MARKET OVERVIEW

The Contact Wafer Temperature Measurement System Market primarily revolves around the development and utilization of sophisticated instruments and technologies that enable precise and real-time measurement of the temperature of semiconductor wafers during various stages of the manufacturing process. These systems have become indispensable in the semiconductor industry, as even minor temperature variations can have a profound impact on the performance and reliability of semiconductor devices.

One of the key factors driving the growth of the Contact Wafer Temperature Measurement System Market is the ever-increasing demand for smaller, more powerful, and energy-efficient semiconductor devices. As semiconductor manufacturers strive to meet these demands, they must maintain strict control over the temperature during fabrication processes, as it directly affects the quality and performance of the final product. Consequently, there is a growing need for highly accurate and reliable water temperature measurement systems.

The Contact Wafer Temperature Measurement System Market encompasses various innovative technologies and solutions, including but not limited to non-contact thermal sensors, contact-based sensors, and infrared temperature measurement systems. These technologies have evolved over time to provide precise measurements with high sensitivity and responsiveness. As a result, semiconductor manufacturers can closely monitor and control the temperature of the wafers during processes such as deposition, etching, annealing, and more, ensuring that the final products meet the strict specifications required for modern electronic devices.

In this market, the integration of advanced sensing and data processing capabilities has become paramount. The measurement systems not only record temperature data but also provide real-time feedback to manufacturing processes, enabling immediate adjustments to maintain optimal temperature conditions. This level of control is essential for achieving the desired performance, reliability, and energy efficiency in semiconductor devices.

Furthermore, the Contact Wafer Temperature Measurement System Market has expanded its horizons beyond traditional semiconductor fabrication. It now finds applications in emerging technologies such as photovoltaics, micro-electro-mechanical systems (MEMS), and even in the production of advanced displays. These diverse applications underscore the pivotal role of wafer temperature measurement in ensuring the quality and consistency of various high-tech products.

The Contact Wafer Temperature Measurement System Market constantly evolves to meet the ever-growing demands of the semiconductor and related industries. It is fueled by a continuous drive for innovation, precision, and control. In a world where technology is advancing at an unprecedented pace, the role of these systems in maintaining the integrity of semiconductor manufacturing processes cannot be overstated. As they continue to advance and adapt, the market ensures that the heart of modern electronics remains reliable, efficient, and ever more powerful.

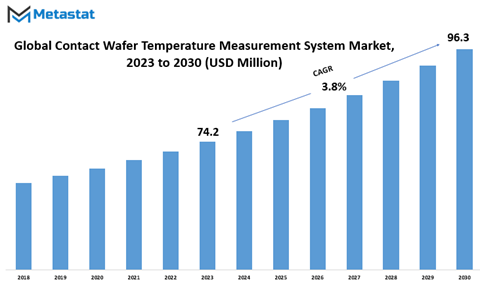

Global Contact Wafer Temperature Measurement System market is estimated to reach $96.3 Million by 2030; growing at a CAGR of 3.8% from 2023 to 2030.

GROWTH FACTORS

The Contact Wafer Temperature Measurement System Market is vital to analyze the factors driving this market's growth and the potential obstacles it might face. Additionally, we need to explore the promising opportunities that could fuel its expansion in the near future. One of the main driving forces behind the Contact Wafer Temperature Measurement System Market's growth is the increasing demand for precise temperature measurement in semiconductor manufacturing. In this high-tech realm, where precision is paramount, the need for accurate temperature measurements during the production process has become indispensable. Manufacturers rely on these systems to ensure the quality and reliability of their semiconductor products. The quest for higher performance and smaller, more intricate electronic devices constantly fuels the demand for more advanced temperature measurement systems.

Moreover, the market benefits from the expansion of the semiconductor industry as a whole. The semiconductor sector, an integral part of the modern technological landscape, continuously seeks innovative solutions to meet the ever-growing demand for faster, more efficient, and smaller electronic components. This expanding industry relies heavily on temperature measurement systems to maintain the integrity of its products, and as it evolves, so too does the demand for more sophisticated contact wafer temperature measurement solutions.

