Apr 14, 2025

The new revelations into the global industrial communication market have been contained in the latest publication shared by the Metastat Insight. The changes continue to tell how the industry continues to reinvent itself in diverse, complex, and ever-changing contemporary industrial contexts. It was also the invisible engine of the manufacturing and production ecosystems: industrial communication is evolving from the simple exchange of signals to a full network-connectivity infrastructure, standing now as the digital backbone of synchronized operations across different devices, systems, and control layers. Under such conditions, the efficiency of communication protocols is critical to the responsiveness and precision of the industrial operations.

Global Industrial Communication market is estimated to reach $27,249.15 million in 2025 with a CAGR of 6.0% from 2025 to 2032.

Clear-drawing acknowledgement towards communication systems that can be dependable yet adaptive to the intricacies of the structures of factories, processing plants, and logistics networks has arisen with the increasingly complex structural needs of these organizations. Now, it is not just transmitting data; it is about transmitting the right data at the right time under very different conditions from one location to another. Hence, there was an increasing focus on specialized communications interfaces that can interwork across varying hardware tiers and interface with broadening varieties of software platforms. The study reveals that the Global Industrial Communication Market is not held by convention. In reality, it has evolved into one critical enabler of performance and efficiency as well as informed decision-making.

This mode of operation is also attached to industrial communications, which should establish a formidable contrast from what passes for those between customer and business communications. Conditions under which the industrial breed of communication has to operate dictate rigorous physical and operational standards. The very loud hum of machines at full capacity, varying extremes in temperature, and electromagnetic interference are all tangible threats to communication signals, bringing them to naught. Yet all of this has been able to lead to protocols and hardware capable of providing stable, accurate exchanges even when the environment challenges the reliability and endurance of traditional electronics. Industrial communication systems operate without being interrupted and under pressure-and that is what makes all the difference between such systems and others, also solidifying the position of such systems in mission-critical scenarios.

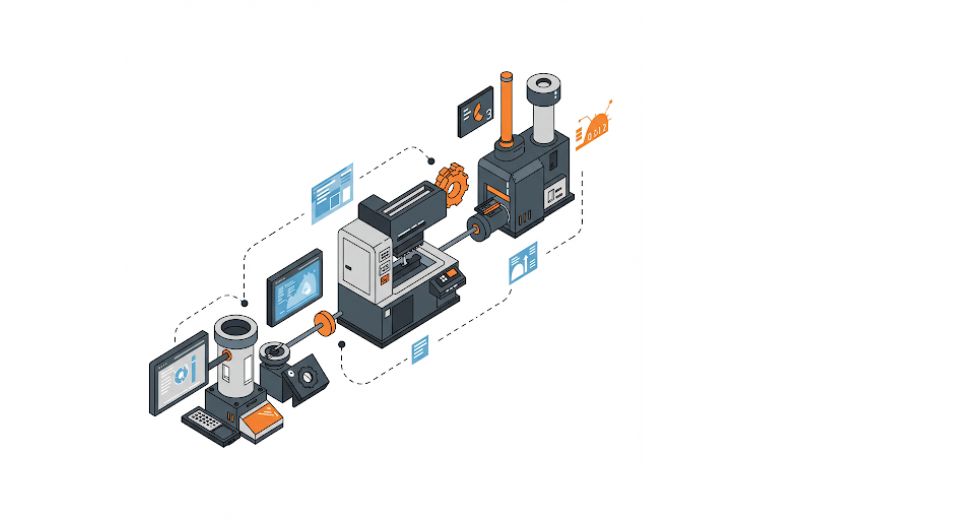

There has also been a clear movement into the unification of divergent systems inside a single installation. Previously isolated control levels are now claimed to communicate freely, with data flowing freely between programmable logic controllers, human-machine interfaces, sensors, and servers in remote locations. Such a situation, however, entailed new thinking from the old communication models. New industrial communication solutions typically will not replace all of the existing infrastructure; rather, they will be designed with the legacy in mind so that they plug into those systems while transitioning to more intelligent and agile networks.

Customization and modularity have increasingly gained popularity in addressing peculiar needs in various industries. What works aptly for automotive manufacturing may not work at all in a pharmaceutical facility, and the adaptability of communication protocols across divergent verticals becomes a measure of their viability. Engineers and architects are engaged further to design frameworks that are flexible while still maintaining stability. The functions of middleware, gateways, and protocol converters have thus evolved as these tools provide the translation of one tongue into another, all while preserving the data flow against disruption by changes in the systems.

Another dimension would be the level of control and visibility these systems provide today. Operators as well as maintenance crews have now stepped out from the classical confines of industrial plants, being able to exercise supervision remotely with a high level of precision and immediacy, thanks to networked communication solutions. Alerts, performance indicators, and diagnostics can now be relayed through dashboards that aggregate real-time data from all production lines. This organic shift not only enhances operation awareness but also accelerates responses to incidents, thus reducing downtime and ensuring continuity.

There is no more question that security is an integral part of the industrial communication infrastructure. With interconnectivity, there have been lots of unauthorized access and data breach concerns. Wherever the industrial communication system used to work in isolation, today they are at risk connected to a wider IT environment. As such, there is now heightened emphasis on building security features into industrial communication protocols to prevent interference with their operation while protecting sensitive operational data. Security becomes integrated into every level of these systems, from secured transmission to access permission layering.

In addition, the whole way in which these communication frameworks are now laid out strategically often coincides with sustainability initiatives. Smooth communication means a well-oiled operation, and less waste, energy consumption, and downtime can also accrue from such operations. Synergies inherent in technical efficiency versus environmental rightfulness are emerging to influence investment decisions within heavy industry. The view regarding communication infrastructure has changed into becoming an active pillar of support for the company's core values, and not just a way of achieving operational efficiency.

The perspective articulated in the Metastat Insight Global Industrial Communication Market Report emphasizes how this realm is not merely reacting to industrial needs but is, in fact, anticipating new challenges and preparing to meet those with innovative strategies. Communication in industrial systems has emerged as a science balancing precision, integration, and durability in view of the challenges in production environments.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479