MARKET OVERVIEW

The global threadlocker market within the industrial adhesives sector will remain in a special position where chemical formulation and precision engineering come together to define how mechanical assemblies maintain their form. Where discussions in the past tended to revolve around demand, material developments, or product categories, the larger scenario to come will be a different story one based on changing application behaviors, regional patterns, and new end-use standards. The paradigms of this industry will not be focused solely on supply chains or transactional data but will encompass behavioral transformations in manufacturing paradigms and maintenance regimes.

As industries trend towards efficiency, strength, and lower maintenance intervals, the future nature of threadlocking agents will become increasingly clear-cut. Instead of being viewed purely as ancillary elements in fastener assemblies, these adhesives will start to become recognized as design-critical elements. Applications like aerospace, heavy machinery, and electronics will not just assume inclusion of them but may begin crafting performance requirements around their particular use. This change of heart will herald the integration of chemical solutions deeper within the mechanical design process itself.

In the years to come, the global threadlocker market will be shaped by an increase in sustainability standards. There will be pressure to innovate with formulations that minimize toxic residues, maximize recyclability, and meet international environmental codes. As regulatory focus heightens across continents, the manufacturers will have the twin challenge of ensuring compliance on one hand while ensuring reliability of performance under stressful conditions like high vibration, severe temperature, and chemical exposure. The threadlocking portion will no longer be about just adhesive strength but about finding equilibrium between formulation sophistication and environmental consciousness.

No one can discount the value change in the way that threadlockers will be sold and made available around the world. With all the growing digitization of industrial procurement, there will be greater reliance on virtual channels for purchasing, assessing, and even product testing remotely through simulation technology. This transition will call for the global threadlocker market to focus on digital impressions, invest in knowledge-based content initiatives, and offer predictive application data to enable remote buyer confidence. Such a context will benefit those willing to learn rather than sell.

Besides, the training and skillset for effective use will change. As equipment becomes increasingly specialized and modular, technicians' and engineers' work applying and assessing adhesive performance will evolve. There could be increasing need for technical alliances, such that product suppliers collaborate with engineers not only at the moment of purchase but over the equipment's lifetime. This contact will reframe what service is in the world of adhesives and will ultimately affect buyer loyalty and product usage consistency.

In the end, beyond the transactions, the global threadlocker market will be defined by how deeply it becomes a part of the design, digital, and sustainability agendas of contemporary industry. It will not simply react to demand but will assist in redefining performance expectations industry-wide. As industrial consciousness matures, this sector will grow from being viewed as a behind-the-scenes requirement to a front-line facilitator of mechanical and operational prowess.

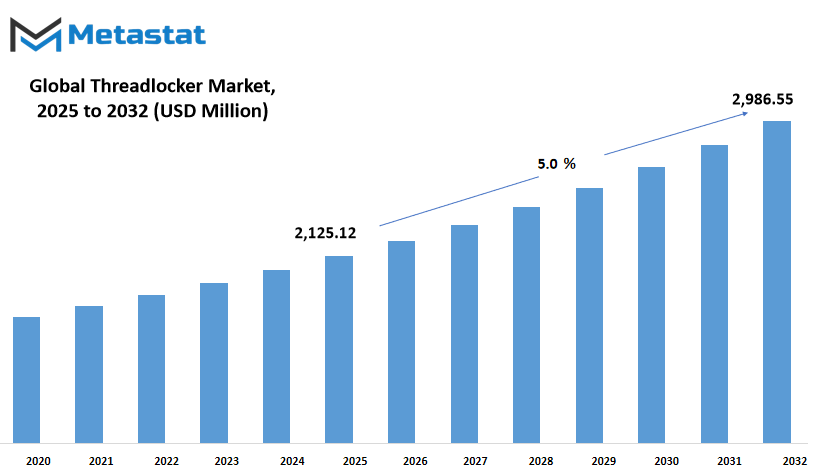

Global threadlocker market is estimated to reach $2,986.55 Million by 2032; growing at a CAGR of 5.0% from 2025 to 2032.

