MARKET OVERVIEW

The global gantry crane market will expand accordingly, with innovations propelling the industry to new heights. As the industries involved- building and construction, shipping and delivery, and manufacturing-prove to be complex, there will be an uptick in demand for robust and versatile forms of lifting equipment, such as gantry cranes. The global gantry crane market will be at the core of that change as it is with growing needs in each sector for efficient material handling systems.

In the future, the logistics and shipping industry will require increasing numbers of gantry cranes to manage heavier loads in both ports and warehouses. The role of these massive machines in supplying large containers on time will assume even greater significance as global trade increases and continues to evolve further. Innovation in design and functionality will make these cranes remain highly valuable in large-scale operations. They will help industries to run efficiently with increased logistical challenges. The efficiency level will be retained at a very high level.

The gantry crane manufacturers will emphasize the inclusion of automated systems and smart technologies, which can seamlessly be integrated into their operations. Such innovations will enable these cranes to operate much more speedily and efficiently. More than ever, one can anticipate the emergence of gantry cranes with Artificial Intelligence (AI) and Machine Learning (ML) capabilities. This means they could offer predictive maintenance, real-time monitoring, and data analytics capabilities. Integrations of these technologies will enhance the life span of the cranes and reduce critical downtime in significant operational phases; this will therefore benefit industries working on constant operations.

The trend of sustainability of industrial operations also has a considerable impact on the global gantry crane market. The future model of the industry will be constructed with energy-saving in mind so that the entire industry can gain some environmental peace. Manufacturers would be more inclined to make energy-efficient cranes with high performances. The electric-powered gantry cranes are expected to replace the diesel-powered ones, thus decreasing the carbon emissions in the processes. To be put in the brackets, the global gantry crane market will become a critical leader in the move towards the sustainable industrial changes.

It is anticipated that the global gantry crane market will be more collaborative on the international level as manufacturers begin to expand into different countries and regions to address increased demand. The development of region-specific gantry cranes to meet the demands of specific industries within different regions will enable the manufacturer to create unique solutions for each industry, which would best answer the challenges imposed on them. This further diversifies the scope of the market by cutting across aerospace and automobile industries down to steel and heavy machinery manufactures.

The global gantry crane market promise a future in which cranes are not machines, but integral parts of an integrated system of operations. All things being equal, with support from good technology, sustainability-oriented designs, and innovation, the market will serve into the futures of these industries. More still, the uses of gantry cranes would only increase further as industries focus on adapting themselves to thrive further in a globally changing economy.

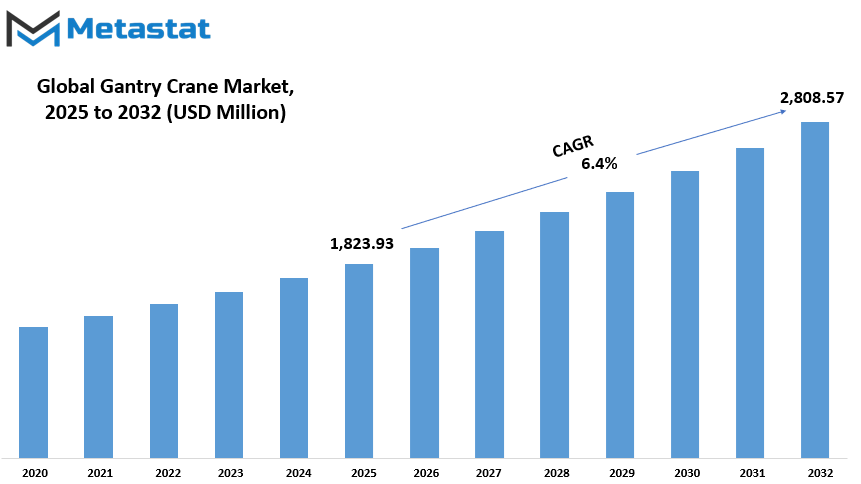

Global gantry crane market is estimated to reach $2,808.57 Million by 2032; growing at a CAGR of 6.4% from 2025 to 2032.

GROWTH FACTORS

Growth within the global gantry crane market is gradually steady because demand for high performance in the field of material handling has surged to meet various industry demands and to streamline processes more significantly, thus satisfying companies like manufacturers or construction operators to reduce their process length. Another reason the market is growing is due to the increase in global port infrastructure. More shipping companies look for ways to improve their operations to keep pace with the increase in demand for goods and trade. This growth in the shipping industry is further straining the need for sophisticated material handling equipment, such as gantry cranes, to move the increased volumes of cargo through the ports.

