MARKET OVERVIEW

The Global Conical Milling market represents a specialized segment of the industrial machinery sector, focusing on equipment designed for the size reduction and uniform distribution of particles in various materials. This industry is integral to numerous applications across pharmaceuticals, food processing, chemical production, and cosmetics. Conical milling machines, characterized by their unique cone-shaped design, excel in achieving high levels of granularity and precision, making them indispensable for industries that demand strict particle size distribution and consistency.

Pharmaceutical companies, for instance, rely heavily on conical milling machines to ensure that active pharmaceutical ingredients (APIs) are processed to a specific size, enhancing drug efficacy and patient safety. The precision offered by these mills aids in producing uniform granules, crucial for consistent dosage in tablet manufacturing. As the pharmaceutical industry continues to advance, particularly with the development of new drugs and formulations, the demand for conical milling equipment will likely see significant growth.

In the food processing industry, conical mills play a critical role in grinding and homogenizing ingredients, contributing to product quality and safety. The ability of these mills to produce a fine, consistent powder is essential for products like spices, flour, and other food additives. As consumers become increasingly health-conscious and demand for processed foods grows, the food processing sector will further integrate conical milling machines into its operations to meet these evolving standards.

The chemical industry also benefits from the precision of conical milling. These mills are used to grind materials to a specific particle size, which is vital for chemical reactions and product quality. In cosmetics, the role of conical milling is similarly crucial. The production of powders, creams, and other cosmetic products requires finely ground ingredients to ensure smooth texture and consistency. As the cosmetics market continues to innovate and expand, the reliance on precise milling processes will become even more pronounced.

Technological advancements will play a pivotal role in the future of the Global Conical Milling market. The integration of automation and digital controls will enhance the efficiency and precision of milling operations. Advanced materials and improved design will also contribute to the durability and performance of conical milling machines. The incorporation of sensors and monitoring systems will allow for real-time adjustments and quality control, further enhancing the reliability and output of these machines.

Sustainability will emerge as a key trend in the Global Conical Milling market. Manufacturers will focus on developing energy-efficient machines that reduce operational costs and minimize environmental impact. The adoption of sustainable practices will not only appeal to environmentally conscious consumers but also align with global regulatory standards aimed at reducing industrial emissions and waste.

The global nature of the conical milling market means that regional variations and economic conditions will influence its trajectory. Emerging markets in Asia-Pacific, Latin America, and Africa will present new opportunities for growth as industrialization and urbanization continue. Established markets in North America and Europe will emphasize innovation and the adoption of cutting-edge technologies to maintain their competitive edge.

The Global Conical Milling market will continue to evolve, driven by advancements in technology, growing industrial applications, and a focus on sustainability. The industry's ability to adapt to changing demands and integrate innovative solutions will determine its future success and growth. As key sectors like pharmaceuticals, food processing, chemicals, and cosmetics expand and innovate, the demand for precise and efficient conical milling equipment will remain strong, cementing its importance in the global industrial landscape.

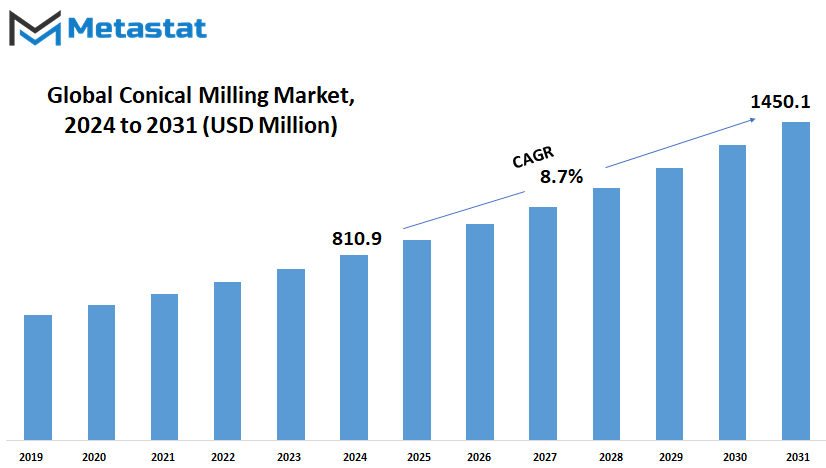

Global Conical Milling market is estimated to reach $1450.1 Million by 2031; growing at a CAGR of 8.7% from 2024 to 2031.

GROWTH FACTORS

The future of the global conical milling market looks promising, driven by a growing demand for pharmaceuticals and food products that require efficient particle size reduction solutions. This equipment is increasingly being adopted due to its versatility and its ability to handle a wide range of materials, making it an invaluable tool in various industries. The need for precise and consistent particle sizes in pharmaceuticals, for instance, is crucial for ensuring proper drug formulation and efficacy. Similarly, in the food industry, conical mills help in producing uniform products, enhancing both quality and consumer satisfaction.

