MARKET OVERVIEW

The Global Thread Rolling Dies market and industry represent a niche area of manufacturing equipment that plays a crucial role in precision machining and threading. Thread rolling dies are important equipment that can be used for the plastic deformation of materials to create threads, particularly metals, instead of cutting. It improves the mechanical strength of the threads, besides ensuring good surface finish and durability. The market is specialized by industry for the use in such industrial applications as automotive, aerospace construction, and general manufacturing-these industries all having specific need for high quality reliable threaded solutions. Thread rolling dies ensure precision and efficiency in creation of threads and also represent something different compared to the rest: they are a cost effective method and at the same time they ensure that least amount of waste is present.

The Global Thread Rolling Dies market is poised to remain at the forefront in promoting the development of manufacturing technology as industries move toward faster and more consistent thread production. The market will see increasing demand as the tools provide for uniform threads, enhanced resistance to fatigue, and improved performance overall of the material. The Global Thread Rolling Dies market is wide, catering to industries that require customized thread profiles, diverse die configurations, and high production volumes. From cylindrical dies, flat dies, and planetary dies to radial dies, the market includes a wide variety of tools suited to specific applications.

Each type serves distinct industrial needs, enabling manufacturers to adapt to complex threading requirements and stringent product standards. Advanced technological sophistication within the industry will lead toward building innovative dies that support modernizing concepts of automation and are highly accommodative in terms of high-speed production techniques of modern thread rolling machines aligned with the evolving trends in production. Geographically, the Global Thread Rolling Dies market covers a wide range of regions; North America, Europe, Asia-Pacific, and rest of the world, while each contributes uniquely to this demand and supply dynamics. The mature industrial bases in North America and Europe will continue to focus on quality and precision. The Asia-Pacific region, with strong manufacturing activities and rising investments in industrial infrastructure, will most likely be a region driving market expansion. The shift in the industries toward lightweight materials and sustainable manufacturing will continue to shape the demand for thread rolling dies.

The manufacturing landscape continues to grow more competitive, while Global Thread Rolling Dies market businesses will focus on increasing their products’ durability and reducing cost-of-operation for their clients. Emerging features such as coatings to enhance die long-term life and advanced materials integrated to improve performance are expected to change the face of the market in the future. In summary, the Global Thread Rolling Dies market plays a central role in the manufacturing industry by providing crucial tools for precision threading applications. The ability to fulfill various industrial needs, together with technological development, makes it a major factor in global industrial development. The demand for innovative and efficient thread rolling dies will be strong, and this market will be relevant and expanded in the coming years.

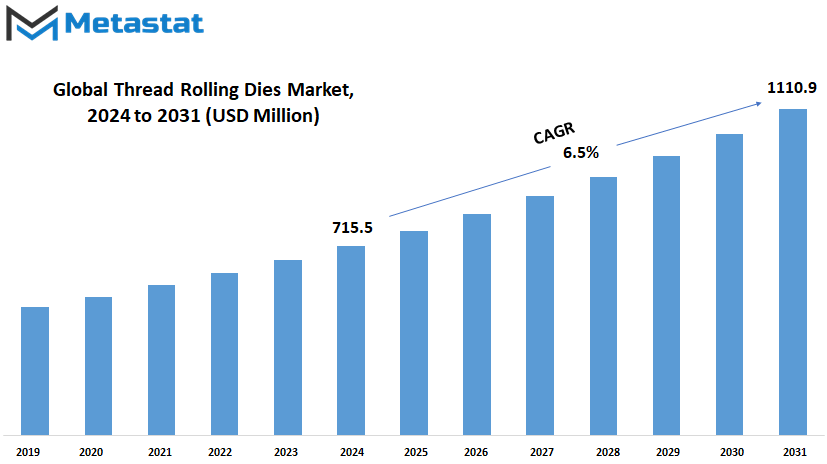

Global Thread Rolling Dies market is estimated to reach $1110.9 Million by 2031; growing at a CAGR of 6.5% from 2024 to 2031.

