MARKET OVERVIEW

The Global Corrosion-Resistant Pumps market is a niche segment of the industrial equipment industry, particularly considering it is a specialized domain that deals with pumps that can handle hostile ambient corrosion. The pumps are extremely important in industries such as chemical processing, water treatment, oil and gas, pharmaceuticals, and food and beverage, due to the common requirement of process handling for aggressive fluids in such industries. With increasing industrialization, the requirement for long-lasting and effective pumping solutions will surge; therefore, the Global Corrosion-Resistant Pumps market will be at the very front in technology innovation as well as industrial growth.

Corrosion-resistant pumps deal with the devastating action of corrosion that, if left untreated, may drastically reduce the performance and lifespan of regular pumps. Pumps of high quality are fabricated with stainless steel or titanium, come with high-performance alloys of lining materials, or use coatings that inhibit chemical contact between the fluid being transferred and the metals. The selection of material and coating is therefore very critical, as it influences the performance, maintenance requirements, and life expectancy of a pump.

Resistance to corrosion in pumps is very vital in the chemical processing industry, since one has to deal with acidic and alkaline materials, among other reactive substances. The precision and reliability of these pumps guarantee safe, leakage-free, and contaminant-free circulation of chemicals. Such pumps are, therefore, extensively used in the water treatment sector in wastewater management and drinking water treatment, where such contact is recurrently exposed to strong chemicals or fluctuating pH levels.

The oil and gas industry also relies on corrosion-resistant pumps in areas associated with the extraction, refining, and transportation of petroleum products. The rigors of the offshore and onshore sites, besides the chemical makeup of crude oil, call for pumps that can take up very severe conditions and, at the same time, maintain operational integrity over long periods. This reliability is very important to minimize downtime and ensure continuous production.

In this very strict hygiene and safety condition, corrosion-resistant pumps are a must in pharmaceutical manufacturing. Such pumps allow for the transfer of sensitive, sometimes corrosive substances used in drug formulation without any contamination or alteration of their pure form and effectiveness. Moreover, in food and beverage processing and transportation of ingredients and finished products, corrosion-resistant pumps are involved in very huge proportions where hygiene and resistance either to acidic or basic foodstuffs are necessary.

Advancements in technologies will further shape the Global Corrosion-Resistant Pumps market through innovations in materials science and better design for more efficient and long-life solutions. Smartening of such pumps by IoT and AI will also enhance their continuous monitoring and maintenance to schedule predictive maintenance, thereby reducing the chances of sudden failures. This proactive approach toward pump management will foster operational efficiency and cost savings across industries.

The relevance of the Global Corrosion-Resistant Pumps market is going to be more and more noteworthy due to the sustained industrialization across the globe. Reliable and long-lasting pumping solutions which can cope with challenging applications will drive this market. Bringing about continuous ongoing research and development will continue propelling manufacturers to strive for additional achievements in what these pumps can do, ensuring that their offerings remain updated and relevant to industries worldwide.

The Global Corrosion-Resistant Pumps market has an intrinsic role in the industrial scenario by dispensing key solutions to handle corrosive substances for a number of applications. Perpetual innovation in pump technology and materials will keep the growth going, wherein corrosion-resistant pumps will turn increasingly imperative to maintain efficiency and safety in vital industrial processes.

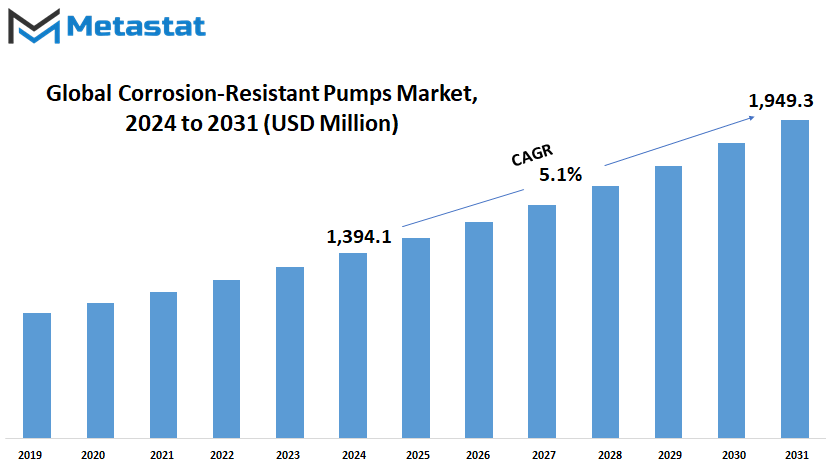

Global Corrosion-Resistant Pumps market is estimated to reach $1,949.3 Million by 2031; growing at a CAGR of 5.1% from 2024 to 2031.

