MARKET OVERVIEW

The global hydraulic piston pumps market is the keystone of the industry, as it continues to support large applications that require pressurized fluid power. This hydraulic piston pump is crucial in converting mechanical energy into hydraulic energy, which is necessary for many industries. The market has a wide and diversified portfolio of products that meet the needs of diversified operations to enhance performance in different sectors.

Hydraulic piston pumps play a core role in industries like construction, manufacturing, mining, and agriculture. With the ability to handle high pressure, they become quite essential for any heavy machinery or equipment. With increasing demand for advanced machinery, the Global Hydraulic Piston Pumps market is booming with new technology innovations and the urge to support more efficient and sustainable solutions.

Important features of hydraulic piston pumps are their high efficiency and long service life. The devices work at high pressures; hence, they are suitable for heavy applications. Durability and reliability are two reasons these equipment are often used in many industries. Besides, improvement in material and production processes will enable the production of more efficient and durable hydraulic piston pumps; thus, their study will remain relevant.

In industry, operational efficiency is almost everything. This is an aspect in which hydraulic piston pumps will contribute a lot via the delivery of constant, reliable power. Several further advances in the technology of pumps will be required for the market to reduce the consumption of energy and increase the overall efficiency of the systems. These developments will be of great importance in fulfilling the demanding needs of the modern industrial application, hence making the Global Hydraulic Piston Pumps market one indispensable need of the industry.

Therefore, these hydraulic piston pumps are also very essential and useful for the farming industry. The modern farming techniques are getting increasingly dependent on advanced machinery for irrigation, planting, and harvesting. Hydraulic piston pumps offer great power to operate this machinery efficiently, hence achieving increased productivity and crop yield. The demand for reliable and efficient hydraulic systems will keep increasing with the evolution of agricultural practices and contribute to the growth of the market.

The other application for the hydraulic piston pump is in heavy machinery used in the construction industry, such as excavators, loaders, and cranes. The requirement by this sector is for hydraulic systems holding powerful, strong, and reliable features, as the operations include tough tasks. The global hydraulic piston market is bound to continue playing a critical role in serving the rising demands made by the construction industry, especially as the wave of urbanization and infrastructure development projects gain even greater magnitude worldwide.

Hydraulic piston pumps also find high application in their ability to achieve high pressure for mining applications. The mining process presents some of the most rugged conditions encountered and requires equipment that is able to withstand extreme pressures with reliable performance. Future demand will continue to be driven by the mining industry, which has a need for hydraulic systems able to effectively and durably sustain large volumes of extraction and processing.

The overall market for Global Hydraulic Piston Pumps in the future will experience continuous innovation and technology advancement. Manufacturers will have to redirect their focus to developing pumps that give higher efficiency, which will result in lower energy consumption and failure rates, and subsequently increase the overall reliability. Further, intelligent technologies and automation will enhance performance and monitoring of hydraulic systems to ensure their optimal operation for any industrial application.

The Global Hydraulic Piston Pumps market forms an intrinsic part of the industry through its supply of critical components for numerous diverse applications. What is going to drive this market are future developments in technology and the ever-increasing demand for effective and high-reliability hydraulic systems. Hydraulic piston pumps will also turn out to be a strategic factor in ensuring the smooth and efficient running of all machinery and equipment depending on them as industries evolve and look for sustainable solutions.

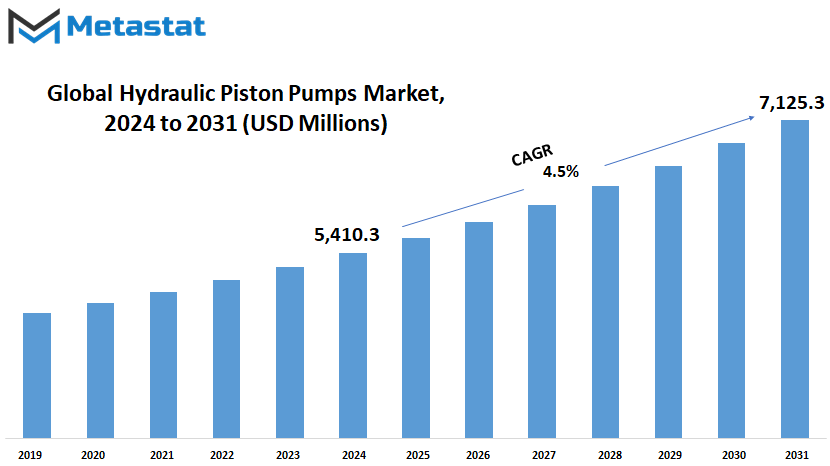

Global Hydraulic Piston Pumps market is estimated to reach $7,125.3 Million by 2031; growing at a CAGR of 4.5% from 2024 to 2031.

