MARKET OVERVIEW

The Global CFRP Recycle market stands at the forefront of an industry poised to revolutionize the way carbon fiber reinforced polymer (CFRP) materials are managed and repurposed. As the world grapples with mounting environmental concerns and seeks sustainable alternatives, the CFRP recycling industry emerges as a beacon of innovation and practicality.

The Global CFRP Recycle market encompasses a spectrum of activities aimed at reclaiming and reutilizing CFRP materials. These materials, prized for their exceptional strength-to-weight ratio and durability, find extensive applications across diverse sectors, including aerospace, automotive, sports equipment, and construction. However, despite their manifold benefits, the disposal of CFRP waste presents significant challenges due to its non-biodegradable nature and complex composition.

Enterprises within the Global CFRP Recycle market employ cutting-edge technologies and processes to address these challenges effectively. Through advanced sorting, shredding, and chemical treatments, recyclers extract valuable fibers from end-of-life CFRP products, thereby mitigating the environmental impact associated with conventional disposal methods. Moreover, these recycled fibers undergo rigorous quality control measures to ensure they meet industry standards, enabling their reintroduction into manufacturing processes with minimal compromise on performance.

The significance of the Global CFRP Recycle market extends beyond environmental stewardship; it also catalyzes economic opportunities on a global scale. By harnessing the potential of recycled CFRP materials, industries can reduce reliance on virgin resources, thereby mitigating supply chain vulnerabilities and fluctuating raw material prices. Additionally, the emergence of a robust secondary market for recycled CFRP products fosters innovation and competition, driving down costs and expanding access to these sustainable solutions.

Looking ahead, the Global CFRP Recycle market is poised for exponential growth and diversification. Technological advancements, coupled with increasing regulatory pressures and consumer demand for eco-friendly products, will propel the industry towards new frontiers. Innovations in recycling processes, such as pyrolysis and solvent-based techniques, hold promise for enhancing efficiency and scalability, further cementing the position of CFRP recycling as a cornerstone of the circular economy.

Furthermore, collaborations between stakeholders across the value chain, including manufacturers, recyclers, and end-users, will facilitate knowledge sharing and best practices, fostering a conducive ecosystem for sustainable development. As the Global CFRP Recycle market continues to evolve, it will not only redefine the way we perceive waste management but also underscore the pivotal role of collaboration and innovation in addressing global sustainability challenges.

The Global CFRP Recycle market represents a paradigm shift in the management of composite materials, offering a sustainable and economically viable solution to the challenges posed by CFRP waste. Through continuous innovation and collaboration, the industry is poised to drive positive environmental and economic outcomes, shaping a more resilient and resource-efficient future for generations to come.

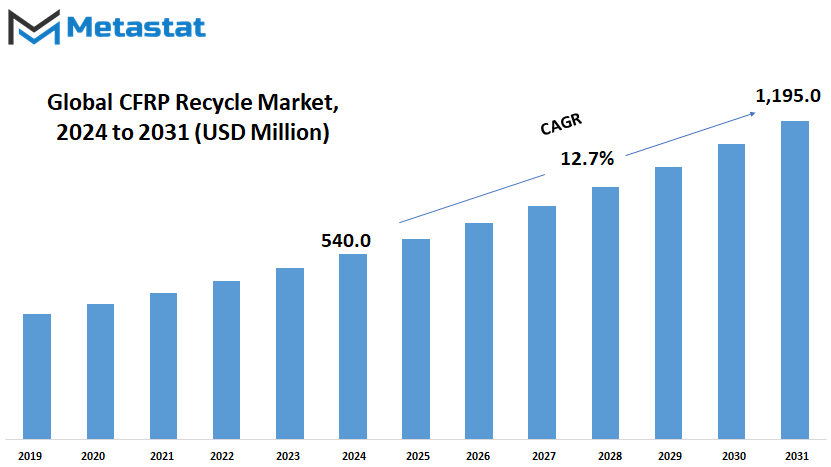

Global CFRP Recycle market is estimated to reach $1,195.0 Million by 2031; growing at a CAGR of 12.7% from 2024 to 2031.