However, despite the market's positive trajectory, certain challenges may pose hindrances. One notable obstacle is the cost associated with implementing advanced contact wafer temperature measurement systems. These technologies involve complex components and cutting-edge materials, which can make them expensive for some manufacturers. This cost factor can deter smaller companies from investing in such systems, potentially limiting market growth.

Another challenge relates to the integration of these systems into existing manufacturing processes. The semiconductor industry is known for its complex workflows, and the introduction of new technologies can disrupt these intricacies. Manufacturers often face challenges in seamlessly incorporating contact wafer temperature measurement systems into their production lines.

Despite these challenges, several opportunities are on the horizon for the Contact Wafer Temperature Measurement System Market. As technology continues to advance, innovative and cost-effective solutions are likely to emerge, addressing the cost concerns. This is expected to open new avenues for small and medium-sized manufacturers to adopt these systems, driving market growth.

Additionally, the increasing demand for Internet of Things (IoT) devices, artificial intelligence, and 5G technology presents a significant opportunity for the market. These emerging technologies require precise temperature control in their manufacturing processes, making contact wafer temperature measurement systems essential. As these sectors grow and evolve, the demand for these systems will likely surge, further expanding the market

MARKET SEGMENTATION

By Type

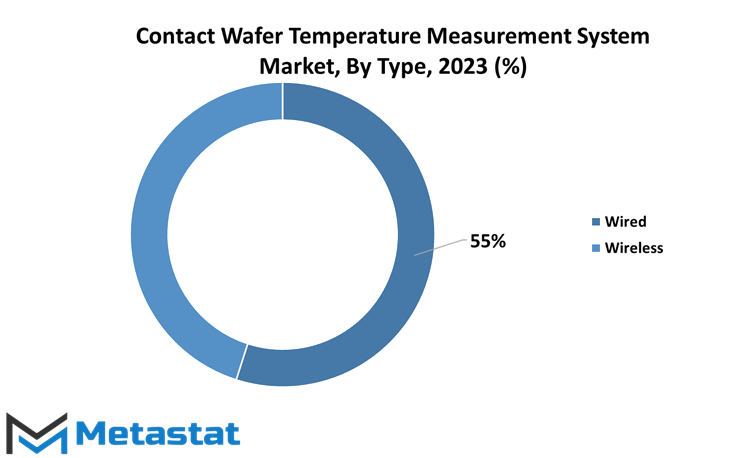

The Contact Wafer Temperature Measurement System Market, a vital component in semiconductor manufacturing, plays a pivotal role in ensuring the quality and efficiency of semiconductor devices. This market is categorized into two primary types: Wired and Wireless.

In the year 2022, the Wired segment held substantial value, amounting to 39.6 USD Million. Wired systems have long been a dependable choice, known for their stability and precision in measuring wafer temperatures. Their consistent performance is particularly crucial in semiconductor manufacturing, where minute temperature variations can significantly impact product quality.

On the other hand, the Wireless segment also contributed significantly to the market, with a value of 32.3 USD Million in 2022. Wireless systems have gained popularity due to their flexibility and convenience. They offer real-time data collection without the constraints of physical wires, making them suitable for applications where mobility and accessibility are essential.

The choice between wired and wireless systems depends on the specific needs of semiconductor manufacturers. Wired systems, with their established reliability, remain the preferred option for applications where precision and consistency are paramount. In contrast, wireless systems offer a more agile and adaptable solution, making them suitable for situations where real-time data collection and accessibility are key considerations.

The Contact Wafer Temperature Measurement System Market reflects the adaptability and diversity within the semiconductor industry. Both wired and wireless systems have their unique advantages, and their relative significance within the market may vary based on the evolving needs and preferences of semiconductor manufacturers. The market's ability to provide a range of options demonstrates its commitment to meeting the distinct requirements of this ever-evolving industry.

By Application

The Contact Wafer Temperature Measurement System Market encompasses a spectrum of applications that influence its dynamics. It is divided into four key segments, each playing a distinct role in shaping the market landscape.

The Wafer Process Equipment Manufacturer holds substantial importance in the market. In the year 2022, this segment had a valuation of 36.7 USD Million. Its role is pivotal in the manufacturing process, as it deals with the equipment necessary for wafer production. Maintaining the right temperature is critical, as it directly impacts the quality and consistency of wafers.