GROWTH FACTORS

Based on the advancement in manufacturing and the growing demand for such accurately engineered components, the coming years are going to increase the Global Thread Rolling Dies market. Thread rolling is a very important tool utilized in industrial production to acquire threaded parts with high productivity and precision. They have vast applications in the automotive and aerospace industries, which necessitate high-quality and reliable component parts for operation. Its growth is driven by manufacturing sectors, which require their products to be made cheaply and efficiently. Perhaps one of the primary driving factors for this market growth is the increasing demand from heavy industries that require components and tools to be durable and very accurate for performance.

For example, the automotive industry has a fast-growing demand for threaded fasteners in vehicle assembly. In the construction sector, dependable tools to create secure fittings are also essential for achieving structural integrity. Advances in thread rolling die technology in terms of improved materials and designs are also motivating the manufacturers to employ such tools in greater proportions. These developments cut down on production errors and increase the life of the dies, thereby making businesses more efficient and cost-effective in their operations. However, some factors may restrict the market's growth. The cost of advanced thread rolling dies is very high in the initial stage, which makes it unaffordable for small manufacturers, especially from developing economies. Moreover, the need for skilled operators and proper maintenance may become a problem for some businesses. Despite all these challenges, the market has a bright future ahead, especially when emerging economies continue to invest in industrial growth and modernization. Technological advancements and sustainable manufacturing practices will bring in new opportunities for the Global Thread Rolling Dies market in the future.

Environmental-friendly processes are likely to motivate innovations in recyclable and energy-efficient die materials. Additionally, the increasing integration of automation and smart technologies into manufacturing facilities will increase the precision and efficiency of thread rolling, thus generating more demand for advanced dies. This trend is expected to be driven even more critically in various industries around the world for being cost-effective and reliable. The Global Thread Rolling Dies market will grow since there will be a greater demand by several industries along with its associated technology. On the one hand, the expenses and skill demand do pose barriers; yet on the other hand, constant innovations coupled with further expansion of industries will fuel this market well into the future.

MARKET SEGMENTATION

By Type

The Global Thread Rolling Dies market is likely to experience rapid growth in the coming years, as it continues to grow due to advancements in technology and the growing need for efficient manufacturing processes. Thread rolling dies are necessary tools in industries that require high-precision threading. They are used to form threads on fasteners, screws, and other parts, which helps in achieving durability and accuracy in the products. This market is divided into several types, such as Flat Thread Rolling Dies, Circular (Cylindrical) Dies, Tangential Thread Rolling Dies, Planetary Thread Rolling Dies, and others, each designed for specific applications and purposes.

Flat Thread Rolling Dies are widely used because of their simplicity and low cost. These dies are favored in industries where consistent threading is required, making them a favorite for mass production. The circular or cylindrical dies are used extensively in applications where high precision and complex thread designs are required. The ability to produce uniform threads in a continuous process makes them indispensable for industries such as automotive and aerospace, where reliability is critical. Tangential thread rolling dies are getting popular due to their efficient handling of complex threading jobs, whereas planetary thread rolling dies are valued for high-speed applications, especially for small-sized components. Other thread rolling dies serve niche markets where specific industries require customized solutions.

The future growth of the market will be determined by increasing adoption of automation and technological innovations. With the current pace of seeking faster, more reliable, and cost-effective ways of threading, manufacturers for thread rolling dies are likely to invest in the development of advanced materials and designs in terms of performance. This would also be due to the environmental concerns and goals toward sustainability, pushing to use eco-friendly manufacturing methods and further changing the market dynamics.

In addition, the construction, automotive, and aerospace sectors require lightweight, high-strength materials that will continue to increase the demand for efficient thread rolling solutions. The trend thus underscores the need for thread rolling dies in producing parts of high quality and performance. As industries worldwide develop, the Global Thread Rolling Dies market will play a pivotal role in driving innovation and growth.

