MARKET OVERVIEW

The global rotary vane vacuum pumps market will remain a staple segment of the industrial machinery and equipment market, supplying a broad range of operational requirements across various industries. The pumps, with their consistent performance and space-conserving design, are utilized to produce partial vacuums in procedures where atmospheric air must be evacuated. As factory environments change and precision demands increase, rotary vane vacuum pumps will continue to be central to maintaining performance in packaging, pharmaceutical processing, and chemical usage, among others. Though frequently confused as merely another component of larger vacuum technology, the global rotary vane vacuum pumps market is an independent entity.

It's not merely a support function but a primary system enabler within industries that require controlled environments. What sets the market apart is the place its products serve in high- and low-capacity operations. Such pumps are typically selected for their working longevity, silent operation, and low maintenance cost, and they fit just as well in small-scale operations as heavy-industry settings. The Future of the global rotary vane vacuum pumps market will not confine itself to conventional uses. It will begin gaining relevance in newer industries where vacuum technology was previously deemed obsolete.

For example, with advancements in laboratory science and small-scale electronic production, the use of rotary vane vacuum pumps will move beyond heavy industry, extending to more sensitive use cases. The pumps will not only stay in the background; they will become essential pieces of machinery for guaranteeing stability and accuracy in contemporary production processes. The importance of this market is not just in machinery production but in the balance it will maintain throughout processes dependent on a consistent vacuum. Where any fluctuation of pressure might change results like with medical devices being coated or specialized materials being made these pumps will still deliver a foundation that is required. Their design, which is not always intricate but sound, provides them with a special advantage over advanced technologies requiring greater maintenance or operational supervision.

It would, however, be an oversimplification to confine the global rotary vane vacuum pumps market to its existing presence. As automation and tailor-made manufacturing procedures come into increasing use, the need for flexible vacuum systems will increase. Rotary vane styles, with their ability to be customized, will satisfy these demands better than the more inflexible options. Even in smart manufacturing environments, they will have a niche, usually coupled with sensors and data monitoring systems to provide smooth functioning.

It would be premature to suggest that this market is no more than an add-on to other industrial functions. It possesses operational significance that will increase as industries trend towards greater reliability and energy-efficient applications. Though the underlying mechanics of these pumps will not radically change, their contexts of application certainly will. As industry lines blur, the global rotary vane vacuum pumps market will assist in underpinning the infrastructure behind innumerable unseen yet critical processes that define the products consumed daily worldwide.

