MARKET OVERVIEW

The global sheet metal market is at a turning point where conventional techniques of fabrication will more and more deliver manner to better-grade, pc-integrated manufacturing strategies. This market, intimately connected with the development, car, aerospace, strength, and client items industries, is about to go through modifications on the way to extend much in addition than its current uses. The 2nd wave of transformation will be driven not most effective by using innovation in manufacturing tactics, however also by transferring call for styles, sustainability standards, and geopolitical forces to be able to compel agencies to reconsider their sourcing, logistics, and tech adoption techniques.

Over the subsequent several years, the sheet steel industry will transcend being a reactive issuer of easy elements. It will reshape its position to become a strategic contributor to lightweight engineering, modular design systems, and structural efficiency across diverse sectors. While automation and laser technologies have already made a mark, what's ahead is a deeper integration of data intelligence and simulation-driven fabrication. The global sheet metal market will pay no attention to output volume alone but will begin prioritizing consistency of performance, traceability, and minimizing waste at each node of production.

Green regulations will keep constricting globally, and it will be unavoidable for businesses to re-examine their operations. Utilization of recycled and high-strength alloys will become more common, not only as a regulatory requirement, but as a fundamental business necessity. Circular economy models will drive this market toward materials that can be easily reshaped, repurposed, and reused. Manufacturers will need to redefine their roles now not as raw stock converters but as solution providers who facilitate end-users achieving technical as well as environmental objectives.

The other direction in which the global sheet metal market will change is toward smart customization. Rather than mass-producing standardized outputs, suppliers in the future will respond to batch-oriented designs, particularly in building design, industrial equipment, and transportation. This will require a digital supply chain platform where information exchange among stakeholders will be in real-time supported by cloud-based design and procurement systems. Agility in responding to fast design iterations will be a compelling differentiator, prompting companies to invest in 3D forming, virtual testing, and materials science development.

Infrastructure growth in emerging economies will reclassify the competitive landscape. Players with access to low-cost energy and labor at home will become valid challengers. To stay feasible, worldwide companies will appearance to hybrid working models that enable localization without compromising key technological standards. Cross-border partnerships and joint ventures turns into increasingly more famous as companies look to share resources, hazard, and reach.

Beyond traditional economic imperatives, the future of the global sheet metal market will rely upon design innovation, digitalization, and environmental durability. Its stakeholders will have to think in terms of systems thinking, where material behavior, user requirements, and planetary limitations are viewed together. Those who succeed in incorporating these factors in their value chains will create the new image of an industry that was otherwise viewed as purely mechanical.

This forward-thinking change won't simply improve operational excellence it will ultimately redefine the identity of the global sheet metal market within the larger industrial context.