GROWTH FACTORS

A number of factors influence the growth of the Global Corrosion-Resistant Pumps market. Basically, industries such as chemical processing and wastewater treatment, among others, all depend on corrosion-resistant pumps to transfer corrosive fluids efficiently. Rising demand from these sectors acts as the main driving force behind the market.

Other factors include the observable drive in environmental protection and safety at work, resulting in more rigid rules and standards put into place. There is, therefore, a surging demand for pumping solutions that not only come reliable but are corrosion-resistant as well. As such, the demand for corrosion-resistant pumps will only continue to rise.

It is worth noting, however, that such pumps do have larger upfront costs compared to their conventional brethren. This is mainly due to the fact that special materials and construction are needed in order to make them resistant to corrosion. Thus, the higher initial investment may scare away some potential users.

Moreover, the availability of materials and components used in corrosion-resistant pumps can be another issue. This limited availability may prolong the lead times and raise costs related to procurement. These factors can be some of the major ones that hamper the growth trajectory of the market.

Though all this opens up a promise of opportunities next in line. There is a growth of interest in sustainable and eco-friendly production methods cutting across industries. This shift towards sustainability creates ways through which corrosion-resistant pump manufacturers can innovate. They are better positioned to come up with more efficient and eco-friendly pumping solutions to the emerging demands in the market.

Subsequently, prospects for the growth of the Global Corrosion-resistant Pumps market in the ensuing years look bright, as industries embrace safety, reliability, and environmental sustainability. Though higher costs and material availability pose a challenge, the potential for growth remains immense. Finding solutions to these challenges and capitalizing on new opportunities will make the market a sure success going into the future.

MARKET SEGMENTATION

By Type

A corrosion-resistant pump forms a part of the dynamically changing scenery for industrial equipment. They form a very important part of any industry because they have to bear liquids with corrosive properties and facilitate smooth liquid flow. The market segmentation of Global Corrosion-Resistant Pumps by type gives a look into the wide variety of pumps available for different industrial applications.

Among some of the basic types of corrosion-resistant pumps lies the centrifugal pump. These make use of centrifugal force to cause flow of fluid through the system, hence highly efficient and reliable in use for a large number of applications. It is hard to imagine a process from chemical processing plants to wastewater treatment facilities that does not use great volumes of centrifugal pumps to ensure the efficient transfer of those corrosive liquids.

One other critical type is the diaphragm pump, a pump designed to handle abrasive and viscous fluids with ease. The diaphragm pumps work by flexing a diaphragm in and out to create suction and discharge, hence can be used in those applications which have a gentle handling of the liquid at a precise control.

Gear pumps are also key contributors to the corrosion-resisting pumps market. Owing to their rugged design and capability to handle high-pressure liquids, gear pumps find applications across industries such as oil and gas, where transfer of corrosive fluids is quite common.

The extremely unbeatable feature of peristaltic pumps is resistance to corrosion too, designed employing a unique pumping mechanism—compressing a flexible tube. These are particularly used in those applications in which the contamination of the fluid has to be at a bare minimum, like in the pharmaceutical and food industries.

Other classifications of the pump market separate out various others that serve special needs. These might include magnetic drive pumps, sealless pumps, or specialty pumps for niche applications. Each type carries the advantages from increased safety, reliability, and greater efficiency straight through to improving performance.

By Material Type

Of the entire spectrum of industrial equipment, pumps are used for many applications—from water management to processing chemicals. The hike in demand for corrosion-resistant pumps is more in the recent years. This reflects a wide trend across the Global Corrosion-Resistant Pumps market: Stainless Steel, Titanium, Nickel Alloys, Fiberglass Reinforced Plastic, and others.

With a view of its strength and resistance to corrosion, stainless steel will naturally remain a preferred material in the market. From water treatment and food processing to chemical industries, the uses it is adaptable to include practically all. Further developments in metallurgy and manufacturing techniques could provide additional impetus to stainless steel pumps to achieve better performance and cost-effectiveness.

