MARKET OVERVIEW

The Global Wafer Pre Aligner market is a niche market within the semiconductor equipment industry, primarily focused on devices that ensure the accurate positioning and alignment of silicon wafers during semiconductor manufacturing processes. As the foundation of integrated circuit production, silicon wafers require meticulous handling to meet the high precision standards necessary for modern electronic devices. The market for wafer pre-aligners is integral to maintaining the functionality and reliability of advanced semiconductor manufacturing lines.

Pre-alignment of wafers, through a pre-aligner tool, ensures the orientation is right for compatibility with processes that have particular demands and exacting requirements downstream of such applications like lithography, etching, and deposition so as to be compatible to realize the required electronic semiconductor properties. With the advancement in manufacturing technology, the specifications related to wafer alignment are increasing day by day and have been driving innovation in this market continuously.

The Global Wafer Pre Aligner market covers a very broad range of semiconductor applications from microprocessor, memory chip, and sensor fabrication, and emerging technologies including advanced packaging and heterogeneous integration. In the past, the market has aligned with traditional locations of semiconductor manufacturing in Asia-Pacific, North America, and Europe but is likely to geographically expand to other regions as they begin to develop their semiconductor capabilities, reducing reliance on existing hubs of production.

Within the ecosystem of the semiconductor, wafer prealigners are necessary to cut down on defects occurring from misaligned wafers. This would increase yield in addition to reducing the costs of producing semiconductor and electronic products, which would respond accordingly to a growing market call for better performance and reduced energy consumption of electronics product offerings. Advancements in material and wafer sizes, from the larger 300mm to even 450mm, will continue to pressure the industry to innovate into more complex alignment technologies. Such developments would shape the playing field of this market, attracting investments in research and development directed toward these future requirements.

Technological innovation will dominate the Global Wafer Pre Aligner market competitive landscape. The introduction of automation and artificial intelligence along with machine learning will make these systems smart and adaptive. These developments would eliminate interventions that involve humans and also provide real-time monitoring and adjustment for improved efficiency of operation. Integration of Industry 4.0 practices into semiconductor manufacturing lines will increase demand for highly sophisticated wafer pre-aligners.

Macro economic and geopolitical variables will have their impacts on the Global Wafer Pre Aligner as well. It will depend much on other factors including resilience of the supply chain of that semiconductor firm and various government incentives and initiatives related to domestic production of this industry.

In a nutshell, the Global Wafer Pre Aligner market is critical in the semiconductor manufacturing industry as it meets the very intricate requirements of wafer alignment. Its impact on yield optimization and manufacturing efficiency makes it an inevitable adaptation and growth in technological advancement and shifting global trends. Importance will only deepen with the semiconductor industry evolving to meet next-generation technologies and applications.

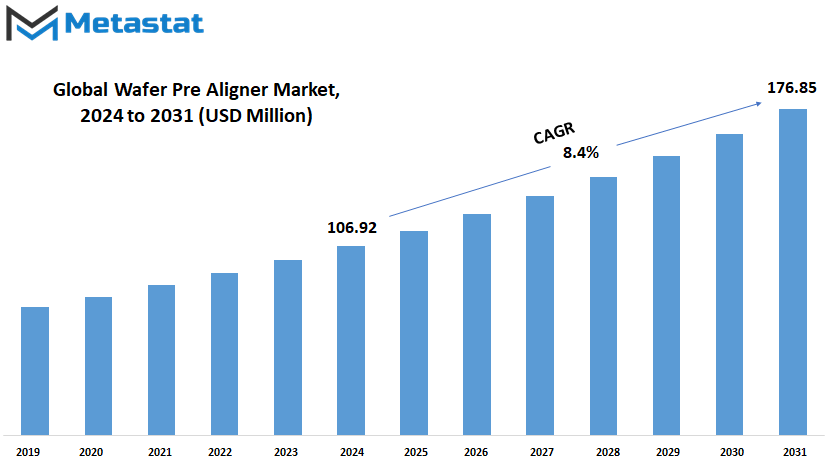

Global Wafer Pre Aligner market is estimated to reach $176.85 Million by 2031; growing at a CAGR of 8.4% from 2024 to 2031.

GROWTH FACTORS

The Global Wafer Pre Aligner market is expected to grow significantly in the future due to key factors driving the demand for advanced semiconductor solutions. With the expansion of electronic devices and Internet of Things (IoT) applications, the requirement for high-precision semiconductor devices becomes more pronounced. The demand fuels the necessity for reliable wafer alignment technologies, which play a crucial role in ensuring the accuracy and efficiency of semiconductor manufacturing processes.

