MARKET OVERVIEW

The global fiber laser market has turned the manufacturing and processing sector into that of precision, efficiency, and high technology. As industries push for more automation and accuracy, fiber laser will be at the forefront of innovative solutions. Such systems will no longer be the only options for traditional devices; Rather, they will determine the standards of tomorrow's production lines. The need for Cleaner, Speeder, And Energy-Saving Technologies nearing obsolescence.

The industry will go beyond its existing applications, touching areas that are still making significant progress in adopting technology. Industries such as aerospace, medical devices and microelectronics will depend a lot on fiber laser for accurate design and reliable output. As miniaturization remains a propelling trend, the capability of fiber lasers to provide Ultra-Fine Detail with Touching Physical Components will set them apart from Other Technologies. The addition of artificial intelligence and IoT in fiber laser systems will create avenues for automated tuning, real-time diagnostics, and preventive maintenance, so that downtime and material waste will become negligible.

Customization will be the other hallmark of the global fiber laser market in the next few years. Manufacturers will require systems that respond to unique operating requirements instead of universal solutions. It will cause new configurations, modularity, and software-based flexibility, making fiber lasers extremely versatile for various manufacturing environments. In addition, sustainability will weigh on purchasing choices, as companies will need tools that reduce energy consumption and emissions. Fiber lasers, which are both efficient and long-lasting, will meet this need, solidifying their reputation as an environmentally friendly option for industries worldwide.

Emerging markets will be the key to the future of this market. As industrialization in untapped regions picks up speed, the technology of fiber lasers will discover new opportunities. Domestic manufacturers will be working to keep pace with global standards and so invest in sophisticated laser systems for cutting, welding, marking, and surface treatment. Mature markets will concentrate on upgrading existing equipment in order to stay competitive, particularly in industries where precision and speed will be the measure of profitability.

Innovation will not be limited to hardware alone. Fiber laser systems will be complemented by software solutions that will transform the way operators interface with these machines. The user interface, predictive analytics, and automation will lower the reliance on human know-how and make operations greater green and dependable. This union of hardware and software program will allow a dynamic environment where fiber lasers get smarter and extra networked.

Essentially, the global fiber laser market will extend much further than what it is today, becoming a cornerstone of contemporary manufacturing ecosystems. It will be a synthesis of speed, sustainability, and intelligence where industries globally become more efficient and have consistent quality standards while opening to a future of technological excellence.

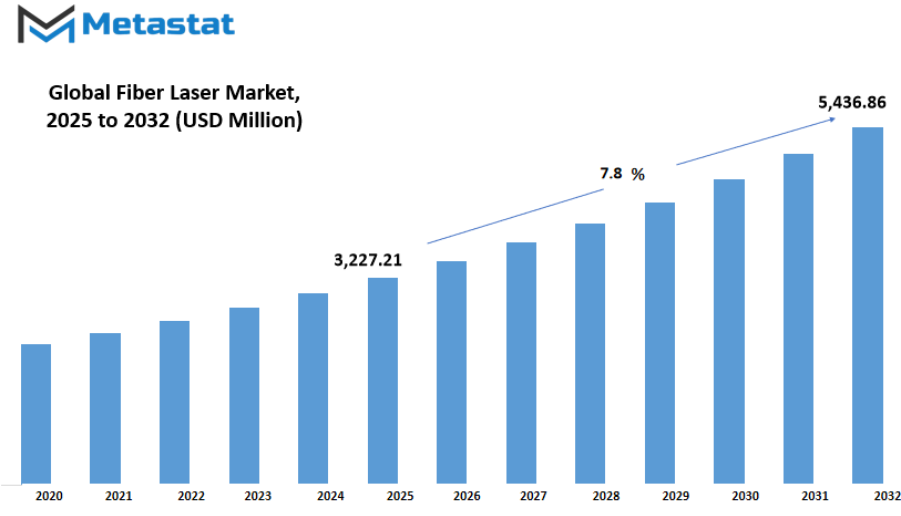

Global fiber laser market is estimated to reach $5,436.86 Million by 2032; growing at a CAGR of 7.8% from 2025 to 2032.

