MARKET OVERVIEW

It is the Global Automatic Clipping Machine market which is growing with its industry beyond traditional applications and propagating the redefinition of efficiency and automation across the various sectors. It has been used basically in food processing, packaging, and even industrial manufacturing, while in fact, it will touch the automation of many different, unexpected aspects. Machinery design has advanced technologically, and the need for operational streamlining will expand the future horizon of machine uses beyond conventional expectations.

While automation has been a key tenet of industrial progress, the advent of smart technology has steadily evolved the role of automatic clipping. Intelligent sensors and data feeds will further refine operational capabilities for manufacturers wanting more precision and efficiency in application. Machines will also have a role in predictive maintenance strategies, thus cutting down on downtime and maximizing productivity along with performing the mechanical functions. Industry processes will now leverage real-time analytics to optimize processes beyond just increasing output from automation.

The Global Automatic Clipping Machine market will have implications for sustainable initiatives as well. The efforts for eco-conscious packaging and waste reduction will lead to more machines that comply with strict environmental regulations in their manufacture. These machines will incorporate future features such as energy efficiency and support for biodegradable materials that help industries meet the demands of tomorrow's consumer for sustainability. Thus, with responsible manufacture, automatic clipping machines will play an important part in redefining standards of industrial packaging.

In the future, these machines will be infiltrating new sectors that were previously untouched, as in the example of the real estate business, where they will perform an immeasurable transformation. The pharmaceutical and medical sciences, for example, will see a revolution in their arena by automation that enables contamination-free, accurate packaging, all around hygiene levels. By placing such incredibly hygiene requirements, the need for contamination-free sealing will increase the need for clip solutions. The agricultural field, similarly, will experiment with more with automated clipping for produce packaging, reducing dependence on manpower while providing integrity to products.

The Global Automatic Clipping Machine market would also bring about a change in the way the workforce is organized. Not only will work involve the use of machines taking the place of human effort but also through machine-efficient operation, skilled people can move into higher-value tasks instead of carrying out their work in the repetitive tasks. Such changes testify to the requirement for more technicians who would be able to manage automated systems as industries move towards intelligent manufacturing. Training courses and workforce adaptation strategies would therefore fulfill an important role in integrating these machines within broader production systems without disruption in employment structures.

The next big redefinition by technology evolution will greatly be on the design structure of automatic clip machines. Modular and adaptable configurations would allow industries to customize their automation processes, therefore reducing dependency on rigid systems. Such companies would seek flexible solutions which could also be integrated with existing machinery to create seamless production lines meeting diverse operational requirements. A cross-product upgrade by software enhancement would crucially determine product life cycles and efficiency maintenance.

While advancing in the direction of automation, it is global regulations that will work the future of the Global Automatic Clipping Machine market. Safety measures and precision-based mechanisms are the latest global requirements that each manufacturer should adopt due to industry change and thus ensure that the manufacturer complies at least with his country's international standards. The adaptability of machines will entail their ability to change with the shifting regulatory environment in the long run for being viable within cut-throat competitive markets.

In the future, the matched efficiency and automation with environmental responsibility will guide the path the market trends take, broadening the context within which automatic clipping machines will eclipse their erstwhile mainstream applications in light of new models for smart and sustainable production.

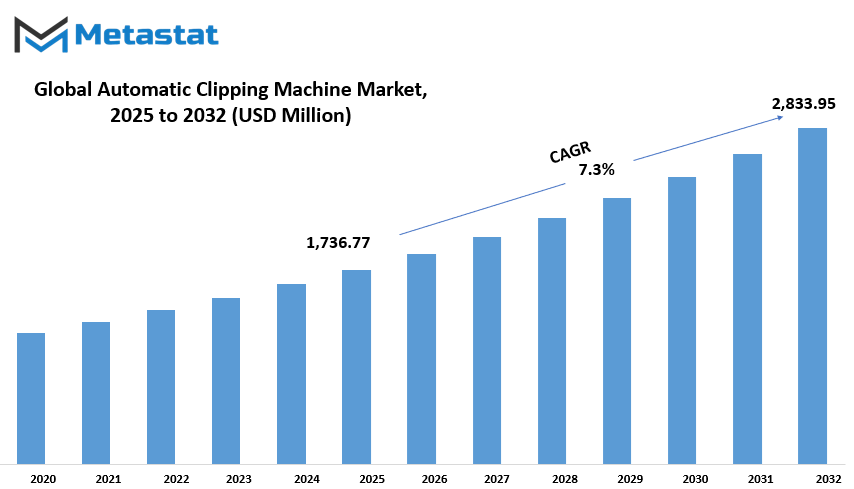

Global Automatic Clipping Machine market is estimated to reach $2,833.95 Million by 2032; growing at a CAGR of 7.3% from 2025 to 2032.