GROWTH FACTORS

The global hydraulic piston pumps market is likely to grow tremendously in the near future. High pressure demand from industries such as construction, mining, and agriculture would be some of the major drivers that would fuel growth in the global hydraulic piston pumps market.

Improvements in hydraulic technology also greatly improve the efficiency and performance of hydraulic piston pumps. Better materials, improved engineering, and advanced control systems allow for the development of more efficient, more reliable pumps that can operate at higher pressures. These improvements not only raise the performance of hydraulic piston pumps but also increase their lifecycle, making them more cost-effective in the long run.

However, there are certain factors that may hinder the progress of this market. The most prominent challenge is the high up-front investment for hydraulic piston pumps. Their purchasing and installation cost appears to be more significant as compared to other similar products available in the market, which discourages certain industries. Secondly, hydraulic piston pumps are costly in terms of maintenance cost, which raises the overall expenditure. The other challenge is the complicated design and operational requirements of hydraulic piston pumps. The pumps require specialized knowledge and expertise to be operated and serviced, and that can act as a limiter in their diffusion process.

Despite these challenging factors, there exist opportunities for a good growth in the Global Hydraulic Piston Pumps market. One such promising area is the development of energy-efficient and durable hydraulic piston pumps. With industries gradually focusing on sustainability and the green agenda, the demand for low-energy, long-life pumps is ever-growing. Companies that can innovate in this area and provide solutions that answer these demands are likely to experience tremendous growth.

Furthermore, growth in industrial applications that require hydraulic piston pumps is likely to benefit the market. With new industries coming up and already existing industries expanding further, demand for proficient and reliable hydraulic systems will increase accordingly. This will provide great opportunities for manufacturers to develop and supply hydraulic piston pumps to service a variety of applications.

In a nutshell, even though the Global Hydraulic Piston Pumps market is beset with the challenges of high costs and complex requirements, its prospects are quite bright. Aiding this demand for high-pressure applications will be technological advancement and prospects for energy-efficient solutions. As the industries continue to evolve and further expand, hydraulic piston pumps' importance will only increase, therefore giving long-term growth in years to come.

MARKET SEGMENTATION

By Type

The hydraulic piston pumps market globally is touted to witness tremendous growth in the near future. The rising demand for effective, high-performance hydraulic systems will surely give this market a significant boost in the industries. Hydraulic piston pumps form one of the most important components of hydraulic systems, which essentially convert the mechanical energy into hydraulic energy to be utilized later for lifting, pressing, and moving material.

By type, the market is segmented into axial piston pumps and radial piston pumps. Axial piston pumps are highly efficient and reliable, and they have always had a larger market share. These pumps can cater to multiple applications that require high pressure and high flow rates, hence are quite suitable for industries such as construction, mining, and oil and gas. With improving technology, the efficiency and performance of axial piston pumps will only get better, thereby giving a further boost to their adoption.

Radial piston pumps, even though they are not as common as axial ones, will also rise steadily. Characterized by their hold on high-pressure applications, these pumps are thus largely used in industrial and mobile machinery. In this regard, demand for radial piston pumps will rise due to an increased quest for automation and precision in the manufacturing process. Such pumps will find more applications in various industries once new materials and manufacturing techniques improve them with respect to durability and performance.

The outlook for the global hydraulic piston pumps market seems bright, with advancements in digital technology. Smart sensors and IoT-based developments would be helpful in real-time monitoring and predictive maintenance of hydraulic systems. It may lower downtime and reduce the associated maintenance cost that would mean higher efficiency in operations. This feature is going to be inbuilt in hydraulic system remote monitoring and control, with substantial benefits accruing to industries dependent on these systems.