The global gantry crane market is, however full of so many opportunities but challenges are a lot to be covered. Some of the concerns of high initial and maintenance cost regarding gantry cranes exist. These cranes are rather complicated machines and installation is not very cheap especially for small enterprises or developing industries which do not have a high budget. The cost of continued maintenance is added to the resources required to keep the cranes running at optimal efficiency and safety. Stricter safety requirements and the complexity of operations may further hinder the expansion of the gantry crane market. To meet the requirements for gantry crane safety, one must constantly check the equipment, train employees, and sometimes update the equipment. All these increase operational costs and diminish the profitability of crane operators.

Despite these difficulties, there is also room for growth in the global gantry crane market. Integrating automation and IoT into gantry cranes can greatly enhance the efficiency and safety of these cranes. Automation minimizes the errors of humans reduces the downtime periods significantly, and precision is increased in the crane operations. With IoT, operators can have a real-time data-based view of the performance of the crane. The capabilities of gantry cranes will not only improve but also make the safety standards of their operations more excellent, which will attract industries that prefer operational efficiency and worker safety.

Rising demand for more efficient and safer material handling solutions would ensure that the global gantry crane market grows highly in the near future. Technology and strategic investment would also be essential drivers of change for this market in the years ahead.

MARKET SEGMENTATION

By Type

The global gantry crane market around the world is growing rapidly with various types. Among these types, Single Girder Gantry Cranes dominated the market, holding a large value of $775.60 million. These gantry cranes are popular as they are simple and inexpensive and used to handle lighter to medium loads in construction, shipping, and manufacturing industries.

Another important model is the Semi Gantry Crane. These cranes are similar to full gantry cranes. However, only one of their sides takes the form of rails, whereas the other side consists of a wheel mechanism or any other type of support. This configuration provides flexibility, especially in environments where full gantries would be impractical or too costly. In general, Semi Gantry Cranes are common in minor yards and places where space is lacking.

Truss Gantry Cranes are ideal for more significant loads and are mainly applied in those industries that require rugged and reliable lifting solutions. A truss structure makes for a higher strength and stability of the structure, making it suitable for large and high-use lifting operations. It is commonly found in shipbuilding, rail yards, and heavy industrial manufacturing settings.

Portable Gantry Cranes are another area of popularity because of their flexibility and mobility. It can be easily assembled and disassembled and hence preferred for small operations or places that require the crane to be moved from place to place. This portability makes a major difference in small to medium-sized businesses, or where cranes are used on an ad hoc basis.

Finally, other gantry cranes exist outside the categories stated above. Perhaps they have something special or even in a peculiar configuration to specifically fit niche application requirements. Therefore, the sheer range of gantry cranes provides companies the ability to source the right machine for their respective needs, which could be used for light-weight operations or heavy industrial applications.

The global gantry crane market, overall, is diverse and in continuous growth with increasing demand in all industries. Companies will be in constant search for more efficient and cost-effective lifting solutions; thus, the global gantry crane market will continue to grow, with improvements from manufacturers as designs and features change to keep pace with their customers' requirements.

By Operation

There are two broad categories of operation in the global gantry crane market: manual and automatic. These categories explain what type of functionality the cranes have and where they can best be applied, such as specific industries. This gives an understanding of the advantages and disadvantages of every operation system and helps businesses determine the appropriate machinery for their specific needs.

Manual gantry cranes are operated by human input, often requiring an operator to move the crane along its tracks, lifting and lowering loads using manual controls. They are usually less expensive to purchase and maintain than their automatic counterparts. They are very popular in small-scale operations or industries that do not require the high-speed, precision lifting that automated cranes offer. Although simple, hand-operated cranes can take loads of tremendous weights and be useful for repeated duties. But it is humanly impossible and strenuous for individuals to perform jobs while using this device.

An automatic gantry crane, by using advanced technology, performs all tasks of lifting and movement almost free from the hands of the user. These cranes are designed to improve the efficiency rate while reducing human error with respect to basic safety measures. Their accuracy and speed make it worthwhile for large-scale operations, with sensors, controllers, and advanced software usually along with them for smooth and continuous operation. The cranes are automated, thereby being very useful where speedy and accurate movement of heavy loads is required, such as at ports or huge storage rooms.

The choice of manual or automatic cranes would depend much on the requirements of industries and the investment they are willing to make. For small businesses with budget constraints, manual gantry cranes would be more suitable as they have a lower initial cost. However, industries that need continuous operation with high precision would opt for automatic cranes, as these have higher productivity and reduced labor costs in the long run.