GROWTH FACTORS

The global fiber laser market is attracting major attention because of its increasing use in manufacturing and automotive industries. Both these industries require high efficiency and precision in cutting, welding, and marking processes, which are achieved through fiber lasers at an impressive speed and accuracy. Since companies are seeking products that boost productivity without compromising on the quality, fiber lasers are proving to be a tempting choice. Their high level of performance with low errors makes them a crucial device in contemporary production lines, leading to their fast growth.

The developing fashion towards automation and sensible factories is any other key driving force inside the market. The international's manufacturers are making investments in state-of-the-art technology to increase performance in operations and lower their fees. Fiber lasers perfectly suit into this shift because they easily combine with automated machines and robotic methods. This compatibility now not best hurries up processing however additionally reduces guide dealing with, which is in line with the targets of Industry four.0. With industries embracing digital and automatic technologies, the software of fiber lasers will maintain to growth, with them becoming a relevant characteristic in future production setups.

In spite of these encouraging developments, a few demanding situations might also arrest marketplace increase. The excessive upfront investment charge of fiber laser systems is still a big dilemma, specially for small and medium-sized companies. Such companies do not locate it smooth to incur the initial value, in spite of the lengthy-time period blessings. Secondly, fiber lasers aren't fully compatible with a few substances, restricting their utilization in a few production tactics. These shortcomings may avert some industries from adopting the technology completely, posing an impediment towards massive-scale adoption.

In the future, increased software of fiber lasers inside the manufacture of scientific devices guarantees to bring new avenues for the marketplace. The clinical enterprise demands precision and reliability whilst manufacturing sensitive contraptions, and this is some thing that fiber lasers can deliver. With the growth in call for excessive-stage healthcare gadget the world over, fiber lasers are poised to take a more proportion in addressing those needs.

MARKET SEGMENTATION

By Type

The global fiber laser market is attracting attention due to its cutting-edge technology and vast application domains in various industries. Fiber lasers are desired due to their high efficiency, accuracy, and decrease protection than traditional laser structures. The automotive, aerospace, electronics, and production industries are increasingly deploying fiber lasers for slicing, welding, engraving, and marking applications. This is precipitated by means of the necessity for more accuracy, pace, and power efficiency in production processes, which fiber lasers are very capable of handing over.

The global fiber laser market is segmented into various fiber laser types, with each of them targeting different applications. Of all these, infrared fiber lasers have the biggest market share, worth $1,853.71 million, because they are most in demand for metal cutting and welding processes. These lasers are identified for his or her energy to system hard materials with regular overall performance. Ultrafast fiber lasers represent every other critical phase, broadly used for applications related to excessive precision, consisting of micromachining and production of scientific gadgets. Their potential to manner without thermal damage makes them a need for sensitive materials and sophisticated applications.

UV fiber lasers occupy a dominant market in packages that involve marking and engraving on delicate surfaces. They can create satisfactory, high-assessment marks with out degrading the substrate fabric, making them not unusual in electronics and semiconductor production. Visible fiber lasers discover market areas wherein colored laser mild is needed to fit precise packages. These lasers diversify the marketplace by using assembly precise requirements that other lasers cannot.

Generally, the global fiber laser market will hold growing considering the fact that industries need solutions which might be both specific, power-green, and adaptable. The extended call for automation and precision manufacturing will pressure call for for all kinds of fiber lasers, ranging from infrared to seen. With technological advancements and extra industry adoption, fiber lasers might be at the middle of defining the destiny of advanced production.

By Power

The fiber laser market is gaining traction global due to industries searching out green and correct processes to system materials. Fiber lasers are most in demand because of the truth that they offer better energy efficiency, progressed beam first-class, and decreased protection over conventional laser structures. The truth that they are able to offer particular reducing, welding, and staining makes them inevitable across industries which includes car, electronics, aerospace, and production. The growing requirement for automation and sophisticated manufacturing approaches will maintain on accelerating using fiber lasers global.

By power, the global fiber laser market is split into low power, medium strength, and high strength segments, each pleasant exceptional business necessities. Low-electricity fiber lasers are in particular utilized for marking, engraving, and fine slicing, and they may be used notably in the electronics and jewellery sectors, in which accuracy is a foremost requirement. They are clean to handle in small spaces and are value-powerful, which suits corporations that want high precision without investing in heavy-responsibility systems.