One significant factor driving the conical milling market is its adaptability to different materials. This flexibility allows manufacturers to use one machine for various applications, reducing the need for multiple types of equipment. This not only saves space but also cuts down on operational costs in the long run. Additionally, the efficiency and reliability of conical milling machinery make it an attractive option for companies looking to improve their production processes. As these industries continue to grow, the demand for such versatile equipment is expected to rise steadily.

However, the market does face some challenges. One of the primary restraints is the high initial investment required for procuring and installing conical milling machinery. These costs can be significant, particularly for small and medium-sized enterprises, potentially limiting their ability to adopt this technology. Furthermore, the stringent regulatory requirements and compliance standards in the pharmaceutical and food industries add another layer of complexity. Meeting these regulations can be time-consuming and costly, posing a barrier to market growth.

Despite these challenges, there are considerable opportunities, particularly in emerging markets. The expansion of pharmaceutical and food manufacturing industries in these regions presents a lucrative opportunity for suppliers of conical milling equipment. As these industries continue to develop, there will be an increasing demand for efficient and reliable milling solutions. Companies that can navigate the regulatory landscape and offer cost-effective solutions are likely to find substantial growth opportunities.

In the coming years, we can expect advancements in technology to further enhance the capabilities of conical milling equipment. Innovations that reduce costs and improve efficiency will make these machines more accessible to a broader range of businesses. Additionally, as global demand for high-quality pharmaceuticals and food products continues to rise, the need for precise and reliable milling solutions will only become more critical.Ultimately, the future of the global conical milling market will be shaped by a combination of technological advancements, regulatory developments, and market expansion. Companies that can effectively address the challenges and capitalize on the opportunities in emerging markets will be well-positioned for success. As industries evolve and the demand for high-quality products increases, the importance of efficient and versatile milling equipment cannot be overstated.

MARKET SEGMENTATION

By Type

The Global Conical Milling market is poised for significant growth in the coming years. This market, crucial for industries like pharmaceuticals, chemicals, and food processing, is witnessing increasing demand due to its efficiency in reducing particle size and ensuring uniformity. Conical mills, also known as cone mills, play a vital role in various manufacturing processes by helping to produce a consistent and high-quality product. This market is expected to expand as industries continue to evolve and seek more efficient methods of production.

One of the major segments in the conical milling market is based on the type of mill. These types are further divided into under-driven and over-driven conical mills. Under-driven conical mills have the drive mechanism located below the milling chamber. This design allows for easier integration into existing production lines and often provides better access for cleaning and maintenance. These mills are particularly favored in industries where hygiene and easy maintenance are critical, such as in the pharmaceutical and food sectors.

Over-driven conical mills, on the other hand, have their drive mechanism situated above the milling chamber. This design often results in a smaller footprint, making it ideal for operations where space is a constraint. Over-driven mills are known for their robustness and can handle a wide range of materials, making them versatile for various industrial applications. As industries advance, the demand for both types of conical mills will likely grow, driven by the need for efficiency and precision in manufacturing processes.

