MARKET OVERVIEW

The Global Returnable Transport Packaging (RTP) market has a rapidly increasing attention due to the realization of such a market's efficiency in making industries around the world more productive and cost-effective. This market deals with packs which are being returned to be reused several times, thus saving from disposable packaging. Rising concern for environmental conditions and limiting the rules on waste reduction, the RTP is anticipated to increase much in the coming few years.

Key players in this field are Nefab AB, IFCO Systems, Schoeller Allibert Group BV, and Orbis Corporation, to name a few, that are pulling the innovation together by meeting the requirements of diverse needs from the industries. Major drivers behind this development include upgraded materials and technologies that enhance the returnable transport packaging in terms of durability and functionality. Presently, firms such as Brambles Limited (CHEP) and DS Smith Plc are trying to develop lighter yet rigid, also eco-friendly packaging systems for diverse industries such as automotive, food and beverage, pharmaceuticals, and retail sectors. Thus, the concern of RTP toward innovation ensures it remains a business's easiest go-to solution in their pursuit for decreasing carbon footprint. The future of the Global Returnable Transport Packaging (RTP) market appears promising, fueled by shifts in consumer preferences and regulatory frameworks that prioritize sustainable practices.

Governments worldwide are emphasizing circular economy principles, encouraging companies to adopt reusable packaging systems. This trend is likely to spur competition among market players to offer better, more efficient solutions, with companies such as Schuetz GmbH & Co. KGaA and Borealis AG envisioned taking the lead on the development of smarter packaging solutions. Furthermore, the growth of e-commerce and global supply chains is forcing companies to rethink their packaging strategies. The reduction of waste and lowering of cost in logistics are compelling reasons to opt for RTP. Companies such as Time Technoplast Ltd. and Cabka Group will certainly undertake to expand their product portfolios and collaborate with several industries to offer customized solutions to cater to diversified demands in the market. In the long term, technologies like RFID tagging, IoT incorporation, and better recycling techniques shall redefine the Global RTP market.

It would not only enhance traceability along with inventory management but also enhance the attractiveness of RTP as the sustainable and practical packaging alternative. With companies like Mauser Packaging Solutions and Amatech, Inc. investing more in R&D, the RTP market will expand into a new avatar of sustainable industrial practices.

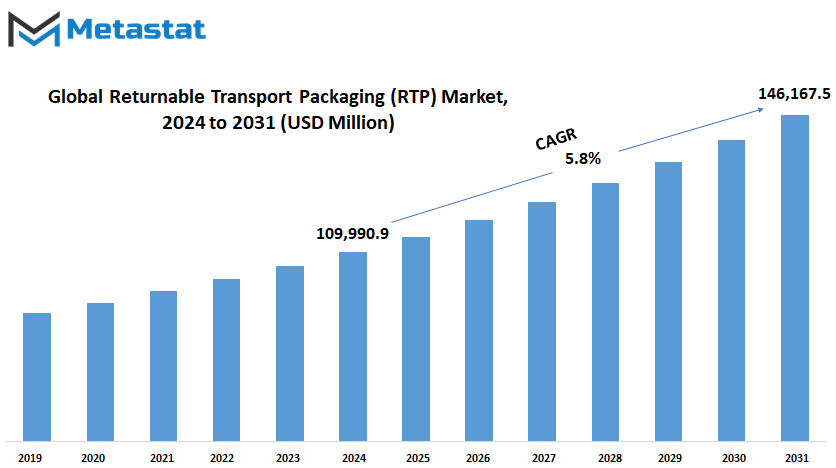

Global Returnable Transport Packaging (RTP) market is estimated to reach $146,167.5 Million by 2031; growing at a CAGR of 5.8% from 2024 to 2031.

GROWTH FACTORS

The Global Returnable Transport Packaging market is rapidly gaining traction as businesses, globally, continue to look at innovative solutions with regard to alignment with sustainability goals. The growing needs of more stringent environmental impact reduction will be one of the prime drivers behind the expansion of this market. Companies are using reusable packaging systems widely to minimize the amount of carbon footprint and reduce dependence on single-use materials. These systems not only contribute to sustainability but also provide a practical advantage in the form of saving on packaging waste. This will consequently reduce disposal costs, giving businesses a sharp economic incentive for transitioning toward RTP systems.