Medium-energy fiber lasers serve a much broader spectrum of programs, specifically in slicing and welding operations. They are broadly utilized in commercial settings that require improved processing pace and performance than in the case of low-electricity systems. The automotive and metal fabrication industries, for instance, are highly dependent on medium-power laser systems for manufacturing parts with higher quality and reduced wastage. Growth in this segment will be substantial with companies further transitioning to more efficient and energy-saving technologies.

High-power fiber lasers rule the space where robust performance is necessary. They are applied in heavy-duty cutting of thick metal, big-scale welding, and other sophisticated industrial applications that demand high-level energy. They find their application in shipbuilding, aviation, and heavy machinery manufacturing, where resilience and toughness are important. As industrialization gathers pace and there is a movement toward automated manufacturing, the high-power industry will witness consistent demand, particularly in those areas with robust manufacturing hubs.

Overall, the global fiber laser market will keep growing as technological advancements enhance efficiency and cost-effectiveness in all power ranges. Every power category targets unique needs, so fiber lasers are great versatile tools for different industries. With increasing industrial use and continuous innovation, the market will continue to be an essential component of the manufacturing industry globally.

By Operation Mode

The global fiber laser market is getting popular because of its efficiency and the number of different applications across many industries. Fiber lasers have the reputation for providing high accuracy, low maintenance, and energy efficiency as compared to conventional laser technologies. They are a rising preference for production, medical devices, the car industry, and aerospace as they allow faster operations with decreased operational expenses. The era is increasingly being used as industries search for answers that decorate productivity whilst minimizing waste and electricity use.

Based on operation mode, the market is also segmented into Continuous Wave (CW), Pulsed, and Quasi-CW. Continuous Wave fiber lasers find enormous packages in tactics that name for consistent and non-stop beam, consisting of welding and reducing heavy fabric. Their regular energy shipping capability makes them suitable for heavy commercial methods. CW lasers tend to be desired in mass production seeing that they provide particular and easy cuts, removing the want for secondary finishing, which saves time and money.

Pulsed fiber lasers are, however, in excessive call for in precision and exceptional element applications like marking, engraving, and micromachining. These lasers offer energy in pulses, which avoids laser warmth accumulation on the fabric floor and permits for laser operation with out inflicting harm to the fabric. Such lasers are commonly used by industries including electronics and jewellery making, in which laser operations require excessive precision. Their capability to without problems adapt and function on sensitive substances makes them a crucial device in industries in which precision is critical.

Quasi-CW fiber lasers offer the advantages of both pulsed and continuous operation modes. They provide a high peak power pulse operation combined with a duty cycle comparable to CW lasers. This is appropriate for programs inclusive of skinny steel cutting and drilling, in which velocity and control need to be performed. The flexibility of Quasi-CW lasers allows companies to perform numerous duties without having to change among diverse units of device, which makes them a cheap desire for maximum industries.

With industries increasingly shifting closer to automation and complex production practices, the need for fiber lasers in those modes of operation will step by step boom. Each mode has distinct blessings that match specific commercial programs, encouraging their adoption globally. As laser era continues to improve and consciousness of benefits increases, fiber lasers will continue to be a important a part of excessive-precision manufacturing's future.

By End Use

The global fiber laser market is gradually picking up pace as industries continuously acknowledge its effectiveness, accuracy, and affordability. Fiber lasers employ optical fibers as the active gain medium, thus making them more energy-efficient, compact, and reliable than conventional laser systems. These features have made fiber lasers a choice of preference for an extensive array of applications, propelling demand across various sectors globally. The technology is still supplanting traditional laser solutions because it can deliver high-quality output while having a very low need for maintenance.

Industrial use is certainly one of the most important fields for the software of fiber lasers. Automotive, metal processing, and heavy equipment producers depend upon fiber lasers for slicing, welding, engraving, and marking due to their precision and pace. Unlike conventional equipment, fiber lasers can take care of numerous substances consisting of steel, aluminum, and alloys with incredible precision, making them necessary in modern manufacturing facilities. Their low running expenses and high durability similarly entice industries aiming to decorate productivity and reduce downtime.

The medical and aesthetics sector is another key contributor to market growth. Fiber lasers are extensively applied in surgical treatments, dermatology, and cosmetic treatments due to the fact that they enable non-invasive or minimum invasive treatments with rapid recovery. Skin resurfacing, hair removal, and vision correction treatment are enhanced by the accuracy offered by these lasers to provide more effective treatment and patient comfort. In the equal vein, the telecommunication quarter relies on fiber lasers for building and sustaining optical communication networks because they permit excessive-velocity transmission of records with exact nice signals.

