MARKET OVERVIEW

With technological evolution and shifting demands, the Global Air Compressor market and the industries catalyzing growth expand beyond traditional applications into sundry diverse sectors. Air compressors are essentially required in the manufacturing, medical, and energy-producing sectors. Their implications extend to underdeveloped domains that challenge industrial efficiency and innovation. As industries transition to processes defined by advanced automation and sustainability, industrial air compressors bordering processes, energy optimization, and state-of-the-art technological integration will remain the rudimentary components in ensuring optimization.

Air compressors are stepping far beyond conventional usage and are becoming an important part of the exploration and research of outer space. With the increasing push toward long-term habitation beyond Earth, various space agencies and private entities will require reliable compressed air systems to support life systems, scientific instruments, and mechanical operations within space habitats. The presence or absence of atmospheric pressure in outer space creates an environment that mandates the need for advanced compression technology to supply oxygen and carry out controlled experiments under microgravity settings. Research institutions are working on how modified air compression systems can provide improved fuel efficiency for spacecraft-and therefore longer space missions and interplanetary travel.

The biomedical innovation sector is another of the unknown sectors that air compressors will gradually expand into. The ongoing advances in personalized medicine, genetic engineering, and bioprinting mean that compressed air will become an essential factor in the creation of sterilized environments, the maintenance of difficult biological reactions, and the efficiency of medical devices. In bioprinting applications, for instance, once the controlled pressures are hit for air delivery of bio-inks during the development of tissue structures, the enhancement of future developments in medicine will rely heavily on refined air compression systems that deliver flexible control, minimal contamination risk, and high adaptation for complex biological pathways.

The film and entertainment sector also has some surprising air compressor applications, particularly in special effects and animatronic implementations. Although for the last few decades, pneumatic systems have played a role in the works of mechanical puppetry as well as cinematic illusions, light production for virtual and real-time animation technologies is now extremely reliant on compressed air. Filmmakers are beginning to experiment with interactive physical effects that react in synchronization with digital ones, calling for air-compression systems that can provide accurate and instantaneous responses. As this entertainment form evolves toward more immersive experiences in augmented and virtual reality, air-assisted haptic feedback systems will also further blur the line between fantasy and reality.

Applied in the fields of urban infrastructure, air compression technology will redefine the way smart cities operate. Various pneumatic solutions are in demand for sustainable architectural and automated construction applications. Compressed air systems will power green building solutions, from pneumatic waste evacuation to energy-efficient chilling systems. Already among the growing cities, underground networks assuring vacuum-powered waste disposal are gaining acceptance due to their low pollution potential and less need for conventional garbage vehicles. At the same time, air-compression assisted cooling schemes will work towards energy-efficient cooling solution alternatives in urban high-rise buildings, thereby reducing the [environmental] impact of conventional HVAC systems.

The Global Air Compressors market will forge ahead into new grounds that will test her technological thresholds. As industries forge into automation, resource efficiency, and unconventional engineering applications, crude air becomes extremely exciting. Air compression technology will, instead, be an adaptive force shaping future innovations in medicine, medical research, entertainment, and outer space missions that deserve an urgent consideration.