But this RTP market faces challenges, which may slow adoption. For example, the initial investment for the installation of RTP systems can be too costly for smaller organizations or organizations that are already under-budget strapped. Companies may not spend large amounts of capital on specialized containers, tracking technology, and infrastructure. Moreover, the logistical intricacies related to the return process of reusable packaging materials present operational challenges. These inefficiencies, if not properly addressed, could undermine the cost savings and sustainability benefits of RTP systems, hence less attractive to potential adopters.

However, we are still looking to a promising future for the Global Returnable Transport Packaging market. Increasing regulatory pressures to adopt eco-friendly practices present a unique opportunity for RTP providers to expand their reach. More stringent waste reduction and sustainable packaging regulations will push more governments and international organizations to set guidelines, which could mean an additional incentive for businesses to switch to reusable systems to meet these standards. Providers of RTP can increase this pool of customer demand by aligning their offerings to reconcile with regulatory requirements.

More importantly, technological progress may alleviate some of the current challenges. Developing a better system for tracking and management will significantly improve the logistics and returns processes, thus making RTP systems more efficient and user-friendly. As these solutions become more accessible and affordable, they could lower the barrier to entry for businesses, thereby fueling market growth.

In the long term, demand for RTP solutions is likely to increase with increasing business concerns about sustainability and cost efficiency. With a proactive approach in addressing challenges and emerging opportunities, the Global Returnable Transport Packaging market is best placed in the continuum of developments that would influence the future of packaging solutions. This approach outlines a way toward RTP systems as a fiducial principle in sustainable global business practice.

MARKET SEGMENTATION

By Type

Global Returnable Transport Packaging is also experiencing unprecedented transformations due to improvements in technology, environmental concerns, changes in consumer and industry needs, and several other factors. This is a growing business towards a reduction of waste, optimization in logistics, and satisfaction of the business with sustainability concerns. As more emphasis is on single-use packaging materials being reduced, companies from various industries are opting for RTP solutions as something reliable and thus eco-friendly.

By type, RTP solutions encompass containers and drums and barrels, pallets and crates, totes and trays and bins, intermediate bulk containers (IBCs), among others. Each of them has special need-serving benefits in the aspects of durability, efficiency, and handling. An example is the flexibility in shipping bulk goods using pallets and crates for bulk goods; whereas totes and trays are used for small or fragile products. Containers and IBCs help fulfill the intent of having larger storage and transportability which certainly finds its niche in chemical, food and beverage, and pharmaceutical manufacturing among other industries. There are different types of RTP products to ensure that various industries find a fitting solution to making their supply chains better.

Going forward, it is projected that demand for RTP will increase at a moderate pace because companies will always seek cost-effective and sustainable ways of handling their businesses. Companies are researching innovative materials for RTP products, with a focus on lightweight, durable, and recyclable materials to enhance performance while reducing environmental impact. Another trend will likely transform the market: smart integration technology.

There will be RFID tags and IoT tracking systems that will revolutionize real-time monitoring of assets and subsequently create enhanced inventory management and reduce losses that occur during transit. Strong support to the growth of RTP also comes from global policies and regulations intended to minimize environmental damage. Governments and organizations have been pushing for change towards reusable and returnable systems to counter the potential effects of wastes from disposable packaging. This change aligns not only with environmental goals but also produces cost savings in the long run for companies, as RTP helps reduce dependence on single-use materials and saves them on waste disposal costs.

Ongoing trends toward adoption of such solutions by businesses are expected to create a growing Global Returnable Transport Packaging (RTP) market, promoting the culture of innovation in packaging designs as well as logistics. This transition marks an important step on the way toward an increasingly sustainable global supply chain with high economic and ecological efficiency.

By Material

The Global Returnable Transport Packaging (RTP) market is going to witness significant growth as industries across the globe seek to adopt environmentally friendly and cost-effective solutions for the transportation of products. RTP is essentially durable and reusable containers, pallets, and other materials designed to facilitate the easy movement of products. This trend towards RTP has been triggered by rising environmental concerns, stringent regulations, and awareness among businesses aiming to reduce waste and carbon footprints.

The market can be classified on a material basis into plastic, metal, wood, foam, and other composite materials, which have different advantages. Plastic, for example, is prized for its light weight and durability; it is popular in many sectors, such as the automotive, retail, and food and beverage industries. It ensures efficient handling while lowering transportation costs. Metal is chosen for strength and reliability, especially in the industries that use heavy-duty solutions, in industrial equipment or machinery. Wood has persisted because of its cost-effectiveness and biodegradability, appealing to companies willing to find eco-friendlier options. Foam and composite materials are also on the rise, especially for sensitive or high-value products that demand a more advanced level of protection against damage incurred during transit.

