MARKET OVERVIEW

The global pharmaceutical granulation equipment market is a specialized sub-segment within the pharmaceuticals manufacturing sector dealing with the equipment and technologies employed to facilitate the process of granulation in drug manufacturing. Granulation is an important process in the production of uniform, high-quality drugs, especially in tablet and capsule manufacturing where powder particles are formed together into larger, multi-particle aggregations. This is done so that active ingredients will be uniformly distributed, increase the compressibility, and material characteristics in terms of fluidity which otherwise would be difficult to handle in mass production. With the pharmaceutical industry progressing even more in its own forms of production, precision in granulation processes will always be a crying need.

The global pharmaceutical granulation equipment market is the pillar of this stage with the provision of equipment for all forms of granulation processes, including wet, dry, and melt granulation. Each process boasts its own technology configurations, relying on the drug compound's nature and intended end-use properties. Manufacturers will keep looking for equipment that will make consistent granules with tight control of size, density, and moisture parameters. These are factors that will be paramount to providing consistency and safety in pharmaceuticals. The market's scope goes beyond the provision of equipment. It covers the wider industrial ecosystem that assists pharmaceutical firms in streamlining their production lines.

This will involve equipment that can scale, from pilot-level production in research facilities to full-scale production in manufacturing facilities. It will also involve ongoing advances in automation of equipment, material transportation, and process control systems. The advancements will respond to the minimization of human error, process efficiency, and conformity with increasingly stringent regulatory standards globally. Subsequent generations will witness the global pharmaceutical granulation equipment market grow even more in alignment with the changing demands of drug makers. That will be evident in equipment technology developments that allow for more versatile manufacturing capabilities, including configurations that accommodate different forms of drugs with minimal retooling. In addition, integration of technology using digital tools will also control the market, with the machines being fitted with sophisticated monitoring systems of data that offer real-time data on the process of granulation.

Such abilities will help manufacturers guarantee quality consistency and open opportunities for process improvement. Outside the immediate confines of equipment manufacturing and supply, this market will overlap with a number of adjoining fields. These will be process simulation, validation, and compliance software technology providers, and raw material providers who have engineered the material to perform better under granulation. Machinery manufacturers and pharmaceutical companies will dictate the standards and parameters of future machines through their collaborative strategy, with emphasis especially on flexibility and efficiency. In the future years, the global pharmaceutical granulation equipment market will remain characterized by the intricate demands of contemporary drug production. Equipment requirements will rise in tandem with the refinement of drug formulation.

With the emergence of new therapeutic areas and traditional treatments being perfected, granulation technologies will have to evolve as a result. This market will be guided by these developments, continuing to be a key part of the world of pharmaceutical production for the foreseeable future.

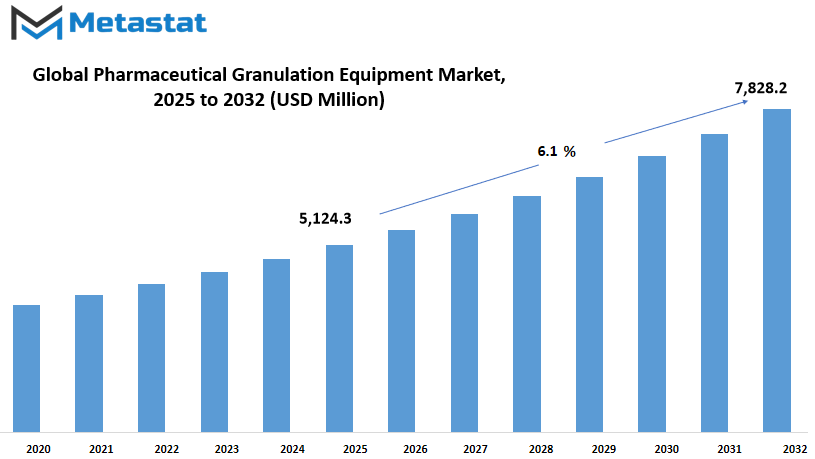

Global pharmaceutical granulation equipment market is estimated to reach $7828.2 Million by 2032; growing at a CAGR of 6.1% from 2025 to 2032.

