MARKET OVERVIEW

The global composite lpg and cng cylinders market is part of the larger energy storage and fuel container market and will further dictate the manner in which gas-based fuels are packaged, stored, and transported for use in diverse applications. This industry entails the manufacture and supply of advanced composite cylinders, usually produced with a blend of fiberglass, carbon fibers, and resin materials, specially designed for liquefied petroleum gas (LPG) and compressed natural gas (CNG). Contrasting with the traditional steel-based options, these composite cylinders contain superior safety, lightness, and corrosion resistance properties, which will establish their niche in industrial and consumer markets in the future years.

The global composite lpg and cng cylinders market will grow across several layers of demand driven by their usefulness for domestic cooking, automotive fuel systems, outdoor recreation, and commercial applications in industries that use portable gas solutions. These cylinders will be used in different environments where metal containers have been problematic, such as marine environments, high-humidity areas, and mobile applications. As nations globally press on with safety regulations and embrace lightweight technologies, composite-based containers will be a choice of preference for organizations interested in efficiency without compromising on structural integrity.

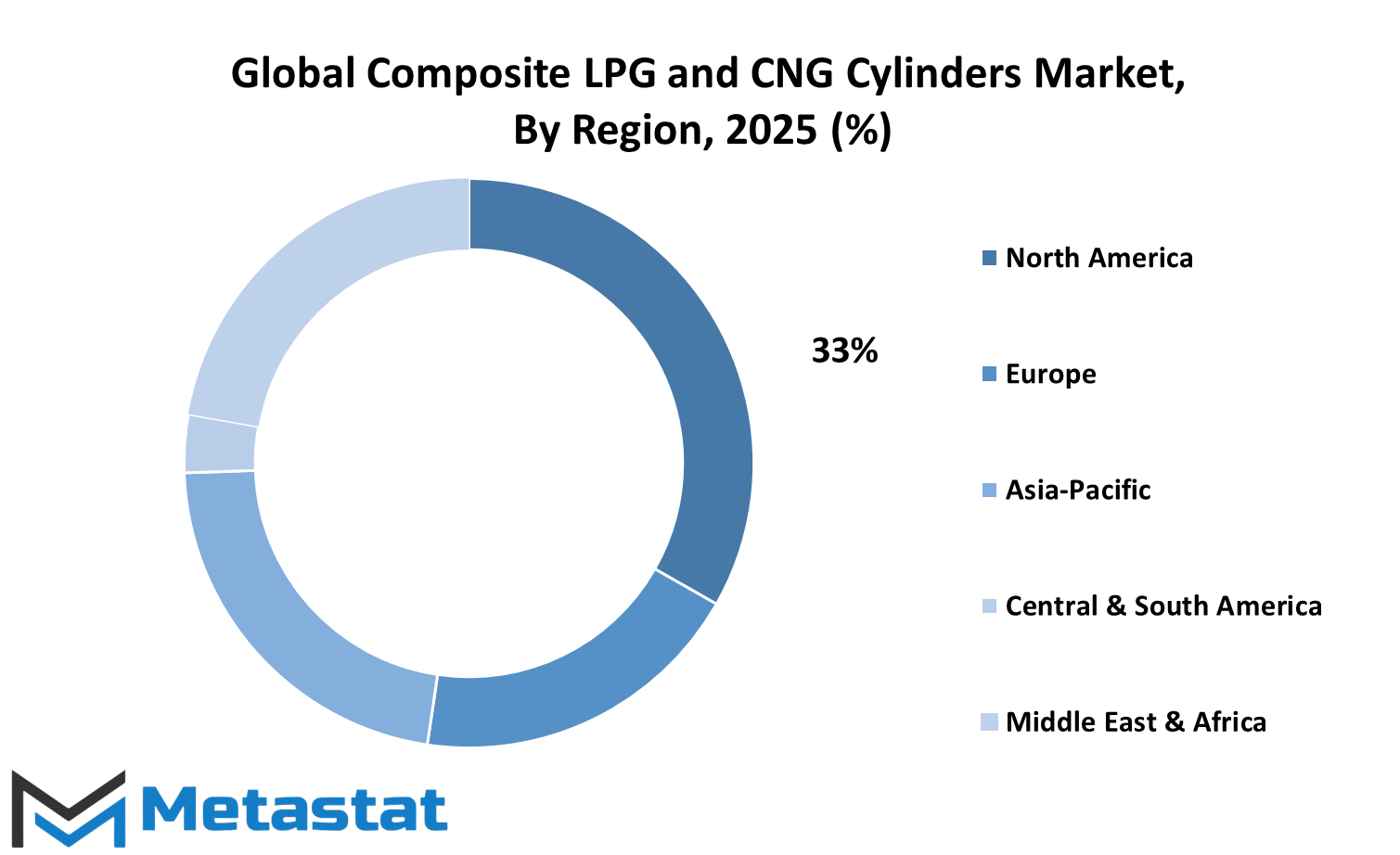

The size of the global composite lpg and cng cylinders market will be determined by its penetration into major markets such as residential use in urban and rural communities, fleets that run on clean alternative fuels, and industrial facilities that use CNG as a low-emission source of energy. North America, Europe, and Asia-Pacific will remain leading areas of adoption, though developing economies in Africa and South America will presumably create an expanding presence because of modernization of infrastructure and widening availability of gas supply networks. Within every region, producers will tailor cylinder options according to individual regulatory codes, models of distribution, and requirements of users so that flexibility becomes a core aspect of competitive strategy.

