Nov 13, 2025

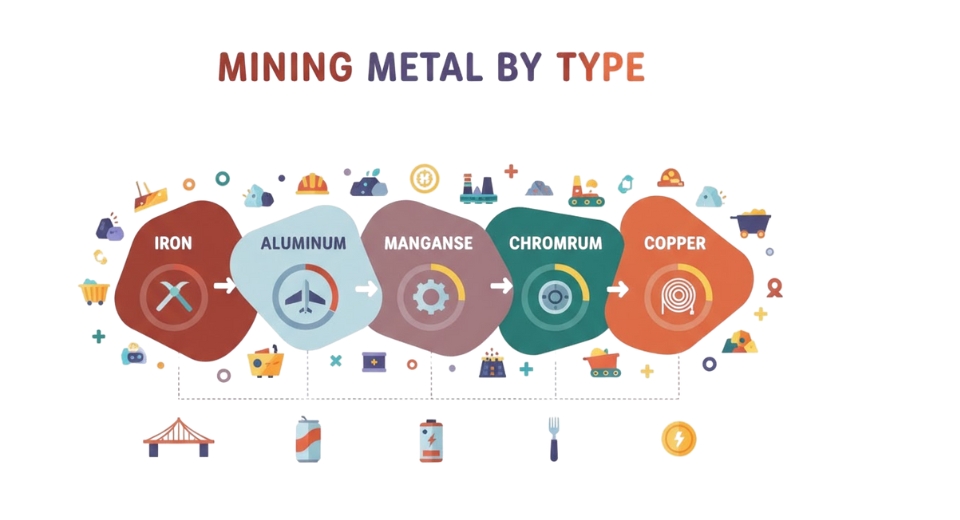

The global mining metal market report published by Metastat Insight brings to light a domain that is intricately linked with our daily lives though often indirectly. The very existence of modern transport, communication, medical and even the cleaner energy systems depend solely on the metals having gone from the mines to the factories and then finally into the hands of the consumers. Whenever new infrastructure projects are started or higher grade materials are required for new manufacturing techniques the demand is automatically increased. During the period of urbanization and the transition of industries to advanced processing and precision engineering, access to high-quality metals becomes a necessity that is already being seen as a standard in the market. The demand for transparency in sourcing and reducing environmental impact is also contributing to the market's visibility.

Industry Context

The global industry demands shorter construction periods, lighter components, and stronger materials all at once. While sometimes traditional sourcing methods are unable to keep up with the output and sustainability expectations from both the manufacturers and the governments. Constant changes in the environmental standards compel the organizations to overhaul their extraction and refining processes. A sudden change in the purchasing strategy of an industry can also create a bottleneck in the supply chain. Consequently, the modern extraction operations resort to sophisticated planning, better refining processes, and data-driven decision support systems. These transformations are what eventually leads to a stable flow of materials and consistency in product quality. The mining metal market assures the availability of the required metals for production in various sectors such as transportation, consumer electronics, healthcare equipment, and large construction projects.

How the Sector Creates Value

The current state of extraction and refining practices is marked by the use of modern technologies and digital monitoring that are well-equipped and less wasteful, resulting in the quality yield and the very efficient tracking of materials all the way from the source to the final destination. The role of automation is to cut the time taken in extraction and increase the accuracy in sorting and processing. The application of new methods for purification is pushing the metals' limits in their performance by removing almost all the impurities and making them applicable in very strict areas like aerospace materials or high-efficient electrical conductors. The improved traceability is giving the buyers a chance to check with the sellers the latter’s pledges regarding the source of the metals and this has the effect of not only helping the sellers avoid reputational risk but also supporting the responsible procurement programs they have set up. The mining metal market is a source of refined metals used in the making of stronger structural components in manufacturing, lighter machinery, and longer product lifetimes. This, in turn, leads to improved durability, better resistance to corrosion, and greater efficiency of the end-use equipment. Because of the constant progress in refinement, industries are able to try out new designs and manufacturing methods that in the past would have required custom alloys or specialty coatings.

Modern extraction and refining practices

The use of advanced extraction and refining techniques has not been very popular at first mostly due to their high costs and therefore, such projects were usually financed by the big companies only. But slowly the accessibility of technologies such as remote monitoring, digital geological mapping and automation led to the noticeable shift in the attitude towards these techniques. The accuracy is greatly improved with the help of computer-guided drilling. The modern sorting machines are analyzing the raw minerals on the conveyor lines, which at the same time is minimizing the contamination risks and lowering the energy consumed in the process of later refinement. The mining metal market has been one of the recipients of the advantages of the research in the area of material science that concentrates on making alloys stronger, developing better recycling paths, and producing multi-metal blends that are specific to advanced product development. The demand for metals has been highly impacted by the rise of renewable energy, electric transportation,

Regional and Global Movement

The strongest uptake of raw materials and metals, however, regions with already developed industrial platforms and future infrastructure investment plans, of course. These, being the richest in mineral resources, still manage to import lower priced metal owing to the fact they are investing in new technology for extracting the metals available in the mines. The collaboration of manufacturers with raw material suppliers through long-term contracts guarantees the uninterrupted flow of such required metals for production. On the other hand, the areas where major infrastructural developments in transport, housing, or electricity supply are taking place are the ones where the demand for metal materials is the highest. The same holds true for new areas, especially those that are fast urbanizing, where the processing of domestic ore is considered to be economically more favorable than exporting for refining. Consequently, the refining capacity to be built in the partnership with various countries will support local industries, create job opportunities, and among others, develop an export market.

Difficulties and Possibilities

Governments and NGOs have made it clear that they expect mining to be done in an environmentally responsible way. Such regulations do not only require constant innovations in the areas of waste handling, water use, and land restoration after extraction but also add huge cost to the operations. Some of the operations encounter the communities’ opposition because of land access or disturbance to their way of life. Occasionally, there are price fluctuations in the international market for mining metals caused by competition which make long-term planning more difficult. However, gradually the demand for the metals is coming back and the situation is improving as recycling methods have been developed. For instance, the digital technology is being used to monitor the machine maintenance and this allows planning the maintenance in the time when the energy use is low. Moreover, the collaboration with the R&D departments of the universities may lead to faster trials of new extraction chemistries, and of every robotic process automation upgrades that will make the worker's risks less. The alliances of the production plants with the logistics and manufacturing sides have made the upgradation of the facilities very efficient.

Why Interest Is Surging Now

Major global trends push industries toward sustainability, reduced material waste, and traceable sourcing. Infrastructure renewal programs require large volumes of refined metals, while advanced manufacturing seeks stronger and lighter alloys. Clean-energy projects rely on copper, aluminum, and specialty metals for turbines, power lines, and energy-storage systems. Without consistent access to refined metals, many large-scale technology projects would stall. The mining metal market research presented by Metastat Insight underscores the growing significance of responsible sourcing and advanced refinement. This field supports progress across transportation, digital connectivity, healthcare, and renewable power systems. Continued advancement in extraction efficiency and material innovation strengthens the foundation for future industrial progress, ensuring societies have the materials required to build safer infrastructure, smarter machines, and a more sustainable future.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479