The growth of this market is majorly contributed by the rapid advancement in semiconductor manufacturing technologies. Modern semiconductor production demands stringent standards for very precise alignment solutions. To address these needs, a pre-aligner of the wafer provides accurate positioning and handling of the wafer. Advanced pre-alignment systems become essential in becoming more efficient and having fewer defects as manufacturers try to do so.

However, there are problems that could hinder the growth of the market. High-end wafer handling and alignment systems are too expensive for some manufacturers, especially those with a lower budget and smaller-scale operations. In addition, it might not be easy to integrate pre-aligners into older manufacturing systems, as well as face possible issues from companies that intend to modernize their facility. This could hinder further its adoption in places and industries where cost barriers are significant.

Despite the challenges, Global Wafer Pre Aligner Market would, after all, see very huge opportunities in the future. Indeed, with constantly changing technology, new solutions would evolve that would be able to overcome the cost as well as integration challenges before the manufacturers. For instance, with modular or scalable prealignment systems, companies are likely to have more flexibility; they do not necessarily have to make significant overhauls in their processes. Additionally, research and development in the semiconductor industry are still on course, and this is sure to lead to better efficiency and cost-effectiveness for alignment systems, further catapulting market growth.

Additional impetus for the growth of automation in manufacturing processes and increased dependence on devices using IoT will also fuel demand for wafer pre-aligners. The companies who invest in overcoming these current limitations by providing adaptable, efficient solutions are best placed to perform well in this evolving context. The Global Wafer Pre Aligner market will dictate the future of semiconductor manufacturing, because it is this market which will be delivering precision as well as scale. It is this pace that further underlines technological innovation and strategic investments, which is necessary to continue sustaining growth in the market.

MARKET SEGMENTATION

By Type

The Global Wafer Pre Aligner market is changing because of technological advances and growing demand for efficiency in the semiconductor manufacturing industry. The growth of the semiconductor industry necessitates precise and reliable wafer alignment. Thus, the use of a wafer pre-aligner to align wafers properly before processing has become very important to uphold the high standards in this industry.

By type, the market is divided into fully automatic, semi-automatic, and manual wafer pre-aligners. For some time, manual wafer pre-aligners have been utilized for small-scale productions, where automation is not the most important factor. As the size and complexity of the semiconductor production increase, semi-automatic and fully automatic wafer pre-aligners are gaining significance. These advanced systems have better precision, speed, and reliability, which are inevitable in large-scale production lines.

One of the major drivers of adoption would be the investment in fully automatic wafer handling systems. Automation is the norm in modern semiconductor production because, apart from increasing throughput, it reduces the chances for human error. Fully automatic pre-aligners for wafers are expected to grow substantially more because they can easily be included in robotic systems, with the result that speed and accuracy in processing wafers are further improved.

The push for innovation is also influenced by the rising demand for smaller, more powerful electronic devices. As manufacturers strive to develop chips with higher performance and smaller footprints, the precision offered by advanced wafer pre-aligners becomes critical. Companies are channeling resources into research and development to improve alignment technologies, ensuring they can meet the stringent requirements of next-generation semiconductors.

Looking forward, the Global Wafer Pre Aligner market is expected to grow significantly. Emerging trends in the form of artificial intelligence and machine learning in manufacturing processes are going to shape the future of wafer alignment systems. These technologies can further optimize performance, reduce downtime, and provide predictive maintenance solutions, which are going to be very valuable in the competitive landscape of semiconductor production.

The Global Wafer Pre Aligner market future seems bright, driven by advancements in automation and continuous demand for accurate semiconductor manufacturing processes. The adoption of innovative solutions will continue shaping the industry to ensure its relevance in the years to come.

By Application

The Global Wafer Pre-Aligner market is integral to the semiconductor industry, as the pre-alignment of wafers is often necessary for various stages of the semiconductor manufacturing process. As the market is going to grow exponentially in the future, various factors including technological advancements, increasing demand for high-quality semiconductors, and expanding the industries that employ these devices play a role.

Based on application, the Global Wafer Pre Aligner Market can be broadly categorized. It comprises applications such as Wafer Processing, Wafer Inspection, Photolithography, Wafer Packaging and Bonding, Thin Film Deposition, and Etching. Each application of these categories is required for the correct alignment of wafers, considering that high-performance semiconductor production largely depends on such alignment technology. In an industry demanding more precise and efficient chips, it will get only stronger in the foreseeable future.