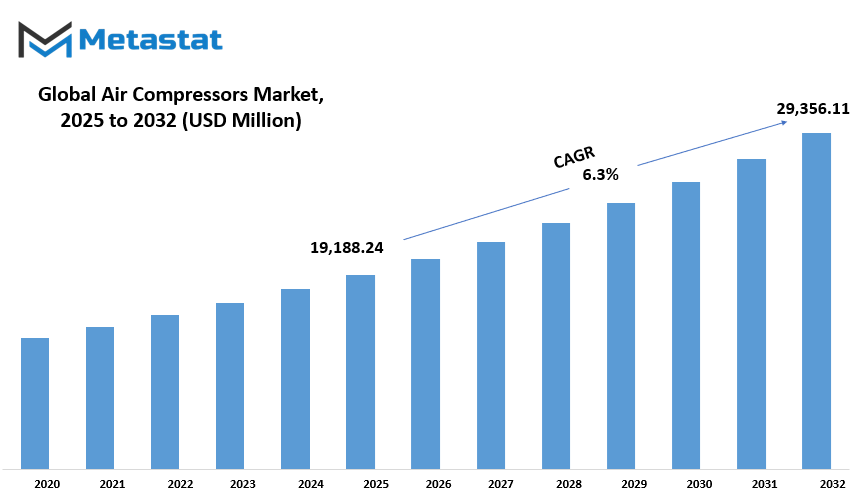

Global Air Compressors market is estimated to reach $29,356.11 Million by 2032; growing at a CAGR of 6.3% from 2025 to 2032.

GROWTH FACTORS

The global air compressor market is witnessing a steady growth trend, driven by the growing trend of industrial automation and the increasing demand for energy-efficient air-compression systems. Air compressors have become widely used in many applications as industrial activities seek to optimize productivity along with minimizing energy consumption. With the reliable and efficient provision of compressed air, air compressors find extensive applications in manufacturing, construction, and other industries that work with pneumatic tools and equipment.

Another major factor propelling market growth is the increasing use of air compressors in the healthcare and food and beverage sectors. These industries require a clean and controlled air supply for safety and compliance with stringent regulations. Oil-free air compressors especially are gaining footholds to benefit these industries with high-quality air that remains uncontaminated. In these applications, such as ventilators and dental tools, where such high purity is required, and in food processing, where product purity needs to be maintained at the highest priority levels, air contaminants can prove detrimental.

Even though the air compressor market is very promising, some challenges are acting as major hindrances toward its growth. The high initial investment required and the maintenance of air compressors could be a real considerable barrier for small and medium enterprises. Noise level and environmental concerns constitute an enormous hindrance. Emissions from conventional air compressors and high energy consumption are garnering scrutiny, prompting manufacturers to build eco-friendly solutions.

In the face of such challenges, oil-free and energy-efficient air compressors are in demand, setting a future trend in the market. Research and development investments by companies seek to bring innovative technologies that lower energy consumption and environmental impact while achieving the highest performance. This shift recognizes the global sustainability agenda and offers significant growth opportunities for manufacturers that respond to eco-conscious customer bases.

As industries advance, demand for air compressors is predicted to rise. Automation, energy efficiency, and sustainability will form the basis of innovation, giving rise to advanced systems that will be more environmentally friendly. Though challenges such as high costs and environmental concerns will remain, the technology advancement will certainly provide solutions long into the future, ensuring that the capacity of the global air compressors market will continue to move ahead.

MARKET SEGMENTATION

By Type

The global air compressors market is experiencing continuous growth due to increasing industrial applications and technological advancements. These devices find relevance over a wide range of sectors including manufacturing, construction, and energy, as they provide compressed air as a utility in various operations. Energy-efficient and low-maintenance compressors are more in demand and this fosters innovation whereby performance is improved and operating costs are lowered.

Air compressors are extensively used in industries where power tools, machines, and automation rely on continuous airflow. Manufacturing firms rely on them for processes, while construction sites use them to run pneumatic tools. The healthcare sector, for example, requires air compressors for powering medical equipment, while the food and beverage industry employs them for packaging and processing. The ample applications thus keep the air compressor demand solid, hence, the growth of the market.

The market is studied through various types classified according to their design and intended function. There are other types within this classification: portable types, worth $12,243.81 million, and stationary types. The portable ones are in demand for their mobility, making them fit for construction and remote jobs, whereas stationary compressors are made for continuous and heavy-duty application in industry. The choice, thus, depends on operational needs, cost-effectiveness, and performance requirements.

Due to rising energy costs and environmental concerns, energy-efficient compressors have been developed. The industries nowadays have a preference for less power-consuming systems that produce high output. Innovations like oil-free compressors and variable-speed drives are becoming popular that allow the businesses to optimize energy consumption while achieving sustainability objectives. Regulations developed by the government on emissions and workplace safety also inform market trends that impel companies to invest in environmental and compliant equipment.