GROWTH FACTORS

The global pharmaceutical granulation equipment market will continue to show significant growth in the future as pharmaceutical companies focus more on improving the quality and efficiency of drug manufacturing. Granulation plays an important role in the production of solid dosage forms like tablets and capsules, making it a key process in the pharmaceutical industry. As the demand for effective and high-quality medicines grows, the need for advanced granulation equipment will rise as well. Several factors are driving this growth. Firstly, the increasing demand for personalized medicine and controlled-release formulations is pushing manufacturers to adopt modern equipment that offers precision and consistency. Pharmaceutical companies are also investing heavily in research and development, which further supports the need for updated granulation technologies.

Another important factor contributing to the growth of the global pharmaceutical granulation equipment market is the growing elderly population worldwide. With age, health problems tend to increase, leading to higher consumption of medicines. This, in turn, encourages pharmaceutical companies to enhance their manufacturing capabilities to meet the growing demand. Additionally, governments and health organizations are putting strict regulations in place to ensure the safety and quality of medicines. Companies need advanced granulation equipment to comply with these standards, which pushes the market forward.

However, there are some challenges that might slow down the growth of the market. The high cost of advanced equipment is one such challenge. Smaller pharmaceutical companies might struggle to afford the latest technologies, which could limit their adoption. Along with that, the lack of skilled professionals who can operate these advanced machines efficiently might create further hurdles for the industry. Training and education will play a crucial role in overcoming this barrier in the future.

Looking ahead, technological advancements will offer lucrative opportunities for the global pharmaceutical granulation equipment market. Innovations such as continuous manufacturing, automation, and the use of artificial intelligence in monitoring and controlling granulation processes will make the equipment more efficient and user-friendly. These developments will not only improve productivity but also reduce operational costs, making them attractive to a wider range of pharmaceutical manufacturers.

In the coming years, the focus will likely shift towards energy-efficient and environmentally friendly equipment, opening up new possibilities for companies in this market. By adapting to changing needs and embracing innovation, the global pharmaceutical granulation equipment market will continue to expand and contribute to the progress of the pharmaceutical industry.

MARKET SEGMENTATION

By Type

The global pharmaceutical granulation equipment market will continue to show steady progress as pharmaceutical companies look for more efficient ways to produce high-quality medicines. Granulation equipment plays a key role in the production of tablets and capsules by helping to form powders into granules that can be easily pressed or filled into dosage forms. Over the years, advancements in this equipment have helped improve product quality, reduce waste, and speed up production. These benefits are expected to attract more investment from pharmaceutical manufacturers who aim to meet growing demand for medicines around the world.

Looking ahead, the future of the global pharmaceutical granulation equipment market will likely be shaped by ongoing innovations and the need for machines that are both flexible and efficient. Different types of equipment are being used to meet various manufacturing needs. Single Pot Granulators are favored for their ability to perform mixing, granulating, and drying in one machine, which saves space and time. High Sheer Granulators are popular for creating dense, uniform granules in a short amount of time, making them ideal for high-volume production. Oscillating Granulators offer gentle processing that helps preserve the quality of sensitive materials, which is important for certain medications. Other types of granulators also exist to support specialized needs in the industry, offering further choices for manufacturers.

The market will likely see even more growth as pharmaceutical companies search for solutions that align with trends in personalized medicine and smaller batch production. This shift is creating a demand for equipment that is easy to clean, quick to set up, and capable of handling a variety of formulations without cross-contamination. Equipment makers are expected to focus on developing machines with automated controls and real-time monitoring features. These advancements will help improve consistency, reduce human error, and lower production costs over time.

Regulatory requirements for medicine safety and quality will continue to push the global pharmaceutical granulation equipment market forward. Companies will need machines that can meet strict guidelines while also being energy efficient and sustainable. As environmental concerns become more important, equipment manufacturers may also focus on reducing energy use and waste during the production process.