GROWTH FACTORS

The Global Automatic Clipping Machine market is on a steady growth curve owing to the food-processing demand coming with a challenge of high labor costs. These machines were designed to increase efficiency with reduced processes performed by humans and thus became fundamental in industries requiring fast and accurate packaging solutions. As companies look to integrate streamlined operations, automatic clipping is the trustworthy alternative that promises constant product quality and minimum human intervention.

High food processing automation demand is the main force driving this market. With the rise in population all over the world and a growing number of consumers asking for packed food products, food manufacturers must find a way to empower productivity but maintain quality. Automatic clipping machines achieve this aim by efficiently sealing foodstuff, maintaining freshness, and prolonging shelf life. In addition, labor shortages in several regions have pushed companies to invest in automation, thus making this technological solution a viable choice for companies that want to maintain production with constraints of labor.

However, there are some hindrances facing the growth of this market. The hefty initial investment needed for these machines is a high barrier, especially for small and medium companies. Many companies would shy away from investing heavily in automation when their production volume does not justify such costs. Moreover, maintenance issues and operational difficulties add to the list of concerns. These machines need maintenance and any breakdown could lead to production disruptions and downtime, further contributing to possible loss. The company should evaluate the benefits of automation against the costs incurred in maintaining such machines.

Even with all these restrictions, the market looks to have rich opportunities with an ever-growing emphasis on sustainable packaging. Environmental issues are becoming more market-changing, with companies searching for innovative packaging designs that reduce wastage and improve recyclability. Automatic clipping machines would help these goals with efficient sealing designs that promote less excess use of materials. Incorporating sustainable practices will give manufacturers an edge in winning green consumers and meeting regulatory requirements.

The next expected technological advancement would further maximize these machines' efficiency and potential. Innovations in material handling, sensor technology, and software integration will subject these machines to a smarter system for production optimization and operational cost-cutting. Companies investing in research and development may also introduce these more user-friendly and cost-friendly solutions, opening automation to a wider array of businesses.

In summary, the Global Automatic Clipping Machines market is driven by increased sales in food processing and the need to address shortages in labor. Even as rising costs and maintenance issues obstacle growth, the demand for sustainable packaging provides an opportunity for expansion. As technology continues to advance, the companies that adopt such automation will stand to gain the most-from improved efficiency to enhanced prosperity in the long term.

MARKET SEGMENTATION

By Type

The Global Automatic Clipping Machine market is quite steady with the industries trying to provide easy, reliable packaging processes. These machines also hold value in securing products from the food-processing industry, pharmaceuticals, and industrial manufacturing processes. For the automation, companies are going a step beyond cutting costs to ensure the best productivity with consistency in packaging.

Manual Clipping Machines are Marketed at $438.95 million, together with Semi-Automatics and Fully-Automatic Clipping Machines, according to machine types. Manual Clipping Machines do not work unless there is a direct human application to operate it, but it is still highly valued by companies with lower production volumes or those needed for special packaging applications. They are not so expensive and quite easy to use, which is good for small businesses.

On the contrary, Semi-Automatic Clipping Machines are used to increase productivity, leaving a certain extent to the operation of man. Fully Automatic Clipping Machines, indeed, feature high-speed operations that eliminate the scope of human involvement in executing procedures, making the entire process of packaging smooth and consistent. These machines are typically found in large manufacturing facilities that are aimed to achieve high outputs but at the same time with a minimum cost of labor involved.

The focus on food safety and hygiene standards has increased the adoption of automatic clipping machines in the paradigm of the food industry. Businesses are investing in increasingly automated solutions to ensure that their products become accepted within the quality standards set by the regulations that become stricter in the setting of the doors. Furthermore, advancement in technology continues to churn out machines with better accuracy and efficiency in operations, rendering these machines attractive to businesses that opt to improve their packaging processes.