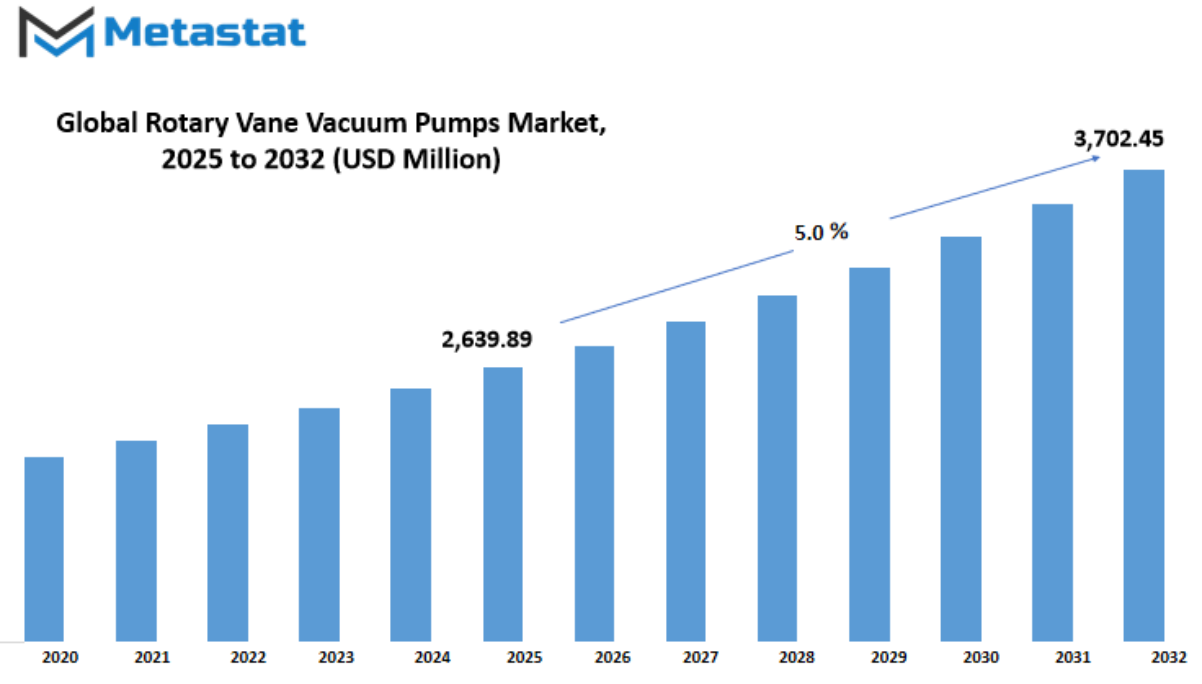

Global rotary vane vacuum pumps market is estimated to reach $3,702.45 Million by 2032; growing at a CAGR of 5.0% from 2025 to 2032.

GROWTH FACTORS

The global rotary vane vacuum pumps market will experience robust growth in the coming years, driven by various prevailing technological and industrial trends. With industries expanding and becoming more advanced, there will be increased demand for efficient and trustworthy vacuum systems. The simplicity and stable performance of rotary vane vacuum pumps will ensure their increasing popularity due to their extensive application in numerous sectors. From production and packaging to medicine and laboratories, their capacity to offer a constant vacuum level makes them a popular pick.

A key driver of growth is the growth in industries such as semiconductors, electronics, and pharmaceuticals. These industries need high-pressure control and contamination-free conditions. Rotary vane vacuum pumps, with their affordability and reliability, fit the bill well. As the demand for high-performance components grows, so too will the need for sophisticated vacuum systems. This in turn is likely to prompt businesses to make investments in machinery that is both cost-effective and efficient, rendering rotary vane vacuum pumps an essential solution.

Apart from industrial development, there will also be a push for energy efficiency driving the market. Industries are developing pumps that consume less power yet provide good performance. This attention to energy-saving technology will create new avenues for innovation. Companies will look to machines that help them achieve their objective of reducing energy expenditures while maintaining productivity. This will lead to further investments in new pump models, particularly those that present good durability and minimal maintenance.

Another field which will have an impact on market growth is automation. With more industries going the way of automated systems, demand for vacuum pumps that can be easily integrated into these arrangements will rise. Rotary vane pumps, due to their rugged build and smooth running, are traditionally the preferred choice for such applications. With better versions that integrate well with smart controls and monitoring devices, these will be more popular in the future. Companies will want pumps that can work with minimal oversight, helping them improve productivity and reduce downtime.

Global trade flows and supply chains also contribute to the development of the global rotary vane vacuum pumps market. With companies seeking expansion across borders, having equipment that is suitable for global standards is a must. Manufacturers that provide products compliant with multiple regulations will benefit. In the future, continuous innovations in technology, increasing environmental awareness, and the continuous demand for improved output will all contribute to the path of this market.

MARKET SEGMENTATION

By Type

The global rotary vane vacuum pumps market will go on to expand consistently in the following years as a result of advanced technology, changing industrial needs, and a shift towards energy-efficient products. Rotary vane vacuum pumps, which find use in a wide range of industries including manufacturing, electronics, and packaging, are finding increased significance as these sectors move towards modernization. These pumps have a simple design, stable operation, and are cost-effective, hence being the preferred choice in most applications. With vacuum-based processes in greater demand, this market will keep developing steadily. Among the categories, single-stage rotary vane vacuum pumps are famous for reliability and being used in applications requiring moderate vacuum pressure.

