MARKET OVERVIEW

In the coming years, the Global Bearing market is bound to witness enormous progress due to several technological innovations and growing requirements in various sectors. With the continued development of modernized industries worldwide, the bearings will be increasingly integral to the future improvement of productivity and performance by machines. Since these mechanical components reduce friction in moving parts, they are to be in ever-growing demand from a wide scope of sectors - from automotive, aerospace, and energy.

Among the trends currently dominating the market is the intelligent bearing. As more and more industries adopt IoT and automation, bearings will continue integrating sensors and advanced materials to allow for real-time monitoring and predictive maintenance. The technology developed in the bearing will make it an integral part of modern industrial operation by reducing downtime as well as extending its life cycle. Smart bearings will detect wear and tear before a possible failure occurs. This will significantly give manufacturers a reliable tool for the maintenance of machinery without failure. This new trend will revolutionize certain industries, especially those in the automotive and manufacturing sectors, where efficiency plays a paramount role.

High-performance bearings will also take up more due to the growth sectors like aerospace and energy continue to gain. Aerospace, for example demands bearing that can withstand high speed and temperature levels. In this regard, the development of bearing materials that can absorb such extreme environments will lead to a market for specialty and custom-designed bearings. These high-tech bearings will be the future of fuel-efficient engines and other advanced technologies, especially as airlines and aviation companies seek to cut costs while increasing performance.

The energy sector, particularly in wind and solar power, will also drive innovation in bearing technology. As renewable energy sources become more mainstream, the demand for bearings that can perform reliably in harsh environmental conditions will increase. Manufacturers of wind turbines, for example will look at bearings which can take on more load while remaining smooth and running for a long time. These would be the improvements that will help renewable energy systems remain economical as well as performance-based in the long run.

In the near future, environment-friendly and sustainable bearings in the Global Bearing market will also shoot through the roof. More and more industries are looking to save on carbon footprints, thus bearings will also have to be designed to be recyclable and energy-efficient along with being produced from ecologically friendly material. Manufacturers would have to go for greener production methods while incorporating sustainable material into the design of their bearing. This is in line with broader global efforts to combat climate change and environmental impact.

Automotive industry is going to remain one of the largest drivers of the growth in the Global Bearing market. With the advent of electric vehicles, the need for bearings is likely to be greater, because bearings for the electric drivetrain require specific applications and higher load-bearing capacity to ensure efficiency without any energy losses. In addition, the growing requirement for self-driving vehicles will result in a demand for high-precision bearings with an ability to sustain the distinct operating conditions of autonomous vehicles.

In summary, the Global Bearing market will see drastic change in the near future. Technological advancement, drive for sustainability, and increased demand from different industries fuel this change. Thus, bearings will keep changing to overcome new challenges and ensure that machinery functions more smoothly. Their importance will increase in relation to these new technologies as they shape the future of the world's industries.

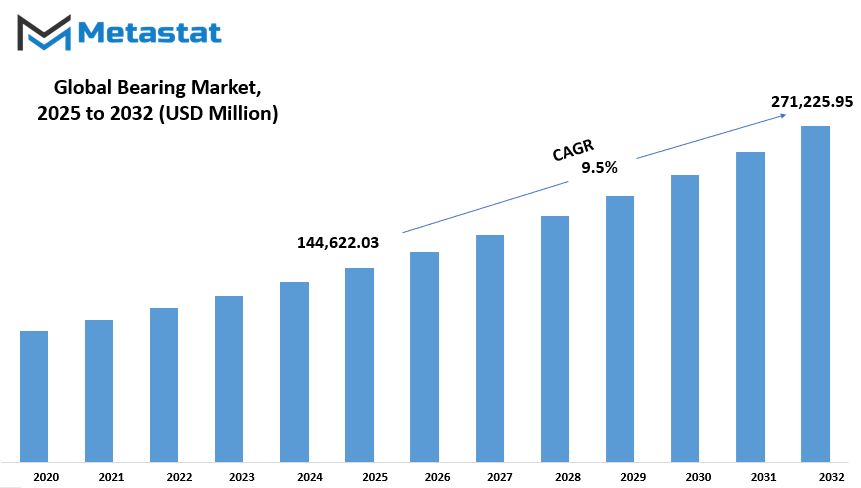

Global Bearing market is estimated to reach $271,225.95 Million by 2032; growing at a CAGR of 9.5% from 2025 to 2032.