Some of the significant uses of wafer pre-aligners is in the treatment of wafers in the semiconductor making. The procedures include cleansing, thinning, and preparation of the wafers for subsequent steps within the process. Proper positioning ensures that the entire process would be conducted efficiently with no flaw, thus raising the quality of chips. As this procedure is getting to be increasingly complicated with several new manufacturing techniques, the total number of precision equipment like pre-aligners will surely increase.

Another significant use of Global Wafer Pre Aligner market is through wafer inspection. It refers to the process of passing the wafers into inspection, where defects or any defects are found or confirmed within the allowed thresholds before carrying out the remainder of the production process. Pre-Aligners ensure that the wafers are aligned correctly as inspection is undertaken, thus ensuring precise inspection processes and minimizing chances for errors.

In photolithography, the circuitry of semiconductor devices is done by transferring patterns onto the wafer surface. Thus, in the application for this technology, prealigners play an important role because they can ensure alignment of the wafer at high precision levels, therefore allowing for an accurate transfer of patterns. Increasingly, because of demand, these photolithography processes need more accuracy levels, making pre-wafer aligners crucial to this technology

Other areas for the application of pre-aligners involve wafer packaging and bonding; such as wafer positioning when packages are being put in place during the packaging process. Key processes in the manufacture of semiconductors-thin film deposition and etching-are completely reliant on wafer pre-aligners to preserve wafer integrity and alignment.

With more advanced and higher-performance semiconductors requirements constantly growing, the demand for wafer pre-aligners will keep going upward. Technology is continuously advancing with new manufacturing methods, which will make wafer pre-aligners even more critical for making reliable and efficient devices.

By End-User Industry

The Global Wafer Pre Aligner market is an indispensable cog in the semiconductor manufacturing process, performing a vital task of precisely aligning wafers before they undergo different stages of production. The market, by all estimates, is going to grow steadily because of the increasing demand for high-performance semiconductor devices as well as the continuous advancement in related industries. Analyzing the Global Wafer Pre Aligner market, it is found that the it caters not only to the semiconductor industry, but also to several industries. All these industries produce goods using wafer alignment processes.

Semiconductor Industry

The prominent end-user industry driving the growth of the Global Wafer Pre Aligner market is the semiconductor industry. This is the greatest consumer of wafer pre-aligners due to the building of microchips and other advanced electronic components. With the requirement for smaller, faster, more powerful devices, semiconductor manufacturers will increasingly have to depend on wafer pre-aligners. As technology advances, so does the precision and efficiency of the process in wafer pre-aligners, thereby supporting the further development of semiconductor devices. More applications, including artificial intelligence, 5G networks, and the Internet of Things, will create more demand for high-quality semiconductors. This, in turn, will provide a huge thrust to the need for reliable wafer alignment systems.

Other than the aforementioned, electronics manufacturing is also another key industry that is contributing to the expansion of the Global Wafer Pre Aligner market. With increasing demand for consumer electronics, companies in the sector will need advanced tools such as wafer pre-aligners to secure the production of high-quality components. Electronics manufacturers will try to meet the growing demand for smartphones, tablets, and other apparatuses by making the most of precision equipment such as a pre-aligner during their process. This trend is likely to continue as electronics manufacturing becomes more sophisticated and automated.

R&D departments significantly contribute to the Global Wafer Pre Aligner market. Innovations in quantum computing, medical devices, and robotics will see the increased need for high-precision wafer alignment. The requirement of the R&D departments on wafers to test new materials, devices, and technology will impact demand as new technologies develop and want to be created with complex and accurate wafer alignment.

The solar industry is increasingly using wafer pre-aligners for the production of solar panels. The rising demand for renewable energy in the world will create a significant amount of demand for solar technology in the future and, subsequently for wafer pre-aligners used in the manufacturing process of solar panels. Lastly, the MEMS (Micro-Electro-Mechanical Systems) industry is also benefited by the growing use of wafer pre-aligners. The MEMS devices will continue to be the driving force for demand in applications such as sensors, actuators, and micro-machines, so all of those require precise alignment technology. The Global Wafer Pre Aligner market will grow highly as the demand for advanced technology and precision equipment increases across multiple industries.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$106.92 million |