GROWTH FACTORS

The global Carbon Fiber Reinforced Plastic (CFRP) Recycle market is witnessing significant growth due to several key factors. One of the primary drivers is the increasing demand for sustainable and eco-friendly manufacturing practices. As environmental concerns continue to rise, industries are seeking ways to reduce waste and minimize their environmental impact. This has led to a growing need for CFRP recycling solutions, as these materials offer a more sustainable alternative to traditional manufacturing materials.

Additionally, the adoption of CFRP materials is on the rise across various industries such as aerospace, automotive, and wind energy. This increased usage is attributed to the unique properties of CFRP, including its lightweight nature and high strength-to-weight ratio. However, with this increased adoption comes a greater need for recycling solutions to manage end-of-life CFRP products effectively.

While the demand for CFRP recycling solutions is growing, there are several challenges that the market faces. One such challenge is the cost-effectiveness of separating and reclaiming carbon fibers from CFRP composites. Current recycling processes can be expensive and inefficient, limiting their scalability and profitability. Another challenge is the limited infrastructure and technological capabilities for CFRP recycling. This necessitates investments in research and development to improve the efficiency and viability of recycling processes.

Despite these challenges, the market presents significant opportunities for growth. The development of advanced recycling technologies and processes, such as pyrolysis and solvent-based methods, holds promise for enhancing the recovery and quality of recycled carbon fibers. These innovations can address some of the existing limitations of CFRP recycling, thereby expanding the market and promoting sustainability in manufacturing.

In the coming years, the market for CFRP recycling is expected to witness substantial growth as industries continue to prioritize sustainability and seek innovative solutions to reduce their environmental footprint. The adoption of advanced recycling technologies will play a crucial role in driving this growth, offering lucrative opportunities for companies operating in the CFRP recycling sector. Overall, the future of the global CFRP Recycle market looks promising, with sustainable practices driving both environmental and economic benefits.

MARKET SEGMENTATION

By Process Type

In today's dynamic world, where sustainability is becoming increasingly important, industries are constantly seeking innovative solutions to reduce waste and environmental impact. One such area of focus is the Global CFRP Recycle market. CFRP stands for Carbon Fiber Reinforced Polymer, a material known for its strength and lightweight properties, commonly used in various industries such as aerospace, automotive, and construction.

The Global CFRP Recycle market is experiencing significant growth due to the rising demand for sustainable practices across industries. This market revolves around the recycling of CFRP materials to minimize waste and maximize resource utilization. It plays a crucial role in the circular economy, where materials are recycled and reused rather than disposed of after single use.

The market is segmented based on the recycling process, which includes Chemical Process and Physical Process. Chemical Process involves the use of chemical agents to break down CFRP materials into their constituent components, which can then be reused in manufacturing processes. On the other hand, Physical Process involves mechanical methods such as shredding and grinding to break down CFRP materials into smaller pieces, which are then repurposed or used as raw materials in other applications.

Both Chemical and Physical Processes offer unique advantages and challenges. Chemical Processes typically yield high-quality recycled materials, but they can be more complex and expensive to implement. Physical Processes, on the other hand, are simpler and more cost-effective but may result in lower-quality recycled materials.

Moreover, increasing awareness and government initiatives to promote sustainable practices will create new opportunities for market expansion. Regulations mandating the use of recycled materials in manufacturing processes and incentivizing recycling practices will further accelerate market growth.

