MARKET OVERVIEW

The Global Coil Coating market is a specialized segment representing the broader paints and coatings industry. The underlying support of that market is the demand for pre-coated metal substrates, which exhibit desirable surface properties and durability. The market therefore concerns the continuous application of organic coatings onto metal coils so that these coatings can be applied with uniformity, efficiency, and cost-effectiveness before the metal is fabricated into end-use articles. It caters to construction, automotive, appliance, and industrial equipment sectors, where performance, esthetics, and corrosion resistance are crucial.

Coil coating technology means applying coatings to rolled metal strips, mostly steel and aluminum, through an automated process ensuring exactitude and controlled curing conditions. The sophistication of coating lines will create a niche in the Global Coil Coating market for the development of custom formulations that fit application requirements. Manufacturers prefer coil-coated materials to paint application on finished components because of advantages such as consistency, environmental control, and reduced post-production waste.

The architecture and construction sectors will use pre-coated coil for roofing, wall panels, and structural components, where color consistency and weather resistance are demanded. These sectors require materials that will maintain appearance and functionality under harsh environmental conditions, and coil-coated metals will meet the expectations through improved formulations. Likewise, in the case of home appliances, coated coils will provide smooth finishes and resistance against scratching, chemicals, and temperature changes. Thus, manufacturers will be supported by the Global Coil Coating market in making good products of lasting aesthetic and structural performance.

Automotive manufacturers will also look at the Global Coil Coating market for interior and exterior components that benefit from reduced processing steps and superior finish quality. With the ever-increasing emphasis on lightweight structures and efficient production methods, pre-coated metal components will act in concert with design trends while adhering to all relevant regulatory and technical standards. In the industrial space, coated coils will find application in HVAC systems, lighting, and shelving systems alike, showing the versatility of this market across several high-demand sectors.

Innovation in this market will extend beyond coating materials. Equipment used in the coil-coating process will undergo continued refinement concerning speed, uniformity of coatings, and cure precision. Manufacturers will employ digital monitoring systems, as well as real-time quality assurance tools, that would ensure the optimal performance of every coated coil. Such improvements will stand at the center of changes in terms of how materials are prepared for downstream manufacturing and final use.

Lastly, environmental compliance will create further ramifications in the Global Coil Coating paradigm. Regulatory pressure will enforce tougher emission and material safety requirements, shifting the coating industry towards waterborne, low VOCs, and chrome-free coatings. Manufacturers will put their energies into research to develop these sustainable alternatives without compromising performance; thus, enabling compliance with international standards.

In the years to come, the Global Coil Coating market will evolve through the increasing integration of technology, enhancement of materials, and optimization of manufacturing processes. With emphasis placed on durability, uniformity, and aesthetic gratification, pre-coated coil technologies will become paramount throughout industrial landscapes. Requirement flow from industries, supported by regulatory influence and continued innovation, will give concept direction in order to ensure continued strategic relevance within the coated metals sector.

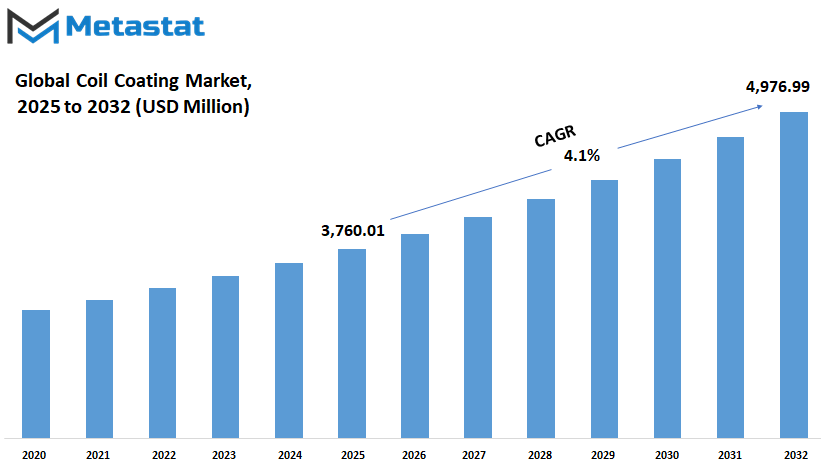

Global Coil Coating market is estimated to reach $4,976.99 Million by 2032; growing at a CAGR of 4.1% from 2025 to 2032.

