MARKET OVERVIEW

A crucial segment of the metallurgical industry, the Global Ferroalloys market deals with the manufacture and distribution of alloys whereby iron is accompanied by one or more other elements such as silicon, manganese, or chromium. Such materials are of prime importance in enhancing many properties of steel and, indeed, other metals through increased durability and corrosion resistance, tensile strength, etc. All industries will experience a strong demand for high-strength steel and specialized alloys. This will greatly increase the room for growth in the ferroalloys market. The main category of ferroalloys includes products, like ferromanganese, ferrosilicon, and ferrochrome, that have particular applications when producing steel, automotive parts, construction materials, and other extremely strong metal products.

The Global Ferroalloys market has a broad scope, cutting across the fields of construction, automotive, aerospace, energy, and electronics among others. It is with the production of specialty steels that are required to be used in these sectors that will account for the great demand of ferroalloys especially in relation to new technologies and regulatory requirements that insist on having the best physical properties of materials. One important characteristic of the ferroalloys market is the intricate supply chain needed for primary raw materials and raw material processing into quality alloys, followed by distribution globally.

Manganese, among other minerals used for manufacturing ferroalloys, is an industry relying on mines that are geographically concentrated in mineral resource-rich countries. As a result, the market will still be dependent on shifting production volumes by mines, changes in governmental policies, and changing overall trade flows in these geographies. This geographical dependency also leads to variation in the cost structure wherein some of the countries can attain lower labor costs or otherwise favourable trade treaties with others, which would make them get priced more cheaply. The shift of the technology landscape itself in the ferroalloys sector will further decide the Global Ferroalloys market.

Changes in production processes, such as energy-efficient furnaces and advanced smelting technologies, will spur advances in the alloy production process. As manufacturing companies invest in these new technologies, they are looking to minimize costs as well as environmental impacts associated with the production of ferroalloys-a consideration gaining significance as environmental regulations are initiated and enacted. This emphasis on sustainability and efficiency will be crucial in the future market dynamics as it will look to create a win-win balance between industrial demand and regulatory compliance. Also, the ferroalloys market is very competitive with many large and medium-sized players fighting for the market share.

Major producers come from Asia-Pacific, Europe, and North America. Market competition will evoke non-stop innovation, forcing manufacturers to find product differentiation strategies as well as ways to partner-based in a better position to drive the game. Thus, companies in the Global Ferroalloys market will look at optimizing their production processes and raising quality in their final products by zeroing in on targeted expansions or acquisitions. Over time, distribution in the ferroalloys market will more than likely embrace digitalization of its platforms to make sales smoother and supply chains more transparent while making it possible to track inventory in real time. Digitalization in the ferroalloy industry will thus play a pivotal role in the fight against inefficiency and optimizing the use of resources for industrialization with the world’s distribution networks.

In short, the Global Ferroalloys market will define itself through its inevitable position as a supporting market to several industries that find broad avenues of utilization in scenarios that can be executed when high-quality metal products are required. As technological progress, alterations in the supply chain dynamics, and increased competition are in the backdrop, the ferroalloys market will witness emerging opportunities and challenges, depicting this critical position within world industrial and economic set-ups.

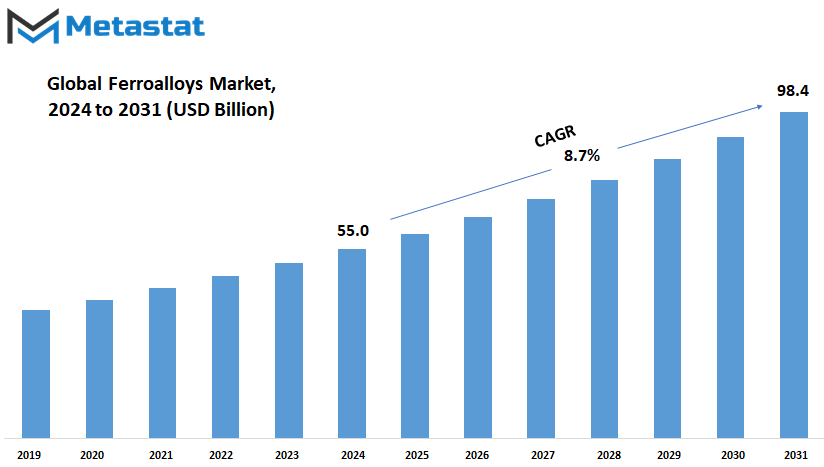

Global Ferroalloys market is estimated to reach $98.4 Billion by 2031; growing at a CAGR of 8.7% from 2024 to 2031.