By End User

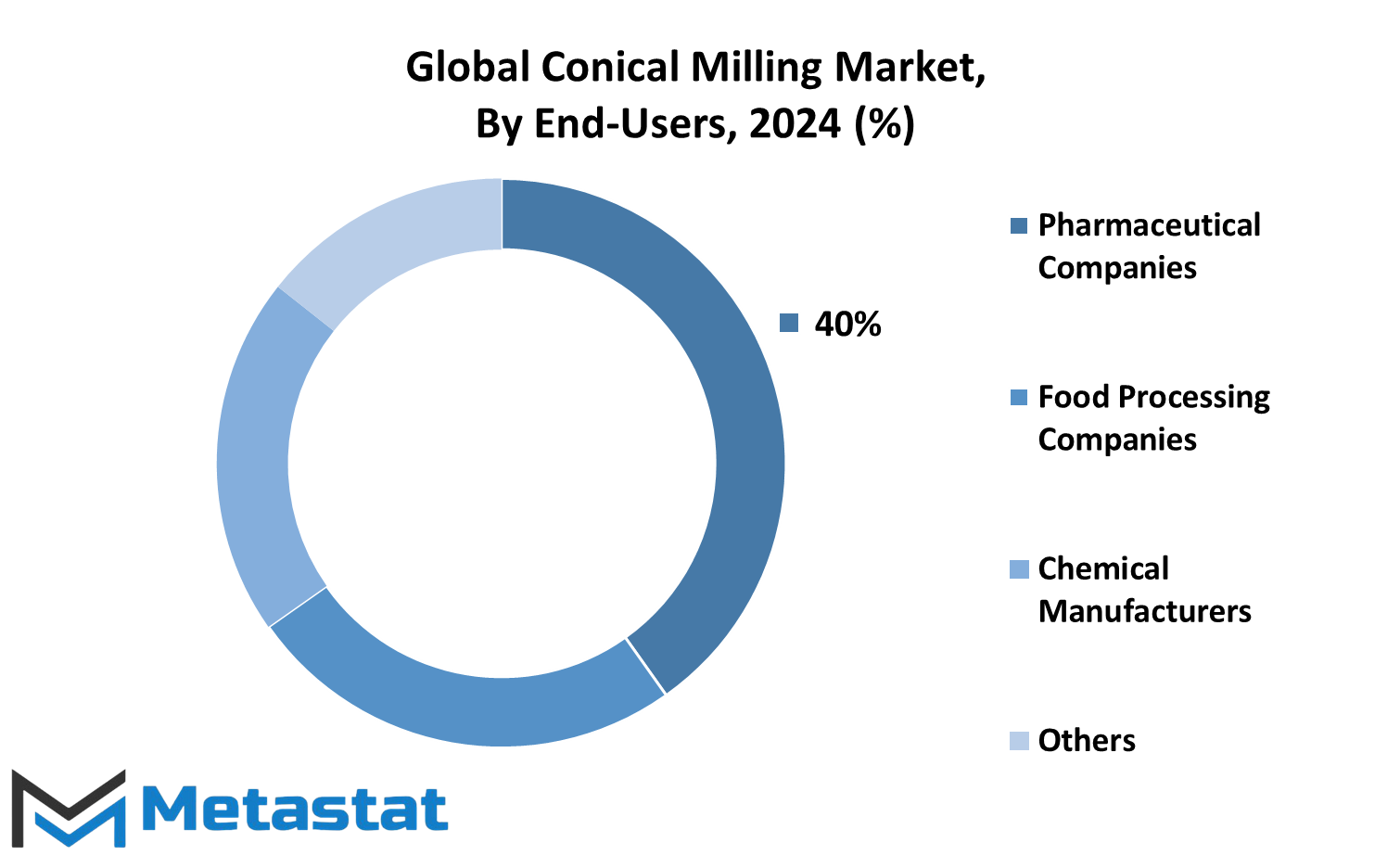

The global conical milling market is poised for significant growth in the coming years, driven by advancements across various industries and an increasing demand for high-quality processed materials. This market primarily caters to pharmaceutical companies, food processing companies, chemical manufacturers, and other industries that require precise particle size reduction and uniformity in their products.

Pharmaceutical companies are a major player in this market. They rely on conical mills to ensure the consistency and quality of their products, which is crucial for both efficacy and safety. As the pharmaceutical industry continues to expand, driven by the aging global population and the rise of chronic diseases, the demand for advanced milling solutions will only increase. Conical mills provide the precision needed for producing medications with exact specifications, which is essential for regulatory compliance and patient safety.

In the food processing sector, the need for uniform particle sizes and high-quality textures is vital. Conical milling helps achieve these standards, ensuring that food products are consistent and meet consumer expectations. With the global population growing and more people seeking convenient, processed foods, the food processing industry will see a steady rise in the use of conical milling equipment. Innovations in food technology and a focus on healthier, more sustainable products will further drive this demand.

Chemical manufacturers also benefit significantly from conical milling. The production of chemicals often requires precise control over particle size to ensure the desired chemical reactions and properties. As the demand for specialty chemicals and high-performance materials grows, so too will the need for efficient and reliable milling solutions. Conical mills offer the versatility and precision necessary to meet these stringent requirements, supporting the development of new and innovative chemical products.

Other industries, such as cosmetics and nutraceuticals, also utilize conical milling to enhance product quality and performance. The increasing focus on quality control and the development of new, high-performance products will contribute to the market's growth. Additionally, advancements in milling technology, such as the integration of automation and digital monitoring systems, will further enhance the efficiency and effectiveness of conical mills, making them an indispensable tool in these industries.

Overall, the global conical milling market is set to expand as various industries seek to improve their production processes and product quality. The continued growth in pharmaceuticals, food processing, and chemical manufacturing, coupled with technological advancements, will ensure that conical milling remains a vital component of industrial production. This forward-looking approach highlights the potential for ongoing innovation and adaptation in response to changing industry needs and consumer demands, securing the future of the conical milling market.

REGIONAL ANALYSIS

The global Conical Milling market is poised for significant growth, driven by increasing demand across various industries such as pharmaceuticals, food processing, and chemicals. Each region, defined by its unique economic and industrial landscape, will contribute to this expansion in distinct ways.

North America, with its advanced manufacturing infrastructure and strong pharmaceutical industry, will likely see robust growth in the Conical Milling market. The United States, Canada, and Mexico are key players in this region, benefiting from technological advancements and high investment in research and development. The demand for precision milling equipment in the production of pharmaceuticals and nutraceuticals will be a major driving force, ensuring that North America remains a leader in this market.