E-commerce, just like all other sectors, brides another reason that fuels this market. Lately, as online shopping continues to make its way into the world, the need for safe and effective packaging solutions grows every day. In this regard, Automatic Clipping Machines are for the major part responsible for sealing and protecting products during the movement. This is especially true in cases where the products need to be sealed inside packaging to provide for airtight and tamper-proof conditions.

The market is full of opportunities, but it also has a long list of challenges, like high initial investment costs and a very complicated process of routine maintenance, which may serve as hurdles to some businessmen. The benefits outweigh these concerns; however, they are mostly long-term gains-from efficiencies that have improved the cost of doing business and reduced labor costs. Companies that are serious about increasing efficiency through investment in advanced clipping machines will not regret being at the forefront of industry competition.

In short, as industries embrace automation in its various forms, so the Global Automatic Clipping Machine market continues to grow. New technological advancements introduce newer and even better packaging systems, therefore, in due course of time, the market is bound to expand further. This will promise the businesses more innovative solutions regarding their packaging needs.

By Application

The Global Automatic Clipping Machine market is expanding as it promises a high degree of efficiency in package sealing and packing processes. They are used in a variety of industries and are increasingly important in food production and packaging, where speed and high precision are critical. They have become more reliable due to technology changing automatic clipping machines, improving performance and requiring less manual labor.

The market application is segmented as Production of Sausages, Sealing of Bags, and Netting Applications. These machines are used in sausage production to provide tight and well-sealed packages with fresh and premium quality of the product. The manufacturer can further increase production by automating the process, reducing waste, and maintaining consistent production. Bag sealing is another significant application for these machines; they will close bags securely and seal them against contamination and spoilage.

Application in food packaging, pharmaceuticals, and many other sectors requiring airtight sealing is extensive. Netting applications are used to secure products with a nettype material. This application is very common in meat processing and some agricultural products; automatic clipping machine performance in this section helps companies to meet the industry standards with enhanced operational efficiency.

A growing consumer market for convenience in the ready-to-eat form has increased the demand for processed and packaged foods, which pushes manufacturers to put up the latest packaging solution in promotion. Hygiene and many food safety regulations drive an increasing number of companies to employ steadfast sealing methods. Thus, the market for machines is again boosted. Using machines improves packaging functions as well as drops strict quality control measures.

Current trends in technology have allowed automatic clipping machines to be made more efficient and user-friendly than before. Modern automatic clipping machines come with a range of intelligent features such as touch-screen operation, adjustable settings, and enhanced safety measures. They therefore enable easy handling together with the demands for high levels of precision. Besides, with smart technology attached to such machines, monitoring functions can be done in real time, thereby minimizing downtimes and increasing overall efficiency.

As of now, many automatic clipping machines recently manufactured come with features tais as a touch-screen operation and adjustable setting redound enhanced safety features; it, therefore, makes one's handling easier along the requirement for very high accuracy. Moreover, through the integration with intelligent technology, such machines can also process activities in real time, thereby removing downtimes and improving the overall efficiency.

Market participants are looking to add innovation and personalize the machines to meet the various industry needs. Such modification offers flexibility for businesses since they can have machines that meet their exact requirements. Greater automation coupled with future advances in technology will allow manufacturers to consider advancements toward high productivity without sacrificing quality.

The market for the Global Automatic Clipping Machine looks bright, as industries widely adopt machinery as a step towards improved efficiency and enhanced quality of products. Therefore, the demand for these machines in food processing, packaging, and other related applications will always be mounting to become an integral part of production lines across the globe.

By Distribution Channel

The global automatic clipping machine market is experiencing phenomenal growth, largely driven by the increasing demand across various end-use industries. These products are primarily used in packaging to seal end products while ensuring that the products retain quality and consistency. The growing market is characterized by technological advancements that offer increased automation, speed, and accuracy in performing functions, which have turned these machines into a necessity in modern production lines.

Manufacturers are emphasizing today on enhancing capacity of machines by coupling with smart sensors and AI-powered automation. Such innovations help to minimize human intervention and bring down errors while improving efficiency. Apart from that, the growing needs for hygienic and secure packaging in the food and pharmaceutical sectors are thereby likely to drive sales of these machines up. Companies are taking interest in machines that provide a better control, less waste, and faster performance to meet the increased production needs.

