MARKET OVERVIEW

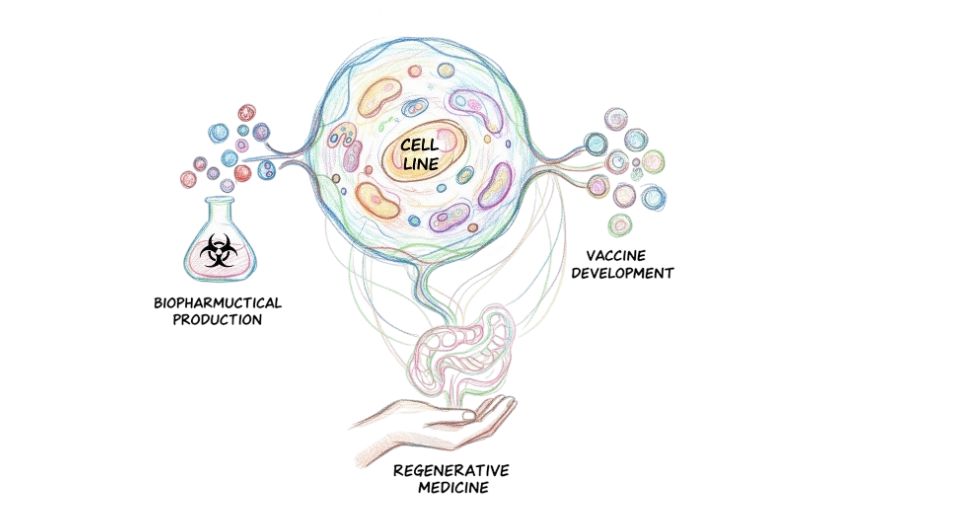

The Global Single-use Bioreactors market is the largest segment of biotechnology and pharmaceutical manufacturing. The single-use bioreactor systems form a market within that zone devoted to single-use bioreactor systems that produce biologics, vaccines, and other biopharmaceutical drugs. Such companies adopt flexible and efficient production processes, which explicitly lay down important effective processes to develop new therapies. Unlike conventional stainless-steel bioreactors, single-use bioreactors primarily employ disposable bags as the primary unit for containment instead of requiring cleaning and sterilization. Hence, single-use technology becomes more novel for laboratories and production facilities worldwide to adopt this concept.

The Global Single-use Bioreactors market consists of Segments - research development, clinical trials, and commercial manufacturing. This system maximizes productivity at lower input costs and resources for biotechnology organizations, contract research organizations, and pharmaceutical enterprises. True, this impact on the environment is not confined to the pharmaceuticals arena; it becomes clear in academia and even beyond where biologics play a more significant role in innovative efforts. Such versatility lends support to easily accommodate changes concerning production volumes thus becoming exigently indispensable to projects requiring agility and precision.

The future prospects of Global Single-use Bioreactors market are assured as technology advances in bioprocessing, with further advancements in material science and engineering further improving the prospects of creating stronger and more adaptable single use that would overcome the present limitations regarding scalability and durability of materials. This will further increase its applications in high-demand production environments. From day to day, demand for personalized medicine and cell and gene therapies increases, and single use becomes one of the commonest applications to be prevalent in the market in the future. Obeying strict levels of quality, but at the same time accommodating small-batch production, makes them an integral part of modern biopharmaceutical workflows.

