Global Vacuum Coating Machines Market - Comprehensive Data-Driven Market Analysis & Strategic Outlook

The global vacuum coating machines market changed from a niche industrial concept to a sophisticated segment supporting some of the most sophisticated practices of modern-day manufacturing industry. The market was concentrated predominantly in research centers and aerospace applications, where surface protection and precision coating initially were explored in the mid-20th century. These early experiments with vacuum deposition techniques marked the beginning of a muted industrial revolution that would eventually find its way into sectors ranging from electronics to automotive manufacturing.

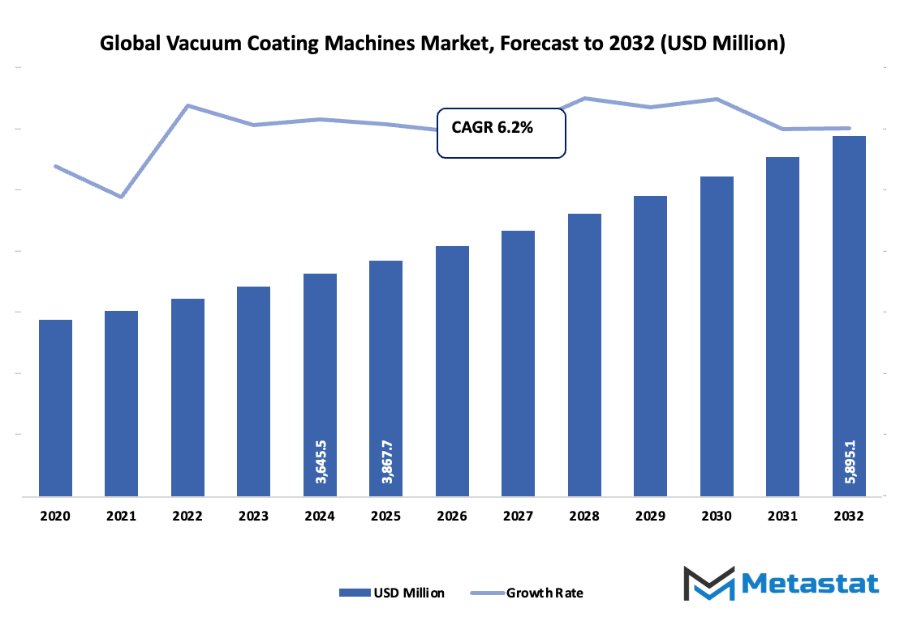

- Estimated global vacuum coating machines market size of approximately USD 3867.7 million in 2025, expanding at an estimated growth rate of about 6.2% CAGR in 2032 and has the potential to grow past USD 5895.1 million.

- Physical Vapor Deposition (PVD) hold close to 41.1% market share, staying at the forefront of innovation and growing applications with aggressive R&D.

- Growth-driving trends: Surging demand for long-duration, high-performance surface coating, Growing application in electronics, automotive, and optics

- Opportunities exist: Harnessing sophisticated, energy-efficient, and mechanized vacuum coating machines

- Key fact: The market will grow tenfold in worth within the upcoming decade, signaling enormous growth prospects.

With the advancement of technology, the industry developed in the 1970s and 1980s when optical and semiconductor industries started accepting vacuum coating in a bid to enhance the performance of the parts.

This was necessitated due to the demand for thinner, cleaner, and efficient coatings that would conserve energy and improve the lifespan of the products. The installation of physical vapor deposition and chemical vapor deposition systems was a breakthrough, transforming a research process into part of industry production lines. Globalization and automation in the 1990s and early 2000s provided the market with a boost. Asian, European, and North American manufacturers started using advanced vacuum systems in order to match the large-scale demand for solar panels, electronics, and protective coatings for precision tools. Consumer demand also changed; the requirement for light weight, high strength, and power-efficient products led manufacturers to enhance material efficiency and coating uniformity. The global vacuum coating machines market is currently a key driving force for innovation in various industries. Regulations have become more stringent, especially in the area of protecting the environment and minimizing wastage of resources. These have made manufacturers design equipment with low emission levels and cleaner production trends. The market now leans towards a convergence of technology and eco-sensitivity, where information-based systems, computerization, and electronic control will characterize the next growth phase.