By Material Type

The Global Thread Rolling Dies market will witness some significant breakthroughs due to advancements in the manufacturing processes and surging demand for efficient and reliable solutions within different industry boundaries. It is also necessary to add that this production of threaded parts incorporates rolling dies and provides precision, with reliability coming as a supplementary. As technologies advance further along with more emphasis being on sustainability, this industry market will rise steadily where companies are working towards a newer solution set to take into the arena of today’s competitive world.

The diversity of material used to make thread rolling dies is one of the critical aspects of this market. High-Speed Steel, for instance, is quite common due to its toughness and high temperature resistance; it is reliable and thus cost-effective in several applications. Nevertheless, with the advancement in metallurgy and material science, an alternative has been provided with carbide, which exhibits excellent wear resistance properties and is very suitable for high-volume operations. It makes carbide thread rolling dies very attractive for extended tool life and superior performance under demanding conditions.

Tool steel is another major material that holds a significant share in the market of thread rolling dies. Tool steel is highly used for making dies because of its strength and versatility to handle heavy-duty tasks. Alloy steel is also being increasingly used due to its adaptability and durability. These materials are used in industries where precision and longevity are the key. In addition, specialized alloys are being developed for specific applications and are finding their niche in the market. These advanced materials are designed to meet the specific demands of modern manufacturing, such as improved efficiency and minimized production downtime.

The future of the Global Thread Rolling Dies market is tied to the progress of these material types. Manufacturers are investing in research and development to enhance the performance of dies while reducing the cost of production. Innovation is expected to propel the market further as industries continue to emphasize quality and cost-effectiveness. Additionally, as sustainability continues to become a concern, manufacturers are likely to use environmentally friendly materials and processes that align with the global trend toward green manufacturing practices.

With industries such as automotive, construction, and aerospace significantly dependent on threaded components, the demand for high-quality thread rolling dies will be on the rise. When material technologies advance, solutions will be found in providing a balance between efficiency, durability, and affordability in the Global Thread Rolling Dies market, making it a crucial part of modern manufacturing.

By Distribution Channel

The Global Thread Rolling Dies market is going to experience a significant growth in the near future due to developments in manufacturing and the high demand for precision tools across different industries. Thread rolling dies are known for efficiency in producing strong, uniform threads, and play an important role in processes that range from automotive to construction. Innovation and the rising need for high-quality tools in industrial applications shape the promising future of this market.

The distribution channels of the Global Thread Rolling Dies market are very important in addressing the different needs of businesses around the world. The direct sales channel is significant because it allows manufacturers to have close relationships with clients and provide customized solutions. It ensures that customers get tailored services, which helps in building trust and loyalty. Distributors and dealers are also a very significant link between manufacturers and end-users. They offer greater accessibility to a wider reach, mostly in areas where direct accessibility to producers may be low. This intermediary is responsible for keeping the thread rolling dies and ensuring timely availability in a wide range across the world.

Online sources are progressively becoming a user-friendly way of distribution channel. The digital shift in commerce has enabled businesses to access products more easily, compare prices, and review technical specifications in real-time. Online sales platforms also offer manufacturers an opportunity to reach untapped markets and showcase their product range to a global audience. This trend is expected to grow as more industries adopt digital procurement practices, driven by the convenience and cost-effectiveness of online transactions.

Technological advances will more than likely lead the course in the future of Global Thread Rolling Dies. Higher-grade materials and manufacturing technologies will be infused into this tool, thus increasing durability and performance. Automating manufacturing processes will add efficiency as companies look to satisfy growing orders without sacrificing quality. The emphasis on environmentally friendly products may also play a role as producers begin to design sustainable thread rolling dies to further align their efforts with those of worldwide initiatives to reduce waste and increase energy efficiency.