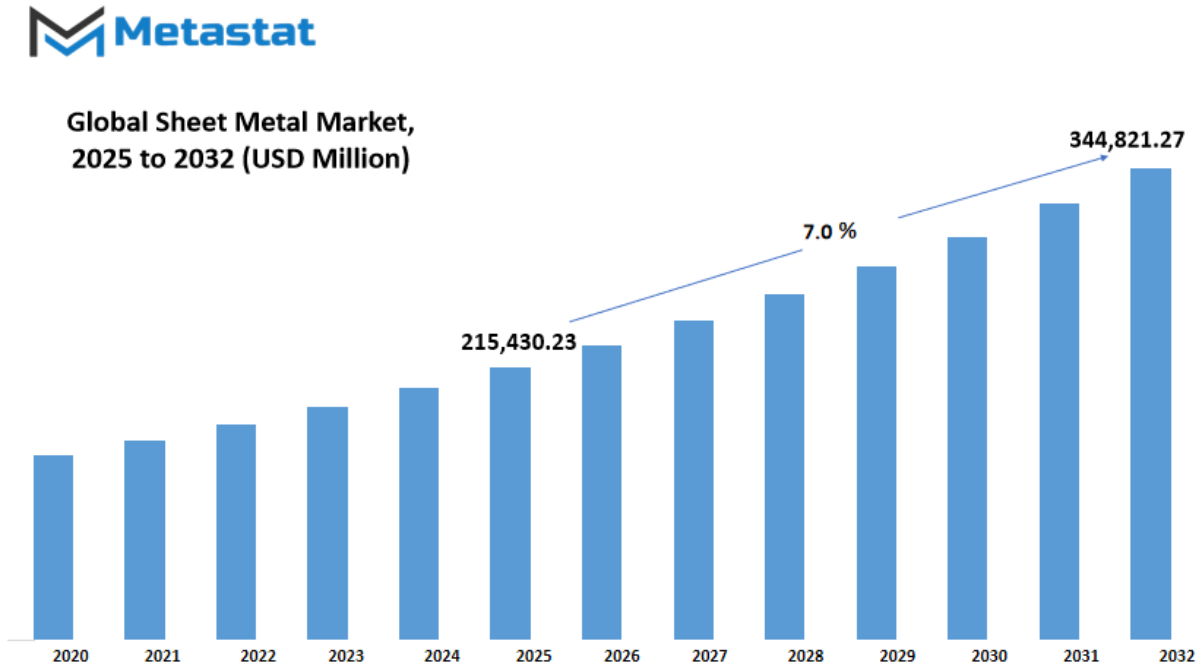

Global sheet metal market is estimated to reach $344,821.27 Million by 2032; growing at a CAGR of 7.0% from 2025 to 2032.

GROWTH FACTORS

The global sheet metal market is going to keep expanding due to the fact industries including automobile and construction need greater durable, lighter, and extra flexible materials. These industries rely on sheet steel because of its sturdiness, flexibility, and simplicity of shaping into complex bureaucracy. Due to the international call for infrastructural development and housing tasks, creation firms are going to use greater sheet metal for something from roofing and ducting to structural support. At the same time inside the automobile zone, the power toward lighter automobiles to decorate gas financial system will preserve to demand sheet metal. All those elements will have a full-size have an impact on on the market's route inside the destiny.

Technology is every other critical force pushing the market forward. As greater producers shift toward automation and precision-based production, superior fabrication technologies which include laser cutting, 3d printing, and CNC machines are being adopted on a broader scale. These strategies permit agencies to supply sheet metal elements quicker and with better accuracy, lowering waste and enhancing layout capabilities. This shift now not most effective improves efficiency but also helps innovation in product design and custom manufacturing.

Nevertheless, there are constraints that might stop the marketplace from progressing. One of the biggest demanding situations lies within the volatility of raw cloth fees, in particular the ones of metals along with aluminum and metal. Such unpredictability complicates it for corporations to estimate the price of production and feature strong pricing for his or her customers. The other limitation lies in the initial high installation expense of automated equipment. Though automation ultimately lowers labor costs and raises production, the capital cost is high and can deter small firms from entering or expanding in the industry.

In spite of all these challenges, new markets are being created. As nations spend more in renewable energy sources, particularly solar and wind power, demand for sheet metal in structures such as frames, mounts, and enclosures will be on the rise. Renewable energy projects tend to need bespoke pieces produced from sheet metal, and this move to cleaner energy will result in constant growth for manufacturers. Parallel to this, the aerospace and defense industries are growing, with sheet metal gambling a key role in constructing aircraft structure, satellite additives, and defense gear. These markets necessitate fabric this is both lightweight and durable, that is ideally fitted to what sheet metal has to offer.

Over the approaching years, the global sheet metal market will stabilize thru an increase in demand and responding to production desires. Businesses that spend money on shrewd era, have adaptable pricing techniques, and tap into expanding sectors along with renewable strength and protection might be high-quality placed to prosper. As the sector constructs extra, travels quicker, and innovates greater, sheet steel might be a foundational cloth underpinning that advancement.

MARKET SEGMENTATION

By Material Type

The global sheet metal market is gaining traction steadily as industries are looking for out robust and versatile materials to cater to production and construction necessities. Sheet metallic, with its strength and ductility, is rising as a middle fabric in sectors like car, construction, aerospace, and machinery. With demand escalating for light-weight yet strong materials, the sheet metallic market will maintain growing, in particular in markets that price high overall performance and lengthy-time period price.

Among the materials present in the global sheet metal market, metallic is a leading one, overlaying a large proportion really worth $145,286.68 million. The splendor of metallic lies inside the fact that it's miles low priced, strong, and flexible in structural as well as in ornamental use. Used either in the layout of tall homes or inside the frame of a car, metallic is a feasible desire. In turn, aluminum is likewise gaining popularity as an alternative, in particular in sectors where weight financial savings are paramount, like transportation and electronics. Corrosion resistance and recyclability similarly decorate its merit, rendering it a favorite for cutting-edge production needs.

Other metals along with copper, titanium, and area of expertise alloys also play a position inside the sheet metal enterprise, albeit a smaller one. They are chosen for certain applications wherein not unusual metals will struggle. For example, below excessive temperatures or in applications calling for superior thermal or electric conductivity, manufacturers are looking to these types for advanced overall performance. As technology continues to evolve and product demands alternate, the demand for numerous materials will no longer slow.