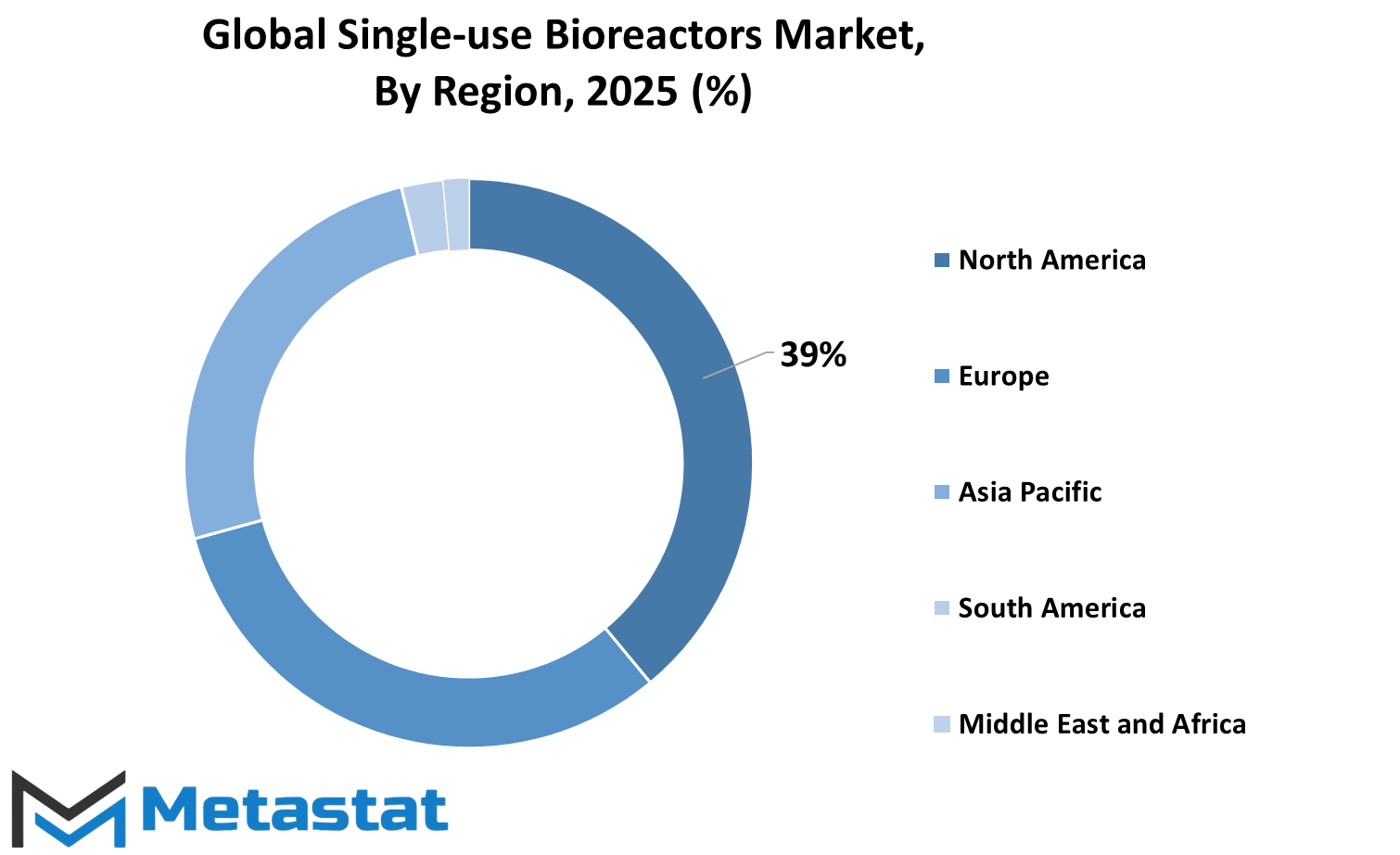

The Global Single-use Bioreactors market can be segmented into North America, Europe, Asia-Pacific, Latin America and Middle East & Africa. Developed regions which are tip-top North America and Europe will be "in the lead" because of their better consolidated biotechnology sectors and significant investments into biomanufacturing infrastructure. Other than the above statements, emerging Asian-Pacific and Latin-American economies will witness a dramatic increase in growth because government initiative increasingly develops as biopharmaceutical production exponentially grows. Pressing demand for affordable and flexible manufacturing technologies will continue to grow with a sustained focus on healthcare innovation.

