Apr 08, 2025

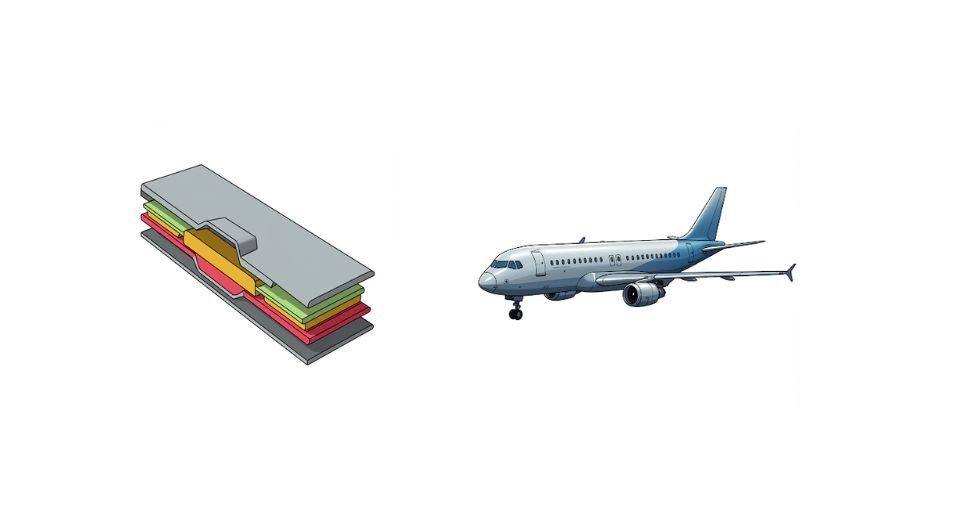

It considers all major factors that are related to the global aircraft interior sandwich panel market, such as the recent developments, emerging technologies, new businesses, factors driving and challenges associated with the industry, the market size keeping this segment in view. Apart from this, the report on the Global Aircraft Interior Sandwich Panel market clauses all possible aspects that are being highly ever looked up to by prospective investors. With this report, a reader can have a comprehensive perspective towards this segment of the aviation industry which quite often works behind the scenes but unarguably becomes an essential part of shaping the passenger experience and enhancing operational efficiency. Carefully engineered as per the requirements of various strict aviation standards, these sandwich panels come out to be more than just structural members, as they are also a delicate interplay of safety, performance, and design, constructed to resist a very high range of pressure with respect to a temperature change, yet on the lightest possible weight. And all of this has a material science intersection being built into precise engineering. As the airlines compete with each other on the promises of enhanced comfort, safety, and fuel economy, the focus on internal components of an aircraft cabin has intensified, and with it has come the relevance of such kinds of panels.

Global Aircraft Interior Sandwich Panel market is estimated to reach $65,821 million in 2025 with a CAGR of 6.0% from 2025 to 2032.

On the current picture, extensive collaboration exists between manufacturers, aviation authorities, and material scientists. This collaboration has largely improved the production methods for making panels with higher durability, fire resistance, and ease of maintenance. Using a honeycomb core made of aluminum or aramid paper has been the conventional way of making these panels; they are now evolving with new advances in composites to make the aircraft even lighter while allowing even more design freedom. Better aircraft weight reduction shall result in a more fuel-efficient aircraft, which benefits operating cost solutions to economics and environmental commitments. The conversation now extends well beyond weight management. It is into sustainability, recycling, and emission reduction over the life cycle, with concerns that at one time went largely unnoticed regarding how an aircraft component was selected, to now have been front and center.

Another aspect worth noting is how the interior arrangement has evolved for both commercial and private jets. Given that demands for custom interiors, high-end finishes, and ergonomic concerns are increasingly rising, manufacturers of sandwich panels will adapt and adjust to provide solutions that will not only meet code specifications as regards safety but would also deliver towards the aesthetics and branding expectations of their clientele. What the airlines want is no longer a common component for all. They desire modern modular interiors that can be adapted with the passage of time to suit changing market trends and changing customer preferences. This transition would demand materials that can provide adaptability without compromising on structural integrity or weight.

Suppliers of these sandwich panels would often be found working within the broader network of the industry with aircraft OEMs, cabin designers, and interior system integrators in order to come up with components that are designed specifically for a certain model or at the request of an airline. There is extreme attention to detail in this collaboration. The components must perfectly correspond with other elements of the cabin such as overhead bins, sidewalls, lavatories, and floor panels. These parts must lock in place very accurately, and any deviation can lead to regulatory issues or delay aircraft delivery.

Regional dynamics have also begun to establish an influence over the market. While the traditional aerospace centers of North America and Europe actively lead work in technological capabilities, newly emerging players in the Asia-Pacific region are aggressively building aviation infrastructure and setting up aircraft manufacturing capabilities. This naturally leads to a demand for advanced interior components, convincing global suppliers to either build production facilities, enter partnerships, or localize supply chains to satisfy regional certification and delivery requirements. Technology, resources, and talent have flowed across continents, thereby introducing healthy competition, which again stimulates developments in product standards and customer expectations.

The advances mentioned above in this industry sector notwithstanding, its challenges are manifold. Stringent regulations for approval, varying prices for raw materials, and the continuous need for investment in research and development keep weighing on the manufacturers. However, they rather take these hurdles as opportunities to fine-tune the design approach, find alternative materials, or implement a digital manufacturing solution. Technologies like automation, digital twins, and predictive maintenance are gradually integrating into the production chain, so that manufacturers can better plan their operations, monitor material fatigue, and limit equipment downtime during installation and replacement.

Metastat Insight report shows that conditions of the market observed will reveal that the Global Aircraft Interior Sandwich Panel market is not just the mere summation of its products. It shows a sector that contains nuances in which innovation, regulatory compliance, customer-oriented design, and global collaboration intersect in fascinating ways. The deceptively simple-looking panels will find more and more relevance as aviation embraces the future of sustainable and customized flight experiences. The interplay of materials science and aerospace design has and continues to keep the Global Aircraft Interior Sandwich Panels market, as described by Metastat, an important thread in the larger story of the advancement of aviation.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479