Industry continues to be transformed by technological innovations. Smart compressors, contained with sensors and automation systems for greater real-time performance monitoring, create a more efficient maintenance and performance regime. Incipient sampling and systems could detect problems early, troubleshoot to reduce downtime, and increase productivity. Digitally available technology allows remote access for large operator control on operations.

Infrastructure development and industrialization in emerging economies propel the expansion of the market. Fast-growing manufacturing and construction countries drive the demand for high-quality air compression solutions. Investments in oil and gas, mining, and transportation also drive market expansion.

The air compressor market will evolve as industries keep changing and new focuses will be directed toward efficiency, innovation, and sustainable development. With technology advancing and an increasing need for air compressor systems in a variety of sectors, growth will remain steady in the coming few years.

By Technology

The global market for air compressors is segregated based on technology into three broad groups: reciprocating compressors, rotary/screw compressors, and centrifugal compressors. Each type of air compressor shows unique specifications, advantages, and applications.

Reciprocating compressors are generally called piston-type compressors. These compressors compress air using a piston driven by a crankshaft. Reciprocating compressors are commonly found in industries that require high pressure, like automotive and manufacturing. The main advantage is their ability to generate high pressures and respond to fluctuating air demand. They are versatile machines and find application from small workshops to large plants. In contrast, maintenance costs increase because of the high maintenance values of their moving parts.

Rotary or screw compressors are yet another type of air compressor. The rotary air compressors rely on two interlocking screws that compress air. These screws are particularly celebrated for providing a consistent flow of air under steady pressure. These compressors are commonly found in food processing, textiles, and healthcare. One of the main advantages is the reliability and efficiency of rotary air compressors, handling volumetric air flow without the pulsation that reciprocating compressors deliver. Less noisy with longer life, they're the economically preferred choice in the long run.

By contrast, centrifugal compressors use high speed rotating impellers to accelerate air and convert this kinetic energy to pressure. These compressors are widely employed aboard large scale industrial applications such as power plants, chemical plants, and refrigeration systems. They are also great for handling huge volumes of air at a relatively low pressure. Their main advantage in life is their efficiency in larger-scale operations; however, they are generally more expensive to install and maintain when compared to other types.

Which compressor is to be used is mainly decided on the specific needs of the industry and application. In scenarios needing high pressures, reciprocating compressors are best suited. On the contrary, rotary/screw compressors are selected for continuous operation with moderate pressure. Whereas centrifugal compressors best fit high volume and low-pressure applications. Recognition of these differences helps a company select the proper type of compressor for its needs, resulting in efficient performance and cost savings over time.

By Lubrication Method

As a result of commercialising air compressors in several sectors, such as manufacturing, automotive, healthcare, and construction, the air compressors market is exhibiting moderate yet steady growth globally. Air compressors are very important in performing various functions, which include powering equipment or managing air systems. The lubrication method used in these compressors is one major factor driving their growth. Thus, this market divides itself into oil-free compressors and oil-lubricated compressors regarding lubrication.

Oil-free compressors are those machines which operate without the need of a lubricant, thus making them apt for industries relying on extremely clean air supplies, such as food and beverage, pharmaceuticals, and electronics. Clean, dry air is produced by these systems and would be beneficial wherever there is a risk of oil contamination. One of the greatest advantages is that they do not rely on regular maintenance operations about oil-level maintenance and oil changes and therefore are ideal for use in air-purity-critical operations. Also, although their initial investment costs would be higher than those associated with oil-lubricated compressors, they justify that cost via reduced maintenance costs over the longer term and the performance that may be achieved.

Oil-lubricated compressors, on the other hand, reduce friction between moving parts with an oil to improve machine efficiency and prolong the lifespan of the machine. These types of compressors are commonly seen in heavy industries, where air quality may not matter much, such as construction and automotive repair. Oil is given to occupy within the body of such compressors, providing an element of compression as well as cooling moving parts and reducing wear and tear. Oil-lubricated compressors would require some oil maintenance, as well as replacement from time to time. Still, they are relatively less expensive upfront, making them the most likely choice for many businesses. They could also be more energy-efficient in some cases due to lubrication-cutting friction and ensuring a smoother operation.