The market can be classified further into Online Sales and Offline Sales. The online platforms are being preferred to a greater extent since businesses have found that it saves their time, money, and provides them with access to more options. E-commerce has simplified procurement by allowing buyers to read reviews, compare features, and make their choices in informed decisions. However, offline sales are extremely important for a buyer who prefers to be shown the machine before purchasing or even demonstrate the machine by himself. This becomes more clear when one considers that many companies do not prefer face-to-face purchases to avail personalized assistance and post-sale support.

Regional trends show that while developed economies slow at a steady pace, emerging economies have quickly adopted leaps in demand owing to industrialization. The companies in these areas tend to invest in automation for increasing productivity and international-standard output attainment. To add to it, government initiatives for promoting automation and efficiency in production processes further increase the market base.

The competition within the market is stiff, as more and more players are into research and development for better and cheaper solutions. Typically, the more popular mergers and acquisition approaches in building market presence and offering better services are resorted to by companies. Sustainable solutions are now manifesting in energy-efficient machines and eco-friendly materials. There are more shaping the future of the market.

In summation, all these aspects point out that the Global Automatic Clipping Machine market will continue to grow with demand from industries seeking round-the-clock automation and efficiency improvements. Continuous innovation will be essential to stay competitive as technological advancements, changing consumer demands, and evolving business models occur. It is also certain that online and offline selling channels provide all buyers the opportunity to reach and rely on these vital machines.

By End Users

From the current market survey, it is apparent that the Automatic Clipping Machine has a great market because of its diverse applications in different sectors. The moment technology will advance, and become relevant in streamlining production and efficiency in most of the sectors, thus having a very large range of applications.

Automatic clipping machines use mainly the food industry. Such machines are instrumental in the packaging of canned, cut, or other processed foods, meats, and perishable items. They offer a sound seam, thus maintaining the product in fresh condition and free from contamination. As more and more consumers prefer packaged food, manufacturers rely on such machines to maintain high quality in products at an increased output. The high efficiency and speed of the machines will allow food processing industries to meet large requirements without compromising hygiene and safety standards.

In addition, these automatic clipping machines have applications in the textile industry. They are also used in fastening textile materials and securing them at various stages of production. They thus help speed up the bundling of fabrics and secure textile products before leaving the company. As the textile industry grows steadily, there is also an increasing demand for industrial automation in every manufacturing process. All companies now seek to obtain reliable solutions that can add to their productivity while reducing the need for labor.

The packaging sector forms a considerable area of automatic clipping machines. These machines will seal and secure not just a few types of packaging but a multitude of different materials. This will ensure the establishment of a necessary protective barrier to the product while in storage and transportation. Now that businesses are trying to focus on an environmentally friendly and economically viable alternative packaging methods, automatic clipping machines can ensure efficient product integrity. Naturally, customers will buy either retail, logistics, or industrial packaging using these machines, which will definitely save time and even waste.

Aside from these vital sectors, different occupations are integrating automatic clipping machines into their work process. Manufacturing has so many different business names, all of which need automatic clipping machines to help with everything from bundling to fastening, or securement of materials during various stages of their production process. As businesses grow, so does the demand for better efficiency, lower operational costs, and fast production with automation.

Thus automatic clipping machines are growing in market numbers due to the fact that many companies have found it necessary for raising productivity and keeping quality standards. These companies have built up the latest models that provide greater precision, speed, and durability. With modernization of manufacturing to include more automation, the need for reliable clipping machines will steadily rise over time. General improvements in operations, waste production, and product consistency will benefit all industries adopting automatic clipping machines. Automatic clipping machines, thanks to the continuous improvements in technology, will have much more important roles to play in industrial processes around the globe.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$1,736.77 million |