GROWTH FACTORS

The global bearing market has been surging over the past few years, with some factors that made this happen. One of them is industrial automation, which applies high-performance bearings. Manufacturing industries, robotics industries, and others in logistics always need accurate components like bearings, ensuring smooth movement and efficiency throughout their operations. All these drive the demand for bearings that may endure higher load, faster speeds, and some challenging environments.

Another important driver of the market is the rapid growth of the automobile industry with the boost in electric vehicles. Going forward, the world is shifting towards more environmentally friendly modes of transportation. Due to this reason, the demand for electric vehicles is increasing and with it, the demand for bearings. Bearings will find an important application in electric vehicles, from motors to wheels, assuring all vehicle actions to be smooth and efficient. Thus, as electric vehicles increase, the demand for bearings will rise to support this new generation.

The growth drivers are strong, but what challenges the bearing market also faces is volatility in raw material prices, which escalates the production cost. Materials, such as steel or other metals, are a fundamental necessity in making bearings; a change in price causes fluctuations in production costs. This kind of volatility leads to unstable pricing of products and challenges the manufacturer's competitiveness in the market.

Further, maintenance costs for bearings also create hindrances to growth in the market. In bearings, particularly the ones in heavy machinery and industries, the necessity of periodic maintenance cannot be eliminated to make it perform well. As time goes by, efficiency deteriorates from wear and tear, leading to higher idle periods and the resultant repair and replacement costs. The problems created through these maintenance operations will negatively impact efficiency and further delay adoption of bearings in those sectors.

On the brighter side, there are emerging opportunities in the market. One such opportunity is the increasing adoption of smart bearings integrated with the Internet of Things (IoT). Smart bearings allow for real-time performance monitoring, which can help detect issues before they lead to failure. This technology provides valuable data for predictive maintenance, improving the lifespan and efficiency of bearings. The adoption of smart technology in more industries will boost the demand in the bearing market, giving viable growth in the future years.

MARKET SEGMENTATION

By Type

This global bearing market is heterogeneous. Many kinds of bearings form parts of it that increase the business and grow exponentially. The prime objective of this category of bearing is to prevent friction between contact points while smooth operating machines, mechanical tools, etc., as per industry and field requirements. Of the leading market share areas of the overall bearings, there exists one crucial ball bearing that solely represents this huge size value: approximately $52,110.36 million. Ball bearings are widely used because of their ability to handle both radial and axial loads, making them essential for applications ranging from automotive to industrial machinery.

The other essential type is the roller bearing, which is meant to carry heavy loads radially better than ball bearings. These bearings make use of cylindrical rollers instead of balls, that can be used in distributing loads. These are thus suitable for high load-bearing applications. Roller bearings come in tapered, spherical, and needle bearings among others providing various benefits depending on the particular requirement of an application.

Another major component of the global bearing market is plain bearings. Unlike ball or roller bearings, plain bearings do not employ rolling elements; instead, a smooth surface supports sliding motion. Plain bearings are known for simplicity and cost effectiveness. They work well in areas where space cannot be afforded and where maintenance will be limited. Plain bearings can be found in most automotive engines, construction equipment, and many household appliances.

Fluid bearings, conversely, function by separating moving parts with a thin layer of fluid. They significantly reduce friction. This is used in various applications where precise machinery requires reduced friction for optimal operation, for example, turbines and high-speed machinery. This fluid acts like a cushion in preventing the actual contact between two surfaces, giving it a potential for higher performance with less wear and tear.

Magnetic bearings have also become popular because they are able to use magnetic fields to support the shaft without physical contact. These bearings are particularly useful in high-speed or highly sensitive equipment where traditional bearings might fail due to excessive wear. Magnetic bearings are often used in cryogenic systems, motors, and generators.