By End User

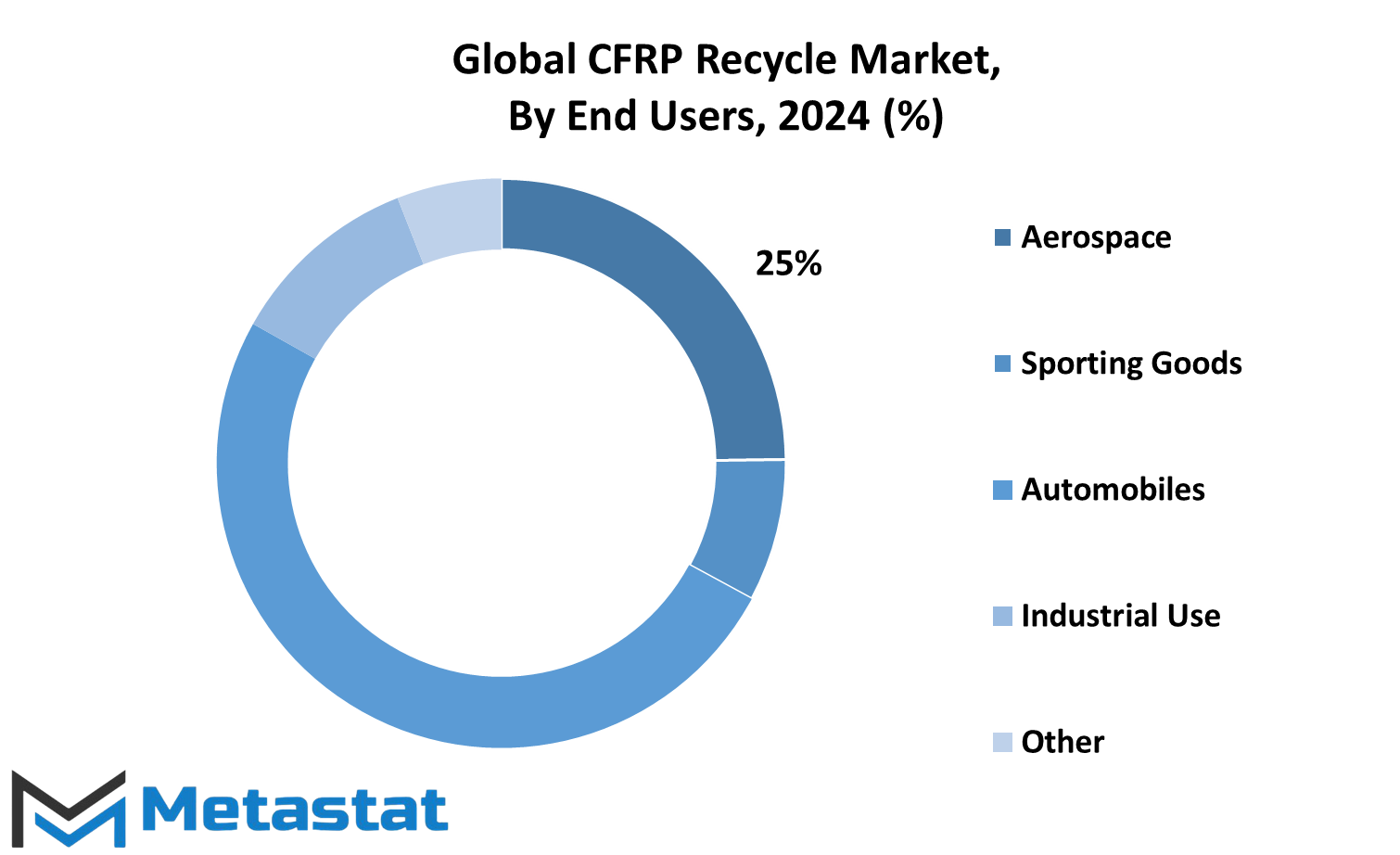

In the global Carbon Fiber Reinforced Plastic (CFRP) Recycle market, the end users are categorized into several segments: Aerospace, Sporting Goods, Automobiles, Industrial Use, and Other Applications. This segmentation helps in understanding how CFRP recycling is utilized across various industries.

The Aerospace sector is a significant player in the utilization of CFRP materials. With the ongoing advancements in aerospace technology, the demand for lightweight yet strong materials like CFRP is expected to increase. This is because CFRP offers high strength-to-weight ratio, making it ideal for aircraft components, thereby enhancing fuel efficiency and reducing emissions. As the aerospace industry continues to innovate, the demand for CFRP recycling solutions will rise accordingly.

Sporting Goods is another sector that extensively utilizes CFRP materials. From bicycles to tennis rackets, CFRP is favored for its durability and performance-enhancing characteristics. As the sporting goods industry witnesses continuous growth, especially with the rising popularity of fitness and recreational activities, the demand for CFRP recycling solutions will follow suit. This is because sustainability is becoming a key focus for consumers, leading manufacturers to adopt eco-friendly practices, including the recycling of materials like CFRP.

Automobiles represent a significant market for CFRP recycling. With the automotive industry shifting towards electric vehicles (EVs) and lightweighting strategies to improve fuel efficiency and reduce carbon emissions, CFRP materials are gaining traction for various automotive components. CFRP recycling will play a crucial role in supporting the sustainable manufacturing of vehicles, as it enables the reuse of materials and reduces the environmental impact of production processes.