In the years ahead, the global pharmaceutical granulation equipment market will likely become more competitive as both established players and new companies work to offer innovative solutions. This competition will drive improvements in performance, safety, and ease of use, all of which will benefit pharmaceutical companies and, ultimately, patients who rely on safe and effective medicines.

By Mechanism

The global pharmaceutical granulation equipment market will continue to see steady growth as the demand for advanced healthcare solutions rises. Granulation equipment is an essential part of pharmaceutical manufacturing, as it helps to create consistent and high-quality products. By mechanism, the market is divided into dry granulators, wet granulators, and mixture granulators. Each type serves a different purpose within the manufacturing process, ensuring that medications meet strict standards for safety and effectiveness. Dry granulators are typically used when moisture must be avoided during production, while wet granulators are suitable when liquid solutions are needed to bind powders together. Mixture granulators offer flexibility by combining elements of both dry and wet processes, making them highly useful for certain pharmaceutical applications.

In the future, the global pharmaceutical granulation equipment market will likely see technology playing a larger role. Manufacturers will aim to develop equipment that not only improves efficiency but also ensures precision in every step. Automation will continue to expand within this sector, helping companies reduce errors and maintain consistency in their production lines. The need for faster production without sacrificing quality will push businesses to seek out more reliable and advanced machines. Companies will look for granulators that offer data tracking and real-time monitoring, so adjustments can be made quickly when needed. This will help reduce waste and ensure that production processes remain both cost-effective and compliant with regulatory standards.

Pharmaceutical companies will also focus on sustainability. Equipment that uses less energy, reduces emissions, and creates minimal waste will be highly preferred. This shift will influence the choices companies make when upgrading or purchasing new equipment. Environmental factors are becoming just as important as performance when it comes to decision-making within this market. As more countries strengthen their regulations on manufacturing practices, businesses will need equipment that can meet these evolving requirements without creating unnecessary complications or delays.

In addition, the growing need for personalized medicine will lead to the development of more specialized granulation equipment. As treatments become more tailored to individual patients, the production processes must also adapt. Machines that allow for smaller batch sizes and more flexible formulations will become increasingly valuable. This trend will likely shape the global pharmaceutical granulation equipment market in the years ahead. The combination of technological advancements, environmental concerns, and the shift towards personalized healthcare will drive the demand for innovation within this space. Companies that invest in modern, adaptable, and efficient equipment will be better positioned to succeed in the future pharmaceutical landscape.

By End User

The global pharmaceutical granulation equipment market is expected to see noticeable changes in the future as the demand for advanced healthcare solutions continues to rise. Granulation equipment plays a key role in the pharmaceutical industry as it helps in producing uniform and high-quality granules that are necessary for making tablets and capsules. These products are widely used across the globe to meet the growing need for reliable and effective medicines. The way this market is divided by end users gives a clear picture of how different sectors contribute to its growth. Pharmaceutical manufacturing companies, contract manufacturing organizations, and other related users are all expected to shape the future of this market in significant ways.

Pharmaceutical manufacturing companies will likely continue to be the largest contributors to the demand for granulation equipment. These companies are always looking for better, faster, and more efficient ways to produce medicines on a large scale. They depend on this equipment to ensure consistency in their production processes, which helps maintain high standards of quality and safety. As regulations around the world become more strict, these companies will need to invest in newer technologies that can help them meet the latest guidelines while improving their productivity. This will create steady demand for innovative granulation solutions.

Contract manufacturing organizations will also play a growing role in the global pharmaceutical granulation equipment market. These companies provide services to larger pharmaceutical brands by producing medicines on their behalf. As outsourcing continues to increase within the pharmaceutical industry, contract manufacturers will look for modern and flexible granulation equipment to meet the different requirements of their clients. Their need for equipment that supports smaller production runs, faster changeovers, and easy cleaning will push manufacturers of this machinery to develop more user-friendly and versatile models.