GROWTH FACTORS

The global threadlocker market remains in the spotlight with the increasing demand for solutions that provide vibration resistance and a maintenance-free process. With businesses becoming increasingly interested in long-term efficiency, the demand for products which are able to fasten fasteners without frequent checks and adjustments is constantly on the rise. Threadlockers provide an easy and efficient method to increase the reliability of assemblies, and hence they are widely used in safety-critical applications where loose fasteners might result in expensive failures or safety issues.

Their burgeoning use in applications such as automotive and industrial machinery is not unexpected. Vehicles, trucks, and heavy equipment tend to perform under rugged conditions, where even a slight movement in the hardware can compromise performance or safety. Threadlockers serve to eliminate that risk by holding everything in place firmly, even under constant vibration or thermal expansion. This move towards strong, tamper-resistant assemblies is becoming the norm in both mass production and precision engineering realms.

Nevertheless, threadlockers have their limitations. Among the most notable is the poor reusability of fasteners after an application of a threadlocker. In most applications, removal of the adhesive results in degrading or deforming the bolt, which can be a challenge in systems where disassembly for inspection or upgrade is necessary. Compatibility with various surface materials and coatings may also pose challenges. Some of those formulations may not stick properly with all finishes, so the users have to exercise care and discrimination when applying them.

In spite of these worries, innovation is leading the way. New formulae that can tolerate high heat or be easily removed are opening doors in niche fields. These newer generations of threadlockers may appeal to industries requiring both endurance and adaptability such as aerospace, electronics, and even renewable energy applications. The trend toward such intelligent solutions shows a market that is not stagnating but is instead molding itself according to the functional requirements of contemporary engineering.

In the years ahead, as producers focus increasingly on reliability and low-maintenance solutions, demand for customized threadlocking products will probably increase. And as new materials and technologies become available, so will demand for adhesives that can adapt. The global threadlocker market, says the analysis offered by Metastat Insight, is on the threshold of significant advances that will chart its course well into the future.

MARKET SEGMENTATION

Product Type

Illustrated in a current guide via Metastat Insight, the global threadlocker market has exhibited the transformation of the way industries value the consistency and dependability of mechanical elements. Threadlockers, sometimes underappreciated in greater structures, are quietly turning into imperative in ensuring the integrity of system via locking fasteners in vicinity beneath pressure, vibration, and temperature changes. With commercial machinery and automation turning into increasingly complicated and ubiquitous, the need for reliable adhesives stays step by step on the upward thrust.

A sizeable segment of the enterprise revolves around product form, and Anaerobic Adhesives are at the vanguard with a valuation of $1,439.87 million. Such adhesives are particularly prized for curing in airtight conditions, supplying a company seal that resists loosening due to movement or environmental exchange. Other adhesives which includes Acrylic, Epoxy, and Cyanoacrylate all have distinct business applications, with desire usually a count of floor fabric, curing time, and overall performance desires. Anaerobic Adhesives lead the manner in mechanical packages, Acrylic Adhesives offer flexibility, Epoxy their metal bonding abilties, and Cyanoacrylate for fast upkeep and small assemblies.

Industries in automobile, aerospace, electronics, and manufacturing sectors are embracing threadlocker solutions not only for holding power but for how they ease maintenance. The adhesives, once applied, tend to minimize constant retightening and inspection needs, providing stability in the long term. This contributes to companies reducing unplanned downtime and its associated costs, which has turned threadlockers into a functional investment as opposed to an optional accessory.

Aside from their fundamental purpose, these adhesives also play a role in safety and reliability that impinges directly on performance. In automobiles, for example, they keep components from vibrating free under driving stress. In electronics, they guard minute fasteners in devices that are handled and manipulated every day. As machines continue to lighten and accelerate, the necessity for secure assembly grows even more critical, and threadlockers have become an easy but essential component of that solution.

The global threadlocker market also illustrates a larger industry shift towards more intelligent, more effective maintenance. With adhesives that secure parts in position without welding or in environments of complex joints, businesses have the ability to achieve flexibility as well as security. This is particularly significant for mass production, where rapid assembly and robust holding can result in huge long-term savings

In short, the global threadlocker market, as put on the table by Metastat Insight, is not only expanding it is becoming key to the way industries maintain their machinery dependable. With Anaerobic Adhesives leading the charge and other types of adhesives filling in various requirements, the market will keep on adapting according to contemporary engineering requirements.