Industrial Use encompasses a wide range of applications, including construction, infrastructure, and consumer goods. CFRP materials are valued for their strength, corrosion resistance, and versatility, making them suitable for diverse industrial applications. As industries prioritize sustainability and circular economy practices, the demand for CFRP recycling solutions will grow to meet the need for resource efficiency and waste reduction.

Other Applications refer to sectors beyond the aforementioned categories, such as marine, renewable energy, and consumer electronics. These sectors also utilize CFRP materials for various purposes, ranging from wind turbine blades to smartphone casings. As technological advancements continue to drive innovation across industries, the demand for CFRP recycling solutions will expand to accommodate the evolving needs of diverse applications.

By End-user

The Global CFRP Recycle market is seeing significant growth, with various end-users driving demand. These end-users include Automotive, Aerospace and Defense, Wind Energy, Sporting Goods, and Other sectors. This growth is projected to continue in the future.

The Automotive sector, one of the major end-users, will play a crucial role in the expansion of the Global CFRP Recycle market. With increasing emphasis on lightweighting to improve fuel efficiency and reduce emissions, automakers are increasingly turning to carbon fiber reinforced polymers (CFRP). These materials offer high strength-to-weight ratio, making them ideal for enhancing vehicle performance. As the automotive industry shifts towards electric vehicles (EVs) and autonomous vehicles (AVs), the demand for CFRP in vehicle structures and components will only rise.

Similarly, the Aerospace and Defense sector will also contribute significantly to the growth of the CFRP Recycle market. Aircraft manufacturers are increasingly utilizing CFRP composites in aircraft structures to reduce weight and enhance fuel efficiency. Moreover, CFRP's high strength and corrosion resistance make it an attractive choice for defense applications, such as military aircraft and vehicles. As the aerospace industry continues to innovate and develop next-generation aircraft and defense systems, the demand for CFRP recycling solutions will increase to manage end-of-life CFRP components effectively.

The Wind Energy sector is another key driver of the CFRP Recycle market. Wind turbine blades, which are typically made of CFRP composites, have a limited lifespan due to wear and tear from harsh environmental conditions. As the global wind energy capacity continues to expand to meet renewable energy targets, the volume of decommissioned wind turbine blades requiring recycling will increase. Recycling CFRP from wind turbine blades will not only mitigate environmental impact but also provide valuable feedstock for manufacturing new composite materials.

Additionally, the Sporting Goods industry presents opportunities for CFRP recycling. High-performance sporting equipment, such as tennis rackets, golf clubs, and bicycles, often incorporate CFRP to improve durability and performance. As consumer demand for lightweight and high-performance sporting goods grows, the need for sustainable end-of-life solutions, such as CFRP recycling, will become more pronounced.

Furthermore, the Other category encompasses various sectors, such as marine, construction, and infrastructure, where CFRP materials find diverse applications. As these industries continue to adopt CFRP composites for their unique properties, the demand for CFRP recycling solutions will expand accordingly.

REGIONAL ANALYSIS

The global market for CFRP recycling is analyzed based on different regions around the world. These regions include North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

North America is a significant player in the global CFRP recycling market and is further divided into the United States, Canada, and Mexico. The United States, being one of the largest economies globally, will continue to drive growth in the CFRP recycling market due to its strong industrial base and increasing focus on sustainability.

Europe, another key region in the global CFRP recycling market, comprises countries such as the United Kingdom, Germany, France, Italy, and the Rest of Europe. These countries have well-established automotive and aerospace industries, which are major consumers of CFRP materials. The adoption of stringent environmental regulations in Europe will further boost the demand for CFRP recycling in the region.

Moving to the Asia-Pacific region, which includes India, China, Japan, South Korea, and the Rest of Asia-Pacific, we see rapid industrialization and urbanization driving the demand for CFRP materials. China, as a manufacturing hub, will play a crucial role in the growth of the CFRP recycling market in the region. Additionally, Japan and South Korea, known for their advanced technology and innovation, will contribute significantly to market expansion.

In South America, Brazil and Argentina are the prominent markets for CFRP recycling. The automotive and aerospace industries in these countries will drive the demand for recycled CFRP materials. The Rest of South America is also expected to witness growth in CFRP recycling activities, driven by increasing awareness of environmental sustainability.