The future of the global sheet metal market may be motivated via automation, sustainability, and new techniques of fabrication. As growing attention is on the green use of strength and reduction of waste, businesses are adopting strategies with maximum usage of cloth and least amount of scrap. Meanwhile, laptop-aided production and unique reducing are making the shaping and assembling of sheet metallic better via extended output nice and decreased labor.

Short and easy, the global sheet metal market is on a high-quality trajectory, with metal taking the lead. Aluminum and other substances will even attract note as industries alternate and are looking for out options that offer strength and performance. With its ubiquitous use and ability to adapt with moving demands, sheet metallic will continue to be a critical issue of worldwide commercial improvement in destiny.

By Process

The global sheet metal market continues to be formed by means of the rising demand for long lasting, lightweight, and without problems customizable substances across multiple industries. Sheet metallic has long played a key role in construction, automobile, machinery, and electronics, and as industries aim for better efficiency and price-effectiveness, this fabric stays significant to many production techniques. Governments and private gamers are making an investment in infrastructure improvement and business improvements, similarly boosting the use of sheet metallic in both structural and purposeful packages. Its capability to be reshaped without dropping strength makes it a desired cloth in high-precision production.

When searching at the process kind, the global sheet metal market is segmented into rolling, bending, and forging. Rolling is the maximum normally used method due to its potential to produce massive volumes with constant thickness. It's specially useful in making parts for transportation and construction. Bending is extensively followed for growing complicated shapes with out cutting or welding, regularly used within the production of shelves, doors, and brackets. Forging, on the other hand, is desired in excessive-power programs which includes aerospace elements and automotive additives. Each method serves particular wishes, and the choice relies upon on the very last product’s purpose, required power, and design flexibility.

Technological upgrades have streamlined these processes, bearing in mind extra precision and efficiency. For example, CNC machines and automation equipment have more desirable bending and rolling accuracy, decreasing waste and increasing output. These adjustments no longer simplest make production quicker but additionally decrease the overall price of manufacturing. As industries keep to upgrade their manufacturing systems, the want for faster turnaround instances and tighter tolerances will push businesses to refine their sheet metallic processing techniques even in addition.

Environmental issues are also influencing market tendencies. Manufacturers are that specialize in lowering power use and cutting emissions in the course of the manufacturing and shaping of sheet steel. Recyclability is every other strong element contributing to sheet metal’s popularity, specially in international locations pushing for greener solutions. The capability to reuse and repurpose metallic without sizeable excellent loss permits organizations to guide sustainability desires at the same time as nevertheless assembly performance requirements.

By End-use

The global sheet metal market has grown into a essential part of industrial development, helping a variety of manufacturing and infrastructure needs. Sheet metal, acknowledged for its electricity and formability, continues to be a popular choice across industries for producing the entirety from structural additives to consumer goods. Its wide usage is tied closely to construction and manufacturing pastime, making it a key indicator of economic energy in lots of regions. As industries modernize and the demand for durable, light-weight, and fee-powerful materials will increase, sheet metallic’s position stays principal to improvement across each conventional and emerging sectors.

One of the main customers of sheet metallic is the constructing and production enterprise. From roofing and cladding to ductwork and framing, this region depends closely on metallic sheets for structural integrity and design flexibility. As urbanization keeps and governments invest in infrastructure upgrades, the call for for sheet metal in production initiatives will maintain rising. Countries focusing on clever towns and inexperienced homes are probably to power further increase, as metallic is not simplest recyclable however also well-desirable to modern architectural traits that favor smooth, long lasting materials.

The automotive and transportation enterprise is another predominant quit-consumer, relying on sheet metallic for both structural and beauty additives of cars. As automakers shift toward lighter cars to improve gasoline performance and decrease emissions, materials like aluminum and superior metallic sheets are seeing a upward thrust in utilization. The electric powered automobile movement is including to this momentum, with manufacturers the use of sheet metal to design safer and lighter battery enclosures and frames. This transition is anticipated to keep the call for robust, especially as greater nations push for greener transportation alternatives.

Machinery and gadget producers additionally make a contribution appreciably to the marketplace. Sheet metal is widely utilized in making components for business machines, agricultural tools, and energy gadget. The call for in this zone will likely grow as automation spreads throughout industries, and organizations invest in green manufacturing structures. Durable and clean-to-fabricate, sheet steel allows manufacturers balance overall performance with production cost an crucial component in global markets.