GROWTH FACTORS

The Global Ferroalloys market is expected to record significant growth in the coming years by virtue of a host of economic and industrial factors that will boost demand in the future. Increasing demand for Ferroalloys, which constitute improvements of the qualities of steel and other metals, are finally getting the help from expanding global industries. This demand is majorly driven by the growth in the construction, automotive, and manufacturing industries, which use high strength, durability, and flexibility provided by ferroalloys. Rising global urbanization leaves deep marks on infrastructure growth that will increase the use of ferroalloys in steel production, hence supplementing market growth.

A major growth driver comes in the form of a requirement for the automotive industry to have their vehicle designs combine light and stronger materials. Ferroalloys, primarily manganese, silicon, and chromium-based ones, improve the properties of steel, which, in turn, could be used to make not only safer but also fuel-saving vehicles. As car manufacturers are increasingly interested in the sustainable production and energy efficiency of their cars, it is likely that they will increasingly embrace higher-value materials based on ferroalloys for steady demand in the sector. The growth of the renewable energy industry, incorporating demand for strong, high-quality materials for wind turbines, solar infrastructure, and hydro facilities, will be favorable to the ferroalloys market. This has set new positions where these metallurgical products are considered critical products in modern applications, hence their relevance in the more sustainable and high-tech future.

Despite such positive factors for growth, a number of challenges would limit further expansion. Raw material price volatility and the ecological problems associated with the production of ferroalloys may also be a hindrance. The mining and smelting stages of manufacturing ferroalloys have negative environmental impacts, which can mean regulations becoming more stringent and the rates at which it can be produced and even the cost of production. Supply chain disruptions here have the recent global events unveiled vulnerabilities impacting market stability. These factors can restrict growth if not properly dealt with.

Advancements in production technology are likely to open new scope for the Global Ferroalloys market in the future. Innovations that improve environmental friendliness in production or effectively recycle scrap metal into usable components support sustainability goals but also satisfy the needs of the industry. The interest in electric vehicles and, consequently, in smart infrastructure is still one of the challenges that require materials to balance strength with flexibility. Here, ferroalloys play a critical role. As industries increase their demand for high-performance materials, the potential for growth in the ferroalloys market appears good, with adjustments made to the industry depending on how it assimilates environmental concerns and supply chain challenges.

In a nutshell, the Global Ferroalloys market should sustain growth through fundamental changes across key industries as well as through technological improvements that would respond to emerging requirements. The drawbacks notwithstanding, this market has prospects for further growth, dependent on the level of investment by companies and industries in new and sustainable production techniques.

MARKET SEGMENTATION

By Product

The global ferroalloys market would still increase because the industries of the world would continue to rely on ferroalloys in manufacturing numerous products, and especially steel, where the incorporation of these alloys would strengthen it, improve its resistance to harsh external conditions, and enhance its longevity. These are alloys combining iron with various other elements, such as chromium, manganese, and silicon, whose properties improve strength, enhance resistance, and increase durability. With demand for steel products on the rise across the construction, automotive, and manufacturing sectors, the need for ferroalloys will automatically rise and place the market in position for steady growth in coming years.

Ferchrome is one of the most significant product segments found in the global ferroalloys market. One of the most widely utilized alloys that result from iron being combined with chromium is stainless steel-an alloy valued for the absence of corrosion and tolerance to very high temperature levels. As industries seek more efficient and sustainable infrastructure and products, the use of stainless steel, and by extension, the demand for ferrochrome, is expected to continue to go up. Regions that are developing cities and wind and solar frameworks have led to the growing demand for high-quality stainless steel in producing high-quality ferrochrome.