|

Market Size by 2032 |

$2,833.95 Million |

|

Growth Rate from 2024 to 2031 |

7.3% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

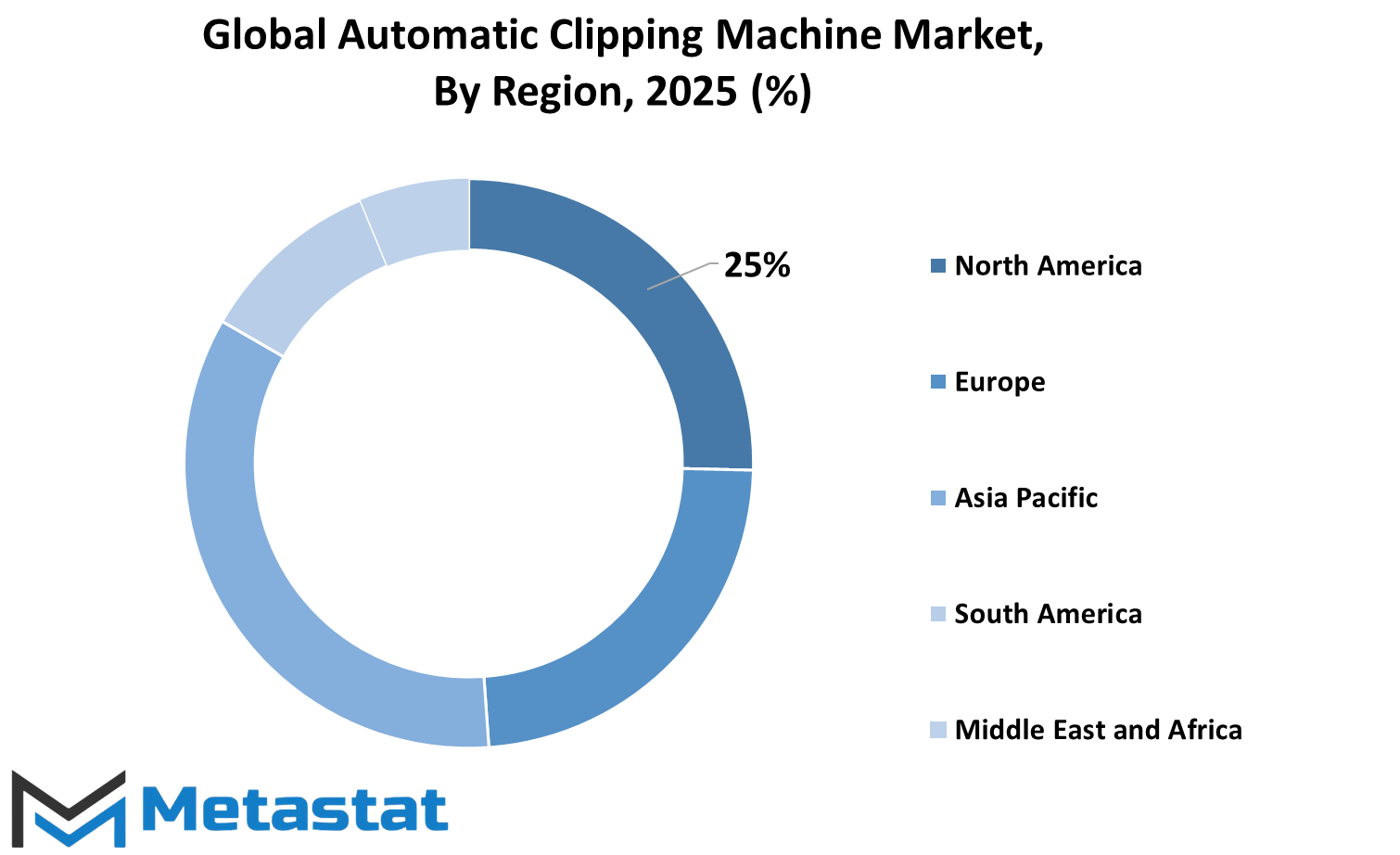

The global Automatic Clipping Machine market has geographical segmentation covering North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Each of these regions contains some key markets that contribute to the total industry landscape.

In North America, the market further splits into the U.S., Canada, and Mexico. Strong industrialized activities, advanced manufacturing processes, and a growing number of automated requirements in varied industries characterize this region. Market growth is facilitated by notable players, continuous technological advancement, and improvements.

Europe refers to the UK, Germany, France, Italy, and the Rest of Europe. The region is strongly focused on innovation, automation, and efficiency in production. Countries such as Germany and France lead industrial automation and support market growth enormously. Demand for excellent machinery and strict regulatory standards are further aiding the growth of the industry.

Asia-Pacific is divided among India, China, Japan, South Korea, and the Rest of Asia-Pacific. Rapid industrial development is taking place in this region, and two major hubs are China and India. These two countries are also among those that have mechanization adoption to improve productivity and to reduce labor costs. Japan and South Korea, with their technological advancement, are major contributors to market growth as well.

