MARKET OVERVIEW

The Global Ammonia Chiller market revolves around an active cooling industrial sector offering solutions to many applications in the food processing, chemical manufacture, and HVAC systems. The ammonia chillers refer to the refrigeration systems using ammonia as their main refrigerant for cooling, thus creating maximum efficiency and least harm to the ecosystem. This segment has a great part to play in the maintenance and steady running temperature control of several industrial processes, thus assuring maximum performance and optimal quality of their manufactured products. Due to these inbuilt advantages, ammonia chillers are taken up in increasing numbers by industries all over the world as environmentally friendly and sustainable refrigeration systems.

These coolants have excellent thermodynamic properties; high efficiency and heat transfer rates, hence considered useful for industrial cooling applications. Besides, ammonia is non-ozone-depleting and with negligible contribution to global warming, thus upholding sustainability-related principles and environmental stewardship. The Global Ammonia Chiller market is one serving multiple industries that include food and beverage, pharmaceutical, petrochemical, data centers, etc. Ammonia chillers, for instance, are key in maintaining cold chain requirements in food processing for all stages in the production cycle, which is a factor in keeping the quality of perishable goods. In a similar manner, ammonia chillers also allow temperature control in chemical processes for conformity and safety.

The major demand drivers for ammonia chillers include increasing requirements for energy-efficient and environment-friendly cooling solutions. With stringent greenhouse gas regulations and increased energy consumption, governments worldwide have stepped in to protect the environment, and indeed the industry now seeks alternatives to conventional refrigeration systems. Ammonia chillers have been positioned favorably with properties that do not harm the environment and this makes them extremely conducive for implementation in a large way.

The Global Ammonia Chiller market, characterized by intense competition and rapid change in technology, also witnesses a spurt in innovations and development driven by manufacturers, with the intention of increasing efficiency, reliability, and safety according to the ever-changing needs and demands of end-users. Such innovations that evolve are geared towards smart compressors, better controls, and integrated monitoring systems with improved control for the efficient operation of cooling.

Apart from that, the industry is affected by other external forces such as economic turmoil, major technological breakthroughs, and changing rules and regulations. There is a very high demand for industrial cooling solutions in the emerging economies that are rapidly industrializing and urbanizing and provide great prospects for market participants to increase their presence and service the demands in these regions.

The Global Ammonia Chiller market is a crucial part of the industrial cooling market which provides efficient and sustainable solutions for all possible applications. With regard to environmental and functional advancement along with continuous innovation, ammonia chillers are still standing in the forefront of increasing productivity, quality of products, and environmental sustainability in sectors all over the world.

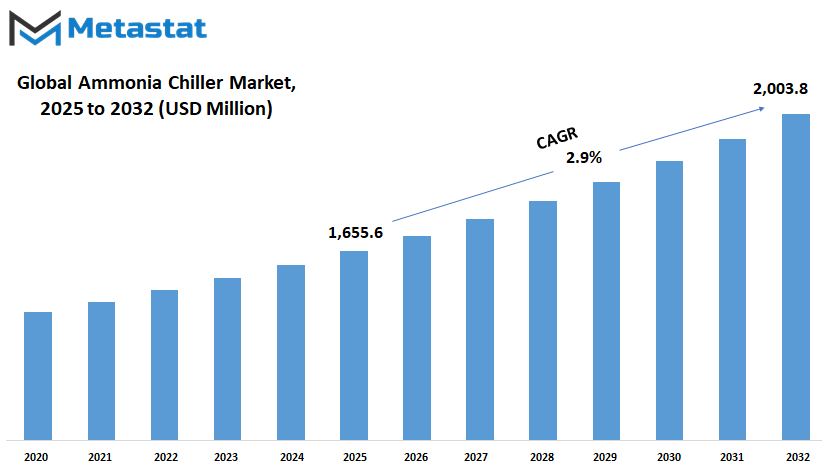

Global Ammonia Chiller market is estimated to reach $2,003.8 Million by 2032; growing at a CAGR of 2.9% from 2025 to 2032.