GROWTH FACTORS

The Global Coil Coating market will see steady growth likely because of increasing demand in many industries such as construction, automobile, and appliances. People and companies, in their quest to replace the materials used with better ones that last longer and require much less maintenance, have come to make coil-coated products popular. These products are well-known for their strength, a consistent finish, and weather and corrosion resistance, particularly in areas where durability and appearance are both equally essential. A lot of companies are looking at waste and energy reduction and coil coating further focuses this with a better approach of attaining efficiency while coating metal.

Growing requirement for environment-friendly practices is one of the major key factors propelling Global Coil Coating market growth. With many governments tightening their noose on pollution and energy use regulations, the manufacturers are resorting to the kind of processes that would help them achieve such standards without the quality cutback. Less of energy and lower emissions are consumed in coil coating as compared to conventional coating methods; this would continue to be effective before industries start adopting eco-friendliness to their operations. Another major driving factor would be the constant advancements in developing new coating materials. This in turn is said to improve performance and cut costs thus providing reason for more companies to adopt the practice.

However, the market also faces certain challenges that would hamper its growth. One of the major issues is the installation of cost-intensive coil coating systems since not every manufacturer can afford such a hefty investment, particularly small businesses. Hence, it may prevent some companies from adopting this new technology even if they understand its long-term benefits. Another constraint is the raw material price instability. Manufacturers find it difficult to plan and remain profitable if the prices of steel or aluminum fluctuate very much at one time. This kind of uncertainty affects the overall market confidence.

Yet, these are strong opportunities, which would likely shape the future of the Global Coil Coating market. The need for good-quality coated materials will increase as more smart building materials and infrastructure projects develop worldwide. More industries are likely to pursue these coatings owing to urban growth and increasing interest in energy-saving solutions. Moreover, increasing research into specialty coatings may open avenues for designing unique products to meet different industry requirements. All this combined will bring a bright future for this market, thereby devising new opportunities with a wider application of coil coating technology across sectors.

MARKET SEGMENTATION

By Resin Type

The Global Coil Coating market is slowly emerging as a game-changing technology for industries in regard to metal finishing and protection. This kind of metal coating is done efficiently and with environmental considerations; hence, it helps to minimize manufacturing waste and conserves energy. As industries have been exploring ways to produce long-lasting yet aesthetically pleasing products, coil coating is gaining acceptance. This is especially true when we observe the changes that have occurred in the market with the various types of resin.

By the year 2025, polyester is slated to dominate the Global Coil Coating market by attaining a value of USD 1,896.43 million. Polyester is often the economical choice, as it provides a balance between performance and cost. It is flexible, retains color, and is resistant to weather effects, thus it has many applications in construction and appliances. Its uptake is ever increasing as manufacturers look at options that last without adding extra cost to the production line.

Fluoropolymer, the product with the highest price tag, is prized for its ability to resist UV light and extreme chemicals and is anticipated to bring in revenues of USD 502.13 million. This resin type is often seen in environments that have intense weather conditions, thus lending protection for a period far exceeding that of any other coating. Its growth will likely continue as more regions across the globe are met with unordinary climates and therefore seek out products that can withstand irregular variations.

Siliconized polyester, which is an important resin type on the market, is set to attain USD 462.08 million. With improved gloss and hardness, this resin is a combination of polyester and silicone. This combination makes it an ideal candidate for applications requiring a nice appearance and scratch resistance. It is a good step-down resin for products that want improved quality without resorting to costly fluoropolymers.

With sales of USD 256.22 million, plastisol is already synonymous with its thick, flexible layer, which provides excellent corrosion protection. Typically used in conditions high in physical wear, it creates a protective barrier that enhances the life of the metal surfaces. Although not the most commonly used, the coating finds high-value application in select niches.

The others category is worth USD 643.14 million, with the aforementioned resin types included. These materials perform several specialized functions and provide certain advantages relevant to specific needs. Their presence in the market indicates that innovations will constantly keep opening new avenues for industries.

The future glory of the Global Coil Coating market is ensured, considering the rising demand for stronger materials and the ability to withstand all. In the near future, as industries continue to march toward efficiency and sustainability, the presence of these coatings will in all likelihood play an even larger role in determining worldwide standards of production.