Both gantry cranes are deployed to execute heavy jobs in places where the task requires heavy lift and transfer operations. Though manual cranes are highly demanded in areas because of the simplicity and cheaper costs, trends for automation continue to fuel more demand for the automatic gantry cranes with a motive toward higher efficiency as well as lowering labor costs within the industries.

By Lifting Capacity

The global gantry crane market is steadily expanding. Material handling equipment demand continues to rise among all the major industries. For such applications, Gantry Cranes are installed at ports, construction sites, shipyards, and warehouses where loads of several tones are frequently shifted with utmost ease. A versatile machine like gantry cranes is expected to accomplish various functions in a respective area. These cranes are categorized according to the lifting capacity and split markets to be well understood with separate demands in these segments.

Gantry cranes that can lift loads weighing less than 30 tons constitute the first part. Gantry cranes are usually suited for light to medium-duty operations. Smaller warehouses, assembly lines, and workshops typically have these. Being relatively compact in size and also being inexpensive, these gantry cranes are used extensively by industries which need to lift lighter loads. The category will likely be constantly in demand because industries remain keen on efficiency.

The second category incorporates overhead cranes within the weight-handling capacities ranging from 30 to 50 tons. Cranes usually function in mid-intensive applications for instances in constructing heavy projects as well as industry firms. Being the heavier category lifts, they manage weights that give an opportunity to complete lots of duties. Companies in construction, manufacturing, and transportation sectors are increasingly opting for these gantry cranes since they balance between the lifting capacity and cost incurred. When industries expand to lift large capacities, higher -value gantry cranes are likely to find more usage in such applications.

High production application cranes are gantry cranes with lifting capacities that can be more than 50 tons. They appear in massive industrial environments, such as shipyards, large manufacturing plants, and ports, where size really matters. They find application in more heavy loads lifting and heavy loads moving. Therefore, high production application projects require high lifting capabilities, which makes these cranes essential. The demand for larger equipment will continue to rise, especially in the transportation and logistics sectors. Therefore, the global gantry crane market with a capacity of over 50 tons is likely to increase because such cranes are designed to perform some of the toughest lifting jobs that make them utterly indispensable for heavy-duty applications.

The global gantry crane market is expected to increase as industries scale up their businesses and require gantry cranes for different lifting capabilities. The demand for gantry cranes will stay strong in all three segments and these machines are going to significantly contribute to productivity and efficiency enhancement in a large number of sectors.

By End-User

The gantry crane market is diversified globally into several end-users. This is leading to the rise in demand and adoption of cranes in different sectors. The major sector contributing to the growth of Gantry Cranes is the automotive sector. These cranes are used more in automobile manufacturing and assembling lines, where there is a necessity for heavy lifting of parts, such as the engine, chassis, and body components. With great versatility and reliability, Gantry Cranes have been the choice for automotive production lines, as it can easily shift large and heavy materials with much accuracy and speed.

Gantry Cranes are absolutely irreplaceable within the metal and mining industries. In mining, these cranes of much importance within the transportation process of raw materials, equipment, and machinery for vast sites at times on even rugged terrains. They might be used as a lifting application for placing heavier equipment like the excavator and drill trucks by improving efficiency, safety, and effectiveness in a mining operation. In the metal industry, Gantry Cranes can lift large metal sheets, plates, and beams that are handled during the metal fabrication plant and the steel mill operation.

Construction is another field where the cranes play a paramount role. The cranes can be used to move, for instance, the following construction materials: steel beams, concrete blocks, and prefabricated structures. They are widely stationed in any construction site to hold up very heavy components that cannot be handled easily. This is why Gantry Cranes are a huge component in modern construction, improving safety in any construction site, as well as productivity.

Gantry Cranes are also used in warehouses and logistics facilities for similar purposes. Since they are able to lift and move heavy goods, they prove indispensable in large storage and distribution centers. They can easily move products from one place to another in the facility without wasting much time in loading and unloading products. This, in turn, enhances the efficiency of operations in warehouses, allowing for faster delivery times and minimizing downtime.

This is mainly used in the aerospace industry to lift heavy and fragile parts of an aircraft. These are critical elements because the parts involved in aircraft manufacturing and assembly or maintenance processes can be quite delicate and heterogeneous, requiring improved lifting capacity and precision from Gantry Cranes.