As the global composite lpg and cng cylinders market evolves, it will indicate a shift away from vintage equipment towards high-performance gas vessels with integrated technologies such as RFID tagging, see-through body designs for level observation, and sophisticated sealing systems to reduce the risk of leaks. These features will maximize user confidence and will facilitate safety procedures that governments and private operators aim to make uniform. Composite material suppliers, cylinder producers, and gas supply companies will forge future product designs and distribution patterns.

The global composite lpg and cng cylinders market will also be driven by shifting customer expectations for portability and safety. Urban residents and transport operators will require solutions that fit their high-tempo business environments. The recyclability and longevity of composite cylinders will also remain a priority as environmental regulation encourages environmentally friendly product designs along industrial supply chains.

In summary, the global composite lpg and cng cylinders market will hold a pivotal position in the larger gas containment industry. With an emphasis on performance, flexibility, and safety, it will keep changing with the changing technological and regulatory environment and trying to meet the increasing need for clean and portable sources of energy worldwide.

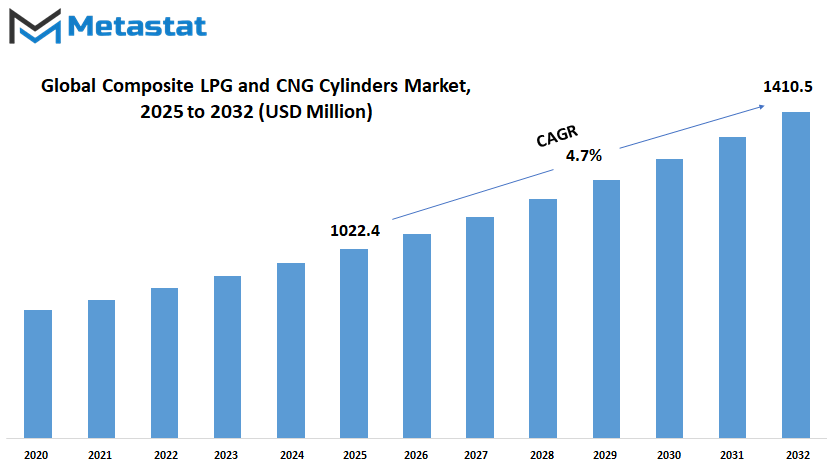

Global composite lpg and cng cylinders market is estimated to reach $1410.5 Million by 2032; growing at a CAGR of 4.7% from 2025 to 2032.

GROWTH FACTORS

The global composite lpg and cng cylinders market will expand steadily in the future because of a number of factors influencing its future. Among the key reasons for this expansion is the growing demand for more secure and lighter-than-metal cylinders as alternatives. As safety, efficiency, and other needs move higher up on the lists of concerns among people and businesses, composite cylinders present an increasingly attractive option. They are not only corrosion-resistant but also easy to use, which makes them convenient for a host of applications.