Titanium is highly valued for its extraordinary corrosion resistance and lightness and, therefore, will find growing applications in highly aggressive environments. It is in industries such as petrochemicals, marine, and offshore drilling that the durability and reliability of titanium pumps offer great service. Once technology improves, the cost of producing titanium will drop, making it viable for many more applications.

Nickel alloys, due to their highly resistant nature to corrosion and high temperatures, will remain crucial in the most demanding industrial environments. These pumps can easily process aggressive chemicals and acids, thus remaining irreplaceable in industries such as mining, oil & gas, and pharmaceuticals. Further research into alloy composition and manufacturing processes is likely to continue enhancing performance and life.

Lightweight and resistant to corrosion, fiberglass-reinforced plastic pumps will continue to build strong niche applications. Rather, FRP pumps will be applied in industries such as wastewater treatment, aquaculture, and agriculture due to the features of affordability and durability they have. With the ever-stricter environmental protection laws and regulations, FRP and other green materials can only be applied on a larger scale.

Besides these, some innovative material solutions will enter the corrosion-resistant pumps market, like ceramic composites and carbon fiber-reinforced polymers. These materials bring differentiated values in chemical resistance, weight reduction, and lifespan to a large number of highly specialized industries and applications.

The Global Corrosion-Resistant Pumps market is nearing a complete paradigm shift in these factors towards better corrosion resistance materials, durability, and efficiency. Innovative breakthroughs in new material sciences and manufacturing technologies continue to give way to fresh promises of further innovation and growth.

By End-Use

Most of the industries, either indulged in production processes or otherwise, rely on dedicated equipment to support their core processes in the rapidly changing global economy. Among these, pumps assume a significant place in transferring fluids across a myriad of industries. The Global Corrosion-Resistant Pumps market caters to this demand for pumps constructed to endure such corrosive environments and ensure efficiency and long-term operation.

The market segmentation based on end-use brings out many distinct sectors with very wide application of corrosion-resistant pumps, including Chemical Processing, Oil and Gas, Water and Wastewater Treatment, Pharmaceutical, Mining, among Others. Every one of these segments is representative of a domain with specific needs for fluid handling equipment.

Chemical processing facilities use corrosion-resistant pumps for the safe handling of aggressive chemicals. The pumps counter the action of the differently aggressive chemicals to ensure reliable performance and life under severe conditions. In the Oil and Gas industry, these corrosion-resistant pumps maintain operational efficiency with reduced downtime since their operations involve contacting corrosive materials like crude oil and saltwater.

Water and wastewater treatment plants also utilize corrosion-resistant pumps to transfer corrosive liquids emanating from treatment processes. Pumps must, therefore, move fluids effectively in service while handling corroding effects of chemicals or any other contaminants in wastewater.

These corrosion-resistant pumps are used in the pharmaceutical industry due to the strict quality and safety standards. They could be used to handle sensitive, corrosive substances in the manufacture without any loss of the integrity of the pharmaceutical products while assuring conformity with regulatory requirements.

Mining processes typically include handling corrosive slurries and chemicals in most mineral extraction and processing operations. Corrosion-resistant pumps form a very important part of mining facilities, as they are required to work continuously with materials that are by their very nature abrasive and corrosive.

The Others category also has industries wherein corrosion-resistant pumps find special applications for purposes related to the food and beverages, pulp and paper, and power generation industries. These industries need special pumping equipment due to the presence of certain corrosive elements.

REGIONAL ANALYSIS

The global Corrosion-Resistant Pumps market is analyzed based on the different regions of the world. The regions are North America, Europe, Asia-Pacific, South America, and Middle East & Africa.

North America is analyzed as the United States, Canada, and Mexico. Europe is segmented as United Kingdom, Germany, France, Italy, and Rest of Europe. As far as the Asia-Pacific region is concerned, it's segmented into India, China, Japan, South Korea, and the Rest of Asia-Pacific. In South America, it's represented by Brazil, Argentina, and the Rest of South America. Lastly, in the Middle East & Africa region, there are GCC Countries, Egypt, South Africa, and the Rest of Middle East & Africa.