Other industries ranging from utilities, shipyards, to ports also generate demand for Gantry Cranes. In the case of ports, they are exceptionally important in the operation of loading and unloading containers, whereas, in the case of shipyards, they help in the construction and repair of ships. The different wide variety of uses in the different sectors makes Gantry Cranes a necessity in global industrial operation.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$1,823.93 million |

|

Market Size by 2032 |

$2,808.57 Million |

|

Growth Rate from 2024 to 2031 |

6.4% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

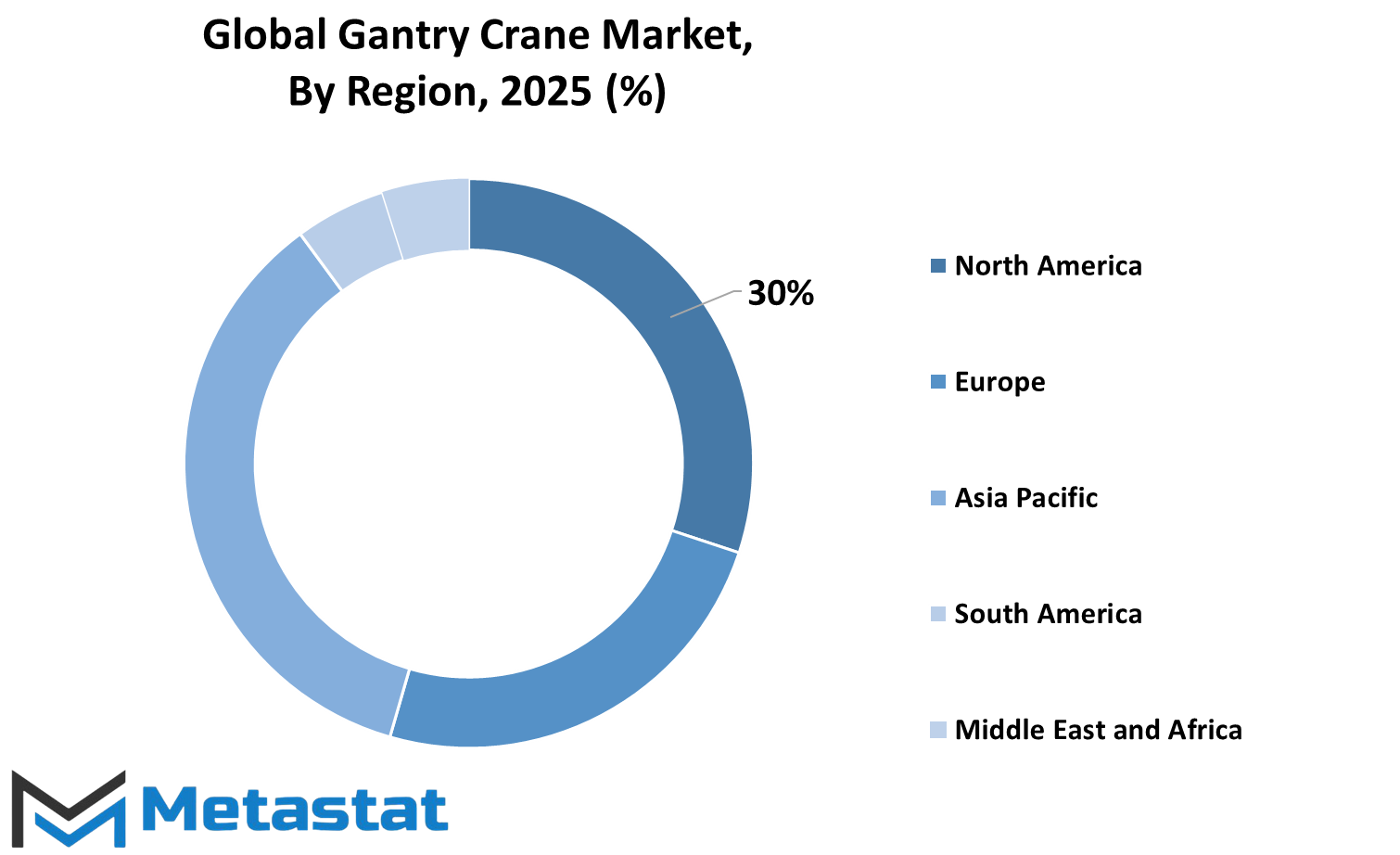

The global gantry crane market can be divided based on geography into five major regions: North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. The growth and development of the market are significant within each region and are influenced by specific countries where demand and supply for gantry cranes exist.

North America is further broken down into the three major countries: the United States, Canada, and Mexico. These countries are important in that they contain large industrial bases that apply gantry cranes for many operations, such as construction, manufacturing, and ports. The United States is leading in this region, due mainly to the rapid growth of infrastructure projects and higher automation levels within the logistics industry.