Applications in aerospace and protection are also on the rise as fiber lasers are integrated into system for focused on, sensing, and high-energy protection structures. Their compact layout and resistance to harsh conditions lead them to perfect for classy military operations. Besides, the electronics and semiconductor industry employs fiber lasers for micro-processing, reducing touchy elements, and offering high precision within the manufacturing of state-of-the-art digital devices. Research and development, as well as clinical makes use of, also contribute to the call for, as fiber lasers are vital system in laboratories for checking out, measurement, and cloth inspection. Even rings design and quality arts comprise fiber lasers for unique engraving and shaping tasks.

In total, the global fiber laser market is being described by way of its versatility and performance in numerous industries. From industrial production and clinical tactics to aerospace technologies and medical exploration, fiber lasers have emerged as a important technology. As groups hold to price precision, sustainability, and affordability, fiber lasers will continue to be at the slicing fringe of innovation, main to increase and new uses in the years yet to come.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$3,227.21 million |

|

Market Size by 2032 |

$5,436.86 Million |

|

Growth Rate from 2025 to 2032 |

7.8% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

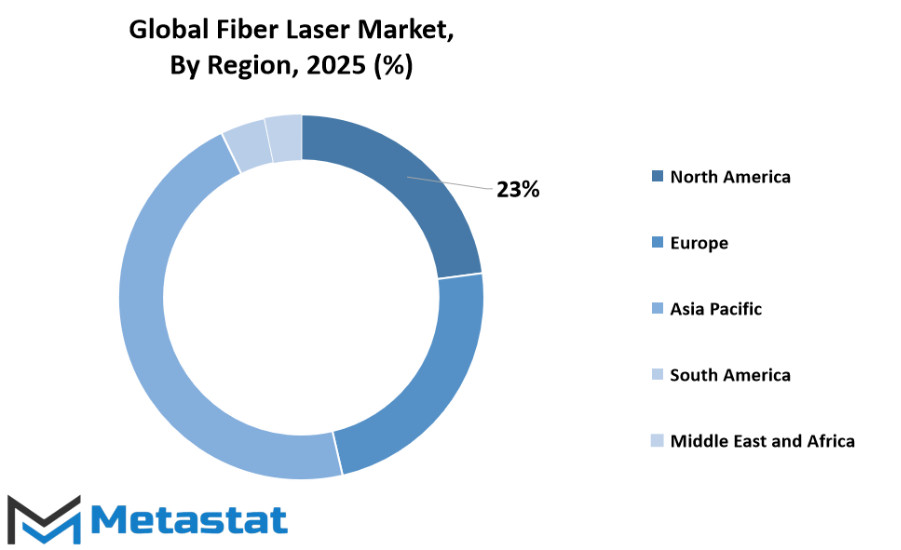

The global fiber laser market is experiencing strong uptake in various regions, facilitated by industrial usage and technological innovation. Geographically, the market is segmented into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Each of the regions is an important contributor to the demand for fiber lasers, with manufacturing expansion, automotive production, and electronics advancements determining regional performance.

North America is a dominant player in this market, with the U.S. being at the forefront, followed by steady growth from Canada and Mexico. The region has a mature industrial base and high investments in automation and laser-based technologies. All these will drive the demand for fiber lasers in cutting, welding, and marking applications for manufacturing industries. Europe is close behind, with nations such as Germany, the UK, France, and Italy being core centers of automotive and engineering industries. The high focus on precision manufacturing and environmental-friendly production processes in Europe will continue to drive the adoption of fiber lasers in multiple industrial processes.

Asia-Pacific is the largest player in the fiber laser market and will keep on growing at a higher rate on account of huge industrialization in nations such as China and India. Japan and South Korea are also dominant players, considering their technological expertise and strong electronics manufacturing industries. The growing emphasis on automation, combined with government incentives for industrial growth in these countries, will further boost the demand for fiber lasers in this market. The Rest of Asia-Pacific, encompassing developing economies, is also likely to witness increasing adoption as industries upgrade their processes.