From laboratory to its critical position at the very core of worldwide manufacturing, the industry has long been changing to suit growing industrial requirements and consumer demand. Its transformation shows the ways in which science-based experimentation will increasingly determine the future of precision engineering and sustainable manufacturing.

Market Segments

The global vacuum coating machines market is mainly classified based on Technology, Application, End-User Industry.

By Technology is further segmented into:

- Physical Vapor Deposition (PVD): Physical Vapor Deposition will expand its significant role in the coming years in the world Vacuum Coating Machines market on the basis of its efficiency of forming thin, tough coatings. The technology would be used extensively to create materials with improved strength, corrosion resistance, and abrasion resistance. Growing demand for high-performance coatings for electronics and automotive components will drive its steady growth. The process will also be transformed with advanced automation and cost-efficient techniques to meet raised production needs without compromising on quality standards.

- Chemical Vapor Deposition (CVD): Chemical Vapor Deposition will be the driver of the global vacuum coating machines market as it allows for the creation of very pure and uniform coatings. This technology will be increasingly developed in semiconductor and solar uses due to its ability to produce complex layer structures. By continued study, coating speed will continually be accelerated and operating cost reduced. The vision of the future for this technology will be nearly more environmentally friendly and wasteful, and therefore will be incorporated as part of future coatings in industry.

- Sputtering: Sputtering will remain a leading process in the global Vacuum Coating Machines industry, especially for those applications requiring precise thin-film coatings. Sputtering will remain the preferred technique of layer deposition in displays, solar cells, and electronics. Companies will become more productive and efficient with advancements in magnetron sputtering and automation. Its capability to span a range of materials will benefit small-scale and high-rate production operations with consistent reliability and performance in applications.

- Other: Additional technologies found in the global vacuum coating machines market will be more recent deposition methods that will try to maximize the rate of production and reduce material loss. These will incorporate smart digital systems to enhance process monitoring as well as quality control. New breakthroughs will offer hybrid systems with a number of techniques that are integrated in order to have multiple coating possibilities. These innovations will help industries deal with evolving specifications and standards for aggressive, efficient, and cost-saving surface treatments.

By Application the market is divided into:

- Consumer Electronics: Consumer electronics will remain one of the most important application areas in the world Vacuum Coating Machines market. Vacuum coatings will enhance functionality, hardness, and performance of smartphones, tablets, and screens. Upcoming innovations will be energy-efficient coatings that enhance the life of devices without impacting the environment to a great extent. With rising demand for green and quality products, the manufacturers will utilize advanced coating technologies to meet the needs of quality and stay competitive.

- Solar Energy: Solar energy will cause incredible innovation in the global vacuum coating machines market by requiring coatings that improve panel efficiency and longevity. Vacuum coating technologies will enable greater control of light absorption and reflectance to increase power production. Next-generation technologies will concentrate on cost-effective, scalable technologies that deliver renewable energy goals. Governments and business will invest in future-generation coating systems to achieve maximum energy conversion efficiency and deliver long-term sustainability goals.

- Medical Devices: Medical devices will continue to be a major driver for the global vacuum coating machines market due to the requirement for biocompatibility and corrosion resistance coatings. Such coatings will improve the functionality of devices, reduce contamination risk, and increase product longevity. New technologies will rely on high-precision coating technology to ensure more reliability in surgery and diagnosis equipment. Such focus will meet stringent regulatory requirements while improving safety and efficiency in medical use.

- Other: Other applications in the worldwide Vacuum Coating Machines market will involve markets like optics, packaging, and decorative coatings. The way forward will be customization according to the material type and desired appearance. The producers will adopt new digital and automation platforms to increase precision in production. Greater focus on sustainability and cost will continue to impact coating design in these many uses.

By End-User Industry the market is further divided into:

- Aerospace: The aerospace segment of the global vacuum coating machines market will benefit from increasing demand for high-performance materials that can withstand extreme environments. Vacuum coatings will enhance durability, reduce friction, and improve heat resistance in aircraft components. Future advancements will focus on lightweight coatings that optimize fuel efficiency and reduce maintenance costs. The integration of digital monitoring systems will also ensure precision and reliability in aerospace manufacturing processes.