GROWTH FACTORS

The global ammonia chiller market has a bright future awaiting significant growth with the increasing demand for energy-efficient and eco-friendly cooling solutions in different industries. Most of the sectors including food processing, pharmaceuticals, and large-scale industrial applications prefer using ammonia as its thermodynamic properties are superior. Low environmental impact, high efficiency, and alignment with global trends towards sustainability and being green will keep ammonia preferred within various industries. Attributes that all come together to character with effective refrigeration, improve safety in food handling, and reduce spoilage will cause the industrial segment to widen.

Majorly propelling the market is the rising food and beverage industry. In addition, with increasing global population growth, there will be an increasing demand for much effective refrigeration solutions for spoiled goods. Ammonia chillers, which are known for their proven reliability and cost-effectiveness, are quickly becoming the go-to solution for these needs.

Technological advancements are also a big contributor to the future of the market. Smart technologies such as the Internet of Things (IoT) are added to ammonia chiller systems to better enhance their functions with real-time condition monitoring and predictive maintenance. These improvements are largely performance optimization and are meant to extend the lifetime of the equipment and promote long-term savings for users.

Some market growth challenges may have to be considered, such as safety concerns related to ammonia since it is toxic and flammable, which requires special equipment for handling it. This factor generally causes an increase in initial investment and operating costs and deters some industries from using ammonia-based systems.

Nevertheless, there is a future in the market because of this factor. Sustainability has forced several global movements toward reducing carbon footprints, making ammonia chillers a clear option for eco-conscious industries. Likewise, hybrid systems that combine ammonia with other refrigerants are developed to minimize safety gaps but retain efficiency to provide more possibilities for market adoption.

The proliferation of the global ammonia chiller market thus appears promising and probably throws up much development, driven by demand for efficient and sustainable cooling solutions. While safety concerns and initial costs may pose obstacles, they are outweighed by technological innovations and the environmental responsibility movement. As industries increasingly pay special attention to sustainability, ammonia chillers could become central in bridging the cooling requirements of future facilities.

MARKET SEGMENTATION

By Product Type

As part of a step towards a more sustainable and energy-efficient world, ammonia chillers will undergo an illusionary transformation. The entire process will be so pronounced when one goes to the very particular differences between the water and air-cooled system.

For many years, water-cooled ammonia chillers have been chosen for their energy efficiency as well as their constant performance. Water is the medium for discharging heat, and these appliances usually require cooling towers for this function. They do work well, but require much water other than the usual maintenance practices to avoid such problems as scaling and corrosion. In future, innovations in water treatments and materials will most likely increase the lifespan and efficiency of these systems and expand the regions where they could easily be adapted, especially those areas blessed with ample water resources.

Air-cooled ammonia chillers, which actually release heat to the ambient air, allow a small unit operation area and the absence of cooling towers makes installing air-cooled chillers much simpler compared to using water-cooled ones. These features offer a high advantage of installation of air-cooled chillers compared to sites with limited water availability or where water conservation is prioritized. However, performance may suffer under harsh weather conditions since they are affected by the external conditions of temperature; they perform poorer in hotter climates than their counterparts. Innovative designs of heat exchangers as well as designing materials with higher thermal conductivity are on the cards to remedy these challenges and enhance the viability of air cooling systems under less healthy conditions.

Several emerging trends will shape the path of the ammonia chiller industry. Environmental considerations are expected to stimulate the adoption of systems with low global warming potential as the demand for natural refrigerants increases; with zero ozone depletion potential, ammonia becomes an increasingly attractive choice. In addition to integrating smart features and the Internet of Things (IoT) to allow real-time monitoring or predictive maintenance, these two are ultimately going to increase reliability and reduce the operation cost of the system.

Energy efficiency shall be "the main course" because the pressure is being put on strict standards by regulations. An example would be those brought with variable speed drives and advanced control algorithms relating chillers to exceed standards. The other element regarded as important and advanced will be capable of using recyclable materials in promoting those systems designed for easier end-of-life disassembly and recycling.