Another compelling reason in favor of market growth is the move toward cleaner fuels. Most countries are striving to keep the air clean and lower greenhouse emissions, and LPG and CNG both appear to be better choices than older, dirtier fuels. Demand for alternative fuel systems both in residential and commercial applications will also keep pushing the market ahead. With increasingly tight environmental regulations, demand for light-weight, durable, and recyclable cylinders is likely to grow.

However, there are certain issues that may hinder this growth. The low cost of production for composite cylinders is not being taken advantage of by smaller enterprises or the developing world. Furthermore, the limited knowledge available regarding the benefits of composite cylinders may slow down their implementation in certain regions. Lastly, the issue with the availability of the raw materials and reliance on skilled personnel can reduce the rate of production.

Even with these challenges, the industry is very promising. Increased investments in clean energy technology and subsidies for environmentally friendly fuel sources have been predicted to open up new avenues for expansion. Improved technology and declining production costs over a period of time will make it easier for people across a wider user base to access these cylinders. Increasing demand from industries like transportation and domestic energy usage will most probably unlock new business opportunities.

Urbanization and increasing population in developing nations will also fuel demand. Consumers are seeking safer, more durable, and convenient fuel alternatives, and composite cylinders fit these requirements perfectly. The increasing volume of vehicles powered by LPG and CNG will enhance this demand even more. With increasing energy demands and attention placed on sustainable lifestyles, the global composite lpg and cng cylinders market will probably experience enduring growth fueled by innovation as well as need.

MARKET SEGMENTATION

By Cylinder Type

The global composite lpg and cng cylinders market is expected to experience significant growth in the coming years as demand for cleaner fuel sources and the retirement of traditional metal cylinders gains momentum. With environmental issues becoming more priority and governments beginning to encourage the usage of lighter, safer, and more efficient methods of gas storage, composite cylinders are expected to find wider usage around the world. These cylinders are also lighter in weight than metal cylinders, less prone to corrosion, and safer in general due to their design. This is not just a case of convenience, though it is part of the general trend of sustainable energy consumption.

When the global composite lpg and cng cylinders market is broken down by cylinder type, it can be divided into LPG composite cylinders and CNG composite cylinders. Each has merits that suit diverse needs, depending on where and how they are used. LPG composite cylinders are widely available in domestic and business use cooking and in small-scale heat solutions. Their lightness allows for easy handling, reducing the chances of damage and making them appealing for residential and business use. CNG composite cylinders are typically found in cars. Their reduced weight will lead to better fuel economy, but their high-strength material provides enhanced protection for occupants and drivers.

The global composite lpg and cng cylinders market will respond to increasing demand for alternative fuel in the future. As countries around the world keep advancing towards reducing carbon emissions and meeting their environmental goals, gas storage with better efficiency, safety, and reliability will be in greater demand.

Materials and manufacturing technologies will further improve the quality of composite cylinders, further sweetening them. There may also be increased public-private initiatives to spread the application of these cylinders to regions that are still stuck with the older, heavier, and less secure models. The future of the global composite lpg and cng cylinders market will depend on these developments and shifts in the energy policies. With technology developing further and people becoming aware of the benefits of cleaner energy, composite cylinders will play a more important role. This growing trend has a clear roadmap towards cleaner, safer, and efficient storage of fuel, building a foundation for long-term change in fuel consumption and storage.

By Material Type

The global composite lpg and cng cylinders market will continue to grow steadily as industries and individuals turn more and more toward cleaner, lighter, and safer fuel storage. The transition from conventional steel cylinders is one of the key drivers toward this growth. They are heavier, rust-prone, and harder to handle. Therefore, composite cylinders are becoming the preferred option due to their reduced weight, corrosion-free properties, and enhanced safety. In the future, as technology continues to improve, these cylinders will be more effective and affordable.

When looking at the global composite lpg and cng cylinders market by material type, there are three main categories shaping its direction: Glass Fiber-Reinforced Composite Cylinders, Carbon Fiber-Reinforced Composite Cylinders, and Hybrid Composite Cylinders. Each type has its own purpose and benefits. Glass fiber-reinforced cylinders are currently favored in markets where affordability and safety are equally important. They are durable, easier to transport, and suitable for daily use. In the long term, developments in glass fiber technology will most likely yield even improved performance without increasing the cost too much. The carbon fiber-reinforced cylinders, however, offer greater strength and are much lighter.