Other end users, which may include academic institutions, research centers, and smaller biotech firms, will add to the demand as well. These groups often require granulation equipment for research purposes or small-batch production. As the search for new treatments and therapies expands, these organizations will need reliable equipment to help them turn their ideas into real products.

Looking ahead, the global pharmaceutical granulation equipment market will likely become more focused on automation, digital monitoring, and energy-efficient technologies. Companies involved in this field will work to meet the expectations of different users while keeping up with advancements in technology. This ongoing progress will shape the market’s direction in the years to come.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$5124.3 million |

|

Market Size by 2032 |

$7828.2 Million |

|

Growth Rate from 2025 to 2032 |

6.1% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

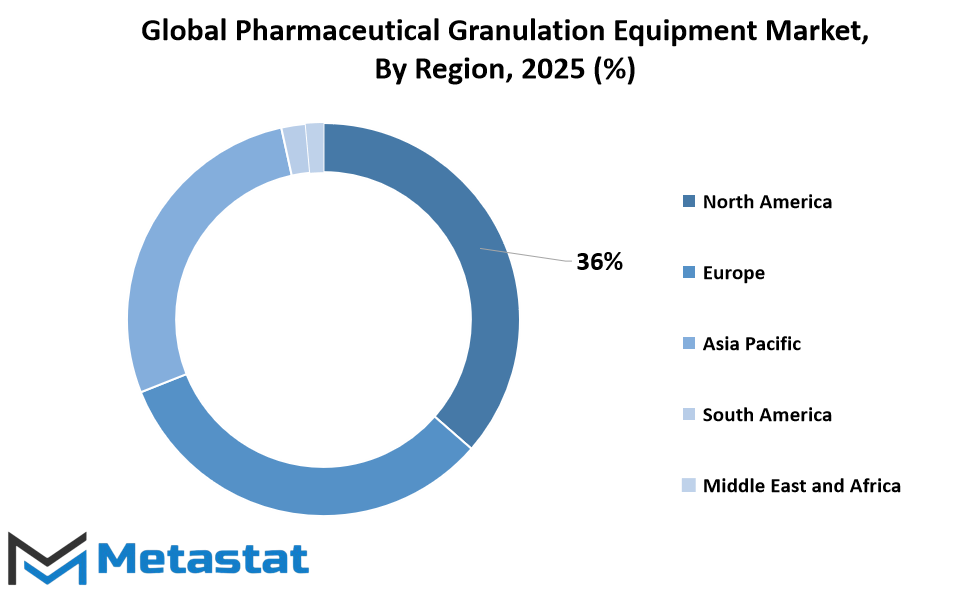

The global pharmaceutical granulation equipment market is expected to continue evolving over the coming years due to advancements in technology and the increasing demand for better healthcare solutions worldwide. This market is influenced by various geographical regions, each contributing to its growth in different ways. North America, which includes the U.S., Canada, and Mexico, has long been recognized as a leader in the pharmaceutical industry. With well-established healthcare systems and significant investments in research and development, this region is likely to maintain a strong position in the global pharmaceutical granulation equipment market. The presence of top pharmaceutical companies and a focus on innovation will continue to drive demand for advanced granulation equipment in this area.

Europe also plays a vital role in this market. Countries like the UK, Germany, France, and Italy have a strong pharmaceutical foundation and place importance on the development of high-quality medical products. Governments in these countries often support pharmaceutical advancements, which encourages companies to adopt more efficient manufacturing equipment. This positive attitude towards technological upgrades will likely help Europe remain a key player in the global pharmaceutical granulation equipment market.

Moving to Asia-Pacific, this region is expected to witness the fastest growth. Countries such as India, China, Japan, and South Korea are investing heavily in their healthcare sectors. The growing population and increasing demand for affordable medicines will encourage companies in this region to focus on improving their production processes. As these nations work towards becoming major exporters of pharmaceutical products, the need for reliable and efficient granulation equipment will rise. This growth is not just limited to the larger countries; other parts of Asia-Pacific are also beginning to strengthen their positions in this market.

