė Despite these growth factors, a few issues trouble the market. The initial high cost and its maintenance expense are big obstacles to hard CMP pads. The cost of investing in, and maintaining these pads, will be too high for smaller manufacturers to afford thus checking the growth of the market. Another challenge lies in the semiconductor fabrication process that requires very-consistent and reliable processes. Making sure that every CMP pad meets these strict standards is not easy at all; it, therefore, may create some potential setbacks in production efficiency and quality of output. Growth opportunities in the Global Hard Chemical-Mechanical Polishing (CMP) Pad market lie in eco-friendly yet cost-effective materials development.

The sustainability trends are not left behind in any industry, and so is in the semiconductor industry. With increasing demands for materials that perform well and are less potentially harmful to the environment, developing effective, eco-friendly CMP pads could create huge new market opportunities. Green and cost-effective CMP pads from manufacturers will meet a receptive market. Furthermore, sustainable manufacturing processes are most likely to dictate the future of the Global Hard Chemical-Mechanical Polishing (CMP) Pad market. Enterprises are increasingly looking at reducing their ecological footprint, and the development of eco-friendly CMP pads resonates with this objective. The shift towards sustainability is not merely a trend but a compulsion, mainly driven by regulatory requirements and consumer preference. With the growing demand, driven by the increasing need for precision and productivity in semiconductor manufacturing, along with rapid technological improvement in pad materials and their design, the global hard CMP pad market is surely bound to grow in the near future. Cost-related and reliability issues, however, will have to be solved. Accordingly, the development of more sustainable and less expensive CMP pads offers huge opportunities; hence, the growth of the market could be sustained over the next few years. This ensures the future of the market because this industry is able to give room to innovation and meet new needs in the semiconductor while showing regard for the environment.

MARKET SEGMENTATION

By Type

This creates a view in which the future of the Global Hard Chemical-Mechanical Polishing (CMP) Pad market will be very promising, with developments and improvement opportunities. The growth in demand by the semiconductor and electronics industries as whole shall make the Global Hard CMP Pad market grow drastically due to the ever-increasing demand for electronic devices and better semiconductor technology. Moving ahead, the Global Hard CMP Pad market is going to evolve with clear and better improvements in the quality and performance of the products.

The CMP process is meant to acquire the planarity and smoothness that semiconductor wafers require. These are the most needed factors when it comes to the fabrication of integrated circuits. We will do the segmentation with regard to type: polyurethane CMP pads and non-polyurethane CMP pads. Each type will deal with certain needs and applications in order to generate more diversity in solution sets to help satisfy the industry demands. Solution Due to their use and effectiveness for large scale applications, polyurethane CMP pads are expected to stay dominant. However, non-polyurethane CMP pads are going to gain further acceptance since research and development efforts lead to the discovery of new materials that offer superior performance and efficiency. The primary focus of CMP technology in the next few years will be on enhancing the pads' efficiency and effectiveness to reduce the whole cost of semiconductor manufacturing. This would be developed through pads that have improved wear resistance, better consistency, and higher precision. Moreover, with advanced monitoring systems integrated, this would enable adjustments in real time while polishing for optimum results and minimum loss of materials.

Another major factor that will be considered is the environmental impact of CMP pads. A large industry move will then be toward greener manufacturing technologies where materials are recyclable and hazardous wastes are reduced. The drivers for this shift will be stringent environmental regulations and a rising awareness of the need for sustainable practices in the semiconductor industry.

Furthermore, increasing complexity in semiconductor devices will require ever-growing sophistication of CMP pads to cope with the complex patterns and features of state-of-the-art integrated circuits. This requires huge research and development investment in making such pads that would be able to help fabricate next-generation semiconductors with their stringent requirements.

The collaboration model is going to take much attention in the global hard CMP pad market between manufacturers and research institutions, and semiconductor companies. Therefore, such collaborations will breed innovation and help develop cutting-edge CMP pads that set new yardsticks in the industry. In the same token, the market will see many product introductions with increased performance, longer lifespan, and reliability.