In Europe, countries like the UK, Germany, France, and Italy will drive market growth. Europe’s emphasis on high-quality production standards and stringent regulations will necessitate the use of efficient milling technologies. The region’s strong pharmaceutical and food processing sectors will continue to adopt conical milling solutions to meet regulatory requirements and enhance product quality. This adoption will be crucial in maintaining Europe’s competitive edge in global markets.

Asia-Pacific is expected to be the fastest-growing region in the Conical Milling market. With booming economies such as China and India, there is a surge in demand for advanced manufacturing equipment. The rapid industrialization and increasing focus on high-quality production in these countries will spur the adoption of conical milling technologies. Japan and South Korea, known for their technological prowess, will also play a significant role in the market's growth by driving innovation and development in milling technologies.

South America, led by Brazil and Argentina, will witness steady growth. The region's expanding pharmaceutical and food processing industries will drive the demand for efficient milling equipment. As these industries seek to improve their manufacturing processes and product quality, the adoption of conical milling technologies will become increasingly important.

The Middle East & Africa region, particularly the GCC countries, Egypt, and South Africa, will also contribute to the global market’s growth. The increasing industrialization and focus on diversifying economies beyond oil and gas in these regions will drive the adoption of advanced manufacturing technologies, including conical milling. The growing pharmaceutical sector, driven by a rising population and increased healthcare spending, will further fuel demand for high-quality milling equipment.

Overall, the global Conical Milling market will see significant regional contributions, each driven by specific economic and industrial dynamics. As technology continues to evolve and industries strive for greater efficiency and quality, the demand for conical milling solutions will only increase, shaping a dynamic and promising future for this market.

COMPETITIVE PLAYERS

The global conical milling market is poised for substantial growth in the coming years, driven by advancements in technology and increasing demand for efficient milling solutions in various industries. Conical milling, known for its ability to produce uniform particle sizes and improve the quality of final products, is becoming an essential process in pharmaceuticals, food processing, and chemical manufacturing. As these sectors continue to expand, the need for reliable and high-performance milling equipment will rise, presenting significant opportunities for key players in the market.

Leading companies in the conical milling industry are focusing on innovation and enhancing their product offerings to stay competitive. Hanningfield, for instance, is known for its high-quality milling machines that cater to the pharmaceutical and food industries. Similarly, SaintyCo provides a range of milling solutions designed to meet the specific needs of its clients, ensuring efficiency and precision in their operations.

IDEX, through its subsidiary Quadro Engineering, has been a prominent player, offering advanced conical milling equipment that combines cutting-edge technology with robust design. Their commitment to research and development ensures that their products remain at the forefront of the industry. MCS Machinery and Bhagwati Pharma are also notable players, delivering reliable and efficient milling solutions to a global clientele.

Hosokawa Micron Powder Systems has established a strong reputation for its innovative milling technologies that enhance product quality and operational efficiency. Jiangyin Junzhuo Machinery Manufacturing Co., Ltd. and Senieer International Group are expanding their market presence by offering cost-effective and high-performance milling equipment, catering to diverse industrial needs.

Freund-Vector Corporation is another key player, known for its comprehensive range of milling solutions that support various applications in pharmaceuticals and other industries. Prochem and Bombayengg have also made significant contributions to the market, providing customized milling solutions that meet the unique requirements of their customers.

Crystal Automation Pvt. Ltd. and United Pharmatek LLC are recognized for their commitment to quality and customer satisfaction, delivering reliable milling equipment that supports efficient production processes. Multipack Machinery Company and Yenchen Machinery Co., Ltd. continue to innovate, ensuring their products meet the evolving demands of the market. Frewitt SA, with its advanced milling solutions, rounds out the list of key players, emphasizing precision and quality in its offerings.

As the global conical milling market evolves, these competitive players will play a crucial role in shaping the industry's future. By focusing on innovation, quality, and customer-centric solutions, they will drive the market forward, meeting the growing demand for efficient and reliable milling equipment. The future of conical milling looks promising, with continuous advancements and expanding applications across various industries.

Conical Milling Market Key Segments:

By Type

- Under-Driven

- Over-Driven

By End User

- Pharmaceutical Companies

- Food Processing Companies

- Chemical Manufacturers

- Others

Key Global Conical Milling Industry Players

- Hanningfield

- SaintyCo

- IDEX (Quadro Engineering)

- MCS Machinery

- Bhagwati Pharma

- Hosokawa Micron Powder Systems

- Jiangyin Junzhuo Machinery Manufacturing Co., Ltd

- Senieer International Group

- Freund-Vector Corporation

- Prochem

- Bombayengg

- Crystal Automation Pvt. Ltd.

- United Pharmatek LLC

- Multipack Machinery Company

- Yenchen Machinery Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252