By Packaging Type

Packing format is a key element in the utilization, distribution, and acceptance of the global threadlocker market. On the basis of packaging type, the market is segmented into Single-use Packages, Bulk Packaging, and Retail Packaging. Each of these segments has an appeal influenced by the requirements of industries, professionals, and even occasional users who rely on consistent adhesives for locking threaded fasteners.

Bulk Packaging is mostly employed in industrial and production settings where sizable amounts of threadlocker are needed on a regular basis. These packages are cost-effective and efficient, suited for workshops or production lines where time efficiency and product waste become priorities. Because heavy machinery, automotive, and aerospace companies tend to seek high-performance adhesives in quantity, bulk packaging provides them with a convenient option.

Single-use Packs are getting an increasing number of popular because of their convenience and less mess. They are specifically handy for protection employees or technicians who have a use-for-it product without worry of infection or overuse. In programs wherein accuracy and cleanliness are paramount, like electronics or high-end equipment restore, these single-dose applications supply the precise quantity of product wished for the task handy.

Retail Packaging is more focused on mass consumers and small users. These tend to be in smaller bottles or tubes and are usually stocked in hardware stores. The selling aspect in this instance is convenience and availability. DIY repairers, small business operators, and occasional repair workers like packaging that is convenient to store and reuse. With increasing consumer knowledge and more individuals doing small repairs themselves, retail packaging will also continue as a consistent market contributor.

Packaging is not merely a product-holding function; it impacts purchase, storage, and even usage. As demand from the industries changes and consumer expectations become higher, types of packaging will in turn dictate how the global threadlocker market as introduced by Metastat Insight evolves and expands. As tastes change and functional requirements dictate, every type of packaging will find its niche, contributing to the global threadlocker market in intricate and dramatic ways.

By Application

global threadlocker market, according to Metastat Insight, is progressively on the rise because of its extensive application across various industries. The adhesives are widely applied to avoid loosening of fasteners, hence their application in environments where wear and vibration are prevalent. Through their ability to keep screws and bolts securely locked, threadlockers ensure reliability and safety, particularly in environments where equipment is subjected to movement, pressure, or changing loads.

This market is determined by the variety of its applications. Based on Application, the global threadlocker market is further segmented as Industrial Applications and Consumer Applications. Industrial application covers industries such as automotive, aerospace, machinery, and construction. In these industries, threadlockers are typically essential to enable equipment and structural stability. Equipment that remains in operation for extended periods or operates at high speeds needs fasteners that will remain in place, and threadlockers provide an economical and easy-to-apply answer. By comparison, Consumer Applications represent repair-and-use items and daily use. Be it putting furniture together or repairing household objects, threadlockers are becoming essential components of tool kits. Their potential for enhancing the toughness of repairs resonates with both DIYers and occasional users.

Producers are meeting this expansion with increased product offerings and greater access to threadlockers. Packaging choices are becoming easier for users, and a few products are even designed for novices who have no experience with adhesives. Through both industrial and consumer markets, as awareness is disseminated, demand for sound bonding solutions keeps growing.

In the future, the global threadlocker market will be positively impacted by greater regard for safety, maintenance, and cost-effectiveness. As more individuals and enterprises prioritize long-term performance over short-term solutions, products such as threadlockers are finding greater recognition. As advancements enhance usability and environmental sustainability, this category is poised to reach an even broader customer base.

Finally, the global threadlocker market, as defined by the analysis provided by Metastat Insight, will continue to be a vital component of professional and everyday usage. Its destiny will be guided by functional necessity, ease of use innovation, and the increasing significance of reliable fastening options at all levels of use.

By End-user

The global threadlocker market, presented by the analysis of Metastat Insight, continues to define numerous industries as it adapts to real needs on production and assembly lines. Threadlockers are adhesives that keep fasteners from loosening under vibration or stress conditions and therefore play a fundamental role in industries where safety, accuracy, and longevity are most important. With the demand for secure mechanical fitting growing, so does the relevance of the product in various machinery and equipment.