By Application

The coil coating market is expected to grow exponentially because every industry wants more enhanced surface finishes and better material durability. Coil coating is a process that helps in applying protective layers to metal sheets before its final formation into end products. This process is greatly valued for its efficiency, cost savings, and environmental benefits. These coils when coated in large metals ensure that all materials are ready for construction, appliances, and transport without any further surface treatment.

The future expectation from this is all going to be dependent on increasing its market in terms of the environment and performance in the coming years. The industry will move more toward using energy-efficient materials and long-lasting materials, which will help in increasing the market of coil coating because it reduces the frequency of required repainting and maintenance, thus aligning itself with global objectives focusing on resource use management and environmental responsibility. Eventually, when such awareness spreads over, many more industries will go on adopting coil coating technologies, satisfying customer demands and regulatory standards.

The market is mainly divided into two core areas-steel and aluminum. Steel is used mainly due to its tensile strength and cost effectiveness, whereas aluminum is used because it is lightweight and corrosion resistant. Coil coating offers good advantages to both these materials, which lengthens their lives and attractiveness. As smarter and more efficient materials are being designed for the construction of newer buildings, vehicles, and appliances, the demand for coated metals will continue to grow in an upward trend. Emphasis was first placed on the use of aluminum in most applications, probably because of its lighter weight, especially now when most industries are looking for fuel economy and reduced emissions. Steel on its part would still maintain its importance due to its structural strength.

In short, the future of the Global Coil Coating forms is tied with the current shades of technology and innovation. The demand for smarter coatings will provide better solutions against harsh weather or chemicals. These improvements will result in lower maintenance costs for manufacturers with longer-lasting products. Most likely, there will also be digital systems that will allow more precise application and quality control. It is a smart and reliable way for companies to produce more from less, as coil coating.

The Global Coil Coating Market will evolve at a steady pace in the future, opening doors to more opportunities for industries dependent on steel and aluminum to shape the products of tomorrow with changing demands and an increasing interest in better performance and sustainability.

By End-Use

The coil coating market remains undeniably important for surface protection and enhancement of metal products in various industries. The demand for coil coating will increase as modern infrastructure projects go ahead and product quality expectations rise. Coil coatings are applied to metal coils before use in production, resulting in final products with better performance, durability, and appearance. Industry leans toward this process when they need materials that are strong, yet equally appealing to the eye.

By end-use, the Global Coil Coating market is broadly classified into various end-use markets, of which one of the largest is the Building and Construction. As cities expand and new structures are drawn, the demand grows for the use of pre-coated metals in roofing, wall panels, and other building components. Resistance to the elements and low maintenance costs of coated coils is especially important in areas with rough climates. Therefore, the more energy-efficient and environment-friendly the buildings get, the demand for life cycle contributing coated materials will incite even more. These materials promote long life and waste minimization.

Transportation is another major area for coat coils. The automobile requires both materials that withstand extreme conditions and resist corrosion, while also maintaining reasonable cost and looks. With electric vehicles gaining traction and much focus being placed on method of manufacture, coil coating will prove impactful in meeting those new expectations in automotive parts. There lies much interest in lightweight, yet durable components and pre-coated metals will ably fill that gap.

Coil-coated metals are also employed in the consumer appliances industry widely. Refrigerators, washing machines, and ovens require smooth, durable, and resistant surfaces to heat and moisture. With fast developments occurring in home appliances, materials must continuously improve. Coil coating acts to keep such products valid from both practical and design concerns.

Other end-uses include packaging and general manufacture as strength and surface protection remain paramount. The Global Coil Coating market shall move forward with and evolve alongside these demands for more packable yet nimble efficiency, stylishness, and sustainability.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$3,760.01 million |

|

Market Size by 2032 |

$4,976.99 Million |

|

Growth Rate from 2025 to 2032 |

4.1% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The Global Coil Coating Market is expected to grow steadily as industries across the globe are working toward modernization with greater focus on efficient and long-lasting solutions. In due course, coil coating, recognized for providing strong protection and aesthetic finishes to metal coils, will only become more relevant. Coated metal solutions will, therefore, find a greater place wherever the demand for good materials is concerned; this shifting trend will have an impact on the growth of this market at a slow pace across regions such as construction, automotive, and appliance manufacturing.