Environmental considerations will also determine the future of hydraulic piston pumps. The increasing focus on developing more energy-efficient and environmentally friendly pumps will become more prominent in the design of pumps. Design-related and material-based pump innovations will give rise to low-energy and low-emission pumps. The stringent regulations and growing awareness of the need to reduce the ecological footprint of industrial activities will characterize this shift towards sustainable solutions.

The global hydraulic piston pumps market holds huge growth potential, with technological advancement, coupled with growing demand for efficient hydraulic systems. Segmentation by type into axial and radial piston pumps will continue catering to the diversified needs of industries. In this respect, hydraulic piston pumps of the future will be more advanced, efficient, and environmentally friendly. Keeping in view new developments in the field of digital technology, hydraulic systems are necessarily going to change the way they are serviced and operated to achieve better efficiency and reliability.

By Operating Pressure

The future of the Global Hydraulic Piston Pumps market is very promising because continuous technological innovation and rapidly broadening industrial applications are responsible for this growth. Hydraulic piston pumps are efficient and reliable, and thus they are considered as the backbone of construction, manufacturing, and agricultural industries. Segmenting on the basis of operating pressure will give in-depth knowledge about the trends and developments.

In the low-pressure hydraulic piston pumps market, growth will be influenced by the rising demand for energy-efficient and cost-effective solutions. These pumps are specifically designed to operate at low-pressure levels for applications typically involving material handling and light industrial processes. As industries strive to reduce operational costs and environmental impact, demand for low-pressure pumps will likely increase. Enhancements in design and materials of pumps will further increase performance and durability, improving their market presence.

The growth in the medium-pressure segment of the hydraulic piston pumps market will be remarkable, as industries are looking for versatile and adaptable solutions. Their broad applications include automotive, aerospace, and mining, among others, where moderate pressure levels are required to be maintained for optimized performance. The segment will definitely be replaced by the invention of smart, connected pumps, including sensors that work with real-time monitoring for predictive maintenance to lessen probable downtime and maximize effectiveness. Demand for medium-pressure hydraulic piston pumps is expected to rise in the future due to industries' increasing adoption of automation and digitization.

High-pressure hydraulic piston pumps hold a significant market share, as they have applications wherever robust and powerful solutions are required. These pumps play a key role in heavy machinery, oil, and gas exploration, hydraulic fracturing. In the future, continuous developments in high-pressure pump technology shall be seeking ways of improving efficiency at the same time reducing energy consumption. Advanced materials and new techniques of engineering shall be used to enhance performance and longevity. Most importantly, tight environmental regulations shall force the invention of eco-friendly high-pressure pumps in efforts geared towards attaining sustainable development goals.

Steady growth in all pressure categories of the Global Hydraulic Piston Pumps market will be accompanied by technological development and changing industry requirement. The low-pressure pumps will grow as a result of their energy efficiency, the medium-pressure pumps due to their integration into automation and smart systems, and high-pressure pumps in demanding applications. With non-stop innovation and a sustainability focus, the future for this market is bright. Unable to turn a blind eye to the changing needs of industries, not to mention the environmental concerns, hydraulic piston pumps will remain a crucial part of industry operations in terms of both efficiency and reliability.

By Application

The hydraulic piston pumps will grow drastically in the future with many applications. Pumps in construction will be needed to generate massive force for heavy machinery to ensure smooth operations in building infrastructures. Demand for advanced hydraulic piston pumps will increase as the construction industry grows with a focus on sustainability and efficiency. Innovations in this area will bring about enhanced performance and longevity in hydraulic systems.

Hydraulic piston pumps will find their way into the mining sector as modern mining operations demand reliability and power in mineral extraction. They will become more prevalent in the near future when mining activities increase and reach deeper levels that require robust hydraulic solutions to support the heavy-duty mining equipment.

Advancements in hydraulic piston pumps will also benefit farming machinery. As the agricultural sector strives to achieve increased productivity and sustainable farming, these pumps will contribute immensely to better irrigation systems, better planting, and harvesting equipment. The future of farming will thus greatly depend on dependable hydraulic technology to satiate the rising global food demand.