They are more likely to be used in processes where the demand for vacuum is consistent but not very high. Two-stage rotary vane vacuum pumps, on the other hand, aim at getting a lower level of vacuum and are usually opted for in more demanding processes. They are particularly suited for those processes with a greater vacuum requirement like in scientific research or advanced manufacturing settings. Both versions will be useful, but the decision will depend on the specific requirements of the user.

In the future, the global rotary vane vacuum pumps market will move towards the more energy-efficient, eco-friendly models. Companies nowadays focus on reducing energy and having smaller carbon footprints. Technological developments will be central to this shift. This will force manufacturers to create pumps with higher performance and less power consumption. Automation and smart technologies will also drive the future of this sector. Pumps that have the ability to auto-tune their performance based on the system demand will gain more popularity. Such smart pumps will reduce maintenance needs and smoothen operations, saving time and cost for companies. In addition, the market will also be driven by the external world's clean energy industries' growth, stricter environmental policies, and on-going industrial system innovation. With the rise in industries and the upgradation of old machinery with new machinery, demand for stable vacuum systems will be on the rise.

The global rotary vane vacuum pumps market, with its balance between performance and affordability, is poised to contribute significantly to this transition. With the advancement of technologies and change in industries, these pumps will continue providing solutions to meet both existing and emerging needs.

By Lubrication Type

The global rotary vane vacuum pumps market will witness considerable transformation over the next few years, especially if one considers the types of lubrication like oil-sealed and dry (oil-free) types. Such pumps have been a fundamental part of the many different industries in the past, and their use can be expected to expand as newer technologies and production needs affect choice and utilization of vacuum systems.

Oil-sealed rotary vane vacuum pumps are specifically known for efficient execution of demanding tasks. They are configured to offer rugged, reliable performance and are widely used in the automotive, packaging, and manufacturing sectors. As industrial automation intensifies and there is a need for efficient vacuum systems, these pumps will continue to be in demand where performance outweighs maintenance issues and oil consumption. Though they have to be serviced every now and then for oil change and have environmental concerns, their long lifespan and heavy capacity make them a good choice for bulk applications. Or, dry or oil-free rotary vane pumps are gaining attention due to their hygiene.

The dry or oil-free pumps have no oil in them, which means less opportunity for contamination and less maintenance. They are the right fit in environments like laboratories, health facilities, or electronic manufacturing, where cleanliness is important. As industries start gearing up towards sustainability and cleaner technology, the demand for dry vacuum pumps will further increase steadily. Although they cannot be compared with oil-sealed pumps in some high-demanding applications, they are catching up fast with the evolution of design and materials. In the years to come, the market for Global Rotary Vane Vacuum Pumps will be driven by a combination of greater environmental control, growing industrial application, and a clean trend towards cleaner, more efficient solutions. Industry players will spend money on pumps that are both high-performance and low-environmental-impact. This would make oil-sealed pumps ever more efficient and clean, while dry pumps would be ever more powerful and versatile. Technological innovation will also be in the form of smart vacuum pumps that use sensors and automation to optimize energy use and reduce downtime.

Both types of pumps will be impacted by this transition, giving users better control and savings in the long term. As businesses become more aware of their environmental footprint and energy usage, the choice among oil-sealed and dry pumps will be based not solely on performance, but on sustainability and long-term value. The global rotary vane vacuum pumps market is not just growing it is headed in the direction of a smarter, cleaner, and more efficient future where both types of pumps will have a certain place depending on what is required for the task at hand.