The global bearing market is diverse, with each type of bearing boasting unique benefits if the needs of the application. Always in demand for better efficiency and performance, such a requirement has sustained the growth of the bearing market across industries.

By Material

The global bearing market is categorized into three types based on material: steel bearings, ceramic bearings, and plastic bearings. Each of these materials gives unique characteristics to make them suitable for different applications. This influences the overall performance and demand in the market.

Steel bearings are widely used in numerous industries and come in a large variety. Their strength, endurance, and resilience to heavy loads and high-speed operations make them one of the most common choices. Steel bearings are found widely in the automobile, industrial, and aerospace fields, where efficiency and reliability become critical. In fact, they are widely utilized because they prove to be the most cost-effective option and perform well under extremely challenging working conditions.

Another option that is acquiring popularity is ceramic bearings, because it exhibits excellent qualities in terms of corrosion resistance, frictional torque, and the very high performance at extreme temperatures. The applications of ceramic bearings are mostly at high precision and high-speed application, such as aerospace, medical, and some advanced industrial sectors. Their ability to run smoothly in the presence of harsh environments makes them top in all application areas. Although more expensive than steel, ceramic bearings perform well in niche applications where the additional investment is worthwhile.

Plastic bearings, consisting of nylon and polyester-based materials, are another significant category of bearings sold. These bearings are light, low friction and corrosion-resistant, and therefore ideal for applications where both weight and cost are high. Plastic bearings are available in various industries, including electronics, automotive, and food processing, to provide excellent performance at lower cost when compared with metallic bearings. They are also used where noise is a major concern due to the silent operations of plastic bearings compared to steel or ceramic bearings.

Each of the materials available in the bearing market has some specific application, thus providing distinctive advantages to meet different needs of diverse industries. The demand for these materials depends on the requirements of the application, cost considerations, and performance expectations. Inevitably, with the constant evolution of industries, the bearing market will be filled with even more innovative and advanced materials for companies to consider. The combination of steel, ceramic, and plastic bearings ensures that industries have access to the right solutions for their diverse needs, driving growth and development in the global bearing market.

By End User

The global bearing market is diverse, with applications spanning across multiple industries. These industries use bearings in various machinery and equipment to support moving parts, reduce friction, and ensure smooth operation. One way to categorize the bearing market is by end user, as it plays a key role in determining the type of bearing required, its specifications, and its intended purpose. The market can be divided into automotive, aerospace, industrial machinery, construction equipment, and energy and power.

In the automotive industry, bearings play a great role because they reduce friction between moving parts, which improves performance and fuel efficiency. They are used in vehicles such as cars, trucks, and motorcycles, so they are necessary for good driving and to ensure safety. The more modern the automotive industry becomes, the more probable it is that advanced bearings will be required, which shall offer a longer lifespan with the better efficiency and resisting wear and tear.

Another big consumer of the bearings market is the aerospace sector. In an aircraft engine, bearings are utilized along with other key components. Its performance requirement must be quite tough since its failure may bring dire consequences. And as air travels increase all over the world, the high performance bearings would increase in demand also. Aircraft manufacturers and maintenance providers have lately been considering bearings that could tolerate extreme conditions such as extreme temperature and extreme pressure.

In industrial machinery, bearings provide for the smooth functioning of the machines used in manufacturing, processing, and packaging. Bearings decrease the need for constant maintenance, thereby ensuring operations will run smoothly even in heavy-duty equipment. The demand for bearings that can efficiently operate in automated systems and robotics will grow as industrial automation spreads. The need is prompted by the demand for increased productivity and precision in manufacturing.

Construction equipment, including cranes, bulldozers, and excavators, is significantly dependent on bearings for smooth operation. Construction machinery requires durable bearing performance for heavy loads and other environmental stresses during operation. As the infrastructure development and construction industries continue to expand around the world, the need for bearings will grow in parallel for larger and more powerful machinery.