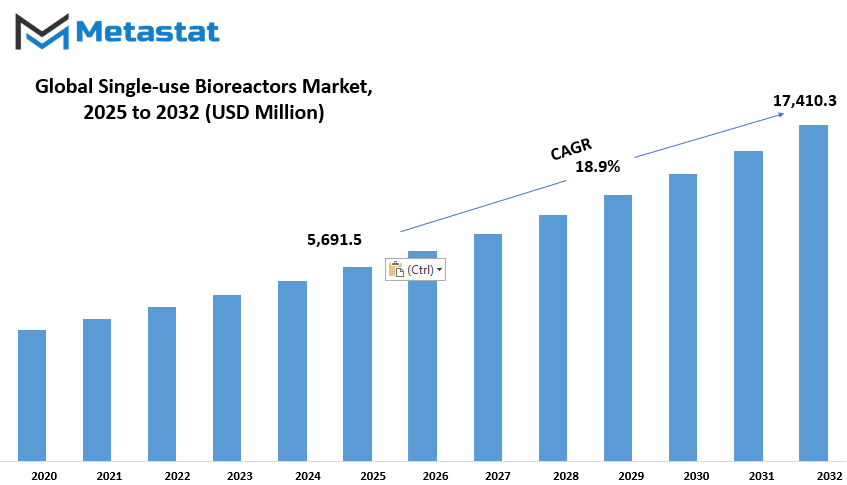

Global Single-use Bioreactors market is estimated to reach $17,410.3 Million by 2032; growing at a CAGR of 18.9% from 2025 to 2032.

GROWTH FACTORS

In conjunction with the improvements and changes in biopharmaceutical production processes, the global single-use bioreactors market is growing at an incredibly quick pace. Benefits associated with these systems include increased upfront investment while at the same time saving on costs for cleaning and sterilizing. This makes these systems amenable to biopharmaceutical companies in their pursuit of efficient and cost-effective production methods. Though, the demand for flexible and scalable solutions has made single-use bioreactors prominent in the development of small batch and customized medicines which now become more relevant with precision medicine advancement.

The primary concern relates to the environmental impact of those single-use systems because they generate plastic waste difficult to be managed sustainably. Questions have arisen regarding long-term sustainability, especially in areas giving great importance to environmental regulations. Further, these single-use bioreactors are impractical when dealing with high throughput bioprocessing. Above volumes, traditional stainless steel replacements become necessary, which lessens their appeal for some applications. However, huge opportunities for growth present.

Single-use bioprocessors are quickly gaining traction in emerging market countries and small biotech firms. Cost-effective for the production of biologics, an area of interest for the world, these systems bear a great advantage therein. Affordability and ease of deployment in these regions and by those companies allow for expedited entry into the biopharmaceutical sector and potentially spur innovation and competition. In the future, this may create avenues for further technological advancement and uptake of single-use systems. In the short term, there will be a series of further innovations that can confront current problems. This very fact makes biodegradable materials for bioreactor systems highly promising as one more line of research to counteract environmental influences around them. Improvements in the design and performance of single-use systems might similarly extend the useable volume across the limitations and needs for high-volume manufacture.

As biopharmaceuticals continue to develop and grow, single-use bioreactors will become relevant production systems in need of efficiency, flexibility, and scalability. Considering the advancements in sustainability and personalized medicine, the Global Single-use Bioreactors market has immense opportunities to develop that will accelerate massive biopharmaceutical innovations.

MARKET SEGMENTATION

By Product

The Global market for single-use bioreactors has an expected growth in its process due to more efficient, progressive movement along with industries towards sustainable bioprocessing solutions. Because of their convenience, economy, and flexibility over steel systems, it is fast rising in popularity to single use bioreactors. This market, products including Single-use Bioreactor Systems, Single-use Media Bags, Single-use Assemblies, and other related products, tend to form a segment that caters to the increasing needs raised in the areas of biopharmaceuticals, vaccines, and research applications.

The main driving forces of this market are the efforts directed toward the minimization of contamination risks as well as the time required to set up and maintain this equipment. It is clear that single-use bioreactors offer all these benefits while allowing companies to streamline production as there would not be a need for offshore cleaning and sterilization activities. Another attraction in their timeline of application is that they suit both research and industrial scales making them well favored in the biotechnology and pharmaceutical firms.

Such adverse effects that the industry is faced with will hugely necessitate the growth and acceptance of its required changes in future innovations. Advances in materials and innovations would further propel the efficiency of these systems regarding environment-friendliness. For example, there is a probability that there will be a development of well-designed bioreactors with improved monitoring and control systems to give real-time information of the processes involved in bioproduction. Such improvements do not only increase yield but also ensure consistency and quality in pharmaceutical production.