By Application

The drivers for the growth of the Global Ammonia Chiller market stem from industries increasingly in the lookout for cooler and greener choices for these alternatives. High efficiencies for cooling and less environmental harm than synthetic refrigerants characterize ammonia chillers. Sustainability being on the radar for various industries, there will be a rising demand for these systems in several industries.

Food and beverage industries rely on refrigeration to keep products cool. The adoption of ammonia chillers will help the industry attain precise temperature control while conserving energy. As food production gears itself to feed the world's growing population efficiently, cooling systems will come into challenge toward preventing spoilage and ensuring product safety. Sodium-based refrigeration is a preferred choice for many manufacturers in the recent past to cater to stricter environment regulation.

In the medical and pharmaceutical industry, the temperature has to be controlled to store vaccines, medicines, and lab samples. Cooling, if even more, will be required now than before as more therapies and biological products come onto the market. The increasing advances in biotechnology will drive further demand for refrigeration systems to maintain sensitive materials. Within this sphere, ammonia chillers meet the reliability and efficiency requisites, putting themselves in a prime position in pharmaceutical and healthcare facilities.

In chemical processing, several reactions generate considerable heat and require advanced cooling mechanisms. Ammonia chillers ensure effective temperature control to allow the processes to run smoothly without compromising on product quality. With industries moving towards sustainable practices, companies are now looking for options that are in line with the environmental aspirations. Ammonia-based refrigeration is expected to shine due to its very minimal environmental impact and high efficiency in addressing industrial cooling requirements.

The logistics sector relies on refrigeration to transport perishable goods. Correct temperatures are crucial whether the commodities being transported are foods, medicines, or other temperature-sensitive products. As the global supply chain becomes increasingly complex, businesses require dependable cooling arrangements to prevent losses during transit. Ammonia chillers are garnering momentum among businesses seeking improved efficiency while attempting to reduce carbon footprints.

Besides these industries, other sectors are adopting ammonia chillers, given their long-term advantages. Data centers, for example, need large-scale cooling solutions for servers to avoid overheating. Given the complex growth of digital infrastructure, energy-efficient cooling systems will become a high-profile opportunity. Innovations in cooling technologies are driven by sustainability, and the attractiveness of ammonia-based systems in various applications is on the rise.

By Cooling Capacity

The Ammonia Chiller Market includes a range of maximum cooling capacities and is suitable for both industrial and commercial needs. Cooling capacity is a major determinant in deciding how well ammonia chillers work with respect to specific applications. In turn, the dimension gives this market in terms of cooling capacity, defining chillers accordingly for their maximum heat dissipation capacity.

Ammonia chillers are the major equipment set needed in industries that deal with temperature control requirements, like food processing plants, chemical plants, and HVAC systems. The maximum cooling output of ammonia chillers is determined by its total cooling capacity, allowing the businesses in question to select the device that would suit its application based on the required cooling power.

The market characterized the refrigeration capacity segment into ranges for a better understanding, and it delineates ranges of up to 100 kW or above 2000 kW cooling, with intermediate ranges such as 101-500 kW, 501-1000 kW, and 1001-2000 kW, each addressing specific needs, thus covering the diverse range of cooling requirements in different industries.

Chillers of this type, having a capacity of 100 kW and below, are generally quite apt for localized cooling-scale applications. They offer a sufficient cooling power rating for relatively smaller spaces or processes with lower heat loads. They are usually applied in places where space and energy conservation come at a premium.

On the other hand, types of chillers with cooling capacities of 101-500 kW can well alleviate moderate to large heat loads. This classification caters for a wider application such as medium size industrial processes, commercial buildings, and mass-scale refrigeration systems. Such chillers in this range also prove to be economic at times besides their applicability, since they are indeed a bridge between size and efficiency and hence comfortably adjust to different cooling needs.