Both types of compressors have their specific advantages, and the choice of one type over the other will depend on the exact requirements of that particular industry and usage. For example, oil-free compressors come in handy for usages demanding high air quality, while oil-lubricated compressors are more preferred because of their cost-effectiveness and efficiency in other areas. Industries continue growing; hence demand on both ends would remain high, with each type serving a specific need in the industrial applications. Further development and innovation in air compressor technology would still play a major role in how such systems would be adaptive to future changes.

By End-User

The global market for air compressors plays an essential role in different business segments such as manufacturing, oil and gas, food and beverages, and health and medical, and is heavily dependent on their respective demands for applications or purposes. This is one of many applications and processes that support air compressors as tools that draw air into their network and push it to improve efficiency and productivity.

One of the primary applications of air compressors in the manufacturing environment would be driving machinery, tools, or equipment, occasionally used in assembly lines, packaging, or even automation systems. They bring reliability, versatility, and energy-saving potential to end-users. Air compressor resources would grow demand in this category as the sector engages in larger automation projects and production improvements. Thus, a compressor becomes a great efficiency tool for a company.

The oil and gas market represents a salient portion of the global air compressor industry segment. There are various applications for compressed air, from the powering of pneumatic tools to their use as pressurized air for drilling and refining. Air compressors also have to be used in this sector for purposes regarding safety and operational continuity, especially in more remote or offshore locations where access to electricity can be limited. This will boost even more the utilization of air compressors in this field, as oil exploration continues to increase and energy efficiency is gaining increasing importance.

In the food and beverage sector, air compressors are used for packaging applications such as bottling and refrigeration operations. They help preserve the safety of food products through regulation of proper packaging and maintain freshness. Demand for air compressors in this industry remains perennial, influenced by increasing consumer demand for processed and packaged foods. Furthermore, with the new regulations and standards focusing on food safety, air compressors will suffice in ensuring compliance with the regulations in place.

The healthcare and medical sector utilizes air compressors to power medical instruments like ventilators, anesthesia machines, and other vital equipment. These functions also include air filtration and medical gas purposing that provides a constant formula of clean air. As the growing industry in healthcare is meant to cater to an increasingly aged population and that rising demands of medical services are boosting, it is thought the need for reliable and efficient air supply devices would also grow.

Thus, these different types of industries affect the future of the global air compressor market. The demands from manufacturing industries, oil and gas, food and beverage, and healthcare will continue growing as the industries evolve. Air compressors will be an indispensable component in providing their operational needs and enhancing productivity across the board.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$19,188.24 million |