The Threadlocker market globally is segregated into automotive, aerospace, electronics, manufacturing, and marine. Each industry relies on threadlocking solutions due to reasons particular to their working conditions. For instance, threadlockers are employed in the automobile sector to stabilize screws and bolts in engines and suspension systems, where incessant movement would otherwise degrade joints. In aviation, the risk is still greater. Aircraft parts need fasteners that remain secure under extreme temperatures and pressure changes, and threadlockers assist in securing such reliability.

Electronics, though smaller in size, are still subjected to the same risks of loosening, particularly in units that create internal movement or are constantly manipulated. In production, threadlockers are used extensively on machinery and tools to provide continual output without any downtime due to mechanical breakdowns. The marine industry, while smaller in comparison, still gains benefits from threadlockers because of the constant wet conditions, which can cause parts to corrode and fittings to be more susceptible.

As businesses keep pushing for greater performance and more durable parts, the threadlocker industry will adapt. Producers will need to prioritize new formulations that can provide quicker curing, greater resistance, and simpler application. What's common throughout these industries is the increasing emphasis on quality and reliability, which makes threadlockers more than an afterthought they're a subtle but integral component of machines remaining in one piece and working. In the future to world, the global threadlocker market, as detailed by Metastat Insight, would continue to remain closely associated with industrial advancement, quietly supporting the pillars of technologies that travel, connect, and construct our contemporary world.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$2,125.12 million |

|

Market Size by 2032 |

$2,986.55 million |

|

Growth Rate from 2025 to 2032 |

5.0% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

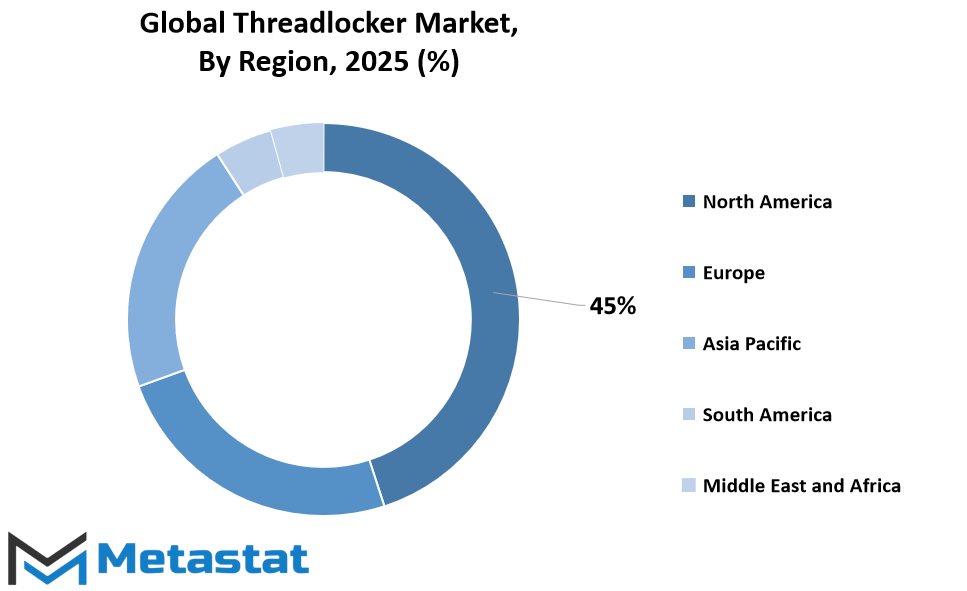

Reported by Metastat Insight, the global threadlocker market is a broad one spanning various distinct geographic regions. It has its own contribution from each region based on the local demand, manufacturing base, and industrial growth. The market is divided among North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. North America contains the United States as its center, with Canada and Mexico becoming a member of it. In Europe, the United Kingdom, Germany, France, and Italy are actively involved, with the Rest of Europe. The Asia-Pacific place is amazing for its strong industrial pastime, with predominant contribution from India, China, Japan, and South Korea, at the same time as the Rest of Asia-Pacific step by step develops.

In South America, Brazil and Argentina dominate market involvement, with aid from other growing countries within the vicinity. The section of the Middle East & Africa comprises GCC Countries, Egypt, and South Africa, with the rest of the international locations falling beneath the Rest of Middle East & Africa. All of these regions play a function in figuring out the bigger marketplace, propelled by using various tiers of industrialization, funding in production, and high-performance adhesive call for.