Other give up-uses encompass household home equipment, fixtures, and packaging, every of which provides to the developing want for sheet metal in every day life. As way of life choices shift in the direction of modern, minimalist designs, the smooth finish and sturdiness of steel make it an appealing preference. Overall, with constant demand from both big-scale infrastructure and everyday merchandise, the worldwide sheet metallic marketplace will remain a important part of industrial deliver chains and purchaser manufacturing for future years.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$215,430.23 million |

|

Market Size by 2032 |

$344,821.27 Million |

|

Growth Rate from 2025 to 2032 |

7.0% |

|

Base Year |

2024 |

|

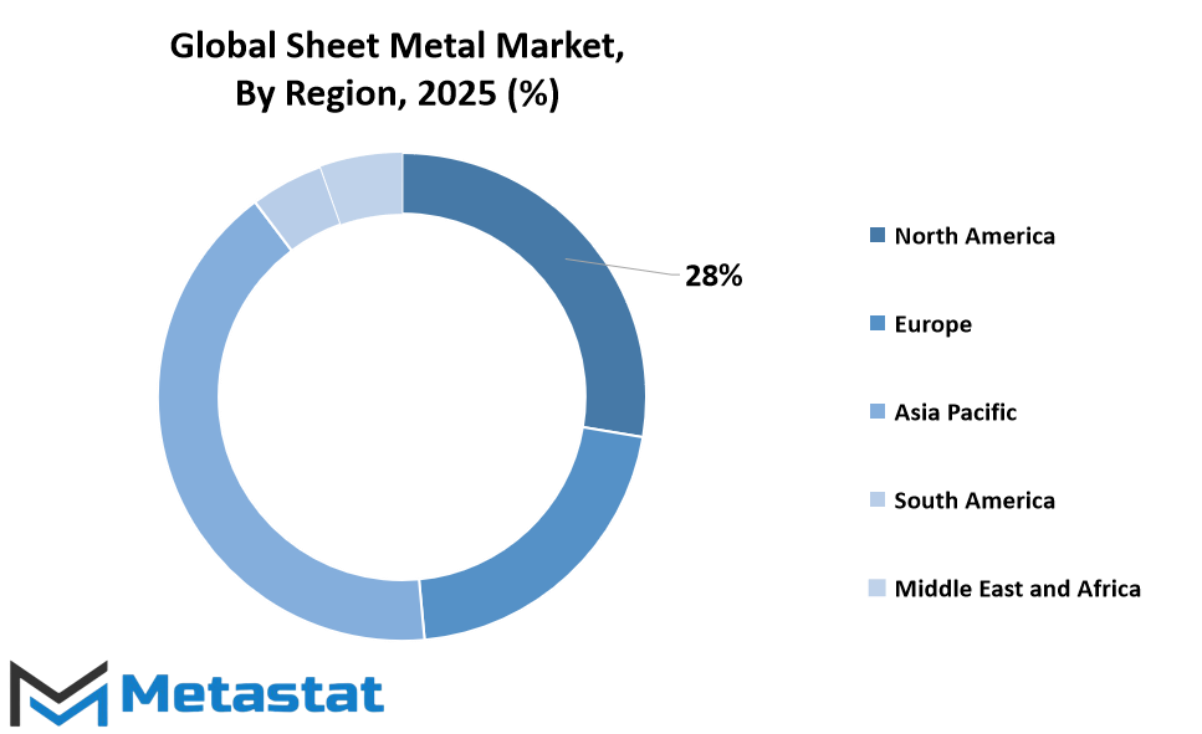

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global sheet metal market has seen significant increase in current years, with geographical regions gambling a key position in shaping its direction. Each area contributes in a exceptional manner, based totally on industrial demand, infrastructure improvement, and technological development. North America holds a sturdy presence, led by means of america, with Canada and Mexico following carefully. The location’s call for is driven by means of the construction, automobile, and aerospace industries, all of which rely closely on sheet metallic for structural and design functions. With strict satisfactory requirements and growing call for for excessive-performance substances, manufacturers across the U.S. Keep to invest in advanced production techniques.

Europe additionally performs a main element in the global sheet metal market, particularly in nations like Germany, the United Kingdom, France, and Italy. These countries have a protracted records of commercial production, and the want for lightweight, long lasting materials in car and equipment production fuels steady call for. Germany, mainly, stands proud because of its strong engineering and automobile sectors. While Western European countries dominate in output and intake, the Rest of Europe is slowly catching up, aided by using favorable exchange policies and funding in regional manufacturing devices. The emphasis on sustainability and recycling in Europe additionally encourages improvements in sheet steel processing and reuse.