The regional bifurcation echoes the overall distribution and performance of the Corrosion-Resistant Pumps market across the world. Individual regions stage changes in market behavior and various other dynamics impacted by factors such as economic conditions, industrialization, policy changes, environmental changes, and others.

North America is presumably among the largest markets based on reasons such as strong industrial infrastructure, technological innovation, and stringent regulation for environmental protection. The United States is one of the largest markets in the region due to its large-scale industrial activities and investments in infrastructure development.

The European market for corrosion-resistant pumps is characterized by mature industries, high environmental norms, but a general tendency to place emphasis on sustainable growth. Advanced manufacturing facilities and an increasing emphasis on renewable sources of energy make countries such as Germany and the United Kingdom among the most prominent players.

The Asia-Pacific region provides lucrative opportunities for the market to grow, with rapidly emerging economies and expanding industrial sectors. Other than that, countries such as China and India continue to attract demand for corrosion-resistant pumps, driven by infrastructure investments, urbanization, and industrialization.

South America presents relatively low market size, although growing at a steady pace through increasing investments in sectors like mining, oil & gas, and water treatment. Brazil, in light of its immense natural resources and vast industrial base, presents a major market for the region.

With a number of oil-based national economies and increasing industrialization efforts, the Middle East & Africa is one promising area for Corrosion Resistant Pumps. Infrastructure and industrial investments in areas such as countries like Saudi and South Africa are driving the demand for corrosion-resistant pumps.

The regional analysis of the global Corrosion-Resistant Pumps market underscores variance in the market bearing, revealing diverse topographies as well as potential heading in specific regions. This perspective on regional dynamics is critical for businesses to have effective strategies and delve into upcoming responsive markets.

COMPETITIVE PLAYERS

It is an extremely broad and highly competitive market inhabited by different players who vie for gaining market share and dominance. Leading companies operating in the Corrosion-Resistant Pumps market are engaged in the supply of pumps used to withstand corrosive environments in industries like chemical processing, water treatment, and mining.

CECO Environmental, Magnatex Pumps, Sims Pump Valve Company, Affetti Pumps, VENTAIX GmbH, Flowserve, SOMEFLU, Lutz-Jesco, Tsurumi Pump, Crest Pumps, Richter, GEKO-Pumpen GmbH, Numatic Pumps, Grundfos, Xylem, Sulzer, Franklin Electric, DAB Pumps, HCP Pump, Kirloskar Brothers, Multiquip, Showfou Electric Machine, and Giant Industries are some of these one, two companies in this competitive landscape.

Each of these companies brings specific strengths and offerings to the table. For example, CECO Environmental offers a full range of solutions pertaining to air pollution control and fluid handling systems. Magnatex Pumps is best known for their expertise in manufacturing magnetic drive pumps, particularly for use with hazardous or corrosive fluids. Sims Pump Valve Company has an engineering heritage in the design and manufacture of high-performance pumps and valves.

With the growing demand for corrosion-resistant pumps across the world, it can be said that competitive players would definitely be those companies shaping the market landscape with the rising industrial expansion, infrastructure development, and strict environmental laws in place. In order to maintain their competitiveness, companies will have to continue innovating in the face of changing customer needs and emerging technologies.

In such a dynamic and competitive environment, companies will have to differentiate on the basis of the quality and performance of their products, with value-added services around technical support, maintenance, and aftermarket solutions. Building strong relations with customers and partnerships with key stakeholders will also become very crucial in the long run.

Corrosion-Resistant Pumps Market Key Segments:

By Type

- Centrifugal Pumps

- Diaphragm Pumps

- Gear Pumps

- Peristaltic Pumps

- Others

By Material Type

- Stainless Steel

- Titanium

- Nickel Alloys

- Fiberglass Reinforced Plastic (FRP)

- Others

By End-Use

- Chemical Processing

- Oil and Gas

- Water and Wastewater Treatment

- Pharmaceutical

- Mining

- Others

Key Global Corrosion-Resistant Pumps Industry Players

- CECO Environmental

- Magnatex Pumps

- Sims Pump Valve Company

- Affetti Pumps

- VENTAIX GmbH

- Flowserve

- SOMEFLU

- Lutz-Jesco

- Tsurumi Pump

- Crest Pumps

- Richter

- GEKO-Pumpen GmbH

- Numatic Pumps

- Grundfos

- Xylem

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383