By Application

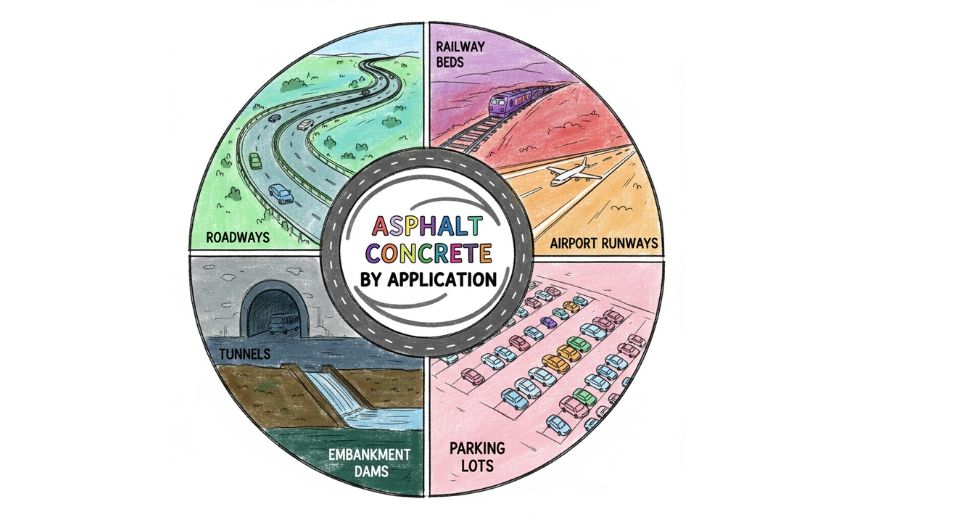

The global rotary vane vacuum pumps market is likely to grow steadily with technology and industrial requirements constantly evolving. The pumps already have widespread use in a number of industries, such as the electronic and semiconductor industry, chemical facilities, laboratories, food processing, and machinery. Since they can eliminate air and gas from an isolated environment, they are applied in environments where a clean and controlled environment is needed. With more and more industries opting for automation and accuracy, these pumps will presumably become increasingly valuable in day-to-day activities.

In the electronics and semiconductor industry, precision and contamination control are crucial. With devices getting smaller and more powerful, the demand for stable and clean environments will only increase. Rotary vane vacuum pumps are a significant contributor to this, and their importance will only become more prominent as demand for sophisticated electronics increases. In the years to come, smart manufacturing will increasingly depend on such systems to ensure stable conditions.

Chemical companies also rely on vacuum systems for safe and precise processing. As newer technologies for producing and working with chemicals become available, these pumps will be required to have higher safety and performance requirements. Because the chemical industry is directly connected to environmental and health laws, having reliable equipment is not only beneficial, it is crucial. The future will likely also introduce cleaner and more energy-efficient designs that more closely align with world sustainability initiatives.

Laboratory work is also an area where accuracy and consistency are important. From medical studies to material analysis, vacuum pumps enable scientists to conduct work under precise conditions. As research techniques become more sophisticated, the need for equipment that can adapt will grow. Rotary vane vacuum pumps will probably be upgraded with improved control systems and intelligent monitoring capabilities to be able to keep up with this trend.

Vacuum systems assist in packaging, freshness preservation, and quality in the food industry. With changing expectations from the customer and increasingly tighter food safety regulations, these pumps must be more efficient with less energy consumption. In the future, there could be more efficient and smaller models suitable for various food production settings.

The vacuum system will also continue to be the equipment used by the machinery industry for functions such as drying, forming, and coating. As machines become more intelligent and versatile, the pumps serving them have to move in line with their development. This can create opportunities for pumps that will automatically adjust according to varying tasks or employ sensors in order to increase precision and minimize waste.

The global rotary vane vacuum pumps market will remain robust across various industries. As every industry progresses, the requirement for intelligent, efficient, and reliable solutions will continue to fuel innovations in new pump technologies.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$2,639.89 million |