Another highly demanding ferroalloy in the market is ferromanganese. This alloy is used to provide the toughest steel qualities by increasing hardness and resistance to wear. It has been most crucial in sectors where long-lasting materials are needed. With populations growing and more cities becoming a reality, these sectors shall consistently demand the usage of ferromanganese. Emphasis globally on infrastructure that lasts keeps ferromanganese an absolutely quintessential component in the market.

This industry also primarily depends on ferro silico manganese and ferro silicon. Ferro silico manganese is an alloy made of iron, silicon, and manganese combining all the properties of these elements. The result is steel that is strong yet flexible. This alloy is quite crucial for manufacturing steel to be used in complex structures and heavy machinery. The more technologically advanced projects undertaken in economies – not only high-speed rails but also bridges – will be so will such alloys required. In addition, ferro silicon will be important for imparting specified properties to steel, such as magnetic strength and heat resistance, in large sectors like electrical manufacturing and transportation.

With the growth of these product segments, the ferroalloys market in the world shall ensure a response to changing demand. It would utilize modern and newer production technologies and sustainable practices in manufacturing. Innovation is being met by using cleaner, greener production technologies that contribute to the reduction of emissions and energy consumption in manufacturing processes. Overall, the future expansion will mirror this demand for more productive and environment-friendly materials by the industries worldwide, and therefore, the global ferroalloys market will have its share of the industrial map for ages.

By Application

Markets for ferroalloys continue to grow rapidly, mainly because of the expansion in consumption from the industrial sectors of steel and iron, which have always found their ultimate end product. Ferroalloys are additives to steel, and they make the latter stronger and more corrosion-resistant and generally adaptable to various applications. These are very important for upgrading the quality of steel and durability, particularly in construction, automotive, and heavy machinery industries. These additives are made of manganese, silicon, and chromium alloys.

Primary divisions of the ferroalloys market are differentiated into: Application types, which, in turn is subdivided into carbon and low alloy steel; stainless steel, alloy steel, cast iron, and other specialized uses. Carbon and low-alloy steels are used in large quantities by infrastructure and construction industries that will continue growing dramatically - especially among emerging economies. Cities, for example will continue expanding and changing, with heightened demand for construction materials that provide durability under increasingly stringent environmental conditions, hence boosting demand for ferroalloys applied in this type of steel.

Stainless steel will have a broad outlook towards sustained demand because this metal finds wide use in household appliances, the medical field and food industry because it is resistant to corrosion. Ferroalloys used in producing stainless steel stimulated primarily by chromium-based alloys are thus expected to remain significant in this sector. Its growth is expected to be in line with the developments of stainless steel, particularly of stainless steel, where more robust and stronger variants that will also cover a wider segment of domestic and commercial applications are under development.

The ferroalloys help impart special properties to the alloy steel, most notably high tensile strength as well as resistance to wear, which is beneficial for high industries such as automotive and heavy machinery. As the world continues to shift towards renewable energy sources and electrification of transportation, the demand for high-quality alloy steels will probably grow highly, especially those reinforced by ferroalloys. That is why many cast iron applications, such as pipes, machines, and cookware, are conditioned to add additional strength and resistance through the use of ferroalloys so that the material can endure severe stress and last for a longer period.

From here, expansion of the global ferroalloys market tends to be directed towards future sustainable developments. As companies have to look for more environmentally friendly alternatives, more relevant research into creating lower-emission ferroalloys will appear. Second, recycling ferroalloys may increase, especially at times when companies focus on minimal waste generation and decreased consumption of raw materials. This vision of sustainability and innovation will probably define the shape of the market, making ferroalloys an indispensable constituent in the production of modern materials.