|

Market Size by 2032 |

$29,356.11 Million |

|

Growth Rate from 2024 to 2031 |

6.3% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

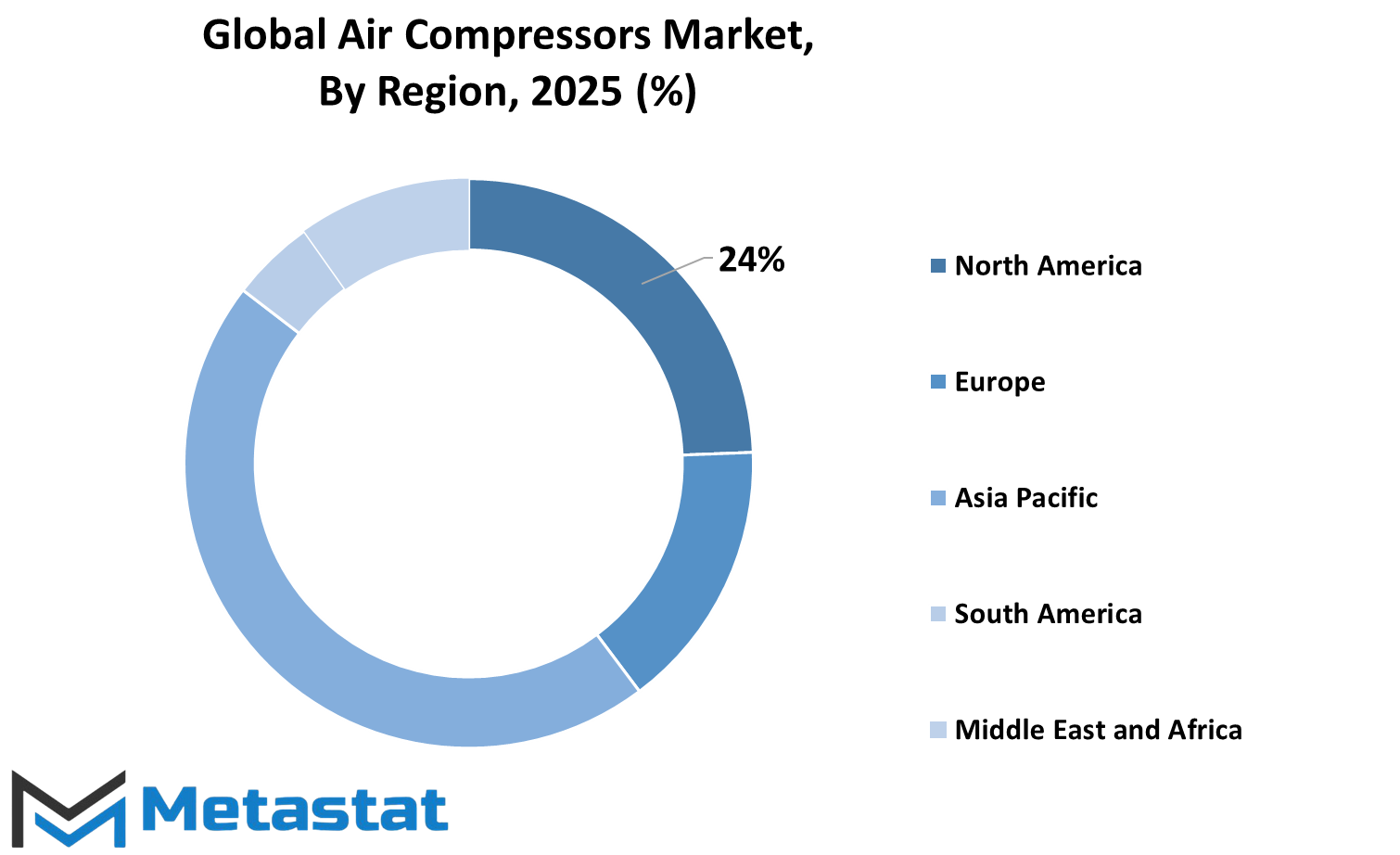

The Air Compressors industry globally divides geographies such as North America, Europe, Asia-Pacific, South America, and the Middle East and Africa. For instance, North America has subcategories, namely,-the United States, Canada, and Mexico. In Europe, it encompasses major countries, like the UK, Germany, France, Italy and among others grouped in that region as rest of Europe. In Asia-Pacific, this market can be divided into India, China, Japan, South Korea, and other countries which are rest of Asia-Pacific. South America has Brazil, Argentina, and the rest of South America, while the Middle East and Africa share the GCC countries, Egypt, South Africa, and the rest of the Middle East and Africa.

With geographical segmentation, it is possible to thoroughly analyze the areas for each of those market trends, demands, and growth potential. The segmentation thus allows businesses and investors to understand the regional market dynamics and adopt their approaches as per that. For an instance, North America and Europe would be considered as mature markets, while most of the growth is anticipated to be in Asia-Pacific mainly due to rapid industrialization and heavy demand for air compressors in such countries as China and India.

