May 23, 2025

The new report published by Metastat Insight offers a deeper look into the changes happening within the global fusion machine market, making note of the changes and improvements which have steered its current path. Fusion machines, vital to fusing materials in construction to utility industries, have existed for a very long period and have served a technical yet vital purpose. These systems have seen gradual but profound changes, adapting to changing demands of businesses dependent on continuous, reliable, and durable material welds. Behind the scenes, though often so, machines for fusion are at the forefront of many high-priority tasks where precision and reliability are not negotiable.

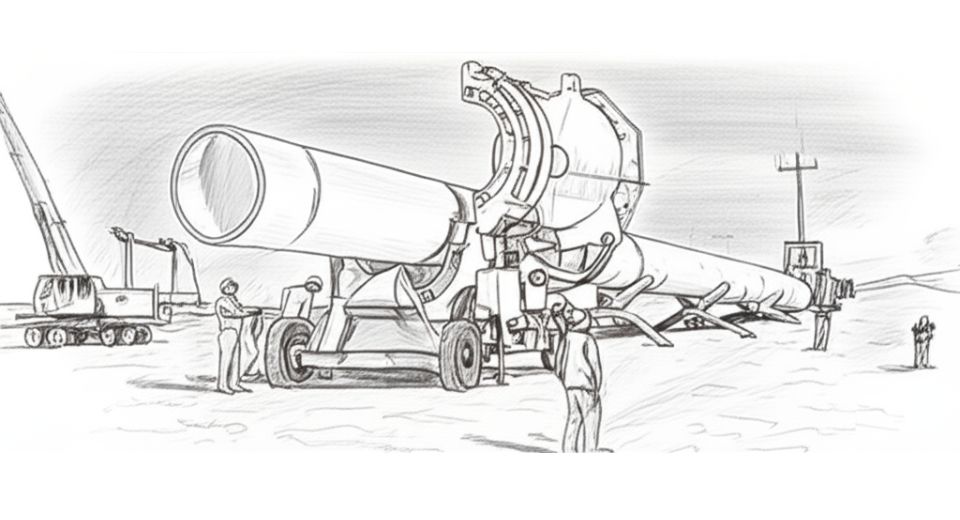

Here, machinery innovation has been a consistent but subtle undertow. The demand for quality performance, minimal downtime, and adaptability in varying operating conditions has prompted manufacturers to re-strategize. These machines are no longer designed merely for stationary workshop conditions; they are now being designed to function competently under erratic outdoor conditions and across rough terrain. Their development has thus increasingly embraced strength, simplicity, and minimal maintenance requirements so that operators can conduct tasks with greater confidence and efficiency.

There has also been a shift in how firms go about the integration of fusion machines in larger operations. Instead of dealing with them as standalone systems, most firms incorporate these systems into longer processes of operation. In the process, they contribute to coordination across different stages of material processing and installation. The integration facilitates smooth flows, reducing the margin of error and turnaround time. Positioning in this manner within broader project environments indicates an increased appreciation of the machine's productive value, not just in terms of technical efficiency but also in project costs.

Today's end-users of fusion machines are as interested in usability as they are in performance. Operators in hostile environments often struggle, and ergonomics and intuitive design have become critical. Machine interfaces, mobility functions, and speed setup functions become more advanced to minimize operational complexity. Companies react with units that are more user-friendly for people of varying skill sets, thereby democratizing the use of high-performance machines across industries that previously relied intensively on technical know-how.

Materials used in pipe systems and infrastructure have also been modified, and fusion machines have also had to adhere in kind. Capability to handle different types of materials with minimal recalibration has been a preferable feature. Such versatility in making sure that the users are not restricted by material compatibility issues prevents incompatibility issues. Through the development of fusion machines that have multipurpose applications, manufacturers are facilitating industries with the requirement for flexible solutions without compromising structural integrity or quality of connections.

Logistics have also entered into the design path of fusion devices. Devices that are easily portable, can be taken apart and put together with fewer tools, and stored compactly give true advantages in massive-scale or off-site use. Such a focus on practicality has made them the equipment of choice for application in field deployments, where the absence of infrastructure tends to undermine equipment installation. Design innovations have therefore been towards portability without sacrificing basic performance features.

Serviceability, similarly, has become a distinguishing feature. Organizations are now looking at how rapidly machines can be serviced, repaired, or upgraded. Rather than having to spend money on entirely new systems when updates need to be implemented, the availability of modular parts and universal components has made downtime a smaller issue. In this instance, the life of fusion equipment is being lengthened, and through intended service maintenance, initial capital cost value is being extended. The customers, from their end, trust machines which promise long-term consistent performance, supported by readily accessible service plants.

The global nature of the market provides an additional complexity. Whereas some applications demand ruggedness in field application work, others demand precision pieces of equipment to work within controlled environments such as laboratories or industrial facilities. Meeting this spectrum has called for manufacturers to produce a range of models while maintaining a level of quality in each model. Understanding regional usage patterns, regulatory requirements, and cultural desires is now a critical prerequisite for companies seeking to stay current across borders.

Beyond the equipment itself, the human element remains a factor in product development. Support systems, training, and operator feedback are now part of product improvement. Organizations now recognize that how well users are served before, during, and after they install equipment is a factor in their equipment's success in operation, as much as engineering effectiveness. Customer engagement, technical support infrastructure, and training programs are being placed more and more on the agenda as a key element of the overall value proposition.

The in-depth observations in the global fusion machine market Report published by Metastat Insight provide a glimpse of the in-depth adjustments that characterize this sector. From usability to logistics engineering, from material versatility to service strategies, the market continues to be responsive to the day-to-day practicalities of those who rely on fusion machinery on a daily basis. Prodded not by spectacle but by earthed innovation and adaptive design, the market transforms so that such machines are not only tools for utility but also enablers of industrial progress. With industries aiming higher in terms of efficiency and reliability in operation, the role of fusion machines is in their ability to quietly but effectively uphold the physical foundation of infrastructure and manufacturing processes across the globe.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479