The energy and power sector widely employs bearings in equipment like turbines, generators, and power transmission systems. Most machinery requires bearings to work at full efficiency for minimal downtime. As the world looks to renewable energy sources, the demand for bearings in wind turbines and other renewable energy infrastructure will increase, as such equipment needs to be strong enough to handle energy generation.

Concluding, the global bearing market can be segmented into several end-user industries with particular demands and requirements. The expansion and development of these industries will include automotive, aerospace, industrial machinery, construction equipment, energy, and power, which would drive the demand for more specific and advanced bearing technologies. These sectors will grow, and bearings will remain integral to smooth running and reliability across a wide variety of applications.

By Distribution Channel

On a global scale, the bearing market can be split according to distribution channels, in which the companies that distribute and sell these goods are very relevant to how people receive them. These distribution channels are direct sales, distributors and wholesalers, and online retail.

The most simplified of these will be direct sales, where bearing manufacturers sell these products directly to the end-user. This is advantageous because it gives companies a direct relationship with the customers and makes sure that the products offered will meet the set requirements. A direct sale tends to bring about higher margins in profit because it does not incur the middleman's cut and can be quite streamlined. Additionally, direct communication between the manufacturer and the customer will help to offer personalized services, which is of high value in industries relying on precision bearings.

Distributors and wholesalers are also very important in the bearing market. They purchase bearings in large quantities from manufacturers and sell them to retailers or other companies. This channel helps expand the reach of bearing manufacturers to a wider market. Distributors and wholesalers often have established networks, which facilitate the distribution of products across multiple regions. In fact, distributors and wholesalers often serve as necessary links to distribute products to small businesses or to customers who could not buy significant quantities directly from manufacturers. Most of the value-added services are also provided, such as storage, packaging, and delivery. This simplifies the supply chain for both the manufacturer and consumer.

Of course, online selling of bearings is gaining much importance in the global bearing market particularly in recent times with the trend of most consumers and businesses shifting to Internet-based buying and selling. Online retail allows convenience to the purchaser from the comfort of homes or workplaces. This e-marketplace provides product descriptions in great detail along with reviews and variations in price enabling better decision-making by a consumer. From a manufacturer's standpoint, selling on the Internet lowers the demand for physical stores as well as costs associated with maintaining them. Furthermore, online retail allows manufacturers access to global markets, markets from which they otherwise would not gain access.

All these distribution channels have their strengths, and most companies use a combination of these to maximize their reach in the market. Businesses can cater to a wide range of customers and enhance their position in the global bearing market by using direct sales, distributors and wholesalers, and online retail. These channels will remain important for shaping the growth and success of the industry in the future.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$144,622.03 million |