Media bags and single use assemblies are increasingly relevant in the Global Single-Use Bioreactors market. It is an important component of bioreactor systems, enabling seamless integration and operation. Media bags are mainly used for the storage and transport of sterile materials and keep the entire production process free from contamination. Single use assemblies offer custom solutions for individual applications, thus improving the efficiency of supporting bioprocesses and their flexibility.

The future of this global single-use bioreactor market will be vast as more and more pharmaceutical companies look for greener and better cost-effective methods in their production processes. Governments and regulatory agencies have also pushed at their end for the adoption of these technologies to meet the global health products demand, which is ever-increasing. With constant innovation and shift towards creating greener technologies, this market is destined to make its mark into the future of biomanufacturing.

By Type

According to market estimations, the global single-use bioreactors market is expected to grow and transform tremendously as a consequence of advancement in bioprocessing technology and the ever-increasing demand for efficient and cost-effective solutions in the biopharmaceutical industry. Recently, single-use bioreactors have gained wide acceptance because they are flexible, present minimal risk of contamination, and are cheaper to run than their conventional stainless steel counterparts. Thus, SUBs are being regarded as an integral component in the production of vaccines, monoclonal antibodies, and other biotherapeutics. The various classes of single-use bioreactors that exist in the market play unique roles in altering the path in which the industry develops.

The most seen segments in this market are stirred-tank single-use bioreactors, recognized for versatility and capability to serve all cell culture processes. Their versatility during pharmaceutical production comes from being able to provide support for various scales of production: in small batches as well as large volumes, thus providing a viable and mainstream option for both researchers and manufacturers while answering growing demand worldwide.

Wave-induced single-use bioreactors are another prime area, with an estimated worth of 337.5 million USD as of 2022. The very essence of these bioreactors' effectiveness lies in application areas where gentle mixing with low shear stress is required for the cultivation of fragile cells. With the relatively simple design and operation supported by good performance, they allow applications in specialized processes, thereby paving the road towards innovative bioprocessing tools.

Bubble-column single-use bioreactors also cover a vital share in the market with a valuation of around 298.6 million USD in the year 2022. These systems are optimal for their energy efficiency and mass transfer capabilities, making them fit for industrial-scale productions. As biopharmaceutical companies are pursuing an increase in productivity while minimizing the environmental footprint for process development, it is likely that even greater levels of adoption will be seen for these submerged bioreactors with benefits not just for reduced environmental impact but also for process simplification.

Other Single-use bioreactors valued at 167.7 million USD in 2022 address niche applications and offer flexibility in viable custom solutions. These systems respond to the unique requirements in research and production and promote innovative advancements across a broad array of fields.

Thus, looking ahead, the Global Single-use Bioreactors market appears set to attain remarkable advances sustained by innovation and with ever-accelerating adoption of biotherapeutics across the globe. With the rise of personalized medicine, super-efficient scalable and flexible models of SUBs will play a defining role in the future of biomanufacturing, forever altering the interface between the world's healthcare and medicines' production.

By Application

The Global Single-use Bioreactors market has grown tremendously in the past years as most sectors try to keep becoming more technologically advanced in dealing with increased demands. Single-use bioreactors (SUBs) are generally target alternatives to traditional systems made of stainless steel, doing away with the risk of contamination in the process. These make them especially ideal for bioproduction processes, process development, and research and development applications. This versatility therefore places these systems at the forefront of the needs of evolving biotechnology and pharmaceutical production.

Bioproduction has evolved and now becomes critical in this case with single-use bioreactors. Scalability looking for easy changes in production would become easy to achieve without the long clean and sterilizing downtime, thus making them attractive to biopharmaceutical manufacturers. More biologic therapies and vaccines are on demand, and therefore, more efficient producing systems are increasingly needed. With the reduction of time for producing a quality product by using SUBs, operational costs are maintained low with faster development and manufacturing cycles.

Successful applications are also in the research on developing processes using single-use bioreactors. These systems have a better option to test and optimize production parameters. Flexibility in volumes and conditions makes them relevant in tuning processes prior to manufacturing. Because of this, SUBs are an adaptable system for experimental and pilot run levels, with industries focusing more on waste reduction and maximum yield. With these merits, they can hold the key to shaping the future of industrial biotechnology.