- Automotive: The automotive sector will be a key contributor to the global vacuum coating machines market, driven by the need for coatings that improve wear resistance and visual appeal. As electric vehicles and advanced mobility solutions expand, manufacturers will rely on efficient vacuum coating systems to enhance performance and energy efficiency. Future developments will focus on coatings that support sustainable materials and reduce carbon emissions, aligning with environmental standards and consumer expectations.

- Electronics: Electronics will continue to be a major driving force in the global vacuum coating machines market. Thin-film coatings will improve conductivity, insulation, and protection for various electronic components. The rise of advanced devices and flexible electronics will encourage further innovation in vacuum coating processes. Future systems will focus on miniaturization and precision, ensuring consistent quality in high-demand production environments.

- Other: Other end-user industries in the global vacuum coating machines market will include sectors like defense, energy, and industrial manufacturing. These areas will adopt advanced coating technologies to enhance efficiency, durability, and sustainability. Future trends will emphasize automation, predictive maintenance, and reduced production waste. Such advancements will help industries meet performance standards while maintaining economic and environmental responsibility.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$3867.7 Million |

|

Market Size by 2032 |

$5895.1 Million |

|

Growth Rate from 2025 to 2032 |

6.2% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

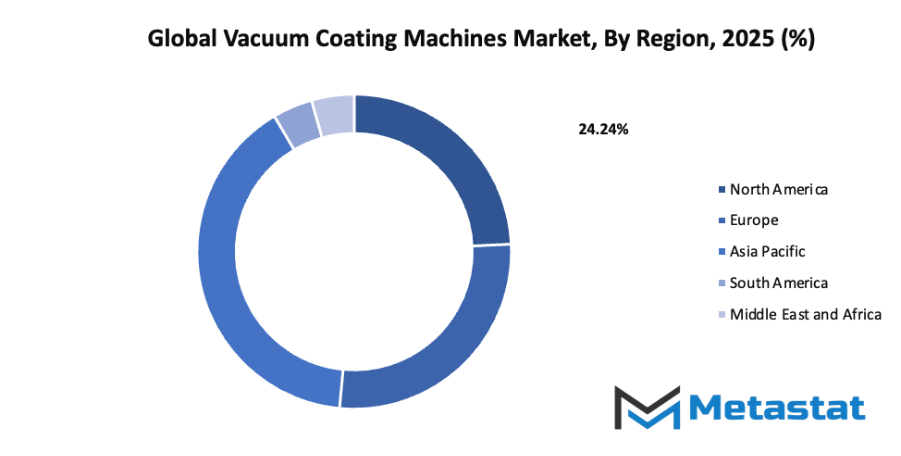

By Region:

- Based on geography, the global vacuum coating machines market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

- North America is further divided into the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and the Rest of Europe.

- Asia-Pacific is segmented into India, China, Japan, South Korea, and the Rest of Asia-Pacific.

- The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and the Rest of the Middle East & Africa.

Growth Drivers

- Increasing demand for high-performance and durable surface coatings: The growing need for high-quality and long-lasting coatings will drive the global vacuum coating machines market. Such coatings enhance performance, reduce maintenance, and improve product aesthetics. With industries shifting toward sustainability and cost efficiency, advanced vacuum coating methods will continue to gain importance, ensuring improved durability and higher production standards.

- Growing adoption in electronics, automotive, and optical industries: The global vacuum coating machines market will see strong growth due to wider use in electronics, automotive, and optical applications. In electronics, coatings help improve conductivity and protection; in automotive, they enhance durability and energy efficiency; and in optics, they support better precision and light transmission. This rising integration will strengthen overall market growth.

Challenges and Opportunities

- High equipment and maintenance costs: The high cost of machinery and maintenance will be a major concern for the global vacuum coating machines market. Initial investments are significant, and upkeep requires specialized resources. These expenses often limit adoption among small and medium enterprises, slowing market expansion despite increasing demand for high-quality coatings.

- Complexity of operation and technical expertise required: Operating vacuum coating systems demands advanced technical knowledge, creating a skill gap that will slow the global vacuum coating machines market. Skilled operators are essential for maintaining precision, safety, and efficiency. The shortage of trained professionals will continue to be a barrier to faster industrial adoption and scalability.