At present, the market of South America is mainly divided by Brazil and Argentina, which lead the market primarily due to infrastructure developments in these countries and expansion of industries. The future of the Middle East & Africa is also very bright because of developing nations such as the UAE and South Africa, which contribute to the market with many of their industrial projects and the adoption of new technologies.

There would be unique openings and challenges for each area, going by the state of the economy, industrial, and technological rise. This understanding of such regional divisions assists a company to make decisions on market entry or expansion apace with careful consideration of each particular area market. Companies can, therefore, go ahead and provide unique offerings as per the need of the regions and thus optimize their products and services for demand sure effective and efficient.

COMPETITIVE PLAYERS

The global air compressor market has made some steady progress and finds the need to make continuous effort on this driving demand of various industries for compressed air. These industries rely heavily on air compressors for a variety of applications ranging from manufacturing, construction, energy, and transportation. Air compressors are those crucial tools that convert power into potential energy and store it in compressed air used afterwards in operating equipment and machines using compressed air, thus becoming an inseparable part of many sectors.

The rapidly rising demand for energy-efficient or sustainable technology has been a major factor in contributing to the growth of the market. Most companies are now interested in installing air compressors that could offer energy savings with performance integrity, with increased focus on environmental sustainability. Thus, high-efficient compressors will play a crucial role in this scenario when it comes to the demand in the market, as the transition is being seen in organizations towards greener technology practices. In this regard, companies with energy-efficient solutions will certainly play a key role in the future development of the air compressor industry.

Several leading players have contributed to the shaping of the global air compressor market. Atlas Copco, a household name in the air compressor industry, is recognized as one among key providers who supply air compressors, as well as the required equipment for air compressors. The company lays a great emphasis on producing and innovating quality products. Ingersoll Rand and Kaeser Kompressoren are great names in advanced air compressor technologies and enjoy significant market shares. Their long and varied product lines satisfy different sectors of industry, thus ensuring competitiveness in this market niche.

Important names in the market also include FS-Curtis, Howden Group Ltd., and Gardner Denver Inc. All of them have a good market presence due to their reliable air compressor systems. The companies are continuously developing following the technology curve to be at par with the ever-changing requirements of the customer. In addition, Aerzener Maschinenfabrik GmbH, Hanwha Power Systems, and Doosan Portable Power (BobCat) play their parts in specialized air compressor solutions, particularly in heavy-duty applications.

Danfoss A/s, Sulzer AG, and Elgi Equipments Ltd. are some of the many companies that provide portable and efficient air compressor units. These brands are known to manufacture technologically advanced, portable products that are best suited for the construction segment and automotive sector. High-end manufacturers, including Boge Compressors, Quincy Compressor, and Pneu-Mech Systems Pvt Ltd offer value and quality when it comes to the diverse needs of customers across different industries.

It can thus be concluded that the world air compressor market is growing in size and will continue to grow with companies such as Atlas Copco, Ingersoll Rand, and Kaeser Kompressoren at the forefront of leadership within the sector. With such increased demands from these industries in living by their sustainability and energy-efficient arguments, competition in the sector will again increase due to prompt innovations and futuristic technology developments.

Air Compressors Market Key Segments:

By Type

- Portable Compressors

- Stationary Compressors

By Technology

- Reciprocating Compressors

- Rotary/Screw Compressors

- Centrifugal Compressors

By Lubrication Method

- Oil-Free Compressors

- Oil-Lubricated Compressors

By End-User

- Manufacturing

- Oil & Gas

- Food & Beverage

- Healthcare & Medical

Key Global Air Compressors Industry Players

- Atlas Copco

- Airman Co., Ltd.

- Ingersoll Rand

- FS-Curtis

- Kaeser Kompressoren

- Howden Group Ltd.

- Gardner Denver Inc.

- Aerzener Maschinenfabrik GmbH

- Hanwha Power Systems

- Doosan Portable Power (BobCat)

- Danfoss A/S

- Sulzer AG

- Elgi Equipments Ltd.

- Boge Compressors

- Quincy Compressor

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252