In research and development, the single-use bioreactor is an irreplaceable tool of innovation. They enable customizable configurations that scientists can use to test new formulations and approaches more effectively. This capability is crucial in fields such as cell and gene therapy, where precision and adaptability are paramount. It makes it possible to minimize the start-up investment in R&D, therefore empowering smaller companies and academic institutions to participate in major research breakthroughs. This democratization of research tools can significantly accelerate advancements in health and science.

But further into the horizon are the new materials and technologies that promise expanded horizons for the Global Single-use Bioreactors market. Advanced designs of bioreactors coupled with enhanced sensors and technologies will also help boost innovative applications. Advances in sustainability and cost-effectiveness are also making this technology quite relevant in today's biomanufacturing. With increasing global acceptance and application of these systems, the future of biopharmaceuticals and biotechnology is sure to be defined through single-use bioreactors as well.

By End User

The Global Single-use Bioreactors market is booming at an exponential rate, especially as the biopharmaceutical industry adapts better, cost-effective production methodologies. The single-use bioreactors differ qualitatively but are single-use products that have been bringing in technological trends in bioprocessing world as one of the important components of modern processes. This end-user segment may be pharmaceutical companies, biotechnology companies, CMOs and CROs, or even academic and research institutes. Each component will be contributing differently to the growth of such a market; in fact, it will be sprawling into several applications and adopting a broad acceptance across the segments. Pharmaceutical and biotechnology companies are leading the market largely due to the high demand for biologics, vaccines, and other therapeutic products.

Cost efficiency is the other aspect of single-use bioreactors in contrast to stainless-steel systems. For single-use options, cleaning and validation requirements are very limited, consequently short-production schedules. This market can be kept leading in progress in the biotechnology space with future trends in custom-made medicines and specialty biologics. These bioreactors are likely to simplify large and small-scale production processes alike and make it suitable for various therapeutic pipelines. Another key trend affecting the global single-use bioreactors market is that of contract manufacturing and research organizations. Thus, CMOs and CROs play an important role as partners to pharma companies that do not have their in-house manufacturing capacities.

These single-use bioreactors enable the companies to offer high quality and scalable solutions in ensuring faster supply of products. The outsourcing demand keeps on rising, making it imperative for CMOs and CROs to embrace more of these new technologies to meet the anticipated demand. This shift towards such bioreactors is being compounded by the industry's focus on reducing costs while still enhancing quality in production. Academic and research institutes form the other segment with high value for the market. Actually, single-use bioreactors are for the teaching, experimental research into biologics, and small-scale production needs. Production creates demand that drives innovation since researchers seek new ways and applications of bioprocessing methods. Increased interest in biopharmaceutical research means that this segment is likely to have a lot to say about the future of this market. Midterm growth in the single-use bioreactor markets globally is primarily going to be shaped by the further developments in automation and analytics integration. Increased process efficiency, coupled with real-time ability for monitoring, will boost attractiveness in these developments. Sustainability and cost-effectiveness priorities across the industries make single-use bioreactors the fundamental component of future modern biomanufacturing.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$5,691.5 million |

|

Market Size by 2032 |

$17,410.3 Million |

|

Growth Rate from 2025 to 2032 |

18.9% |

|

Base Year |

2025 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

REGIONAL ANALYSIS

The worldwide Single-use Bioreactors market is coming to stand as one of the crucial aspects of the modern biopharmaceutical production industry. The growing use of the product provides an in-depth scenario about its future outlook. This market has been regionally segmented into five major regions: North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. Each region bears its unique opportunity and challenges, further propounded by factors such as infrastructure, technical advancement, and demanding biopharmaceuticals.

Among the regions, North America is playing the lead role in such trade primarily due to its established pharmaceutical industry and also early adoption of newer technologies. The different levels of growth in the bioreactors can be seen in the U.S., Canada, and Mexico. The first place is taken by the U.S. in investing in the research of bioreactor technologies. Availability of expertise and stable regulatory systems are factors conducive to new developments in single-use bioreactors.

The market major contributors in Europe are the UK, Germany, France, and Italy. The region demands sustainable manufacturing and the continuous need for flexible processing solutions, which drives demand. Research institutions continuously innovate, and alliances between biotech companies always ensure their growth.