Moreover, the IC Manufacturer is another significant player. With a value of 14.9 USD Million in 2022, it focuses on the production of integrated circuits. Temperature control is paramount in this process, as even minor fluctuations can lead to defects or inefficiencies in the ICs.

Reticle Manufacturer, contributed to the market with a value of 13.5 USD Million in 2022. This segment revolves around the production of reticles, which are a crucial component in photolithography processes. Maintaining the appropriate temperature during their manufacturing is essential for ensuring precision and accuracy in semiconductor production.

The market includes the Others segment, which encompasses various smaller players with unique roles. In 2022, this segment had a total value of 13.5 USD Million. These players could be involved in diverse activities related to wafer production or semiconductor manufacturing, each with its specific temperature requirements.

In essence, the Contact Wafer Temperature Measurement System Market thrives on the synergy of these segments, each contributing its part to maintain the delicate balance of temperature crucial for semiconductor production. These applications underline the market's versatility and the critical role it plays in ensuring the quality and functionality of semiconductor products.

REGIONAL ANALYSIS

The Contact Wafer Temperature Measurement System market is influenced by various factors, with geographical segmentation being a key aspect. Understanding how this market is divided based on geography provides valuable insights into its dynamics and growth patterns. In the context of the Contact Wafer Temperature Measurement System market, geographical segmentation is a vital consideration. This segmentation divides the global market into distinct regions, each with its unique characteristics and influences on the market's behavior.

North America stands out as a prominent player in the Contact Wafer Temperature Measurement System market. This region encompasses the United States and Canada, and it exerts a substantial influence on the market's growth. The presence of leading semiconductor manufacturers and the constant demand for advanced wafer temperature measurement systems contribute to North America's significance in this market.

The United States, in particular, is a hub for technological innovation and semiconductor production. As a result, it plays a pivotal role in shaping the market for contact wafer temperature measurement systems. The high concentration of semiconductor fabrication facilities and research centers drives the need for precise and efficient temperature measurement solutions.

Further, Europe is another key player in the Contact Wafer Temperature Measurement System market. European countries such as Germany, France, and the United Kingdom have well-established semiconductor industries. The demand for reliable and accurate temperature measurement systems in semiconductor manufacturing processes fuels market growth in this region. The European market is characterized by a focus on innovation and sustainability. As a result, there is a growing emphasis on the development of advanced temperature measurement solutions that not only enhance performance but also align with environmentally friendly practices.

COMPETITIVE PLAYERS

The Contact Wafer Temperature Measurement System Market is a dynamic and competitive sector that plays a pivotal role in the semiconductor industry. The key players operating in this industry are instrumental in shaping its trajectory and driving innovation.

KLA Corporation, a prominent name in the Contact Wafer Temperature Measurement System Market, is renowned for its cutting-edge technology and solutions. The company has consistently delivered high-quality temperature measurement systems, meeting the stringent demands of the semiconductor manufacturing process. KLA Corporation's commitment to precision and reliability has earned it a strong reputation in the industry.

Phase IV Engineering Inc., another key player in this market, brings its expertise and innovation to the forefront. The company's temperature measurement systems are highly regarded for their accuracy and efficiency. Phase IV Engineering Inc. has carved a niche for itself by providing solutions that address the specific needs of semiconductor manufacturers.

These key players are at the forefront of the Contact Wafer Temperature Measurement System Market, driving advancements and setting industry standards. Their dedication to research and development, coupled with a focus on meeting the ever-evolving demands of semiconductor manufacturing, positions them as pivotal figures in this competitive landscape.

Contact Wafer Temperature Measurement System Market Key Segments:

By Type

- Wired

- Wireless

By Application

- Wafer Process Equipment Manufacturer

- IC Manufacturer

- Reticle Manufacturer

- Others

Key Global Contact Wafer Temperature Measurement System Industry Players

- KLA Corporation

- Phase IV Engineering Inc.

- Thermo Electric

- SPM Instrument

- ERS electronic GmbH

- Advanced Energy Industries, Inc.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383