Innovation and various types of distribution channels are expected to play out the future of the Global Thread Rolling Dies market. By harnessing direct sales, distributors and dealers, and online platforms, companies will be able to increase their customer base, keep up with changing industrial demands, and drive the expansion of this critical industry.

By Application

The Global Thread Rolling Dies market is very crucial because industries are demanding accurate, efficient, and long-lasting tools for manufacturing and assembly processes. Thread rolling dies are necessary for making threads on fasteners and other parts, which will be a non-cutting process that will strengthen the product and make it accurate. In the future, the application of thread rolling dies will increase and expand because of technological advancement and the growing needs of the industries.

Segmentation by application: The global thread rolling dies market can be divided into several industries, which are as follows: automotive, aerospace and defense, construction and infrastructure, industrial machinery, electronics and electrical components, medical devices, and fastener production. Each of these sectors is a dynamic area of development that might reshape the demand for thread rolling dies in unique ways. In automotive industry, for example, is always seeking the edge through innovation in light weight yet high performance vehicle. A fastener or a component must meet strict quality requirement, and thread rolling dies are an integral part in this process. That would only increase as electric vehicle becomes mainstream and autonomous technologies takes over.

Aerospace and defense also demand great precision and durability from the components. Thread rolling dies contribute to the production of fasteners that can withstand extreme conditions, making them indispensable in manufacturing aircraft and defense equipment. In the construction and infrastructure industry, the use of thread rolling dies ensures reliable connections in structural elements, which is vital for long-term safety and sustainability. With urbanization on the rise and the demand for green building, this sector will continue to focus more on efficiency and reliability in production processes.

Industrial machinery and electronics require compact, high-strength components. Thus, thread rolling dies are a must in the production of parts that fulfill these needs. As technological advancements increase miniaturization and efficiency, the importance of thread rolling dies in these sectors will be increased. Another growth area is the medical devices sector, which requires precision and quality; the demand for these dies will increase with the growing healthcare industry and innovation. Fastener production is a core application and is likely to benefit from increasing global demand for durable and high-performance fastening solutions.

The global thread rolling dies market is, therefore, well positioned for steady growth. Its applications are bound to expand as industries evolve, thus making it relevant for both current and future manufacturing challenges.