Looking forward, there is enormous potential for the Global Returnable Transport Packaging (RTP) market. Businesses are increasingly looking toward a model of circular economy, which means minimum waste and maximum resource efficiency are hugely in line with reusable materials. Innovations in material science will likely make RTP solutions more durable, multifunctional, and environmentally sustainable. For example, these biodegradable composites and recyclable plastics are supposed to revolutionize the market with improved performance and environmental concerns.

Technological advancements will also support growth in the market. Incorporating features such as RFID tags and IoT-enabled tracking into RTP will enable firms to track their supply chains in real-time, leading to optimized asset management and resulting loss prevention. The growth in demand for smarter and technology-enhanced RTP options will be very high as industries continue to adopt more automation and data-driven operations.

The Global RTP market is going to take center stage in fashioning the future of sustainable logistics. Companies are increasingly becoming concerned about their environmental responsibilities and cost efficiency. Consequently, plastics, metals, woods, foam, composites, and many others will continue their innovations to serve a wide range of needs while advancing global sustainability agendas. It is this dynamic change that underlines the increasing significance of RTP solutions across various sectors worldwide.

By Application

The Global Returnable Transport Packaging (RTP) market is steadily gaining momentum as industries look for cost-effectiveness and greater sustainability. This is a market focused on reusable packaging solutions; hence, there is an alteration in how supply chains are traditionally operated. RTP reduces dependence on single-use material to minimize waste, thereby also cutting costs that businesses incur in packaging.

A major growth driver for the Global Returnable Transport Packaging market is the increasing demand for environmentally friendly practices. Each government worldwide is promoting sustainable approaches, and RTP aptly goes with the trend. The applications can be used multiple times, thus decreasing the cycle of frequent production and disposal. In the long term, such a pattern significantly decreases the pollution caused by packaging waste.

The applications of the market cut across industries, with everyone in a different way enjoying an RTP. In the automotive industry, for instance, robust packaging presents the safe and efficient transportation of large or complex parts. In the food and beverage industry, RTP is valued for hygiene and freshness while cost-effectiveness is enhanced. The pharmaceuticals and healthcare industry relies on RTP for handling sensitive products securely and contagion-free. Likewise, consumer goods and retail enjoy the efficiency and durability of reusable solutions as these simplify their operations in the supply chain. Electronics, chemicals, industrial manufacturing, logistics, and transportation are also important implementers; RTP can provide a customized solution for fragile, dangerous, or oversize materials.

The market for RTP is set to undergo further changes, improving with the ongoing advancement of technology. New materials and smart packaging solutions will help improve the durability and traceability of products. Soon, the incorporation of sensors or RFID tags will be a standard, bringing the traceability of products from the source to the consumer; this would improve the management of inventories and reduce losses, making RTP a more efficient choice for global activities.

So, the Global Returnable Transport Packaging market is perceived to have huge potential for shaping supply chains in any industry. This market has a focus on reusability and environmental responsibility, which dovetails with the increasing global focus on sustainability.

As industries like automotive, food and beverages, and pharmaceutical and healthcare continue to adopt and evolve RTP solutions, the market is well positioned for long-term growth. With more and more businesses realizing that these solutions will benefit them financially and environmentally, RTP will be at the center of a more sustainable future for worldwide trade and logistics.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$109,990.9 million |

