Sep 24, 2025

The Metastat Insight latest aerostructures market report exemplifies how aerospace production continues to shape transport, defense, and worldwide connectivity. Aviation has been integrated into the fabric of everyday life, tying human beings, goods, and industries around the world together faster and more efficiently. Behind each plane is always a structure of engineered components designed to balance performance, safety, and price. These designs not only form the airplane itself but also the overarching supplier, engineer, and end-user community. Their applicability becomes more clear with the heightened need for lighter, stronger, and more sustainable aircraft.

Aerospace production is more under pressure than ever to produce designs that respond to operational efficiency, sustainability, and safety needs.

Airlines seek products that minimize maintenance time and maximize reliability, and defense entities emphasize strength and durability in rugged conditions. Increased material and production cycle costs put pressure to perform. In such circumstances, aerostructures play critical roles facilitating manufacturers to meet these demands. By minimizing weight, realizing optimum aerodynamics, and maximizing fuel efficiency, they directly facilitate aircraft performance to fly economically and sustainably.

Aerostructures are the physical strength of an aircraft, including wings, fuselage parts, empennage, and other load-carrying items. They define how an airplane flies, withstands stress, and carries onboard systems.

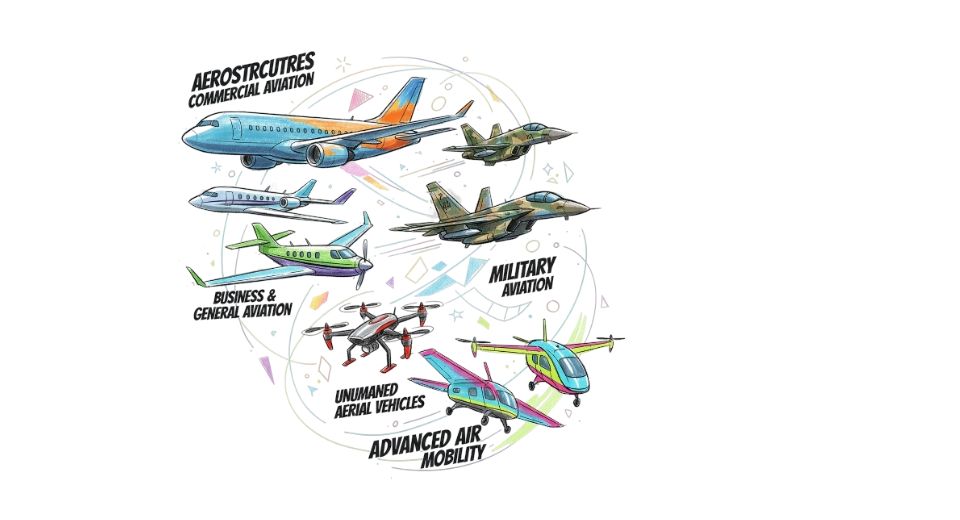

Their worth is a combination of strength and weight, maintaining operation reliably while reducing efficiency. Technological breakthroughs in materials with composites and new alloys have enabled high durability levels to be maintained at lower weight. The advantage trickles over commercial, defense, and cargo aviation, where improved performance translates into cost saving in operation, range increase, and increased sustainability. Structures' flexibility to engage against a broad range of aircraft categories talks about applicability across an extensive base of market segments.

Aerostructures' development is one of progressive refinement and revolutionary innovation. Early dependence on metal fabrication yielded to composites minimizing weight loss at the expense of neither fatigue nor corrosion resistance.

Gradual addition of automated manufacturing and computer-aided design systems enhanced accuracy and manufacturing efficiency.

Collaboration between suppliers and aircraft builders over recent years has encouraged modular designs to enable quicker assembly and more convenient maintenance. These changes have further entrenched the position of aerostructures as core components, yet as pacing agents for wider aerospace innovation. Special application to widespread adoption, the path follows normal development to address industry needs and technological advancement.

Advanced aerostructure uptake is strongest where mature aerospace industries exist, in which established producers and research institutions pace innovation. These markets demand high-performance solutions that enhance efficiency at the expense of following regulatory requirements rigorously. Concurrently, the rising markets are displaying strong potential, fueled by increased investments in aviation infrastructure and manufacturing capabilities.

Partnerships with worldwide suppliers in these regions enhance the technology and experience transfer, providing a rich foundation for growth. This two-way direction of established dominance and increasing involvement illustrates the wide geographic versatility of aerostructures.

In spite of progress, there are problems to production cost, certification procedures, and supply chain resilience. More sophisticated manufacturing methods and dependency on advanced materials represent a threat to add expense and lengthen development time. Stringent safety and regulation standards make the pressure more forceful. These are offset, however, by opportunities.

Greater utilization of automation, additive manufacturing, and computer-aided design will lower costs and be more adaptable.

New demand is being created by emerging region markets, and sustainability efforts allow designs to be used for environmental ends. These prospects make aerostructures a steadily improving industry, where challenges generally lead to creative solutions.

The aerostructures sector highlighted by Metastat Insight is pertinent as the aviation industry experiences increasing demands for efficiency, sustainability, and reliability. Additional global trends like digitalization, ecologism, and calls for resilient supply chains relate directly to progress within this arena. From lighter, stronger, and more efficient aircraft, aerostructures offer solutions that echo far outside aerospace. Their contribution to safer skies, cleaner journeys, and faster connections keeps them at the forefront of the future of transport and defense. The sector is not just driving today's needs but also fitting tomorrow's technologies.

Drop us an email at:

Call us on:

+1 5186502376

+91 73850 57479