Hydraulic piston pumps will bring in a revolution in the automotive industry when integrated into various applications from manufacturing to vehicle systems. With the world moving faster towards electric and hybrid vehicles, hydraulic systems will be more in demand. These pumps provide optimum performance during the manufacturing process and vehicle operation, thereby supporting this change towards greener modes of transport.

Hydraulic piston pumps will remain essentially indispensable in the oil and gas industry, given their use in powering exploration, drilling, and production. Hydraulic pumps will also conform to the future demands of the industry related to efficiency and reduced impacts on the environment. This kind of innovation will focus on improving the reliability and performance of hydraulic systems at extreme operating conditions.

Hydraulic piston pumps will still be greatly needed by industrial machinery for their versatility and power. With industries gradually modernizing their systems and integrating automation, advanced hydraulic systems are only going to be in higher demand. These pumps shall help different applications, right from manufacturing and processing, to run smoothly and with efficiency.

Aerospace, marine, and renewable energy will also make use of the benefits of hydraulic piston pumps. In the future, new applications and innovations in these areas will continue to spur growth in the Global Hydraulic Piston Pumps market. New tech will make the pumps more efficient, reliable, and sustainable to meet the changing needs of the industries involved. The market will grow further, opening up newer prospects for technological advancement across a diverse range of industries.

By End-User

In the future, the Global Hydraulic Piston Pumps market will be segmented into end-users such as OEMs and Aftermarket. Hydraulic piston pumps have been the most imperative component for industries like construction, agriculture, and manufacturing, and play a very vital role in powering hydraulic systems.

The demand for OEMs, essentially manufacturers incorporating these pumps into their machinery at the time of its initial production, will also be high. As industries grow worldwide, particularly in developing economies where the pace of infrastructure development is considerably strong, OEMs would witness a demand based on the requirement for reliable hydraulic systems. These are crucial in heavy-duty applications such as excavators, loaders, and agricultural machinery to ensure efficient transmission of power and control.

At the same time, the growth in the Aftermarket segment will also be considerable. The segment caters to products and services for the servicing, repair, and replacement of hydraulic piston pumps after they have been installed. With industries getting cost-conscious and focusing on the life of machinery, this segment will flourish. Through providing authentic spare parts and offering maintenance on time, service providers and distributors will prove extremely important in keeping the operations alive, allowing minimal disruption to business due to downtime.

Technological developments will also drive the market landscape. The next generation of hydraulic piston pumps will be characterized by innovations in materials, design, and efficiency. Improving durability, performance, and energy efficiency of pumps to comply with strict environmental regulations and cater to customer demand for more environmentally friendly solutions, as well as the integration of digital technologies like IoT-based monitoring and predictive maintenance into hydraulic systems, will change how they are managed reducing operational costs while enhancing their reliability.

Geographically, the market will be in a state of constant dynamism. Developed regions will continue to lead the way in terms of technological innovation and stringent regulatory standards necessitating constant product improvements, while emerging economies will provide new opportunities through infrastructure investments and efforts to strengthen their industries.

In a nutshell, the Global Hydraulic Piston Pumps market is growing robustly due to its expanding applications across industries, advancements in technology, and changing customer needs. The OEM segment and the Aftermarket segment will both have a crucial role in the trajectory of the market based on continuous innovation and a commitment to sustainability. With industries worldwide, increasingly turning toward hydraulic solutions to meet their power transmission needs, the market shall continue to prosper with bright prospects for all stakeholders across the value chain.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$5,410.3 million |