By End-Users

Global demand for ferroalloys will definitely see phenomenal growth in the short term, especially with the rampant demands of various industries and sectors of the economy. In light of its needs to increase material strength and resilience, it draws much on alloys. The metals whose production involves the processing of ferroalloys would therefore be used in these modern applications, considering that they have maximized endurance requirements. As the industries grow in developing matters and developments coupled with improving the materials used, the requirement of the ferroalloys is likely to be on a par, contributing valuable improvement to the metals used in construction, automotive, and technology, to name a few.

The steel Industry has always been a significant demand driver for ferroalloys market as steel products are extensively used to enhance the strength and resistance of the alloys. Ferroalloys include ferrochromium and ferromanganese, which play a crucial role in fighting corrosion and wear of steel, making them fundamental in constructing buildings, bridges, and infrastructure that can stand harsh conditions. With infrastructure projects on the growth ladder globally, especially emerging economies, prospects of using ferroalloys in the steel industry will continue going up gradually. In addition to steel, the ferroalloys market is expanding in niche areas, especially in superalloys for applications that face extreme stress such as aerospace and energy.

Superalloys provide superior heat resistance due to certain requirements of parts exposed to high temperature levels. With rising global energy demands, especially renewable and clean energy applications, there is a need for long-lasting superalloys.

This growth will resonate in the ferroalloys market as all industries are going to look for long-lasting, effective materials. Ferroalloys have much promise in welding electrodes. Welding is critical in many industries that demand precision, strength, and strong final products. Ferroalloys refine the welding process and quality of the final product. With growing automobile manufacturing and construction industries, there will be a demand for high-quality welding material, thus indirectly increasing ferroalloy market.

The casting industry will also fuel demand for ferroalloys. Ferroalloys contribute to adding fluidity and toughness to the metals in casting, thereby allowing complex shapes and structures to be produced with more ease. With the increased deployment of custom parts in machinery, electronics, and manufacturing equipment, demand for advanced casting materials is sure to increase and benefit the market of ferroalloys directly.

New uses for ferroalloys will also continue to be developed based on the shifting global industries moving forward. As materials science matures with ever-evolving innovations, ferroalloys will continue to be discovered adding durability, efficiency, and sustainability to the several sectors of industries. Therefore, the market for ferroalloys will be promising and bright, based on the market requirement For flexible and robust material applications in a given industry.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$55.0 Billion |