There are several geographical regions considered as segments of the Global Coil Coating market, each with progression and focus areas of its own. In North America, the United States leads with a high level of demand within the industries that are upgrading infrastructure and manufacturing processes. Canada and Mexico also participate, largely through the influence of trade agreements and shared industrial objectives. Alternatively, Europe has a heavier focus on sustainability and durable projects that further increases the drive for coated materials. Countries like Germany and the UK focus on energy-efficient buildings that often require long-lasting and low-maintenance metal products.

Asia-Pacific looks to have a bright future ahead. Key enablers include enhanced urban growth and greater investments in manufacturing across countries like China, India, Japan, and South Korea. The demand for materials that are not only affordable but also reliable is on the rise, and coil coating provides that. With ever-increasing emphasis on infrastructure and smart city development in the region, this market will gain even more prominence. In the same way, South America is gradually heating up its market, especially Brazil and Argentina, where the pace of construction and industrial projects is picking up.

The Middle East and Africa are also looking forward to entering this market. The GCC countries, Egypt, and South Africa are investing in new infrastructure projects with an aim to make use of materials capable of withstanding harsh environmental conditions. This naturally pushes demand further for coated metal products.

Looking beyond, the Global Coil Coating Market is likely to enjoy support from technology and shifting consumer consideration patterns. The industries around the world are now gallantly thinking of less wastage and longer-lasting materials with fewer maintenance requirements. These factors tie in very well with the positive effects of coil coating, putting our eyes on this market for the coming few years.

COMPETITIVE PLAYERS

The global coil coating market is likely to drive steady growth in the future from increasing demand from various end-use sectors, coupled with eco-friendly and long-lasting material acceptance. Coil coating is the continuous painting of metal coils before further processing into end products. This might improve the aesthetic part of the metal, but it also prolongs the metal's life by placing it under a protective layer against corrosion, UV rays, and wear. Such coated metals are extensively used in industries such as constructions, automotive and motions and appliances. Growing demand from these industries will automatically lead to increased demand for coil coating.

Future advances in technology will also define the path that coating will take in terms of application, with a greater emphasis on efficiency and the environment. Investment will be directed to water-based and low-VOC (volatile organic compound) coatings to comply with increasing environmental regulations and consumer scenarios for acquiring safer products. Increased climate concern will drive that much more need for coatings that will withstand extreme situations, specifically for infrastructures and energy-related industries. There might be a continuation of further innovations in the market as this grows to possibly introduce smarter coatings that respond to changes in the environment or perhaps improve energy efficiency.

The fact that strong competitive players are present in the Global Coil Coating Market plays an essential role in an industry's development. Key players include AkzoNobel N.V., BASF SE, PPG Industries, Inc., and the Sherwin-Williams Company. They continuously check the upgrade of new products with the expansion of their market presence. Most of these companies usually take the lead in research and development and introduce new solutions into the market that can be more cost-effective and friendly to the environment. Nippon Paint Holdings Co., Ltd., Beckers Group, and Axalta Coating Systems make their attempts as well, focusing on regional needs and adjusting to market demand.

Smaller innovative firms such as JSW Paints, Blygold, and HUEHOCO go further beyond the limits and offer specialty products for certain niche areas of the bigger market spectrum. While this happens, companies like DuPont, Henkel AG & Company, and Wacker Chemie AG improve their footing through expanding their range into multi-functional coatings with better properties. Competition heats up as players forge partnerships, expand their production footprint, and invest in digital technology to enhance operation efficiency while outmaneuvering rivals.

The present trend that is destined to penetrate the Global Coil Coating market will be an increasing focus on customization, smart features, and sustainable practices. Over the years, this will redefine the industries and use of coated materials between them.

Coil Coating Market Key Segments:

By Resin Type

- Polyester

- Fluoropolymer

- Siliconized Polyester

- Plastisol

- Others

By Application

- Steel

- Aluminum

By End-Use

- Building & Construction

- Transportation

- Consumer Appliances

- Other End Uses

Key Global Coil Coating Industry Players

- AkzoNobel N.V.

- BASF SE

- PPG Industries, Inc.

- Sherwin-Williams Company

- Nippon Paint Holdings Co., Ltd.

- Beckers Group

- Axalta Coating Systems

- Wacker Chemie AGCloverdale Paint Inc.

- Kansai Paint Co., Ltd.

- Teknos

- Dörken MKS-Systeme GmbH & Co. KG

- KCC Corporation

- DuPont

- Henkel AG & Company

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252