The Middle East & Africa region, which includes GCC Countries, Egypt, South Africa, and the Rest of Middle East & Africa, is also emerging as a potential market for CFRP recycling. The region's growing construction and infrastructure sectors will drive the demand for recycled CFRP materials, supported by government initiatives promoting sustainable practices.

The global CFRP recycling market is segmented into various regions, each offering unique opportunities and challenges. As industries worldwide embrace sustainability, the demand for recycled CFRP materials will continue to grow across different geographical regions.

COMPETITIVE PLAYERS

The global Carbon Fiber Reinforced Plastic (CFRP) Recycle market boasts several competitive players driving innovation and sustainability in the industry. Leading the pack are Carbon Conversions, Inc., Gen 2 Carbon Limited, Mitsubishi Chemical Holdings Corporation, The Japan Carbon Fiber Manufacturers Association, Carbon Fiber Remanufacturing, The Composite Recycling Technology Center (CRTC), Adherent Technologies Inc., HADEG Recycling GmbH, Procotex Corporation SA, SGL Carbon SE, Carbon Fiber Recycling, Inc., Sigmatex, Toray Industries Inc, Vartega Inc, ACMA (American Composites Manufacturers Association), Carbon Recycling International, and Recykal.

These key players are instrumental in shaping the future of CFRP recycling, utilizing advanced technologies and sustainable practices to address the growing demand for eco-friendly solutions. With a focus on circular economy principles, they are committed to reducing waste and maximizing the value of recycled materials in various industries, including aerospace, automotive, and construction.

Carbon Conversions, Inc., for instance, specializes in converting carbon fiber scrap into usable products, offering cost-effective solutions for manufacturers looking to minimize their environmental footprint. Gen 2 Carbon Limited, on the other hand, leverages innovative recycling techniques to produce high-quality recycled carbon fiber materials suitable for a wide range of applications.

Mitsubishi Chemical Holdings Corporation plays a pivotal role in advancing the recycling infrastructure for CFRP materials, investing in research and development to improve recycling efficiency and quality. Similarly, The Japan Carbon Fiber Manufacturers Association promotes collaboration among industry stakeholders to establish standardized recycling processes and enhance the sustainability of carbon fiber production and usage.

The Composite Recycling Technology Center (CRTC) serves as a hub for innovation in CFRP recycling, fostering partnerships between academia, industry, and government agencies to drive technological advancements and promote the adoption of recycled carbon fiber materials.

Adherent Technologies Inc. and HADEG Recycling GmbH focus on developing novel recycling technologies that enable the recovery of valuable carbon fiber components from composite waste streams. Procotex Corporation SA and SGL Carbon SE specialize in processing recycled carbon fiber materials into high-performance products tailored to specific customer requirements.

Carbon Fiber Recycling, Inc., Sigmatex, and Toray Industries Inc. are renowned for their expertise in carbon fiber manufacturing and recycling, contributing to the establishment of a closed-loop supply chain for CFRP materials. Vartega Inc., ACMA, Carbon Recycling International, and Recykal are actively involved in promoting awareness and adoption of sustainable practices in the composites industry, driving market growth and environmental stewardship.

The competitive landscape of the global CFRP Recycle market is characterized by a diverse array of players committed to driving innovation, sustainability, and circularity in the industry. Through collaboration and investment in advanced recycling technologies, these key players will continue to shape the future of CFRP recycling, paving the way for a more sustainable and resilient materials economy.

CFRP Recycle Market Key Segments:

By Process Type

- Chemical Process

- Physical Process

By End User

- Aerospace

- Sporting Goods

- Automobiles

- Industrial Use

- Other Applications

By End-user

- Automotive

- Aerospace and Defense

- Wind Energy

- Sporting Goods

- Other

Key Global CFRP Recycle Industry Players

- Carbon Conversions, Inc.

- Gen 2 Carbon Limited

- Mitsubishi Chemical Holdings Corporation

- The Japan Carbon Fiber Manufactures Association

- Carbon Fiber Remanufacturing

- The Composite Recycling Technology Center (CRTC)

- Adherent Technologies Inc.

- HADEG Recycling GmbH

- Procotex Corporation SA

- SGL Carbon SE

- Carbon Fiber Recycling, Inc.

- Sigmatex

- Toray Industries Inc

- Vartega Inc

- ACMA (American Composites Manufacturers Association)

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383