|

Market Size by 2032 |

$271,225.95 Million |

|

Growth Rate from 2024 to 2031 |

9.5% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

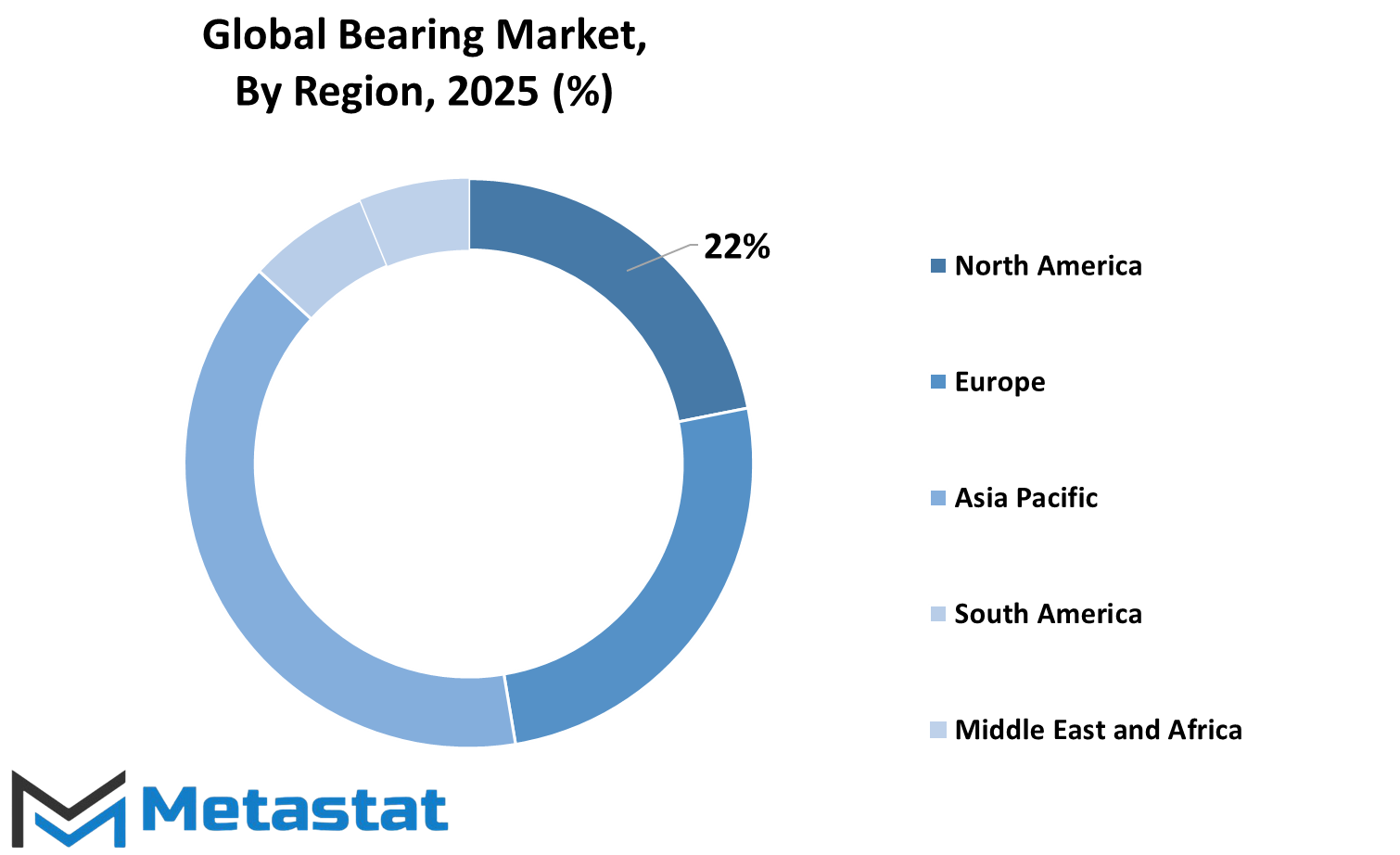

The global bearing market is further segmented geographically into five major regions, that is, North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. This has been divided further to enable a better look at the market dynamics and how consumers behave within specific countries.

The region of North America is further divided into the three major countries: U.S., Canada, and Mexico. Most of the demand in these countries comes from the sophisticated manufacturing industries, such as automotive, aerospace, and machinery. The U.S. country alone dominates the bearing market, being the largest economy in this region. This country continues to witness steady improvement in technology and production processes that keep it moving forward. Automotive and mining sectors remain crucial to the bearing markets of Canada and Mexico.

Its key countries include the UK, Germany, France, and Italy, along with the rest of Europe. Germany is one of the largest markets for bearing, as it boasts heavy manufacturing and industrial production. Britain and France also possess a strong industrial base, contributing significantly to demand in the automotive and machinery sectors. Italy is the prime country for manufacturing high-quality bearings, which find application in industrial fields. Other countries in Europe, such as Spain and Poland, also help the market increase its share in terms of growth in industrial production.

Asia-Pacific is a highly developing region. It accounts for a large part of the world's bearing market. This includes India, China, Japan, and South Korea, with China being the major contributor. Mass demand in China is motivated by the country's high booming manufacturing sector, particularly automotive and heavy machinery industries. Japan and South Korea also contribute to this demand, especially in technology-driven industries. India, with its growing industrial base, is developing into a vital market for bearings as well. The rest of Asia-Pacific, including Thailand and Indonesia, is promising for the bearing sector due to growing industrial and construction activities.