|

Market Size by 2032 |

$3,702.45 Million |

|

Growth Rate from 2025 to 2032 |

5.0% |

|

Base Year |

2024 |

|

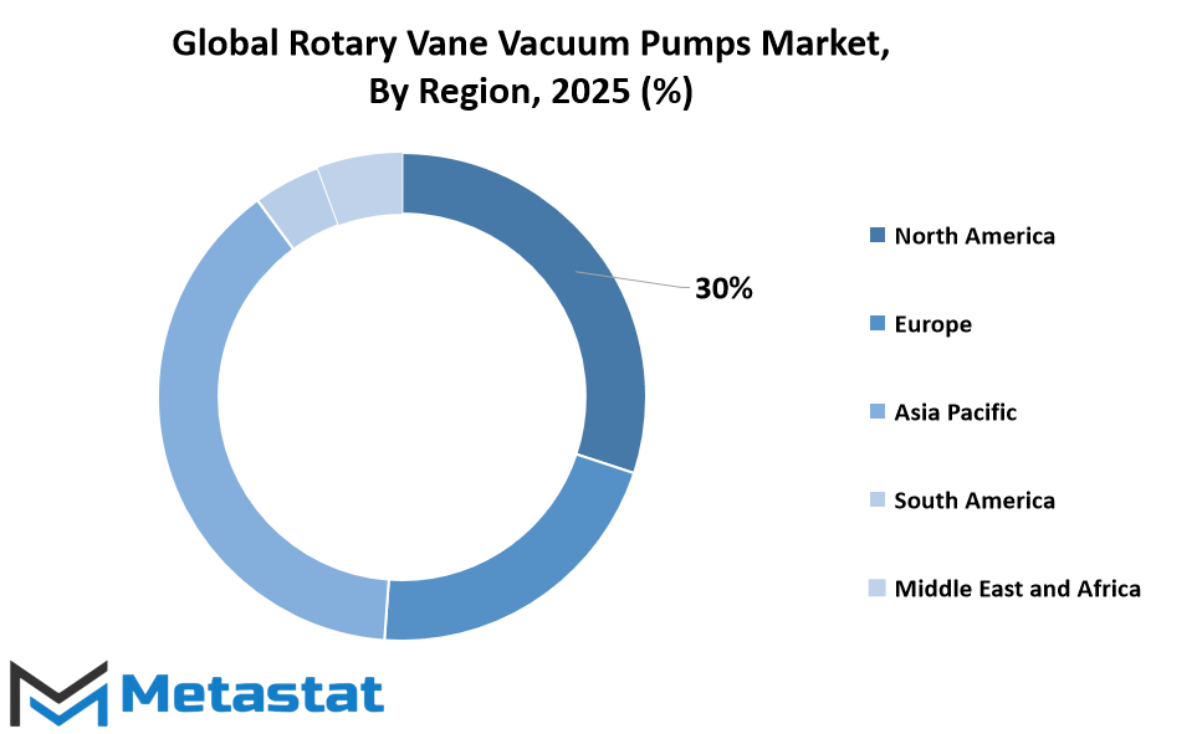

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

The global rotary vane vacuum pumps market will grow steadily in the next few years, with regional trends being a major factor in determining its future. With industries globally adopting automation and enhancing manufacturing standards, demand for stable vacuum technology will rise. Rotary vane vacuum pumps, due to their space saving design and efficiency, are being implemented across industries including packaging, healthcare, electronics, and chemical processing. This trend is not only expanding the market at the global level but also motivating regional players to invest in R&D, production, and distribution channels. In North America, the demand will increase in the market because of growing investments in the electronics and healthcare industries.

The United States and Canada are also prioritizing local manufacturing, which will boost the application of vacuum pumps in small and mid-sized manufacturing facilities. With greater concerns about energy-efficient machinery, rotary vane vacuum pumps are being utilized in place of older models. These developments are gradually redefining the market scenario in the region. Europe is yet another significant region where growth is likely to remain. Germany, France, and the UK are concentrating on establishing eco-friendly industrial systems.

This will create a surge in demand for efficient and low-maintenance vacuum solutions. As European nations transition towards cleaner technologies, vacuum pump designs that are more energy-efficient and emit less will find increasing adoption. These regional targets facilitate long-term growth of the global rotary vane vacuum pumps market, providing new opportunities to manufacturers as well as suppliers. In the Asia-Pacific, nations such as China, Japan, South Korea, and India will remain robust drivers of market growth. Heavy industrial growth, an expanding middle-class population, and high-technology manufacturing support by the government will fuel demand. Local industries are also joining in to make high-quality products competitively.