Europe is a major region; it includes the UK, Germany, France, Italy, and more of Europe. The European market is characterized by some established manufacturing sectors and advanced technologies, which raises the demand for efficient material-handling equipment. Germany is industrial automation leader that plays a central role in this European gantry crane market.

Asia-Pacific is the largest and most diversified region with gantry crane demand. Major industrial nations include India, China, Japan, and South Korea within this region and other countries of the Asia-Pacific area. The largest market in this region for gantry cranes would be China with a rapidly developing industrial and manufacturing sectors. With an increase in infrastructure projects in India, demand for such cranes is also rising in that country. In addition, the Japan and South Korea markets, known for their sophisticated technology and automation practices, further fuel the global gantry crane market growth in this region.

South America is the region of Brazil, Argentina, and the rest of the area. The South American market is developing, primarily because of the growth of main industries such as mining, construction, and transportation. Brazil, the largest economy in the region, leads in demand for gantry cranes, mainly for ports and infrastructure projects.

The Middle East & Africa is the other key market, segmented into the GCC countries, Egypt, South Africa, and the rest of the Middle East & Africa. The Middle East is seeing a surge in construction projects, especially in the United Arab Emirates and Saudi Arabia, which in turn is creating a demand for efficient lifting equipment. South Africa, with its growing industrial base, also adds to the regional demand for gantry cranes.

The overall global gantry crane market is still growing globally, because this market expands itself across all regions with industrial growth, infrastructure development, and technological advancements.

COMPETITIVE PLAYERS

The global gantry crane market is expanding at a rate that is quite high as of now, concerning efficient material handling solutions across the various industries. Konecranes, Demag Cranes & Components GmbH, JASO Industrial Cranes, Liebherr Group, and Aicrane Machinery Group are considered to be some of the leading market players. These companies are very essential in determining the global gantry crane market because they provide advanced technologies and customized solutions to meet the diverse needs of their clients.

Konecranes has been one of the major crane manufacturing companies, which provides a wide range of gantry cranes all around the world. Commitment towards innovation and quality has given the competitive edge for Konecranes. Demag Cranes & Components GmbH is another prominent firm known to provide robust, effective cranes in manufacturing lines, construction lines, and shipping lines.

JASO Industrial Cranes is a headquartered organization in Spain that has been remarkable with highly performing cranes. The company is known for providing customized solutions ranging from the most pervasive industrial applications. Yet another giant in the heavy equipment market is Liebherr Group, which remains a market leader in global gantry crane market. The group's strong presence in the market for heavy equipment has established its position as a reliable supplier of sturdy cranes to several industries around the globe.

Another key player is Aicrane Machinery Group, which focuses on the design and manufacturing of gantry cranes for different applications in construction, shipping, and others. Its products are known for reliability and performance and are preferred by industries for effective material handling.

Other companies include Mi-Jack Products, Inc., Mammoet Holding B.V., TNT Crane & Rigging, GH Cranes & Components, and American Crane & Equipment Corporation that are contributing to the global gantry crane market by providing high-quality crane solutions. The other significant player from China is Shanghai Zhenhua Heavy Industries Co., Ltd, whose advanced technology and capacity for large-scale manufacturing further benefit the company.

SANY Group is a known company in terms of heavy machinery and equipment, which also covers the global gantry crane market by providing innovative, cost-effective cranes. Eilbeck Cranes has a good reputation in the industry for delivering strong, efficient cranes for industrial purposes from their base in Australia.

The main players are the ones who drive the global gantry crane market through investment in research and development, extension of product offerings, and embracing latest technologies to respond to the industry's needs that are evolving constantly.

Gantry Crane Market Key Segments:

By Type

- Single Girder Gantry Cranes

- Semi Gantry Crane

- Truss Gantry Crane

- Portable Gantry Crane

- Other

By Operation

- Manual

- Automatic

By Lifting Capacity

- 30-50 Tons

- >50 Tons

By End-User

- Automotive

- Metal & Mining

- Construction

- Warehouses

- Aerospace

- Utility

- Shipyards & Ports

- Other

Key Global Gantry Crane Industry Players

- Konecranes

- Demag Cranes & Components GmbH

- JASO Industrial Cranes

- Liebherr Group

- Aicrane Machinery Group

- Mi-Jack Products, Inc.

- Mammoet Holding B.V.

- TNT Crane & Rigging

- GH Cranes & Components

- American Crane & Equipment Corporation

- Shanghai Zhenhua Heavy Industries Co., Ltd.

- Aicrane

- SANY Group

- Eilbeck Cranes

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252