The future of the Global Hard CMP Pad market appears to be promising, as it is full of opportunities in growth and innovation. Keeping in mind the ever-increasing demand of electronic devices, improvement in semiconductor technology will undoubtedly make the future market evolve to meet the demands of the industry. Emphasizing research and development and introducing sustainable methods by cooperating properly among different stakeholders will find the Global Hard CMP Pad realizing considerable developments to take secure positions as an integral portion of the semiconductor manufacturing process.

By Application

The future will unleash significant transformations in the Global Hard Chemical-Mechanical Polishing (CMP) Pad market. It is these semiconductor manufacturing processes that are going to need effective and accurate methods more, especially as technology will continue to upgrade. It is this market, therefore, that will account for the growing demands from memory devices, logic devices, MEMS devices, and others.

With growing requirements in data storage solutions, memory devices will gain traction in the near future. Artificial intelligence, big data analytics, and cloud computing, in this regard, will definitely require memory devices in the near future, thus fueling the demand for advanced CMP pads. These CMP pads will become prominent, as high levels of precision and reliability are achieved since the fabrication requires these memory devices.

Another important factor that will play a key role in the growth of the CMP pad market is logic devices, which play a critical role in processing and executing instructions in most electronic systems. As more sophisticated and smaller logic devices are developed, demand for CMP pads that can provide the kind of surface finish and planarity needed will surge in order to have these devices work efficiently and reliably in many applications, starting from consumer electronics to industrial automation.

The demand for CMP pads will also increase with MEMS devices, which have recently been applied to many sensors, actuators, and microelectromechanical systems. The miniaturization of these devices is realized by using extremely accurate methods of polishing to attain better performance and reliability. CMP pads will be very essential in the manufacture of MEMS devices to ensure that the quality standards that are set for them by the industry are met.

Other areas, such as advanced packaging and photonics, will be additional drivers for the growth in CMP pad markets. New and innovative technologies in these fields require more developed polishing solutions to get the desired surface characteristics and corresponding performance. CMP pads will play a central role in making these advancements possible. Thus, the industry is better positioned to meet the ever-growing demand for high-performance and reliable electronic devices.

By End-User

The Global Hard Chemical-Mechanical Polishing Pad market will become imperative in different industries, more so as technology advances. Demand for CMP pad inclusion will be derived from quality and precision in manufacturing. It plays an important role in achieving smooth and flat surfaces for semiconductors and electronics. Moving forward in terms of technology, the global market will record a better performance resulting from growth in complexity and miniaturization of electronics.

In the near future, CMP pads will be part and parcel of the semiconductor industry in the making of smaller and more powerful chips. The manufacturers will need CMP pads to attain the level of fineness expected in chip production to meet the increasing demand for faster and more efficient devices; this demands higher chips that support higher processing speeds and larger storage capacities. As companies work harder to try and keep up with modern technology, the market for CMP pads will keep growing.

Takings from better CMP pad technology will also help the electronics sector. This trend of sophisticated electronic devices will call for quality components. CMP pads will be an integral part in providing flat and smooth surfaces of various parts that go into the making of these electronic devices for better performance and reliability. The manufacturers will continue to innovate and improve upon their products because of the ever-increasing consumer expectation, and it is this factor which will fuel market growth.

These CMP pads will find applications in other types of industries too. For instance, the automotive industry will require these pads to manufacture sensors and other electronic components for advanced automobiles. With increasingly sophisticated car features—like self-driving and more digital connectivity—the demand for high-quality, premium electronic components will increase, thus boosting the CMP pad market growth.