Asia-Pacific is emerging because the fastest-developing phase in the worldwide marketplace. Countries like China, India, Japan, and South Korea have unexpectedly increasing industrial bases. China's dominance in manufacturing and creation results in massive-scale intake of sheet metal, while India is witnessing growing demand due to city increase and infrastructure initiatives. Japan and South Korea contribute thru advanced manufacturing techniques and high-tech applications, particularly in electronics and automotive industries. The Rest of Asia-Pacific additionally holds promise, with international locations making an investment in local industries and steadily growing their presence on the global map.

In South America, the sheet metal market is basically centered around Brazil and Argentina. These nations are seeing improvements of their business sectors, which include car production, creation, and agriculture system production. Although the increase price is slower in comparison to Asia, the vicinity indicates consistent improvement, in particular in urban infrastructure. Brazil leads the marketplace, taking advantage of developing investments and policy help aimed at boosting domestic manufacturing and exports.

The Middle East & Africa region suggests blended progress. GCC international locations, specifically the UAE and Saudi Arabia, have ongoing construction and development initiatives that require a consistent supply of sheet metal. Egypt and South Africa are also witnessing increase via infrastructure investments and mining gadget production.

COMPETITIVE PLAYERS

The global sheet metal market will preserve to shape crucial industries like creation, automobile, aerospace, and manufacturing. Sheet metallic, recognized for its electricity, flexibility, and sturdiness, performs a significant role in growing the whole thing from buildings and automobiles to electronic devices. Its enormous use may be traced to the call for for substances that provide both form and feature. As extra industries shift towards light-weight, recyclable, and power-green materials, sheet metal is gaining attention for its adaptability and performance under diverse situations.

With new technologies rising, automation and advanced forming techniques are streamlining the production of sheet metal. Manufacturers are specializing in pace, precision, and reduced waste assembly rising expectations for pleasant at the same time as additionally dealing with price performance. The use of robotics, AI-assisted fabrication, and laser-reducing structures is changing how groups produce and bring together metallic components. This shift isn't always simplest about output, but also approximately protection and sustainability. Smarter manufacturing lines reduce errors and cloth waste, aligning with worldwide efforts to decrease environmental effect.

At the identical time, the call for for sheet metal in inexperienced construction and electric automobile manufacturing is accelerating. Lightweight yet long lasting substances are critical in achieving better electricity performance and overall performance. Sheet metallic suits perfectly into those wishes, presenting structural assist without adding useless weight. In regions pushing for stricter emissions standards, specially in Europe and Asia, its function will handiest grow extra crucial. From public infrastructure to commercial machinery, the material supports innovation with out compromising strength.

Major players are riding this momentum via making an investment in research, capacity growth, and deliver chain enhancements. Companies like ArcelorMittal, Nippon Steel Corporation, POSCO, Hulamin Limited, and JFE Steel Corporation are enhancing their international footprint through joint ventures, acquisitions, and superior manufacturing skills. Indian corporations consisting of Tata Steel and JSW Steel also are stepping up with a stronger presence in each domestic and international markets. Other key contributors include Thyssenkrupp AG, United States Steel Corporation, Hyundai Steel, Voestalpine AG, AK Steel Holding Corporation, Outokumpu Oyj, China Steel Corporation, Shanghai Ninesteel Materials Group Co., Ltd., and Khodal Industrial Engineering Company. Their strategies replicate a sturdy recognition on reliability, first-class, and innovation.

As the sector continues to demand green and adaptable solutions, the global sheet metal market will continue to be an important part of international development. From clever manufacturing to sustainable creation, its contribution spans throughout industries and geographies. The coming years will see organizations competing no longer simply on volume, but on how efficaciously they can innovate and supply substances that meet both business and environmental requirements.

Sheet Metal Market Key Segments:

By Material Type

- Steel

- Aluminum

- Others

By Process

- Rolling

- Bending

- Forging

By End-use

- Building & Construction

- Automotive & Transportation

- Machinery & Equipment

- Others

Key Global Sheet Metal Industry Players

- ArcelorMittal

- Nippon Steel Corporation

- POSCO

- Hulamin Limited

- JFE Steel Corporation

- Tata Steel

- Thyssenkrupp AG

- United States Steel Corporation

- Hyundai Steel

- Voestalpine AG

- JSW Steel

- AK Steel Holding Corporation

- Outokumpu Oyj

- China Steel Corporation

- Shanghai Ninesteel Materials Group Co., Ltd.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383