South America includes Brazil, Argentina, and the Rest of South America. While the market here is still not at par with that of North America or Asia-Pacific in size, it is rapidly growing due to rising automation needs in food processing and packaging. There is huge potential in Brazil, where investments in industrial automation are growing, which will, in turn, lift demand for Automatic Clipping Machines.

Middle East & Africa is subdivided into GCC countries, Egypt, South Africa, and the Rest of Middle East & Africa. The market in this region is growing owing to investments further development in manufacturing, food processing, and packaging industries. The countries of the GCC, along with their initiative focused on diversifying economies beyond oil and gas, are embracing automation in a bid to realize enhanced efficiencies. South Africa, too, is showing constant growth catalyzed by its growing industrial sector.

Summing up, demand for automation increased in the Automatic Clipping Machine market across various regions, with support from technological growth and production efficiency. The expansion of industries such as food processing, packaging, and manufacturing offers various opportunities to the players operating in this market around the globe.

COMPETITIVE PLAYERS

The worldwide automatic clipping machine market is thriving with the expectations that industries will always need an efficient solution to facilitate packaging processes. The machines find prominent application in food processing, especially in meat and poultry packaging: secure and proper sealing is vital to keeping products fresh. With advancing automation, manufacturers are putting innovative technologies into these machines to increase efficiency and precision while minimizing the need for human involvement and errors in the packaging process.

Increased concern for hygiene and food safety has driven many enterprises to invest in automatic clipping machines that allow the execution of hygienic and clockwork sealing, complying with industry regulations. Furthermore, demand for convenience foods is set to draw higher production volumes, thereby establishing automation as a critical market factor. These machines, being process-efficient, assist companies with the minimal production waste; hence, they are viable in modern and sustainable food production.

Innovation within this sector is driven by a few major players. For example, Poly-clip System GmbH & Co. KG, TIPPER TIE TECHNOPACK GmbH, A. Lorenzo Barroso S.A., Affeldt Maschinenbau GmbH, Kompo North America Inc., Gasparin S.r.l. Brevetti, Inox Meccanica S.p.A. CT Cliptechnik Deutschland GmbH, Boss Verpackungsmaschinen KG, Shanghai Kingrun Machinery Equipment CO., LTD, Sorma S.p.A., and Talleres Daumar S.L. are continuously innovating the clipping technologies. Focus recognized by manufacturers aims the enhancement of machine robustness, precision, and speed targeting the different demands of their clients.

Automation in packaging has become a necessity to remain competitive and maintain high standards by packaging companies. The efficiency of automatic clipping machines increases production rates and ensures uniformity in product packaging, which improves brand reputation and consumer trust. With their operational cost optimized and productivity improved, companies investing in these technologies benefit greatly in the market.

Given the advancement in technology, the future of the Automatic Clipping Machine market looks very bright. New-age manufacturers are now embracing smart features like real-time monitoring and remote operation for effective control and maintenance of equipment. The integration of digital technologies interlinked with the production processes will curtail downtimes and add to the efficiency of operations. With the increased demand for quality packaging, companies capable of automating their production facility will be in a great position to satisfy consumer demands and regulatory requirements, consequently forming a sustainable enterprise.

Automatic Clipping Machine Market Key Segments:

By Type

- Manual Clipping Machines

- Semi-Automatic Clipping Machines

- Fully Automatic Clipping Machines

By Application

- Sausage Production

- Bag Sealing

- Netting Applications

By Distribution Channel

- Online Sales

- Offline Sales

By End Users

- Food Industry

- Textile Industry

- Packaging Industry

- Others

Key Global Automatic Clipping Machine Industry Players

- Poly-clip System GmbH & Co. KG

- TIPPER TIE TECHNOPACK GmbH

- A. Lorenzo Barroso S.A.

- Affeldt Maschinenbau GmbH

- Kompo North America Inc.

- Gasparin S.r.l. Brevetti

- Inox Meccanica S.p.A.

- CT Cliptechnik Deutschland GmbH

- Boss Verpackungsmaschinen KG

- Shanghai Kingrun Machinery Equipment CO., LTD

- Sorma S.p.A.

- Talleres Daumar S.L.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252