This large geographic spread points to the need to know local tendencies, regulatory environments, and client requirements. Although developed markets which includes North America and Europe have set up infrastructures and regular product use, speedy-developing regions in Asia-Pacific and sub-Saharan Africa and South America gift new opportunities with increasing industries and infrastructure tendencies.

As the global threadlocker market continues to expand, as introduced by Metastat Insight, the impact of every geographic segment will continue to be strong, underlining the importance for businesses to remain reactive and regionally inclined.

COMPETITIVE PLAYERS

Presented thru the lens of Metastat Insight, the global threadlocker market indicates no signal of slowing down. What turned into once a modest segment of the adhesive enterprise has regularly taken middle level, broadly speaking because of its potential to make certain mechanical balance. Threadlockers, normally used to save you the loosening of fasteners, have grown in significance across production and assembly strains. These adhesives are not simply convenient they’ve grow to be crucial in guaranteeing lengthy-term reliability in merchandise uncovered to continuous motion or vibration. Whether it is machinery, automotive additives, or digital elements, the need for a reliable locking answer is growing with every passing year.

What makes the global threadlocker market so compelling is the way it quietly helps large industries with out disturbing the highlight. In sectors like automotive, aerospace, production, and electronics, the smallest parts frequently require the strongest help. This is wherein threadlockers find their value. They lessen the risk of injuries, lower maintenance frequency, and in the long run aid product longevity. As industries intention for safer, more green operations, the demand for dependable adhesives is now not optionally available it’s anticipated. This expectation is progressively reworking how corporations source and follow fastening answers.

The push closer to automation and precision in production has only amplified the importance of threadlockers. As machines end up faster and greater intricate, so does the want for solutions that hold company beneath pressure. Manual tightening and basic fasteners regularly fall quick in modern-day setups, main many producers to rely on adhesives that lock screws and bolts with chemical actuality.

Several essential gamers are riding this increase with innovation and scale. Henkel is still a the front-runner, regarded for its regular research and product reliability. Arkema, H.B. Fuller, DuPont, and 3M also are strengthening their positions with a mixture of area of expertise services and global outreach. Meanwhile, brands like Sika Automotive GmbH, Coim, Vibra-Tite, and ThreeBond Holdings Co., Ltd. Are making their presence felt via area of interest know-how and local strategies. Devcon and Cromwell Group (Holdings) Ltd. Aren't far in the back of, contributing to the wider sort of threadlocking merchandise and application-specific answers available in the marketplace nowadays.

With rising issues approximately protection, sustainability, and product overall performance, corporations are beginning to respect the role of adhesives extra than ever. Instead of being seen as an afterthought, threadlockers are now incorporated into the early stages of product design and engineering selections. Companies are starting to understand that a minor fastening trouble can cause a first-rate failure if omitted. That shift in mind-set is one of the maximum big adjustments shaping this space.

Looking beforehand, the global threadlocker market, as offered by way of Metastat Insight, will possibly keep growing in quiet yet substantial ways. It won’t make headlines the way excessive-tech devices do, however its role backstage will maintain expanding. More industries will turn to superior adhesives now not simply as a solution, but as a popular. In this diffused however vital shift, the market is carving out a area that’s each constant and considerable evidence that even the smallest additives can have a massive impact.

Threadlocker Market Key Segments:

By Product Type

- Anaerobic Adhesives

- Acrylic Adhesives

- Epoxy Adhesives

- Cyanoacrylate Adhesives

By Packaging Type

- Bulk Packaging

- Single-use Packages

- Retail Packaging

By Application

- Industrial Applications

- Consumer Applications

By End-user

- Automotive

- Aerospace

- Electronics

- Manufacturing

- Marine

Key Global Threadlocker Industry Players

- Henkel

- Arkema

- H.B. Fuller

- DuPont

- 3M

- Sika Automotive GmbH

- Coim

- Vibra-Tite

- ThreeBond Holdings Co., Ltd.

- Devcon

- Cromwell Group (Holdings) Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383