South America and the Middle East & Africa are fast-growing markets for fiber lasers with considerable growth prospects. South America, with Brazil and Argentina being at the forefront of manufacturing growth, will lead the demand for state-of-the-art laser solutions in cutting and fabrication operations. The Middle East & Africa, comprising countries like GCC nations, Egypt, and South Africa, are, in turn, slowly embracing fiber lasers for construction, infrastructure development, and industry. These regions might not be up to the scale of North America or Asia-Pacific, but the continuous industrial investments reflect constant future expansion for the market worldwide.

COMPETITIVE PLAYERS

The global fiber laser market is experiencing stable growth as industries become increasingly dependent on sophisticated laser technologies for precision and efficiency. Fiber lasers are greatly appreciated for the capability to produce high-quality output with little maintenance and reduced operating costs compared to conventional laser systems. Their use spreads across industries like automotive, electronics, aerospace, and manufacturing, where precision cutting, welding, and marking are of paramount importance. As businesses keep emphasizing automation and energy conservation, the need for fiber lasers will continue to grow, making them a fundamental aspect of contemporary manufacturing processes.

One of the main drivers of this market is the added performance provided by fiber lasers. They offer superior beam quality, greater electrical efficiency, and longer lifespan. Unlike other laser technologies, fiber lasers are highly compact and consume less energy as they need minimal cooling. These characteristics make them best suited for applications where industries aim to maximize production while maintaining quality. Their application in medical devices, micro-machining, and metal processing demonstrates their adaptability. As demand for precise and environmentally friendly solutions increases, the demand for fiber lasers will find new markets in evolving industries.

A few of the leading firms are driving the path of this industry with innovation and cutting-edge product lines. Major players in the market include Coherent Corp., Fujikura Ltd., Han's Laser Technology Industry Group Co., Ltd., IPG Photonics Corporation, Jenoptik AG, and Lumentum Operations LLC. Other major contributors like Maxphotonics Co., Ltd., nLIGHT, Inc., Trumpf GmbH Co. KG., and Wuhan Raycus Fiber Laser Technologies Co., Ltd. are also enhancing their position through technological innovations and strategic alliances. Firms such as MKS Instruments Inc., Omron Corporation, NKT Photonics A/S, Toptica Photonics, Cy-laser S.r.l, Eagle Group, and Amonics Limited remain central to fulfilling the increasing demand around the world.

The rivalry is characterized by sustained investment in R&D. Firms are working towards producing more intense and energy-efficient fiber lasers in order to meet the needs of industries whose production requirements change over time. Advancements in technology are facilitating the creation of systems that provide greater accuracy for cutting intricate designs and processing sophisticated materials. This drive for innovation, as well as growing automation in manufacturing industries, will propel the fiber laser market to continue growing in the next few years.

In the future, the global fiber laser market will keep growing as companies look for ways to improve productivity at lower operational expenses. As there is a strong rivalry between incumbent players and new entrants, clients can anticipate continued performance, efficiency, and application flexibility improvements. With global manufacturing evolving towards increased precision and reduced environmental impact, fiber lasers will stay at the center of technological advancement, solidifying their role as a key tool in industrial processes.

Fiber Laser Market Key Segments:

By Type

- Infrared Fiber Lasers

- Ultrafast Fiber Lasers

- UV Fiber Lasers

- Visible Fiber Lasers

By Power

- Low Power

- Medium Power

- High Power

By Operation Mode

- Continuous Wave (CW)

- Pulsed

- Quasi-CW

By End Use

- Industrial

- Medical & Aesthetics

- Telecommunications

- Aerospace & Defense

- Semiconductor & Electronics

- Research & Development / Scientific

- Others

Key Global Fiber Laser Industry Players

- Coherent Corp.

- Fujikura Ltd.

- Han’s Laser Technology Industry Group Co., Ltd.

- IPG Photonics Corporation

- Jenoptik AG

- Lumentum Operations LLC

- Maxphotonics Co., Ltd.

- nLIGHT, Inc.

- Trumpf GmbH Co. KG.

- Wuhan Raycus Fiber Laser Technologies Co., Ltd.

- MKS Instruments Inc.

- Omron Corporation

- NKT Photonics A/S

- Toptica Photonics

- Cy-laser S.r.l

- Eagle Group

- Amonics Limited

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252