|

Market Size by 2031 |

$98.4 Billion |

|

Growth Rate from 2024 to 2031 |

8.7% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

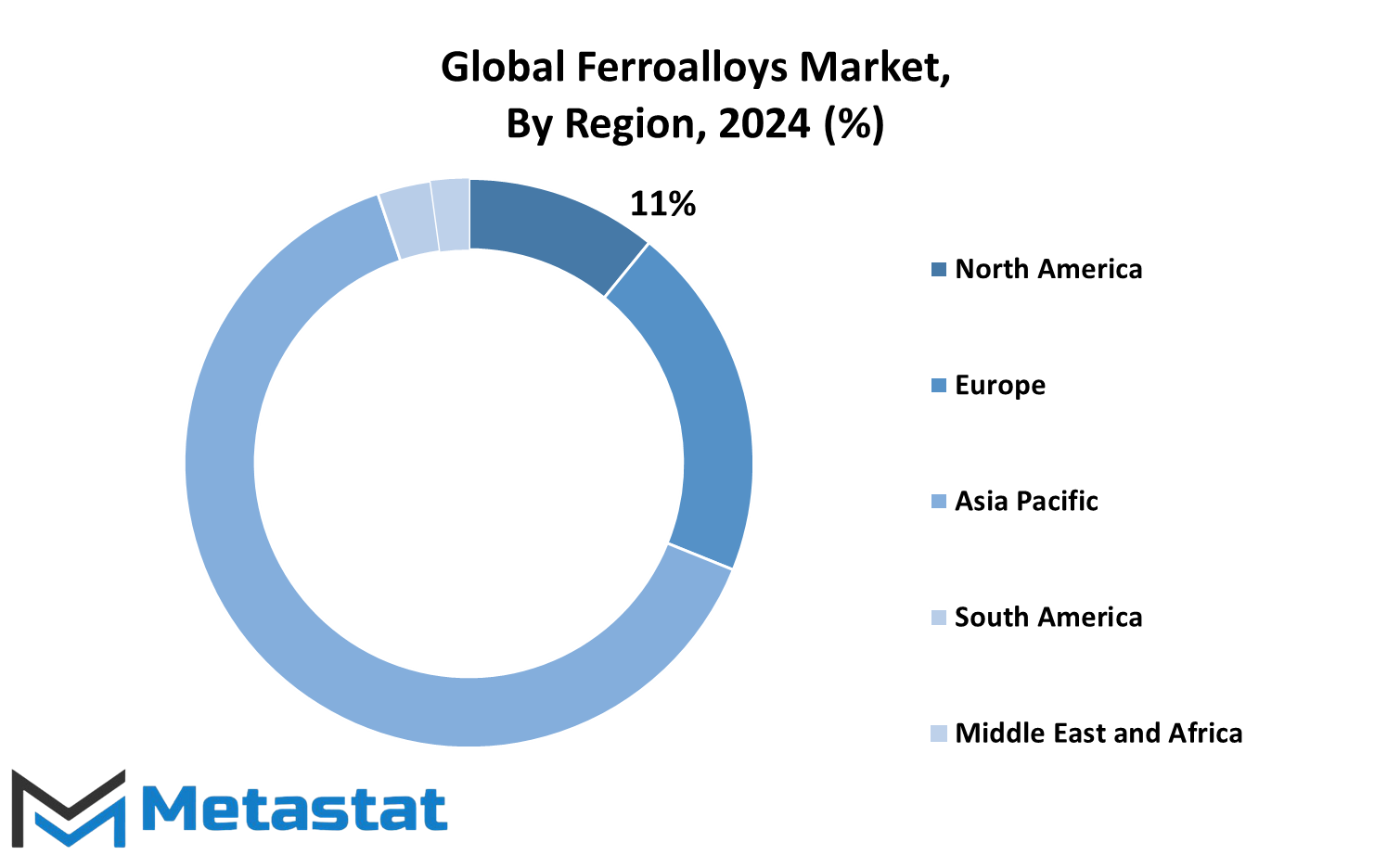

REGIONAL ANALYSIS

The global market for ferroalloys is segmented in regions such as North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. This segmentation provides an impression of different trends followed in these regions and the demand created for ferroalloys. The consumption of and the production of ferroalloys are separately carried out as well as prospects of growth in the future in each region.

North America, effectively the U.S., Canada, and Mexico, has stable demand for ferroalloys based on ongoing construction and automotive sectors. Their country, the U.S., is one of the major players in this region with a strong share, provided by infrastructural growth and expansion of domestic production of steel. Canada and Mexico may also be able to add to the growth of the region. Mexico's automotive manufacturing and Canada's resource-based strong economy are some of the ferroalloy requirements. In the future, the technological advancement in sustainable production of steel may enhance the consumption of high-quality ferroalloys in North America.

In Europe, the market includes the UK, Germany, France, Italy, and the rest of Europe. This region has solidly manufactured sectors especially in Germany and Italy which have long histories of the steel and automobile industries. In this region, with tightening environmental regulations across the European Union, environmentally friendly ferroalloy products and processes are going to gain more traction. Recyclable as well as energy-efficient technologies-driven companies within the European continent are going to focus on sustainability goals, which may change the demand for various ferroalloys in the region.

Asia-Pacific is the biggest market for ferroalloys and harbors countries like China, India, Japan, and South Korea, where there have been strong industrialization and urbanization trends over the past century. Demand for ferroalloys in these two countries, namely com China and India, is expected to rise on account of infrastructure projects and rapidly growing populations. Ferroalloy is in high demand from both of these countries, Japan and South Korea, primarily in electronics as well as automobile manufacturing. A strong sentiment for economic growth and modernization adds positive undertones to the outlook of ferroalloy demand as these countries enhance the quality and production capabilities of their steel. This market is also likely to remain at the number one position globally as Asia-Pacific countries are investing in their industries.