At the same time, those giant installations would have huge cooling requirements that install 501-1000 kW and 1001-2000 kW chillers for their cooling capability. Often, these great chillers are used in industrial processes and data centers and are also seen to be used in facilities requiring that a very precise temperature be maintained for maximum operational efficiency and product quality.

Chillers whose cooling capacity is above 2000 kW are generally customized to meet the cooling requirement of these industrial giants. High-capacity chillers are generally applied in mega manufacturing plants, power generation facilities, and other large installations where heat dissipation is to be massive to sustain continuous operations.

By Type

The ongoing transformations in the global ammonia chiller market are largely due to technological developments and an increasing appreciation for sustainable industrial development. With ammonia chillers' efficiency already well appreciated, businesses crowding toward the eco-friendly end of the spectrum are putting a further premium on ammonia chillers as eco-friendly solution providers.

The market is generally classified into open and semi-hermetic chillers. Open chillers provide rugged design and good adaptability, so they are suited for large-scale working operations in which customization is essential. This simple construction allows easy maintenance and parts replacement, traits that are very much appreciated in industries that require continuous and reliable cooling.

Conversely, semi-hermetic chillers promote compact and sealed designs so as to greatly reduce refrigerant leakage concern and elevate operational safety. This design works well in places with constrained space or where environmental regulations are stringent. Lesser leakage would be in harmony with other global efforts, making semi-hermetic chillers the preferred in atmospheres governed by stringent environmental policies.

The future looks quite promising for innovations as manufacturers increasingly direct their focus upon the integration of smart technologies in ammonia chiller design. Introduction of internet-of-things technology enables real-time monitoring and predictive maintenance, contributing to performance improvement and reduction in downtime. These improvements provide further operational benefits and will translate into savings over time.

Furthermore, the pace at which the ammonia chiller market will prosper will depend on the efforts toward carbon footprint reduction made by various industries worldwide. Ammonia is an eco-friendly refrigerant since it has no potential to deplete the ozone layer and very low potential for global warming. This type of refrigerant meets the criteria of international sustainable development and regulations that encourage the phasing out of synthetic refrigerants with a greater harmful effect on our environment.

The global ammonia chiller market will prosper on account of the technological advancements and sustainability perspectives. The special features of both open type and semi-hermetic chillers serve varied industrial applications, making ammonia chillers a constant cooling solution for many industrial applications even going into the future.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$1,655.6 million |