REGIONAL ANALYSIS

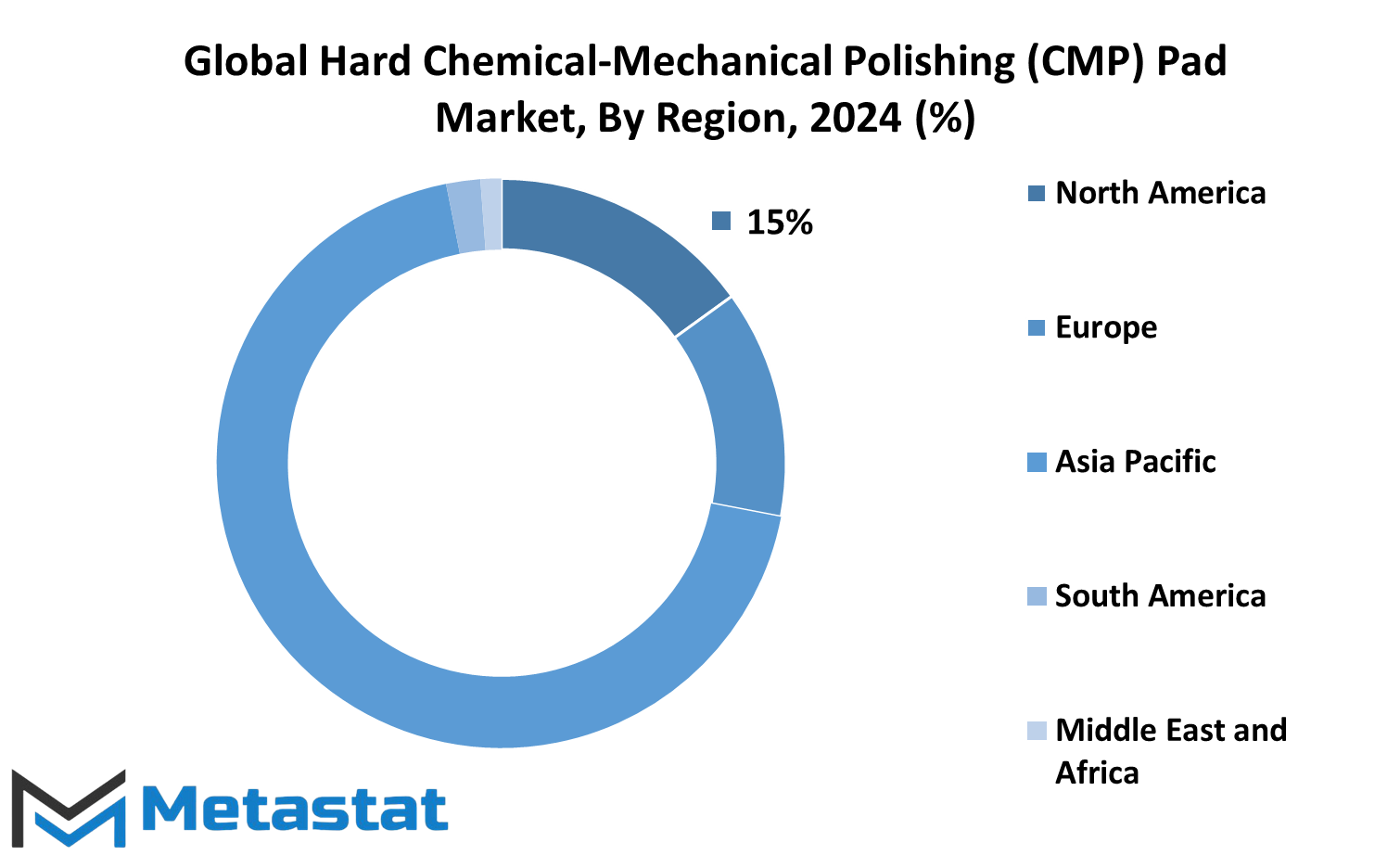

Now, talking in terms of regional analysis, the global market of hard Chemical-Mechanical Polishing CMP Pads witnesses prominent geographical segregation in the major continents. North America, which involves the United States, Canada, and Mexico, is an important region in the global scenario owing to its established technological platform and heavy investment in semiconductor manufacturing. This unintended positive engagement of the region in research and development activities also keeps innovating CMP pad technologies, thus making the region a vital factor across the global market scenario.

It is in Europe, including the UK, Germany, France, Italy, and the rest of the European countries, where a massive market exists for CMP pads. There is a great emphasis on precision engineering and high-quality manufacturing standards. The strict regulatory frameworks of this region enforce stringent environmental and safety standards, thereby driving growth in a light manner and promoting advancement in technology related to CMP pad materials and designs.