Asia-Pacific is home to emerging economies being India, China, Japan, and South Korea. The region has enormous market potential in terms of growth. The region has been increasing production of biopharmaceuticals in light of increased healthcare demand, better infrastructure, and government policies for biotechnology development. China aims to become a biotechnology center internationally, and with increasing clinical trials in India, those two countries are likely to play a very significant role regarding the future entrance of the single-use bioreactor.

Indeed, the bulk of the South American region is inclined toward this technology, especially Brazil and Argentina, as it seeks to strengthen its pharmaceutical sector. Although it is still at its nascent developmental stage compared to other regional countries, this shall eventually speed up progress in subsequent years as investment and partnerships are on the rise.

The Middle East & Africa, which includes the GCC countries, Egypt, and South Africa, has also gradually started taking to single-use bioreactors. This was mostly due to the improvement of their healthcare systems and the attempts to localize pharmaceutical production.

These regions differ in their future expectations. However, the global Single-use Bioreactors market is maturing due to the importance of development in automation, recognition of environmental concerns, and interest in cost-effective production. Therefore, the market promises to stand as an anchor of biopharmaceutical innovation around the globe.

COMPETITIVE PLAYERS

The Global Single-use Bioreactors market revolutionizes biopharmaceutical production and nurtures innovation and efficiency. Single-use bioreactors with their ready-to-use components are now indispensable to the manufacture of biologics, vaccines, and cell therapies. This method minimizes the risk of contamination and streamlines production processes, making it increasingly sought after as biopharmaceutical companies aspire to develop faster and have adaptable manufacturing operations.

Research and development in this area are led by the incumbent companies- Sartorius AG, Thermo Fisher Scientific, and Merck KGaA. They are actively engaged in improving product performance with a view to scaling, automating, and adapting to a range of cell culture applications. Sartorius AG is recognized for addressing the particular needs of very large-scale manufacturing, while Thermo Fisher Scientific has been gradually expanding its portfolio to fulfill quasi-accuracy and reliability high demand.

Innovative bioreactors, for specific therapeutic applications designed by these new players in the competitive landscape, promise to add further diversity to the market. Such technologies would thus be available to small-scale operations in the biomanufacturing sector. Established players such as Eppendorf SE and Parker Hannifin Corporation have contributed significantly toward the development and integration of advanced materials and designs clinching the market growth trajectory.

The Global Single-use Bioreactors market will undergo several transformations forward due to the definite strides being made by Personalized Medicine and Advanced Therapies being placed within the avenue of the health care competitors. Fast adaptability to changes for production scales through S.U.B. will be the password in fulfilling the changing demands of health care. Innovation for Sustainability: Players like Lonza and Saint Gobain have further advances in sustainability to diminish detrimental effects of such disposable components on the environment.

Thus, with the more investments being drawn to bioproduction capabilities, the market is entirety set to be flooded with partnerships and collaborations that encourage better technical capabilities within single-use bioreactors while also lowering costs to be afforded by emerging biopharmaceutical companies. The Global Single-use Bioreactor market is set for dynamic growth through the joint action of these key players committed to the furtherance of healthcare manufacturing technologies. This sets a pace where, into the future, the industry will be one of efficiency and adaptability promising even more opportunities for old and new entrants alike.

Single-use Bioreactors Market Key Segments:

By Product

- Single-use Bioreactor Systems

- Single-use Media Bags

- Single-use Assemblies

- Other Products

By Type

- Stirred-Tank Single-use Bioreactors

- Wave-Induced Single-use Bioreactors

- Bubble-Column Single-use Bioreactors

- Other Single-use Bioreactors

By Application

- Bioproduction

- Process Development

- Research & Development

By End User

- Pharmaceutical & Biotechnology Companies

- CMOs & CROs

- Academic & Research Institutes

Key Global Single-use Bioreactors Industry Players

- Sartorius AG

- Thermo Fisher Scientific

- Merck KGaA

- Avantor

- New Horizon Biotechnology

- PBS Biotech

- Getinge AB

- Eppendorf SE

- Parker Hannifin Corporation

- Entegris

- Saint-Gobain

- Corning Incorporated

- Lonza

- TECNIC Bioprocess Equipment Manufacturing

- Kühner AG

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252