|

Market Size by 2032 |

$2,003.8 Million |

|

Growth Rate from 2025 to 2032 |

2.9% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

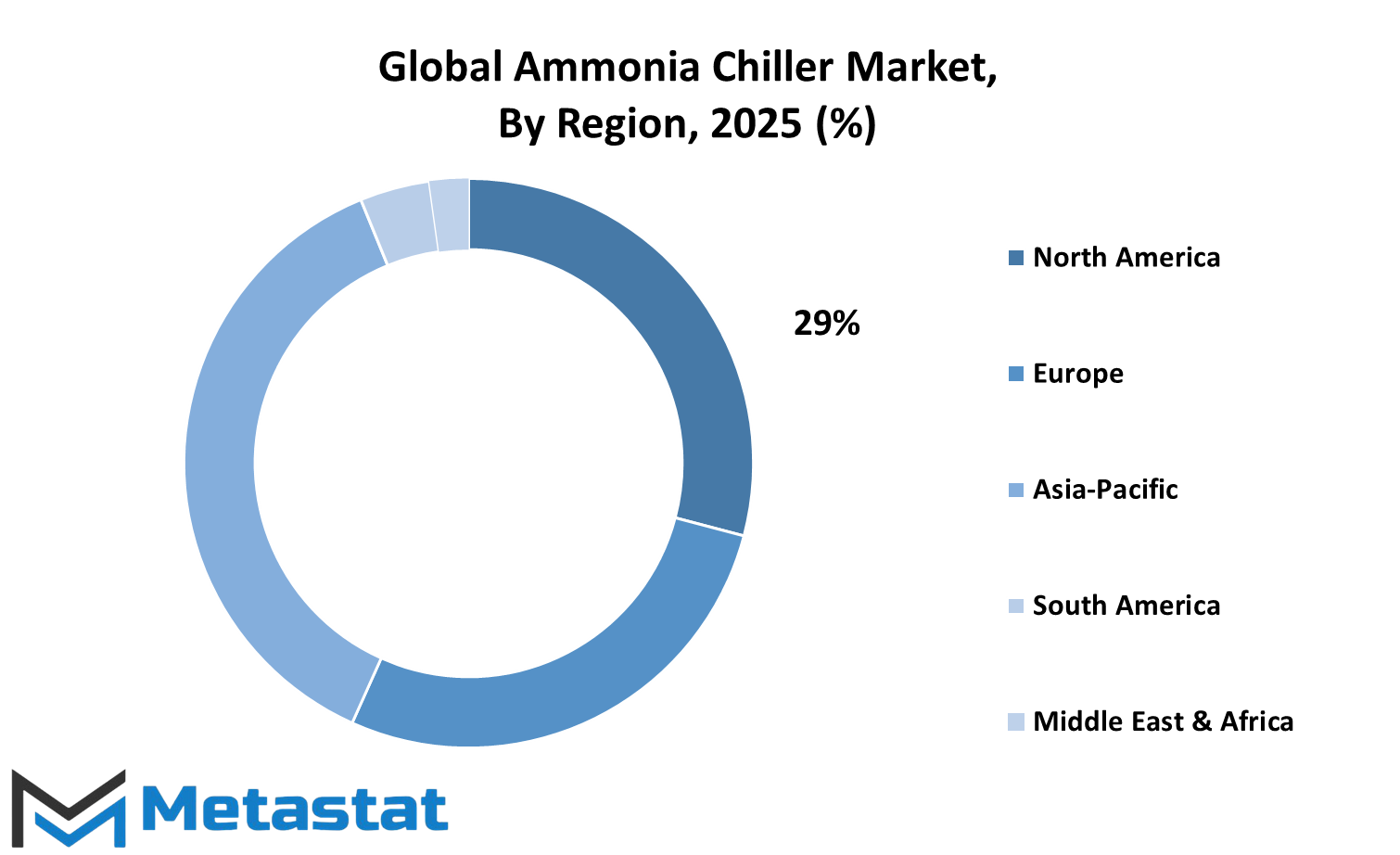

The market for Ammonia Chillers is examined on a worldwide basis in terms of different geographical areas: North America, Europe, Asia-Pacific, South America, and Middle East and Africa.

North America, for instance, is subdivided into the United States, Canada, and Mexico. For example, Europe comprises the United Kingdom, Germany, France, Italy, and the Rest of Europe. Similarly, important economies in the Asia-Pacific region include India, China, Japan, South Korea, plus Rest of Asia-Pacific.

Moving on, South America contains Brazil, Argentina, and Rest of South America. Last but not least, the Middle East & Africa region is divided into three categories: GCC Countries, Egypt, South Africa, and the Rest of the Middle East & Africa.

Such a regional analysis gives the comprehensive picture how this market has been distributed worldwide. It helps in understanding the internal market dynamics under each location owing to the difference in economic conditions, regulatory framework as well as the technology available.

For example, in North America, the market is bound to respond differently in terms of demand and acceptance within the United States, Canada, and Mexico owing to differences in industrial infrastructure and the government policies within these countries. Similarly the rest of Europe countries, the market dynamics within Germany and France, for instance, would be affected by energy efficiency regulations and environment policies, unlike most others.

The Asia Pacific is turning out to be a factory for manufacturing as well as rapid industrialization, and indeed it has promising opportunities for the Ammonia Chiller market. Countries like China and India, by which their industries are going to rapidly develop, will be the main demand regions for the efficient cooling solutions, which includes Ammonia Chillers.

Being emerging economies like Brazil and Argentina, South America would also see some improvement regarding acceptance of Ammonia Chillers because of the rapid increase in investments in food processing, pharmaceuticals, and chemicals.