Opportunities

- Development of advanced, energy-efficient, and automated vacuum coating systems: The creation of energy-saving and automated vacuum coating technologies will open new prospects for the global vacuum coating machines market. These innovations will lower energy use, reduce human error, and improve overall productivity. As automation expands, the industry will move toward cost-effective, sustainable, and intelligent manufacturing solutions.

Competitive Landscape & Strategic Insights

The global vacuum coating machines market is positioned for significant transformation in the future as technology advances and sustainability becomes a stronger focus across industries. The market brings together both long-established international leaders and ambitious regional competitors, each driving innovation in unique ways. Companies such as Applied Materials, ULVAC Inc., Oerlikon Balzers, Bühler Group, Veeco Instruments, CVD Equipment Corporation, Guangdong Huicheng Vacuum Technology Co., Ltd., Singulus Technologies AG, STATON s.r.o., IHI HAUZER TECHNO COATING B.V., Sumitomo Heavy Industries, Ltd., ELECSHINE ENGINEERING PRIVATE LIMITED, Dubois, Trivec, Zhaoqing Kerun Vacuum Equipment Co., Ltd., Alliance Concept, and Impact Coatings play a vital role in shaping the direction of this market. Their combined efforts reflect a strong global network focused on efficiency, precision, and advanced coating solutions.

The future of the Vacuum Coating Machines market will be influenced by increasing demand for energy-efficient and eco-friendly technologies. Growing concerns about resource consumption and environmental impact are encouraging manufacturers to adopt cleaner production methods. Advanced coating systems will likely focus on reducing waste, improving coating uniformity, and extending product lifespan. These advancements will not only support industries like automotive, electronics, aerospace, and packaging but also open opportunities for newer applications in renewable energy, such as solar panels and energy storage components.

Automation, digital monitoring, and artificial intelligence will become more common features in vacuum coating equipment. These technologies will make production lines faster, more accurate, and easier to control. As data becomes an essential part of industrial operations, companies will invest more in smart systems that can predict maintenance needs, enhance product quality, and reduce downtime. The market will continue to see competition between established leaders that emphasize large-scale production capacity and regional players that focus on customization and flexible solutions.

In the coming years, collaboration between research institutions and equipment manufacturers will likely lead to the creation of new coating materials with improved performance. The development of nanotechnology and thin-film innovations will further expand the possibilities for precision coating. As industries seek to meet stricter regulations and performance standards, Vacuum Coating Machines will remain central to achieving both quality and sustainability goals.

Market size is forecast to rise from USD 3867.7 million in 2025 to over USD 5895.1 million by 2032. Vacuum Coating Machines will maintain dominance but face growing competition from emerging formats.

Overall, the Vacuum Coating Machines market will continue to grow through technological progress, environmental awareness, and strategic global partnerships. The competition between key international and regional companies will drive continuous improvement and ensure that the market keeps evolving toward a more efficient and sustainable future.

Report Coverage

This research report categorizes the global vacuum coating machines market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global vacuum coating machines market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global vacuum coating machines market.

Vacuum Coating Machines Market Key Segments:

By Technology

- Physical Vapor Deposition (PVD)

- Chemical Vapor Deposition (CVD)

- Sputtering

- Other

By Application

- Consumer Electronics

- Solar Energy

- Medical Devices

- Other

By End-User Industry

- Aerospace

- Automotive

- Electronics

- Other

Key Global Vacuum Coating Machines Industry Players

- Applied Materials

- ULVAC Inc.

- Oerlikon Balzers

- Bühler Group

- Veeco Instruments

- CVD Equipment Corporation

- Guangdong Huicheng Vacuum Technology Co., Ltd.

- Singulus Technologies AG

- STATON, s.r.o.

- IHI HAUZER TECHNO COATING B.V.

- Sumitomo Heavy Industries, Ltd.

- ELECSHINE ENGINEERING PRIVATE LIMITED

- Dubois

- Trivec

- Zhaoqing Kerun Vacuum Equipment CO.,LTD.

- Alliance Concept

- Impact Coatings

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383