|

Market Size by 2031 |

$146,167.5 Million |

|

Growth Rate from 2024 to 2031 |

5.8% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

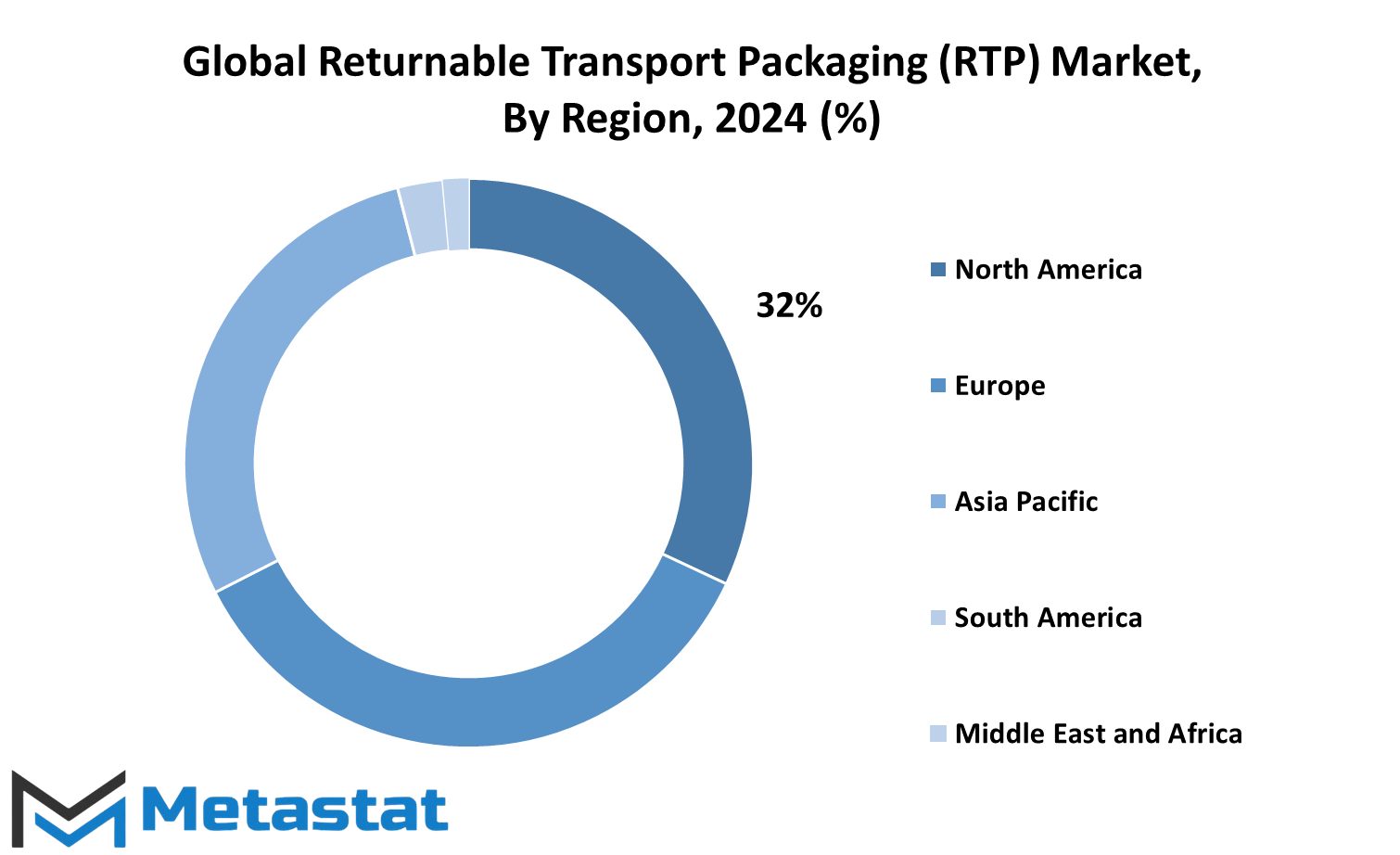

The Global Returnable Transport Packaging (RTP) market continues to grow as industries worldwide focus on sustainable and cost-effective transportation solutions. This packaging system has become an essential part of waste reduction and operational efficiency for logistics and supply chains. When analyzed regionally, considerable differences in trends and opportunities surface, which are tailored by the unique economic and industrial conditions of each region.

In North America, the market mainly drifts toward established industries and advanced technological infrastructure. The U.S., Canada, and Mexico have witnessed aggressive adoption of RTP systems, especially in food and beverage, pharmaceuticals, and automotive. Companies in this region are ever-increasing and focusing on sustainable practice, making RTP a practical option for reducing single-use packaging materials.

In Europe, RTPs take priority in the UK, Germany, France, and Italy, for stringent environmental regulations and a growing need for circular economies. Manufacturers in this region are adopting RTP systems based on higher demand for sustainability along with cost savings of transportation. The collaborative initiatives of logistics in the region, most notably shared networks, help improve RTP systems.

