Aug 19, 2025

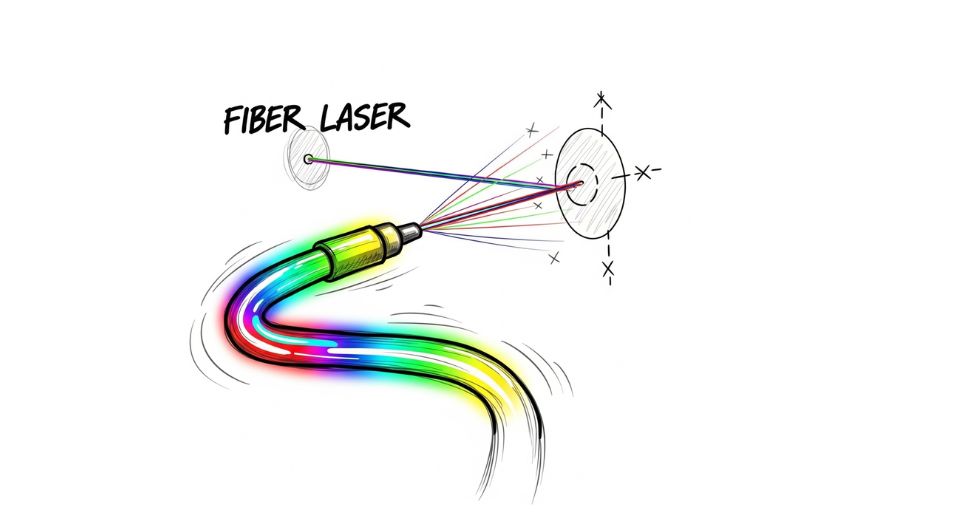

The Global Fiber Laser Market report by Metastat Insight provides a visionary overview of how the segment has acquired importance in various industrial scenarios. Fiber lasers have emerge as fantastically reliable and efficient fabric processing answers that find application in industries where precision and uniformity are critical. These lasers utilize optical fibers as the benefit medium, imparting blessings in phrases of energy performance, beam excellent, and flexibility, making them a favorite preference for slicing, welding, and marking programs.

One of the maximum outstanding features of fiber laser technology is how nicely it supports varying industrial wishes with out sacrificing overall performance tiers. In comparison to conventional systems, fiber lasers have higher electricity density and help non-stop operation with little downtime, raising their interest to manufacturers who are trying to find precision and reliability. This has resulted in extensive use in industries dealing with complex processing operations, where the end product quality directly affects overall production results.

The improvements in the design of fiber laser systems have also been a factor in their popularity. Contemporary designs provide a compact design, longer lifespan, and higher stability against harsh conditions. This makes them viable for applications that need a constant output with less frequent interruptions from maintenance. Furthermore, improvements in cooling systems and embedded automated controls have also been a prime factor in their application within industrial automation systems, where efficiency and accuracy must be balanced.

World industrial growth continues to provide opportunities for technologies providing greater productivity with fewer costs of operation, and fiber lasers are well within this discussion. They have proven very important for enabling precision production in electronics, automotive, and aerospace industries. Precision, repeatability, and speed are important for these industries, and they are all capabilities provided by fiber lasers. Beyond cutting and welding, fiber lasers are increasingly used for engraving and micro-machining, which expands their reach into specialized domains.

Environmental factors are also influencing the application of fiber lasers. Their energy-efficient design minimizes power requirements relative to much other technology, which is in line with environmentally friendly manufacturing processes to which industries are increasingly committing. Their efficiency comes without any compromise to output quality, making them an appealing option for organizations requiring a balance of performance and ethical energy use.

The competitive environment of fiber lasers is characterized with the aid of ongoing technology and production approach development. In this context, producers are specializing in innovation not just in laser overall performance but additionally on top of things systems and software program integration. The combo permits easy integration into modern manufacturing strains where virtual solutions and actual-time tracking are the norm. With automation turning into a crucial function of business boom, fiber lasers are being designed to complement clever production structures, ensuring compatibility with superior robotics and intelligent method manage.

Geographical trends also point to significant changes in the use of fiber lasers. While developed industrial centers maintain their dependence on these systems as a source for high-end production, new regions are increasingly making investments in new technologies in an effort to build stronger production bases. This builds up a world network of users appreciating the merits brought by fiber laser technology and further underpinning its position as a determinant of future manufacturing paradigms.

With continued technological advancements, the number of potential uses for fiber lasers is likely to expand even wider. Production sectors that need detailed cutting or exact welding will be integrating these systems as a normal offering, underpinned by a stable demand curve. Furthermore, their interfacial compatibility with automation and Industry 4.0 approaches makes them a key component in the industrial processing of the future.

Overall, the Global Fiber Laser Market as mapped by means of Metastat Insight shows the growing significance of this generation in cutting-edge production. With its capacity to provide efficiency, flexibility, and first-rate outputs, fiber laser technology has the capability to be a key issue of commercial advancement around the globe. Its ongoing innovation holds the prospect not just of extra productiveness but of innovative makes use of with a view to remodel how industries do material processing inside the close to future.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479