Not only will this fulfill local demand but also enable them to enter the export market. As automation and digital technologies spread throughout Asia, demand for advanced rotary vane vacuum pumps will increase. Looking ahead, regional strategies will play a significant role in determining the direction that the global rotary vane vacuum pumps market will take. The emphasis of each region whether sustainability, innovation, or cost-effectiveness will be what drives future trends. Those businesses able to adapt to these regional demands will better be able to succeed and determine the future of this expanding market.

COMPETITIVE PLAYERS

The global rotary vane vacuum pumps market is increasingly heading toward a future led by innovation, efficiency, and adaptability. As the electronics, pharmaceuticals, packaging, and automotive sectors continue to advance, the demand for vacuum technology is on the rise. These pumps are characterized by the reliability and consistent performance shown in processes that require a steady vacuum supply. Their simple design is what distances them from others, as it is easier to maintain yet good enough for nearly all applications. The need for these low-maintenance and dependable systems will just intensify as automation and smart manufacturing gain ground. This places rotary vane vacuum pumps in position to be the most preferred in several setups. Looking ahead, the market is expected to benefit from trends focused on energy efficiency and environmental responsibility.

Manufacturers are developing pumps that use less power and release fewer emissions, answering the global call for sustainable solutions. The shift toward eco-friendly technology is not just a temporary trend but a long-term movement that will continue to shape product development in this field. It will be a standard equipment in upgrading systems as industries enhance, and energy-efficient pumps are also likely to contribute to the growth of the global rotary vane vacuum pumps market. Several key players are making strong contributions to this space. Companies like Atlas Copco AB, Busch Vacuum Solutions, and Gardner Denver Inc. are consistently investing in research to bring better performance and smarter technology into their products.

Becker Pumps Corporation and Pfeiffer Vacuum Technology AG are also known for their commitment to innovation, helping drive the market forward. Firms such as ULVAC Inc., NAVAC, and Thomas Pumps are focusing on meeting global demand through improved product lines and better distribution channels. Others like Vacuubrand GmbH + Co KG, Gast Manufacturing, Inc. (IDEX Corporation), and Elmo Rietschle are making their mark through durability and efficiency, qualities that are increasingly important to end-users. Meanwhile, Pneumofore SPA, Zhejiang VALUE Mechanical & Electrical Products Co., Ltd., and Nash continue to serve a wide range of industries with solutions that are both practical and forward-thinking. Since automation, intelligent factories, and more stringent energy policies are increasingly prevalent, the global rotary vane vacuum pumps market will continue to grow. Such shifts create new prospects for those businesses that are willing to greet the future with adaptable, efficient, and dependable products.

Rotary Vane Vacuum Pumps Market Key Segments:

By Type

- Single-Stage Rotary Vane Vacuum Pumps

- Two-Stage Rotary Vane Vacuum Pumps

By Lubrication Type

- Oil-Sealed

- Dry (Oil-Free)

By Application

- Semiconductor and Electronic Industry

- Chemical Industry

- Laboratory Research

- Food Industry

- Machinery Industry

- Other

Key Global Rotary Vane Vacuum Pumps Industry Players

- Atlas Copco AB

- Busch Vacuum Solutions

- Gardner Denver Inc.

- Becker Pumps Corporation

- Pfeiffer Vacuum Technology AG

- Pneumofore SPA

- ULVAC Inc.

- Zhejiang VALUE Mechanical & Electrical Products Co., Ltd.

- Elmo Rietschle

- Agilent Technologies Inc.

- Vacuubrand GmbH + Co KG

- Gast Manufacturing, Inc. (IDEX Corporation)

- NAVAC

- Thomas Pumps

- Nash

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252