The Asia-Pacific region is developing rapidly in RTP. This growth is primarily driven by countries like China, India, Japan, and South Korea, becoming new hubs for manufacturing. The rapidly growing e-commerce sector, coupled with increased industrialization, indicates great demand for efficient and reusable packaging solutions. Long-term benefits and initial investment of RTP systems are gradually being realized by businesses in this region. Government policies that support eco-friendly initiatives are also major contributors to this upward trend.

South America holds huge promise for the penetration of RTP, especially in Brazil and Argentina. There has been an increasing export-oriented agricultural and manufacturing sector that is giving a drive to demand durable and reusable packaging. Limited infrastructure and awareness, though, are expected to dampen the growth somewhat.

The market for RTP systems has a mixed outlook in the Middle East and Africa. Countries in the GCC, Egypt, and South Africa are embracing RTP systems to support growing industries such as oil and gas, automotive, and retail. Economic diversification efforts here continue to spur innovation, but infrastructural and financial barriers may create hurdles elsewhere in the region.

The Global Returnable Transport Packaging (RTP) market will probably grow more considerably in the future years as global industries focus more on greener practices. Advanced materials, digital tracking systems, and regional collaborations will play significant roles towards driving efficiency and sustainability in this evolving market.

COMPETITIVE PLAYERS

The Global Returnable Transport Packaging (RTP) market has a rapidly increasing attention due to the realization of such a market's efficiency in making industries around the world more productive and cost-effective. This market deals with packs which are being returned to be reused several times, thus saving from disposable packaging. Rising concern for environmental conditions and limiting the rules on waste reduction, the RTP is anticipated to increase much in the coming few years.

Key players in this field are Nefab AB, IFCO Systems, Schoeller Allibert Group BV, and Orbis Corporation, to name a few, that are pulling the innovation together by meeting the requirements of diverse needs from the industries. Major drivers behind this development include upgraded materials and technologies that enhance the returnable transport packaging in terms of durability and functionality. Presently, firms such as Brambles Limited (CHEP) and DS Smith Plc are trying to develop lighter yet rigid, also eco-friendly packaging systems for diverse industries such as automotive, food and beverage, pharmaceuticals, and retail sectors. Thus, the concern of RTP toward innovation ensures it remains a business's easiest go-to solution in their pursuit for decreasing carbon footprint. The future of the Global Returnable Transport Packaging (RTP) market appears promising, fueled by shifts in consumer preferences and regulatory frameworks that prioritize sustainable practices.

Governments worldwide are emphasizing circular economy principles, encouraging companies to adopt reusable packaging systems. This trend is likely to spur competition among market players to offer better, more efficient solutions, with companies such as Schuetz GmbH & Co. KGaA and Borealis AG envisioned taking the lead on the development of smarter packaging solutions. Furthermore, the growth of e-commerce and global supply chains is forcing companies to rethink their packaging strategies. The reduction of waste and lowering of cost in logistics are compelling reasons to opt for RTP. Companies such as Time Technoplast Ltd. and Cabka Group will certainly undertake to expand their product portfolios and collaborate with several industries to offer customized solutions to cater to diversified demands in the market. In the long term, technologies like RFID tagging, IoT incorporation, and better recycling techniques shall redefine the Global RTP market.

It would not only enhance traceability along with inventory management but also enhance the attractiveness of RTP as the sustainable and practical packaging alternative. With companies like Mauser Packaging Solutions and Amatech, Inc. investing more in R&D, the RTP market will expand into a new avatar of sustainable industrial practices.

Returnable Transport Packaging (RTP) Market Key Segments:

By Type

- Containers

- Drums & Barrels

- Pallets

- Crates, Totes, Trays & Bins

- Intermediate Bulk Containers (IBC’s)

- Others

By Material

- Plastic

- Metal

- Wood

- Foam

- Others (Composite Materials)

By Application

- Automotive

- Food and Beverage

- Pharmaceuticals and Healthcare

- Consumer Goods and Retail

- Electronics

- Chemicals

- Industrial Manufacturing

- Logistics and Transportation

Key Global Returnable Transport Packaging (RTP) Industry Players

- Nefab AB

- IFCO Systems

- Schoeller Allibert Group BV

- Mugele Group

- Orbis Corporation

- Brambles Limited (CHEP)

- DS Smith Plc

- Time Technoplast Ltd.

- Mauser Packaging Solutions

- Schuetz GmbH & Co. KGaA.

- Borealis AG.

- Cabka Group

- Amatech, Inc.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252