South America is home to Brazil and Argentina. The remaining portion of South America contributes to the market. Among all these, Brazil is the leading country with growing demand in the automobile and industrial sectors for bearings. Argentina, although relatively small in size, still makes a regional market contribution by way of its manufacturing and agriculture-based industries.

Lastly, the Middle East & Africa is further split into GCC countries, Egypt, South Africa, and the rest of the Middle East & Africa. GCC countries like Saudi Arabia and the UAE are large consumers of bearings. They are led by the oil and gas, construction, and manufacturing industries. Egypt and South Africa are important African countries, where industrial activities in mining and automotive sectors are picking up pace. The rest of the region is beginning to slowly grow in bearing demand as economies diversify and industrialize.

COMPETITIVE PLAYERS

The global bearing market is the largest part of the machinery and automotive sectors because it provides support for rotating parts in most machines. Bearings provide a means to reduce friction among moving parts; hence, their importance cannot be underestimated for the smooth operation of various industries. The leading companies in the bearing industry include established firms such as SKF Group, Schaeffler AG, The Timken Company, NSK Ltd., NTN Corporation, JTEKT Corporation, RBC Bearings Incorporated, THK Co., Ltd., Nachi-Fujikoshi Corp., C&U Company Limited, ZWZ Bearing, and Luoyang LYC Bearing Co., Ltd.

SKF Group is a Swedish multinational company and among the leading firms in the bearing industry. SKF is one of the world's leading producers of bearings and services, providing innovative technologies and high-quality products to industries ranging from automotive to industrial machinery. Another giant in the industry is Schaeffler AG, based in Germany, which has a wide variety of bearings designed for automotive, aerospace, and industrial applications. The Timken Company, in the U.S., is another market leader and holds a high market share position in tapered roller bearings and other bearings for heavy machinery.

NSK Ltd. and NTN Corporation are two significant Japanese companies which contribute to the global bearing market. Both have a wide variety of bearings to cater to diverse sectors, where performance and reliability are given immense importance. The other Japanese company is JTEKT Corporation, which is highly recognized for having a wide bearing portfolio that serves automotive and industrial machinery. Another American manufacturer, RBC Bearings Incorporated, is also an important player, especially in aerospace and defense sectors, providing precision bearings for a variety of applications.

Other significant players include THK Co., Ltd. of Japan, which is renowned as a producer of linear motion systems, and Nachi-Fujikoshi Corp., which has a bearing range covering almost all types of bearings for different applications. C&U Company Limited, ZWZ Bearing, and Luoyang LYC Bearing Co., Ltd. are the top companies in China that provide high-class bearings and have significantly contributed to the growth of the global bearing market.

This has led the leading companies into a competitive space, ensuring constant innovation in this market. Improving product performance, durability, and expanding markets across the world are some of the objectives among these players so as to stay ahead in capturing the ever-increasing demand in the automotive, manufacturing, and aerospace industries. These companies help shape the bearing industry's future and its value to the economy of the world.

Bearing Market Key Segments:

By Type

- Ball Bearings

- Roller Bearings

- Plain Bearings

- Fluid Bearings

- Magnetic Bearings

By Material

- Steel Bearings

- Ceramic Bearings

- Plastic Bearings

By End User

- Automotive

- Aerospace

- Industrial Machinery

- Construction Equipment

- Energy and Power

By Distribution Channel

- Direct Sales

- Distributors and Wholesalers

- Online Retail

Key Global Bearing Industry Players

- SKF Group

- Schaeffler AG

- The Timken Company

- NSK Ltd.

- NTN Corporation

- JTEKT Corporation

- RBC Bearings Incorporated

- THK Co., Ltd.

- Nachi-Fujikoshi Corp.

- C&U Company Limited

- ZWZ Bearing

- Luoyang LYC Bearing Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383