|

Market Size by 2031 |

$7,125.3 Million |

|

Growth Rate from 2024 to 2031 |

4.5% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

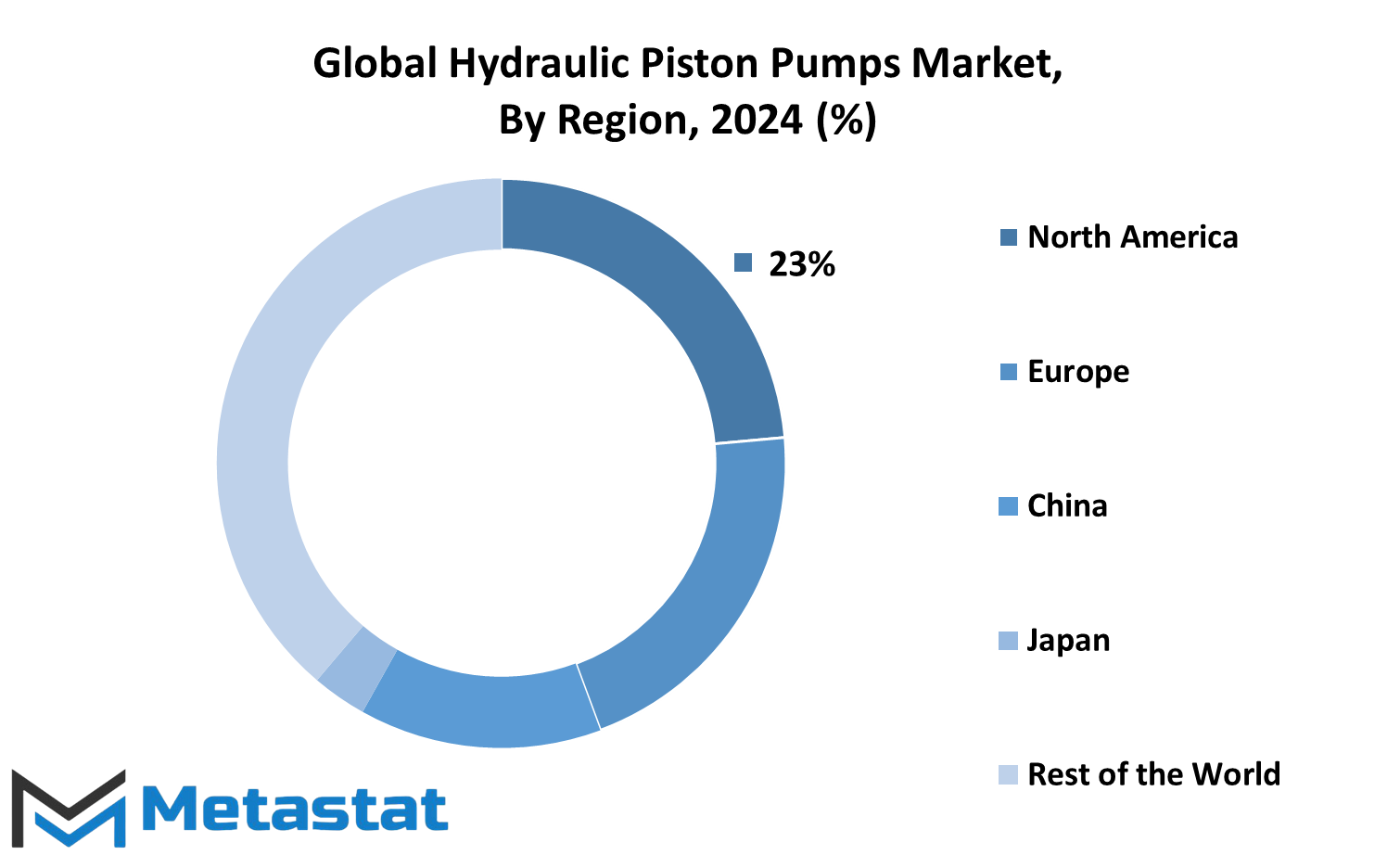

Considering the regional dynamics of the Global Hydraulic Piston Pumps market, one has to take into account its segmentation across various geographical regions. The market has been geographically segmented into four key regions: North America, Europe, Asia-Pacific, South America, and Middle East & Africa. Each region plays a critical role in the formation of the market landscape and thus further influences the growth trajectory.

First is North America, consisting of the United States, Canada, and Mexico. This region will continue to witness enormous presence in the hydraulic piston pumps market. The U.S. is a leading industrial market that is likely to drive demand due to its strong manufacturing sector and the ongoing infrastructure development investments. Canada and Mexico are countries with an emerging industrial base, which, coupled with their geographical advantages, would help in the regional growth of the market.