Factors such as climate conditions and government plans to induce sustainable technologies may cause variance in the way countries within Middle East Africa to accept Ammonia Chillers.

Overall, the stakeholders and businesses can understand the localized trends, competitive landscape, and growth opportunities by region. In this sense, this regional analysis is very valuable to the stakeholders since they can utilize the information to strategize their decisions. Such strategy enables decision-making in marketing and product offerings and making developmental plans as per each region's specific needs.

COMPETITIVE PLAYERS

Several key players in the global Ammonia Chiller market have presence as these companies are important to the market. They influence the market dynamics and direction. The most pertinent players in this market sector include GEA Group, Refteco, Budzar Industries, INTARCON, Tempest Engineering, Johnson Controls, PATKOL Public Co., Cooltech Finland Oy, Refcon Technologies and Systems, and Reynold India Pvt. Ltd., Fujian Snowman, MAYEKAWA Global, Azane-Inc (Star Refrigeration Group), Berg Chilling Systems, EVAPCO, Kirloskar, and Voltas.

All these companies bring their unique strengths, strategies, and offerings in creating a competitive atmosphere for the Ammonia Chiller market. For instance, GEA Group has cutting-edge solutions and huge experience in the industrial refrigeration arena. Refteco meanwhile concentrates on energy efficiency combined with environmentally friendly cooling solutions. Budzar Industries, on the other hand, is better known for reliable and high-performance chiller systems which can target different industries with varying applications.

INTARCON is committed to technological innovation and customer satisfaction, offering probably the widest range of chiller products catering to specific needs. Tempest Engineering specializes in bespoke chiller systems, uniquely tailormade for clients' needs. Johnson Controls is the market's most prominent player in areas such as building efficiency and sustainable solutions through HVACR technology.

PATKOL Public Co. is more synonymous with its quality and reliability in the manufacturing of industrial refrigeration equipment. Cooltech Finland Oy is in magnetic refrigeration technology that manufactures innovative and eco-friendly cooling appliances. Refcon Technologies and Systems are known for a much wider range of refrigeration and air conditioning products, offering solutions to different sectors.

Reynold India Pvt. Ltd. has already made its name as a frontrunner in industrial refrigeration equipment manufacturing. Renowned for creating powerful and advanced energy-efficient solutions for its customers, it is now a giant in industrial refrigeration. Fujian Snowman is a global player in the refrigeration industry specializing in ice-making and cold storage solutions.

MAYEKAWA Global is well-known for providing world-leading reliable and efficient refrigeration solutions based on advanced technology and engineering expertise. Azane-Inc (Star Refrigeration Group) aims at low-charge ammonia refrigeration systems focusing on the environment while performing optimally. Berg Chilling Systems presents customers with a wide range of industrial cooling solutions for a variety of applications and industries.

EVAPCO has specialized in evaporative cooling equipment using energy-efficient and sustainable cooling solutions. Kirloskar, a well-renowned name in the engineering domain, produces cost-effective and reliable chiller systems mainly for industrial and commercial use.

Ammonia Chiller Market Key Segments:

By Product Type

- Water-Cooled

- Air-Cooled

By Application

- Food & Beverage

- Medical & Pharmaceuticals

- Chemicals

- Logistics

- Others

By Cooling Capacity

- Up to 100 kW

- 101-500 kW

- 501-1000 kW

- 1001-2000 kW

- Above 2000 kW

By Type

- Open Type

- Semi-Hermetic

Key Global Ammonia Chiller Industry Players

- GEA Group

- Refteco

- Budzar Industries

- INTARCON

- Tempest Engineering

- Johnson Controls

- PATKOL Public Co.

- Cooltech Finland Oy

- Refcon Technologies and Systems

- Reynold India Pvt. Ltd.

- Fujian Snowman

- MAYEKAWA Global

- Azane-Inc (Star Refrigeration Group)

- Berg Chilling Systems

- EVAPCO

- Kirloskar

- Voltas

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252