May 29, 2025

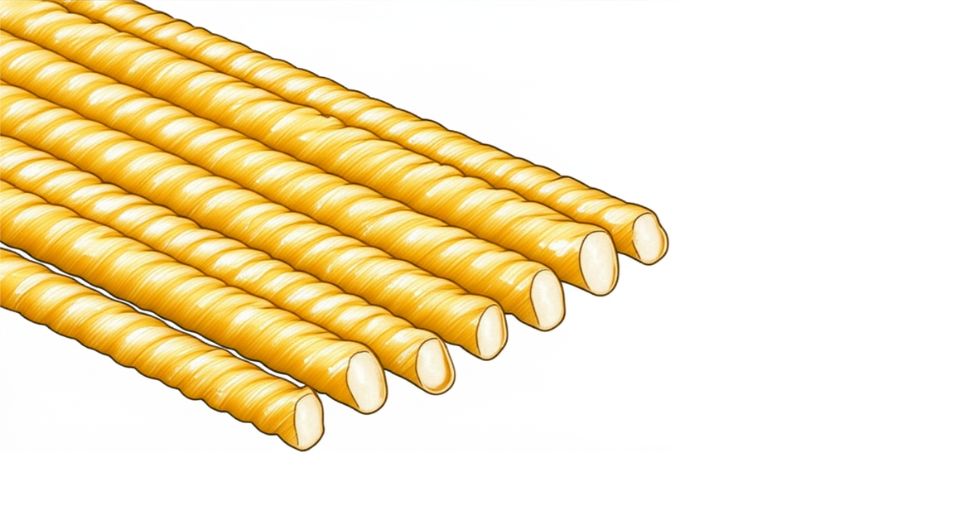

The recent publishing global glass fiber reinforced polymer (GFRP) market by Metastat Insight highlights the market, providing a wide understanding of how this industry is progressing in many fields. With a mixture of overall innovation and industrial applications, the GFRP sector has created an important place in various manufacturing domains. Research attracts attention to emerging production patterns, investment preferences and transfer focus of industries that are rapidly dependent on mild and corrosion-resistant materials. The emergence that emerges from this exploration is a comprehensive picture of a material that is not only versatile in the function, but is also achieving relevance in a high-mang environment such as construction, aerospace and automotive.

Global Glass Fiber Reinforced Polymer (GFRP) market is estimated to reach $51,060.0 million in 2025 with a CAGR of 6.3% from 2025 to 2032.

In the manufacturing world, traditional materials such as steel and aluminum are gradually giving way to options that provide better combinations of power and weight. Of these, glass fiber reinforced polymers are standing out, roughly due to their adaptability and performance in the atmosphere where there is a concern with exposure to moisture, chemicals and ups and downs temperature. These characteristics have allowed GFRP to be used in bridges, wind turbines and marine applications. This material is being seen as a permanent solution with long-term benefits in areas where safety and durability are non-pervasive. It is also worth noting that the adoption of GFRP opened opportunities for new design options, which are first inaccessible with traditional metals.

The report states that regional markets are developing differently, which are affected by separate regulatory environment and investment capabilities. In some countries, environmental mandate and stability targets are acting as accelerators to adopt advanced material. Meanwhile, countries with expander infrastructure programs are actively searching for overall options that reduce the cost of maintenance and expand the asset life. This difference in regional speed provides a broad reference to understand the GFRP landscape, indicating a future that is diverse and strategically fragmented. There is also a growing trend towards local production, as nation looks to reduce dependence on imports and create flexible supply chains for industrial content.

It is also striking about the data presented that the research institutes and private firms working together to refine the methods of production and expand these polymers' are the role of research institutes. There is a significant investment in developing mixtures that are more resistant to wear and stress, ensuring cost-efficiency. Between innovation and commercial demand, this coordination is exposed to a new generation of GFRP products that meets special applications from interiors of the aircraft to high performance sports equipment. This progress not only indicates the depth of capacity in this location, but also points to a developed consumer base that is more informed and technically oriented.

While the market continues to expand, the economic background cannot be ignored. Raw material prices in the supply chain and ups and downs in logical challenges have tested the flexibility of manufacturers. However, many have adapted by embracing automation and smart manufacturing techniques that improve yield and low production waste. In this light, the GFRP region follows a trajectory that aligns well with the broader goals of industry 4.0, where efficiency and stability are closely connected. These technical integrations have added a new dimension how companies see overall materials-only as an alternative, but as strategic components in the future ready infrastructure.

It is also important to consider how consumer behavior and market expectations are affecting product development. The end-usagers are today more conscious of the life cycle effect, carbon footprints and recurrence of materials. The GFRP market is responding with solutions that are not only high in performance, but also in environmental impact. For example, development in thermoplastic-based GFRPs, receiving traction for their better re-purpose. This reflects a change in market values, where performance and environmental responsibility must be in co-existence.

Documents introduced by Metastat Insight on Global Glass Fiber Reinforced Polymer (GFRP) market paint a picture of an area that is rapidly maturing while adaptation to contemporary demands. The expansion of material in industries is not only the result of technical benefits, but also with its alignment with global trends in stability, durability and design flexibility.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479