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$715.5 million |

|

Market Size by 2031 |

$1110.9 Million |

|

Growth Rate from 2024 to 2031 |

6.5% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

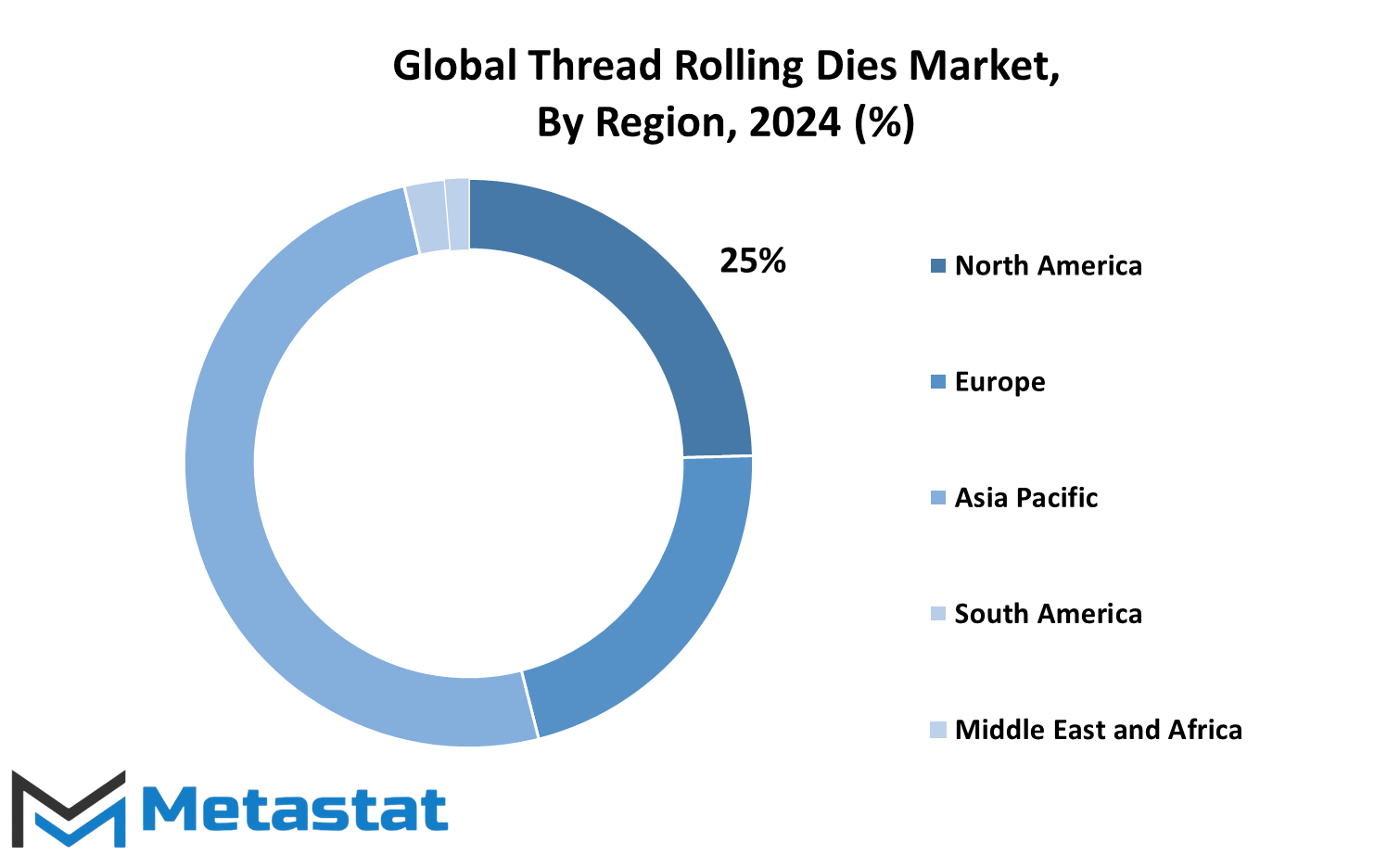

Based on geographic location, the international market for Thread Rolling Dies can be divided into five regional markets. It makes provision for an all-around viewpoint on its current and probable future growth opportunities. Its market in North America, Europe, Asia-Pacific, South America, and Middle East & Africa will display various prospects and challenges before its growth.

North America, which includes the United States, Canada, and Mexico, continues to be a major contributor to the market, mainly due to consistent advancements in manufacturing technologies and the strong presence of industrial machinery industries. The demand for thread rolling dies in this region is supported by efforts to enhance productivity and reduce operational costs across industries. Europe is ahead of the world with regards to the use of highly developed industrial equipment. By adopting automation and sustainability in its manufacturing processes, countries within Europe are bound to take a leading position within the global market as it relates to the implementation of “green” and efficient processes.

The major contributors to the Thread Rolling Dies market in the Asia-Pacific region are India, China, Japan, and South Korea. Rapid industrialization and investment in infrastructure and manufacturing have highly increased demand in this region. China and India are likely to experience a huge growth rate due to their automotive and construction industries expanding at a rapid pace. The rest of Asia-Pacific also holds potential that has not yet been tapped, as smaller economies seek to upgrade their industrial capabilities to global standards.

South America, which is dominated by Brazil and Argentina, provides a growth market that is driven by the gradual modernization of industrial processes and the increasing regional manufacturing base. Challenges such as economic instability could create hurdles, but growth in the long term would be fueled by the adoption of advanced machinery.