The Asia-Pacific region acts as a dynamic hub of CMP pad production and consumption, spearheaded by key economic performers such as China, Japan, India, and South Korea. These are very key players in the semiconductor industry supply chain, driven by high investment in semiconductor fabrications and rapid technology adoption. The growing electronics sector and increasing semiconductor production capacity of the regions spur the demand for CMP pads, further fueling market growth through technology integration.

South America and the Middle East & Africa region are looking forward to slowly progressive growth in the CMP pad market. While on the part of South America, Brazil and Argentina would be holding crucial positions, it would base its activities on the developing electronics manufacturing sectors. Further, the Middle East & Africa region, including GCC countries, Egypt, and South Africa, would boost their semiconductor manufacturing activities with the aid of infrastructural developments and strategic investments in technology.

While unique economic dynamics and technological capabilities in each region will go on to set the global landscape of the hard chemical-mechanical polishing pad market in the future, so it is further expected that improvements in materials science, manufacturing processes, and semiconductor technologies will keep fueling innovation and competitiveness across geographical markets, building a resilient, interrelated global CMP pad industry.

Regional analysis of the global hard CMP pad market explains the dynamic interaction between technological innovation, market expansion, and regional economic factors in determining the future course of this vital industry segment.

COMPETITIVE PLAYERS

One such competitive landscape would be this global Hard CMP pad market—by drawing major players like DuPont, IVT Technologies Co., Ltd., CMC Materials, Inc., and others. Companies like those mentioned above would be innovation pioneers and strategic managers that could define the future of CMP pad technology.

DuPont, one of the top leaders in advanced materials, the likelihood is going to be that it holds its leading position with new synthesized CMP pad solutions aimed at extending semiconductor manufacturing efficiency. IVT Technologies Co., Ltd. will also join in the race as it responds to emerging demands of the industry for higher performance and reliability with its well-recognized precision-engineered CMP pads.

CXC Materials, Inc. is likely to use its R&D capabilities in both the new materials and process expertise to come up with CMP pads that feature advanced polishing performance and reduced defectivity, all of which help to differentiate it in a competitive market.

FNS TECH and FOJIBO are looking to join the CMP pad market with innovative product offerings to further shake things up in this space. Their Agile models for business and customer-centric solution focus will drive market penetration and growth.

3M and SKC are big in product diversification and global presence, and that further makes their increasing foothold in the CMP pad market. This goes hand in hand with a promise of sustainability and technology advancement, affecting market dynamics and setting the trend for the industry.

In addition, strategic partnerships and acquisitions will further raise the competition by Topco Scientific Co. Ltd, Dow Electronic Materials, Dow Inc., Entegris, Inc., Saint-Gobain, Nippon Steel Corporation, and SK enpulse for an increased market position and chasing new opportunities.

In the view of the developing CMP pad market, these competitive players will also look forward to progress in product performance, process optimization for lines that will go into production, and material science. Having taken a forward-looking approach in this field will prop them to fulfill ever-increasingly demanding keyicoptic requirements on precision, reliability, and cost-effectiveness.

At the very core of the competitive landscape in the Global Hard Chemical-Mechanical Polishing CMP Pad market lies innovation, strategic partnerships, and a relentless pursuit of advancing technology. In this regard, the leading players will essentially define the future of the manufacture of semiconductors and further drive expansion and innovation within the sector.

Hard Chemical-Mechanical Polishing (CMP) Pad Market Key Segments:

By Type

- Polyurethane CMP Pads

- Non-Polyurethane CMP Pads

By Application

- Memory Devices

- Logic Devices

- MEMS Devices

- Others

By End-User

- Semiconductor Industry

- Electronics Industry

- Others

Key Global Hard Chemical-Mechanical Polishing (CMP) Pad Industry Players

- DuPont

- IVT Technologies Co, Ltd.

- CMC Materials, Inc.

- FNS TECH

- FOJIBO

- 3M

- SKC

- Topco Scientific Co. Ltd

- Dow Electronic Materials (Dow Inc.)

- Entegris, Inc.

- Saint-Gobain

- Nippon Steel Corporation

- SK enpulse

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383