Carbon fiber-reinforced cylinders are optimal when weight is crucial, such as with cars that need to reduce fuel and increase efficiency. Although more costly, the performance and durability added will see them become even more sought after. As new manufacturing methods reduce the cost of carbon fiber composites, industries will find they use these cylinders more and more for personal and business needs. Hybrid composite cylinders take the best of glass and carbon fibers. They are affordable, safe, and robust and hence a smart choice for uses where both performance and affordability are needed. Hybrids will continue to gain momentum in the times to come as manufacturers strive to improve the material and production process.

The future of the global composite lpg and cng cylinders market will be shaped by ongoing changes in how energy is stored and consumed. As the world becomes more and more focused on reducing carbon emissions and increasing security features, demand for strong and light gas cylinders will keep increasing. With continued innovation, all three types of composite cylinders will become more and more common, safer to handle, and better suited to the future.

By Application

The global composite lpg and cng cylinders market is anticipated to grow steadily because of increased demand from various industries. The more individuals and organizations continue to look for safer, lighter, and efficient means of carrying and storing gas, the more composite cylinders gain popularity. Composite cylinders are recognized as strong and lightweight, making them convenient to maneuver and minimize the chances of accidents. They do not rust like conventional steel cylinders, which makes them last longer. This has made them appeal not only for domestic use, but also in industry where efficiency and safety are vital.

In the domestic market, demand for composite cylinders is expected to rise as households seek safer and more convenient means of controlling their cooking fuel. The lower weight ensures simpler handling, particularly in areas where individuals continue to use LPG for ordinary cooking. In the case of commercial environments like restaurants and food kiosks, the cylinders can enhance working conditions and ensure compliance with fire safety regulations. Their neat appearance and dependability further ensure them as a suitable option for busy kitchens and enterprises that utilize gas on a regular basis.

The manufacturing industry will also continue to rely on composite cylinders because they are safe and durable. Businesses that operate with gas to produce or heat will enjoy less downtime and more durable equipment. Composite cylinders can be employed in harsh environments without worrying about rust or damage, which can be expensive in the long run. As industries struggle to improve downtime and enhance safety, the application of composite cylinders will be significant.

The transport industry is going to dominate the future of this market. The trend towards cleaner fuel and greener transport will make progressively more vehicles run on LPG or CNG. Composite cylinders are lighter and contribute to better fuel efficiency as well as lowering the vehicle's weight. This is significant because the automakers and transport operators attempt to achieve tighter green goals. In private cars and public transportation as well, these cylinders provide a safer and more efficient means of fuel storage.

While the marine and other smaller industries are smaller in size, their place cannot be overlooked. Boats, ferries, and other vessels might adopt these cylinders more and more for safety and fuel efficiency. With new applications emerging and technology evolving, the global composite lpg and cng cylinders market is going to undergo further transformations, creating new opportunities in all areas of applications.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$1022.4 million |

|

Market Size by 2032 |

$1410.5 Million |

|

Growth Rate from 2025 to 2032 |

4.7% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global composite lpg and cng cylinders market will keep on gaining traction worldwide as the priorities for energy change and safety, portability, and efficiency gain prominence. These cylinders, used extensively for storing liquefied petroleum gas (LPG) and compressed natural gas (CNG), are on the rise because of their light weight and enhanced safety. They are becoming increasingly viewed as a smart alternative to the conventional metal cylinders, and this is only going to continue as various nations seek cleaner, safer, and more sustainable ways to generate energy.

Globally, in various regions of the world, this market is growing at its own rate. In North America that encompasses the U.S., Canada, and Mexico, government policies aimed at clean fuel consumption are driving the market ahead. Increased numbers of households and industries are developing interest in alternative energy sources that are safer and more economical. Likewise, Europe comprising the UK, Germany, France, Italy, and others is experiencing a transition in consumer trends. Consumers are becoming increasingly environmentally conscious and searching for fuel storage systems that not only perform well but are green energy compliant too.

