Nov 06, 2024

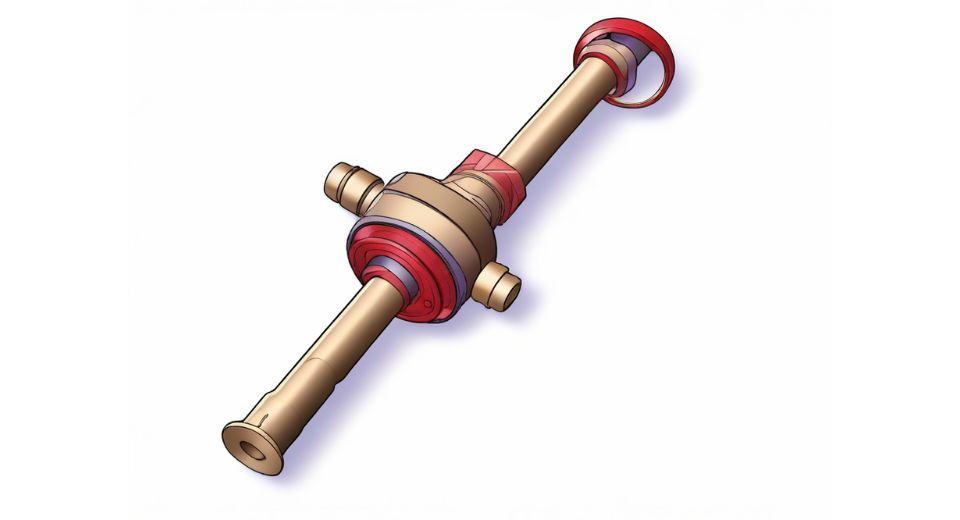

Metastat Insight introduced an in-depth study on the global refrigeration valves market, bringing to light the most critical shifts and trends affecting industries reliant on advanced refrigeration systems. Though often unseen, refrigeration valves play a vital role in the functionality of refrigeration and cooling equipment across sectors such as food storage, pharmaceuticals, and industrial cooling. With changes in automation, energy efficiency standards, and environmental consciousness, the global landscape of industries is changing. This report will illuminate the latest developments, challenges, and future potential of this essential market, providing an in-depth perspective on the components and technology driving growth within it. Valves play a regulatory role in the refrigeration sector, managing the flow, pressure, and temperature of the refrigerant to ensure that the systems work at their optimal levels.

From controlling refrigerant flow to stabilizing pressures, these valves help systems maintain desired temperatures in various industrial applications. With the steady growth of the urban population and extension of food and pharmaceutical supply chains, refrigeration valves are emerging as a priority in production for manufacturers who would look to meet the harsh requirements of operations. The industry is now witnessing the birth of new materials, designs, and operational innovations which will enhance the service life and durability of the valves, indicating the adaptation and change in the needs of different industries as well as raising awareness of sustainability. This fact has contributed to the idea that refrigeration is heavily influenced by technological advancements along with heavy regulations that influence manufacturers into making more and more efficient valves. Presently, systems that offer refrigeration were primarily considered for use in cold storages whereas nowadays they expect to have refrigeration which can help them to conduct complex cooling jobs along with adapting towards newer diverse fields.

The third reason is that, along with growing global concerns toward environmental sustainability, innovations in refrigeration technology are constantly being applied to reduce energy consumption and greenhouse gas emissions. Therefore, this revolution within the industry has driven companies to reconsider traditional designs and start embracing more versatile, long-lasting, and eco-friendly materials for making valves. Advanced refrigeration valves are used with improved flow modulation, better pressure controls, and more resistance to wear and tear. Here, loss due to failure or lay-up is heavy, which has made high-performance or advanced refrigeration valves indispensable in such scenarios. The latest trend, however, also includes minimizing the harmful potential of used refrigerants. That has become a dictum for using refrigeration valves. While the less-harmful refrigerants evolve, along with them come new performance specifications that are compatible as well, and safety aspects. Valves must now be compatible with a much wider range of refrigerants, many of which differ significantly from the conventional ones in chemical properties. This requires an investment in much research and development in order to produce valves reliably operable with these alternative refrigerants; still, the demands of international standards should not be compromised.

This evolution has brought about a change in the practice of engineering, focusing the main interest on improving thermal management, reducing the risk of leakage, and adaptation of valves in complex refrigeration systems. In addition to these regulatory pressures, digital technology is now increasingly added to the refrigeration sector, adding intelligence and automation to what was once the mechanical domain. These valves, with their integration of a digital control system and various sensors, allow the real-time adjustments and the precise monitoring of flow. This saves the energy input for the system and also increases their life span. This great technological leap has enabled various businesses to make data-informed decisions, optimize operational performance remotely, and take proactive maintenance to avoid hefty repairs.

With growing industrial deployments of digital connectivity, it is expected that smart refrigeration valves will increase its adoption prospects, and they will provide significant competitive advantages to manufacturers through lower running costs and better energy efficiency. From a market standpoint, regional aspects of industrial development and, therefore, energy policy continue to determine demand from the standpoint of refrigeration valves. Emergence in Asia-Pacific and Latin America is rapidly industrialized and includes the expansion of food processing and storage capabilities. These regions are likely to be very attractive with good growth opportunities, since the manufacturers are setting infrastructure to support long-term demand.

Europe and North America continue to show steady demand. Their demand is based upon environmental policies and consumer consciousness. These mature markets target upgrading current systems using modern, energy-efficient valves that will keep pace with increasingly stringent regulations and the needs of their corporate customers’ sustainability programs. Regionally, this demand can fluctuate as a function of local economic growth, the regulatory environments, and expectations from the consumer populations which impacts the supply chain as well as the form the refrigeration valves take. Going forward, the global refrigeration valves market, as studied in the report by Metastat Insight, is going to face challenges and opportunities that will define its future path.

The call for low environmental impact, energy efficiency, and more advanced digital integration will highly influence product innovation and application across various industries. The manufacturing of these sectors will continue on their paths of evolution along with improvements in refrigeration systems using durable and versatile valves. As the investments in the industry continue going into cutting-edge solutions with changing needs, the scale for growth remains strong and healthy. Refrigeration valves are no longer an engineering component but are now integrated to ensure operational efficiency with sustainability in critical cooling applications worldwide.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479