Nov 12, 2025

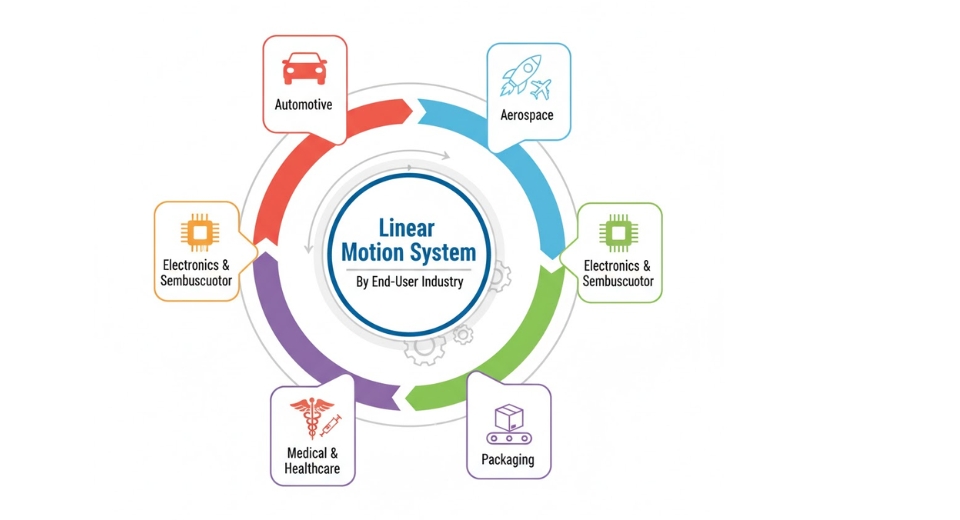

It can be noted that motion with precision and reliability is a common requirement of factories, logistics centers, research labs, and production of medical devices, to name a few. The global linear motion system market as depicted by Metastat Insight not only illustrates this requirement but also links various industrial activities to more fluent production, stricter quality checks, and uninterrupted workflows. In the present-day production scenarios, the loss of production time means loss of income and loss of good name. Linear motion system is the one that allows the machines to move smoothly on a straight line, giving support to the precision tasks without the need for manual intervention. Every finished assembly, every scanned package, and every automated laboratory sample get their success thanks to motion technology that is reliable. The increasing demand for quicker output and less waste has slowly transformed linear motion from a mere supporting mechanism to a strategic advantage.

Industry Landscape and Increasing Need

The manufacturing and automation industry is still struggling with shrinking production schedules, material shortages, skill gaps, and constantly rising performance expectations. The misalignment or breakdown of equipment results in loss of quality and time, leading to disputes over quality. Hence, the need for components that provide consistently dependable, accurate, and clean movement is becoming more and more intense. This scenario leads to the adoption of solutions that minimize friction, noise, and maintenance demands in machines.

Linear motion systems give automated equipment the ability to move in straight line. Rather than creating mechanical solutions that rely on constant servicing and hence require improvisation, production teams opt for structured assemblies which not only provide reliable guidance but also support the load. Machines that are equipped with guided movement minimize human participation, keep the product consistent, and even during long operations they remain efficient. As more and more factories are moving towards automated workflows, the demand for the structured movement of machines is also increasing.

Functionality and Value

A linear motion system directs motion along a predefined path using rails, guides, actuators, and drive mechanisms. Movement stays consistent because guided assemblies maintain alignment under heavy loads or continuous use. Precision benefits industries where even slight deviations create defective output or downtime.

Beyond accuracy, these solutions contribute to cleaner operations. Low friction components reduce particulate generation, enabling safer use in laboratories or food production facilities where cleanliness matters. Actuators powered by electric motors or pneumatic sources offer smooth transitions without abrupt stops or vibration. The entire assembly is designed for longevity, minimizing maintenance intervals and enabling predictable scheduling for service tasks.

Compact footprints offer additional convenience, as advanced designs fit into smaller machines without sacrificing strength. This enables engineers to design equipment with greater flexibility and reduced bulk, improving floor layout efficiency.

Progress and Innovation Over Time

Earlier versions of guided movement systems served basic mechanical alignment. Precision expectations were modest, and many tasks relied on manual calibration or custom mechanical setups. With increased automation, manufacturers sought smoother, consistent linear guidance capable of handling continuous loads without overheating or deformation.

Material improvements changed performance expectations. Hardened metals, advanced surface coatings, and refined bearings lowered friction and extended lifespan. Designs now support clean manufacturing environments, sensitive research spaces, or robust industrial automation.

Digital control solutions increased relevance further. Smart actuators and sensing components detect misalignment, adjust force, or signal degradation before failure occurs. These advances transformed linear motion from a passive component to an active contributor to operational intelligence. The result is a more resilient infrastructure, helping factories anticipate issues and reduce unexpected stoppages.

Regional and Global Adoption Patterns

Strong adoption currently appears in established manufacturing regions with dense concentrations of automotive, electronics, and pharmaceutical production. These regions maintain advanced automation ecosystems, supporting faster upgrades and integration of new technologies. Engineering expertise and vendor networks bolster confidence, allowing manufacturers to implement sophisticated motion solutions in new equipment designs.

Rapid growth also emerges in expanding industrial territories where demand for automation increases due to rising labour expenses, modernization of existing equipment, or new investments in high-quality production. Growing focus on clean manufacturing and energy-efficient systems positions linear motion technology favourably, encouraging adoption beyond mature markets.

Barriers and Prospects Ahead

Certain challenges remain. High-performance systems require specialized engineering and skilled installation. Some manufacturers hesitate to upgrade legacy equipment due to perceived complexity or budget constraints. Competition among solution providers also introduces pricing pressure and increases the need for differentiation based on durability and service capability.

Despite these hurdles, opportunities continue to widen. Advances in materials science, lubrication-free components, and smart sensor integration reduce servicing concerns and optimize performance. Rising investments in automated inspection lines, medical device manufacturing, and compact robotics support consistent demand for guided motion. Synergies with collaborative robots and precision machining expand relevance beyond large-scale automation and into smaller, specialized applications.

Why This Moment Matters

A new generation of manufacturing strategies seeks lower waste, higher repeatability, and reduced environmental impact. Cleaner production, digital quality tracking, and lights-out manufacturing require motion systems that deliver reliability without constant oversight. As automation spreads to more industries, the importance of dependable movement increases.

The linear motion system aligns with these goals by supporting accurate, low-maintenance, and energy-efficient machinery. Each advancement helps organizations improve output while consuming fewer resources. This creates a ripple effect: smoother equipment performance enables faster development cycles, better product consistency, and stronger customer trust.

Modern production now demands more than speed. Sustainability targets require solutions that reduce energy loss, minimize wear, and extend equipment life cycles. Linear motion assemblies support these objectives, contributing to smarter machinery designs and reduced operational waste

A manufacturing future defined by accuracy, consistency, and responsible production invites technologies that convert motion into measurable performance. The global linear motion system market presented by Metastat Insight highlights that guided motion now supports far more than mechanical movement. Guided motion supports confidence—confidence that each production line will meet demand, each product will match specifications, and each process will perform without interruption.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479