In Asia-Pacific region, which encompasses rapidly developing economies such as India, China, Japan, and South Korea, there is an increasing demand for alternative fuel options capable of addressing both urban and rural development. With industrial activity set to continue increasing and populations increasingly mobile, demand for safe and easy-to-use fuel cylinders will only increase. South America, including nations like Brazil and Argentina, is also trending towards such alternatives with improving fuel infrastructure and regulations favoring cleaner fuel uptake. In the Middle East and Africa, including Egypt, South Africa, and the GCC Countries, there is growing demand for composite cylinders. This is mostly promoted by safety standards and the requirement to upgrade mature systems.

In the future, it is probable that the global composite lpg and cng cylinders market will continue to grow, with the introduction of new materials and shapes to suit local demands. With nations placing greater emphasis on energy autonomy and sustainability, the application of these next-generation cylinders will be increasingly prevalent. In urban areas or rural communities, the future suggests greater usage, fueled by shifting lifestyles, government incentives, and increased attention to safety and eco-friendliness.

COMPETITIVE PLAYERS

The global composite lpg and cng cylinders market shall experience significant growth as the world continues to drift toward safer, lighter, and more efficient gas storage options. Metal cylinders have long served their own purpose, yet the trend is changing toward composite material as the industry heads toward the future. These newer cylinders are more resistant to corrosion and much lighter, reducing the difficulty of transportation and handling. This innovation is gaining acceptance in a wide range of industries, from domestic and commercial use to industrial applications. With countries becoming more interested in cleaner fuels and environmental alternatives, the demand for sound and contemporary gas storage solutions is on the increase.

Composite cylinders are being valued for their safety, longevity, and versatility of design. These traits render them attractive not only for one-time use but also for future use in large energy plans. The future will most probably witness these cylinders being a cornerstone in places where energy efficiency and portability are critical. Top firms are already investing in enhanced manufacturing processes and implementing smart technologies to make their products more reliable. As this market continues to grow, the application of composite materials will become the norm, replacing dated techniques that can no longer serve the increasing demands of contemporary existence.

Major players in the global composite lpg and cng cylinders market are always looking forward. Organizations like Hexagon Composites ASA, Faber Industrie S.p.A., and Worthington Industries are investing in research and development. Others such as Luxfer Gas Cylinders and Time Technoplast Ltd. are attempting to grow international presence and manufacturing capabilities. Companies like Aburi Composites and The Supreme Industries Ltd. are also investing in new designs for enhanced user safety and less environmental impact overall. While manufacturers like Santek Industrial Products And Technologies San.Tic.A. and Zhejiang Cylinder Technology Company Limited are focusing on providing high-performance products that fulfill increasing customer expectations. As more territories target the implementation of clean energy policies, firms such as Amtrol-Alfa, Anhui Clean Energy Co., Ltd., BURHAN GAS COMPANY, and Indoruss Synergy Pvt. Ltd. will come to play a vital part.

In the future, demand is anticipated to grow for these cylinders as infrastructure becomes more advanced and energy systems more modern. This continuing transformation presents opportunity for both incumbent makers and new companies to provide toward a cleaner, safer, and more efficient future in energy. The market will not just expand but also provide direction toward the way the energy is consumed throughout much of the world.

Composite LPG and CNG Cylinders Market Key Segments:

By Cylinder Type

- LPG Composite Cylinders

- CNG Composite Cylinders

By Material Type

- Glass Fiber-Reinforced Composite Cylinders

- Carbon Fiber-Reinforced Composite Cylinders

- Hybrid Composite Cylinders

By Application

- Household

- Commercial

- Industrial

- Automotive

- Marine

- Others

Key Global Composite LPG and CNG Cylinders Industry Players

- Hexagon Composites ASA

- Faber Industrie S.p.A.

- Aburi Composites

- Indoruss Synergy Pvt. Ltd.

- The Supreme Industries Ltd

- BURHAN GAS COMPANY

- Amtrol-Alfa

- Santek Industrial Products And Technologies San.Tic.A.

- Anhui Clean Energy Co., Ltd.

- Zhejiang Cylinder Technology Company Limited

- Worthington Industries

- Luxfer Gas Cylinders

- Time Technoplast Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252