Move to Europe added to the mix of major economies such as the UK, Germany, France, Italy, and other European nations—and technological advancements with an inclination for industrial automation define the market for Hydraulic Piston Pumps. Countries like Germany and Italy will lead from the front in adopting advanced hydraulic technologies, thus bolstering the market expansion across the continent.

The hydraulic piston pumps market of Asia-Pacific is driven by rapid industrialization, urbanization, and infrastructure development initiatives taken up in major markets like India, China, Japan, and South Korea. The largest market share will still be captured by China because of the large industrial base and the government initiatives towards technological innovation.

Looking further to South America, precisely Brazil and Argentina, the countries are growing steadily in their industrial activities, motivating an increased demand in hydraulic equipment applications—mining, agriculture, and construction. Economic recovery and infrastructure projects would further drive the growth of the market in the region over the next few years.

Least at the last position, Middle East & Africa region, comes with immense potential in terms of opportunities, driven by infrastructure investing by GCC Countries, Egypt, South Africa, and others. In these regions, the market will be accelerated by the hydraulic equipment adoption for industrial applications.

In a nutshell, regional analysis offers some insight into the various growth opportunities available in the Global Hydraulic Piston Pumps market across North America, Europe, Asia-Pacific, South America, and Middle East & Africa. The different scenarios in each region, such as economic and industrial development or investments in infrastructure, encourage further development of this market in the future and put it on the threshold of further growth and technological innovation.

COMPETITIVE PLAYERS

The competition is high in the Global Hydraulic Piston Pumps Market, with many industry leaders exhibiting diversity, and are poised to shape the future trajectory. Prominent market players within this dynamic market include Atos Spa, Bosch Rexroth AG, Bucher Hydraulics, Casappa S.p.A., Caterpillar Inc., Daikin Industries, Danfoss Power Solutions, Denison Hydraulics, Dongguan Blince, Eaton Corporation, GEA, HAWE Hydraulik SE, HYDAC Technology GmbH, Kawasaki Heavy Industries, Ltd., Komatsu Ltd., KYB, Liebherr-International AG, Linde Hydraulics, Moog Inc., Oilgear, Parker Hannifin Corporation, Tokyo Keiki Inc., and Yuken Kogyo Co., Ltd.

Looking ahead, these industry leaders will further make use of technology to be ahead of competition. Innovating efficiency, reliability, and environment sustainability in pumps that will foster growth in the market. The company will, therefore, put a high investment in research and development to introduce the next generation of hydraulic piston pumps with higher performance and lower energy consumption.

Furthermore, the strategic alliances and mergers to be undertaken are bound to reshape the market dynamics. The joint undertaking of key players will bring in greater technological synergies and hence improved market penetration across the globe. With this proactive strategy, companies would be better placed to face new challenges from stringent regulatory standards and changing raw material costs while still upholding profitability and market leadership.

The market landscape will bend more towards customer-centric solutions. Customization and flexibility will be key to serving the diverse requirements of end-users across industries such as construction, agriculture, automotive, and aerospace. The development of value-added service offerings, including predictive maintenance and remote monitoring capabilities, will further cement relationships with customers and assure long-term loyalty.

With stiff competition yet to come in amongst key players, the Global Hydraulic Piston Pumps market will experience appreciable growth. The players target innovation and strategic partnering as ways to be customer-centric in the years ahead, which would set new benchmarks for efficiency, reliability, and sustainability in hydraulic pump technology.

Hydraulic Piston Pumps Market Key Segments:

By Type

- Axial Piston Pumps

- Radial Piston Pumps

By Operating Pressure

- Low Pressure

- Medium Pressure

- High Pressure

By Application

- Construction

- Mining

- Agriculture

- Automotive

- Oil & Gas

- Industrial Machinery

- Others

By End-User

- OEMs

- Aftermarket

Key Global Hydraulic Piston Pumps Industry Players

- Atos Spa

- Bosch Rexroth AG

- Bucher Hydraulics

- Casappa S.p.A.

- Caterpillar Inc.

- Daikin Industries

- Danfoss Power Solutions

- Denison Hydraulics (Parker Hannifin)

- Dongguan Blince

- Eaton Corporation

- GEA

- HAWE Hydraulik SE

- HYDAC Technology GmbH

- Kawasaki Heavy Industries, Ltd.

- Komatsu Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383