|

Market Size by 2031 |

$176.85 Million |

|

Growth Rate from 2024 to 2031 |

8.4% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

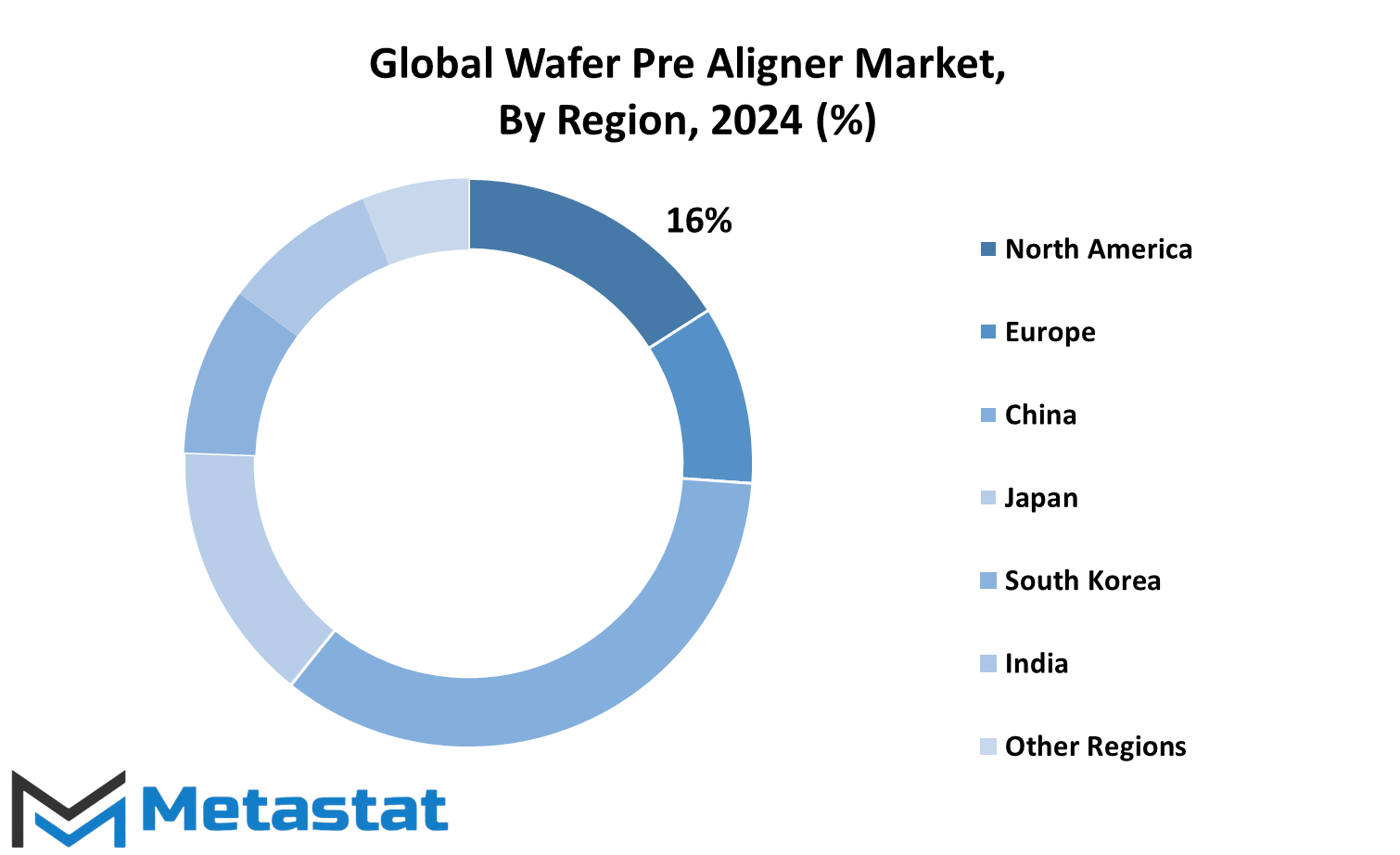

The global wafer pre-aligner market is spread across different regions, each playing a vital role in its development and adoption. Understanding regional dynamics will be crucial to identifying how this market is evolving and growing in the coming years. Geographically, this market can be divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Each of these geographies has its unique driving factors in terms of demand and adoption of wafer pre-aligners. They are used in semiconductor manufacturing processes where wafers are aligned at specific stages precisely.

North America - The U.S., Canada, and Mexico account for the largest share of the market globally. Advanced technology sector has been on the rise in North America, especially in the U.S., with increasing demand for wafer pre-aligners. With further innovation and better semiconductor production in the region, demand for precision alignment tools like wafer pre-aligners will grow. New electronics and technologies, such as AI and 5G, will drive more demand from North America.

Europe, a key region for the market, includes some of the big markets in the world. The UK, Germany, France, and Italy are few of the countries which are seen as important to the world. The European semiconductor industry is undergoing transformation, where several countries are looking for ways to reduce dependency on foreign imports of semiconductor technology and components. Since Europe is investing in its capabilities for manufacturing semiconductors, demand for wafer pre-aligners will increase, as it ensures that wafers align with high quality in production processes. Other factors supporting growth in the market in this region include further innovation in automotive electronics, consumer goods, and industrial segments.