The South American region, including Brazil, Argentina, and other nations, is promising due to increased mining and construction activities. Brazil holds an important status because the country has ample raw materials available for domestic ferroalloys production. The economic growth of the region may lead to improvement in its manufacturing capacities, which, in turn will attract better ferroalloys demand.

The Middle East & Africa is another high growth market primarily through the construction and the energy sector, which mainly includes the GCC Countries, Egypt, and South Africa. With massive investment by the countries in this region on infrastructure projects, demand for ferroalloys will gradually increase. The regional market will grow through partnerships and imports of sophisticated ferroalloy products to realize the ambition of the projects undertaken.

COMPETITIVE PLAYERS

The ferroalloys market globally is defined and influenced by highly divergent competitive players in terms of growth, technological advancement, and the respective market strategies pursued. Steel and other alloy-based products continue to be in increasing demand, and it is also essential to use ferroalloys to enhance the property of materials in construction, automotive, aerospace, and infrastructure. There are several leading companies in this regard that drive the market through innovative production techniques, optimization of supply chains, and the development of strong global networks. Major Players: Brahm Group, Vedanta (Ferroalloy Corporation Limited), Glencore plc, Gulf Ferro Alloys Company (Sabayek), Jindal Group, Pertama Ferroalloys Sdn. Bhd., S.C. Feral S.R.L, Steel Authority of India Limited (SAIL), Samancor Chrome, Shanghai Shenyun Ferroalloy Co., Ltd., OM Holdings Ltd., Tata Steel Limited.

Generally, these companies seem to be interested in the incorporation of advanced technology that can make processes more efficient in production with quality control and a reduction of impacts on the environment. For example, energy-efficient smelting technologies and low emissions are now something that a company would like to have, especially as environmental laws tighten across the world. Companies are also finding the use of renewable energy sources in their production, which is not only on the regulatory lines but also lying on the increasing lines of greater sustainable practices within the industrial lines. This advancement in green production methods may alter the competitive map in favor of those companies that embrace the green culture.

With increasing urbanization and the establishment of manufacturing capacity globally, especially in new industrialized economies across Asia and Africa, the international ferroalloys market is destined to expand even more. Even as these markets expand internationally, larger players will capitalize on these opportunities by opening new facilities or forging alliances within the demand driving regions. Producers like Tata Steel and Glencore already dominate the Asian market, and others hope to tap vast available resources in the African continent.

Advances in technology, especially automation and AI, are now showing their impact more and more in the ferroalloy market, allowing even further efficiency and tighter control over production processes. With these technologies together, companies can make better use of schedules in production, monitor supply chain risks better, and keep flexible enough to respond to immediate market need. These kinds of developments may be very important for differentiation in business strategies with shifting patterns of demand and consumer expectations.

With the constantly evolving strategy and advancement in technology, major players in the global ferroalloys market are likely to continue their growth journey. Companies aligned to sustainable production, expansion in the market, and advancement in technology will be able to set up a stronghold in the market. As the industry grows, competitive players will play an important role in the future production and distribution of ferroalloys.

Ferroalloys Market Key Segments:

By Product

- Ferrochrome

- Ferromanganese

- Ferro Silico Manganese

- Ferro Silicon

- Others

By Application

- Carbon & Low Alloy Steel

- Stainless Steel

- Alloy Steel

- Cast Iron

- Others

By End-Users

- Steel Industry

- Superalloys Industry

- Welding Electrodes

- Casting Industry

- Others

Key Global Ferroalloys Industry Players

- Brahm Group

- Vedanta (Ferroalloy Corporation Limited)

- Glencore plc

- Gulf Ferro Alloys Company (Sabayek)

- Jindal Group

- Pertama Ferroalloys Sdn. Bhd.

- S.C. Feral S.R.L

- Steel Authority of India Limited (SAIL)

- Samancor Chrome

- Shanghai Shenyun Ferroalloy Co., Ltd.

- OM Holdings Ltd.

- Tata Steel Limited

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383