South America, including Brazil and Argentina, is gradually increasing its contribution to the pharmaceutical industry. Though the pace of growth is slower compared to other regions, the demand for better healthcare infrastructure and the desire to modernize manufacturing processes will support the growth of the global pharmaceutical granulation equipment market here as well. Lastly, the Middle East & Africa, with countries such as those in the GCC, Egypt, and South Africa, are also showing signs of growth. As these regions invest more in healthcare advancements and seek to become more competitive globally, the demand for such equipment is expected to grow steadily. Looking ahead, it is clear that technological improvements and increasing healthcare needs will shape the future of this market across all regions.

COMPETITIVE PLAYERS

The global pharmaceutical granulation equipment market is expected to grow steadily in the future as the demand for advanced healthcare solutions continues to increase. This growth will mainly be driven by the rising focus on improving the quality of medicines and the growing need for efficient production processes. Granulation equipment plays an important role in the pharmaceutical industry because it helps ensure that the final products are of consistent quality. Tablets and capsules, which are the most common forms of medicines, require uniform granules to guarantee accurate dosage. This makes granulation equipment essential for companies that want to meet strict regulations while also maintaining high production standards.

Looking ahead, the global pharmaceutical granulation equipment market will likely see further advancements in technology. Automation and digital control systems will become more common, allowing manufacturers to achieve greater precision and efficiency in their production lines. These advancements will not only reduce human error but also save time and costs for pharmaceutical companies. The focus on sustainability will also influence the design of future equipment, as businesses seek machines that reduce waste and energy consumption.

Several key players are shaping this market and will continue to influence its direction. Companies such as GEA Group, Glatt GmbH, Hosokawa Micron Powder Systems, IMA Group, Kevin Process Technologies, Freund-Vector Corporation, and DIOSNA Dierks & Söhne GmbH are recognized for their contributions to innovation in this field. Others like Romaco Group, Syntegon Technology GmbH, LB Bohle Machines and Processes GmbH, and ACG Group are also highly regarded for offering reliable and advanced solutions. In addition, Fitzpatrick Company, Quadro Engineering, Alexanderwerk AG, O'Hara Technologies Inc., Prochem Tapasya, SaintyCo, Hanningfield Process Systems, Gerteis Maschinen + Processengineering AG, and Frewitt Fabrique de Machines SA play vital roles in providing equipment that meets the changing demands of the pharmaceutical industry.

The future of the global pharmaceutical granulation equipment market will likely involve closer collaboration between equipment manufacturers and pharmaceutical companies. This partnership will help ensure that the machines continue to meet the specific needs of drug producers, especially as new types of medicines are developed. Innovations will focus on making the granulation process even more reliable and adaptable to different production scales. As patient needs and healthcare systems evolve, this market will keep progressing to support the creation of safe and effective medicines that people can trust.

Pharmaceutical Granulation Equipment Market Key Segments:

By Type

- Single Pot Granulators

- High Sheer Granulators

- Oscillating Granulators

- Others

By Mechanism

- Dry Granulators

- Wet Granulators

- Mixture Granulators

By End User

- Pharmaceutical Manufacturing Companies

- Contract Manufacturing

- Others

Key Global Pharmaceutical Granulation Equipment Industry Players

- GEA Group

- Glatt GmbH

- Hosokawa Micron Powder Systems

- IMA Group

- Kevin Process Technologies

- Freund-Vector Corporation

- DIOSNA Dierks & Söhne GmbH

- Romaco Group

- Syntegon Technology GmbH

- LB Bohle Machines and Processes GmbH

- ACG Group

- Fitzpatrick Company

- Quadro Engineering

- Alexanderwerk AG

- O'Hara Technologies Inc.

- Prochem Tapasya

- SaintyCo

- Hanningfield Process Systems

- Gerteis Maschinen + Processengineering AG

- Frewitt Fabrique de Machines SA

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252