Nov 05, 2025

The recent report by Metastat Insight on the global packaging machinery market, a report by Metastat Insight, impresses the world with its 'silent' role every time a product finally reaches a consumer's shelf in its perfect state, sometimes even unnoticed. All that is packed and sealed properly and all that is hidden from view due to packaging depends on machines that create, fill, seal, label, and ship the products. The era of online shopping has set the bar high—fast delivery, tamper-proof wrapping, and clean presentation are now the norms. Good reliability of the packaging process not only supports the brand but also increases productivity and customer satisfaction making the packaging machinery an unseen but very much alive force in the manufacturing areas. The trend for the hygienically packed products, the habit of consuming them, and the driving of retail customers to factories through easy transportation are the major factors that contribute to the widespread awareness of the modern packaging systems.

On the one hand, the present-day manufacturing industry is becoming more and more complicated, and on the other hand, it is not the same as before. The company's production line changes quite often, especially with the seasonal promotions, introduction of new flavors, shorter product life-cycles, and diversifying the product range by varying the container shapes. Manual packaging is simply unable to meet the high speed and accuracy that are required in the production halls. One missing seal or damaged carton can lead to the whole supply chain being disrupted, increased levels of waste, and higher operational costs. Automated and semi-automated packaging machinery is the answer to all these challenges, allowing the operators to keep up with the pace of production while maintaining the same pressure, strength and accuracy in sealing and labeling.

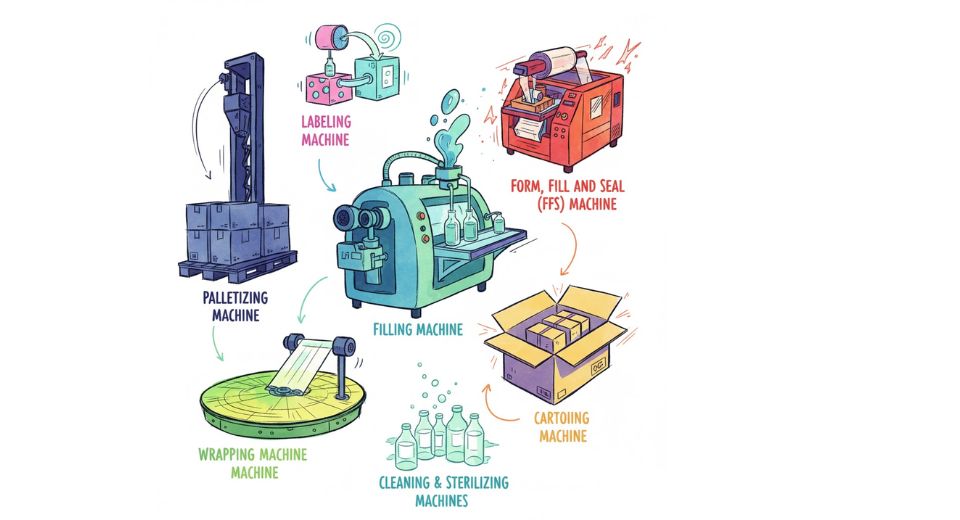

The operation of packaging machinery is simple but also sophisticated. The machinery will first check how much of the product there is, then the product will be placed in the container, after that the container will be sealed and finally it will be labeled or coded for traceability. Automated solutions are bringing about lesser contact of the product with the machine, thus, the company is able to support hygiene efficiently and also limit the risk of contamination in the food, beverage, pharmaceutical, cosmetic, and personal care industries. Changeover parts enable a transition from one product to another with minimal downtime. By using the improved software, it is possible to keep a very precise record of the machine's health, usage patterns, and maintenance schedules. High-speed conveyors synchronize machines' movements, thus avoiding bottlenecks or misalignment. All these features bring about lower waste, higher throughput, and better presentation on the shelves. The precision, quick packaging cycles, and labor pressure reduction associated with the machinery have made manufacturers to embrace the machines.

It took a long time for packaging machinery to evolve from a low-tech mechanical sealer to a fully automated line with digital monitoring and changeable modules. The first systems had only speed and basic sealing as their main features. The later ones introduced servo control, automatic quality checks, and components that consume less energy. Recent inventions are quick-change tooling, predictive maintenance notifications, and material-saving designs. The process that manufacturers gradually went through was to try smaller units with automation and then upgrade the entire line. Besides the continuous improvement of control systems, integration with enterprise software, and modular design, manufacturers' trust in advanced packaging solutions is being constantly strengthened.

Certain areas show a very high uptake of technologies in particular in places where automation investments receive industry-wide support together with high manufacturing intensity. Established industrial areas utilize machinery for the quick and efficient handling of very large volumes of production. However, the new growth areas tend to be more and more interested as local manufacturers are able to expand their exports. In these places, the finishing machinery is helping to meet the quality standards set by the international market and at the same time it is reducing the risks to the workers from manual operations.

Growth of infrastructure, building of new food processing plants and increase in demand for consumer products that are positioning a few developing countries as major future adopters have already taken place. In fact, the entrance of manufacturers into the global market through cross-border trade reduces the packaging machines to a bare minimum, which is good in that they only have to comply with the labeling and safety standards that are required by the foreign market.

The packaging machines have made great strides but the machines still come up against real-world difficulties. The investment needed to buy the top-of-the-range equipment tends to drive away new entrants or small companies with little financial resources who are on a limited budget and thus only able to afford the basic models. Very often the advanced machines are not compatible with the older factory set up and this sometimes leads to extra costs for changing the layout, electrical systems, or even training of the workers. Regulations that deal with food safety or pharmaceutical authentication usually require constant changes to be made to the coding and traceability systems. The competition among the manufacturers of machines is so keen that there is a constant push for differentiation in the products and this practically translates into the software being more connected, the materials being more efficient, and adapting to the changes in the market without raising cost. Nevertheless, every problem has a plus side. The design of modular equipment makes it possible to gradually implement upgrades rather than replacing the whole plant at once. The sustainable material handling technology is opening up new cooperation possibilities with the producers of packaging materials. The growing interest in automation also creates opportunities for educating the workforce.

At present, demand is on the same wavelength with the aforementioned wider trends like conservation efforts, overall efficient use of resources, and the growing demand of the customers for packaging that is clean and secure. Every packaged good is a moment of trust between brand and customer, and it is the machinery that seal this trust. Gradual advancements in automation, material handling, and software monitoring show that the market has longevity. Meanwhile, packaging machinery is available to facilitate the change as new industries come up and classical ones transform their lines for more agility.

The reach of sophisticated packaging technologies is becoming more widespread and the impact is felt in the whole assembly line, throughout the regions and markets across the globe. The sales report from Metastat Insight which unveils the trend of the global market for packaging equipment supports this added force of demand. After all, the machine that secures goods, lowers waste and balances production is placed right at the heart of the modern manufacturing capabilities’ advancements.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479