The Middle East & Africa region, divided into GCC Countries, Egypt, South Africa, and the rest, is full of promise since there is an increase in infrastructure projects and economies’ diversification away from being dependent on oil. This region will see a stable growth of the market for thread rolling dies as governments here are keen on industrial development and innovation.

As industries continue to embrace innovation and technology globally, the global market for Thread Rolling Dies will expand significantly in all regions because of the need for manufacturing solutions that are both efficient and durable.

COMPETITIVE PLAYERS

The Global Thread Rolling Dies market is a vital part of industrial manufacturing that enables the mass production of threaded components widely used in different applications, ranging from the automotive to aerospace industries. The thread rolling process, a cost-effective and environmentally friendly method, is a key element that can increase productivity and quality in mass production. As industries continue to evolve and demand higher precision, the thread rolling dies market is expected to witness significant advancements, shaped by the efforts of leading players in the field.

Some of the key players in the thread rolling dies industry include companies such as Precision Castparts Corp., Harold Habegger SA, HEROSLAM, Plan-E-Tech Industries Inc., and Jieng Beeing Enterprise Co., Ltd. These companies, not to mention others such as Rolling Tools, OSG Corporation, and Taiya RDP Mould Jiaxing Co., Ltd., are increasingly contributing to the growth and progress of the market. Development is no longer just toward high-performance tools but also catering to durability, efficiency, and the ability to produce according to modern manufacturing requirement. Profiroll Technologies GmbH, Rollwalztechnik Abele + Höltich GmbH, Mayes & Warwick Ltd., and Yamawa Manufacturing Co., Ltd. contribute their expertise in this competitive landscape, ensuring the steady supply of advanced products.

The future of the Global Thread Rolling Dies market is full of immense change, mainly driven by technological innovation and the growing demand for greater sustainability. One notable trend is the integration of automation into the manufacturing process, enabling the production of thread rolling dies with higher precision and consistency. Automation not only enhances the quality of the tools but also reduces production costs, which is vital for meeting the competitive pressures in this industry. Further, developments in the area of material science will create more rugged dies, supporting loads to a higher capacity, thereby working for much longer and reducing replacement necessities.

Since manufacturers are catering for many types of industries, individual customization has become a crucial requirement for this market. Increased R&D investments by various companies towards developing custom product offerings in line with distinct client demands are common sights these days. This strategy will not only improve customer satisfaction but also enhance the competitive advantage of these companies. In addition, the trend of eco-friendly manufacturing is going to increase, which will follow the world's move toward sustainability. Innovation, adaptability, and environmental responsibility are going to be the drivers of the Global Thread Rolling Dies market in the future, as it will be able to meet the emerging needs of modern industry.

Thread Rolling Dies Market Key Segments:

By Type

- Flat Thread Rolling Dies

- Circular (Cylindrical) Dies

- Tangential Thread Rolling Dies

- Planetary Thread Rolling Dies

- Other Types

By Material Type

- High-Speed Steel (HSS)

- Carbide

- Tool Steel

- Alloy Steel

- Other Specialized Alloys

By Distribution Channel

- Direct Sales

- Distributors and Dealers

- Online Platforms

By Application

- Automotive Industry

- Aerospace and Defense

- Construction and Infrastructure

- Industrial Machinery

- Electronics and Electrical Components

- Medical Devices

- Fastener Production

Key Global Thread Rolling Dies Industry Players

- Precision Castparts Corp.

- Harold Habegger SA

- HEROSLAM

- Plan-E-Tech Industries Inc.

- Jieng Beeing Enterprise Co., Ltd.

- Rolling Tools

- OSG Corporation

- Taiya RDP Mould Jiaxing Co., Ltd.

- Profiroll Technologies GmbH

- Rollwalztechnik Abele + Höltich GmbH

- Mayes & Warwick Ltd.

- Yamawa Manufacturing Co.,Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252