Asia-Pacific, which hosts countries such as China, Japan, South Korea, and India, is expected to experience significant growth in the market for wafer pre-aligner. Asia is home to some of the world's leading semiconductor manufacturers, and going forward, there will also be a growing need for highly precise manufacturing equipment for the technology. China will be a growing technological country, and Japan will be one that has expertise in semiconductor manufacturing. South Korea's semiconductor industry, headed by the global leaders like Samsung, will keep on demanding the wafer pre-aligners so that the production process will remain precise and efficient.

South America is a small market, but there is a growing interest, especially in Brazil and Argentina. The more countries in South America upgrade their industrial sectors, the more semiconductor manufacturing technologies, including wafer pre-aligners, will be used. The Middle East & Africa region, including countries such as South Africa, Egypt, and the GCC nations, is expected to grow in semiconductor production. As these areas begin to take on roles as hubs for advanced manufacturing, the demand for wafer pre-aligners will likely increase as the industries expand. In the coming years, the global wafer pre-aligner market will likely witness a shift in demand as these regions continue to modernize and integrate new technologies. Growth will be driven by the increasing need for precision in semiconductor production and the continuous advancements in electronics across various industries.

COMPETITIVE PLAYERS

Technological advancements in the industry have placed the Global Wafer Pre Aligner market on a strong growth curve. A growing demand for precision in the semiconductor manufacturing industry also supports growth in this market. An increasing reliance by industries on integrated circuits to produce consumer electronics and automotive applications has heightened the importance of the role that wafer pre-aligners play in the production process. Proper alignment of wafers during the manufacturing process increases the yield and quality of the resulting devices. Over the years, companies in this market have innovated continually to stay ahead, and competition among them will only get intense in the coming years.

Competitive players in the Global Wafer Pre Aligner market are strategically positioning themselves to meet the growing demand for wafer processing tools. Among them, ASML Holding NV, Tokyo Electron Limited, and KLA Corporation are major leaders of semiconductor equipment. These companies continually keep working on technological boundaries in pursuit of more advanced solutions with the increased complexity in the semiconductor fabrication process. Moving to smaller nodes and high accuracy would likely position these companies in leading positions for the market in its future direction.

Other major players, such as Brooks Automation, Inc., and ROBUST Technology Co., Ltd, bring specialized expertise to the market. Brooks Automation, for example, specializes in automation solutions that streamline wafer handling to minimize the risk of contamination and enhance operational efficiency. Companies like Genmark Automation and isel Germany AG are also making strides in developing more compact and reliable systems that can support high-volume manufacturing.

In addition to these industry giants, smaller players like Milara Inc., TAZMO, and TEX E. G. CO. are introducing unique innovations aimed at capturing niche segments of the market. Their ability to develop specialized technologies may allow them to cater to specific customer needs that larger companies may overlook. Companies like Hangzhou SIASUN Robot & Automation are integrating robotics and AI to make the alignment process much more optimal, which will increasingly be a necessity as the industry becomes more automated and highly efficient in manufacturing environments.

Going forward, the Global Wafer Pre Aligner market will only grow in competition. Companies that can deliver faster, more accurate, and cost-effective solutions will have a competitive advantage as technology continues to evolve. Innovation will be fueled by the ongoing demand for smaller, more powerful semiconductors, so the market will only grow in dynamism and only the most adaptable and forward-thinking companies will succeed in the years ahead.

Wafer Pre Aligner Market Key Segments:

By Type

- Manual Wafer Pre Aligner

- Semi-Automatic Wafer Pre Aligner

- Fully Automatic Wafer Pre Aligner

By Application

- Wafer Processing

- Wafer Inspection

- Photolithography

- Wafer Packaging and Bonding

- Thin Film Deposition

- Etching

By End-User Industry

- Semiconductor Industry

- Electronics Manufacturing

- Research and Development (R&D)

- Solar Industry

- MEMS (Micro-Electro-Mechanical Systems)

Key Global Wafer Pre Aligner Industry Players

- ASML Holding NV

- Tokyo Electron Limited

- KLA Corporation

- Brooks Automation, Inc.

- ROBUST Technology Co., Ltd

- Genmark Automation

- isel Germany AG

- Kensington

- mechatronic systemtechnik

- Milara Inc.

- TAZMO

- TEX E. G. CO.

- Hangzhou SIASUN Robot & Automation

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252