MARKET OVERVIEW

The Global Prefabricated Steel Building Systems market and industry basically involve the manufacture, design, and deploying off-site fabricated steel structures on the on-site location. These systems are utilized for industrial, commercial, residential, and institutional construction. The industry is described as a path that necessitates a move toward efficiency, sustainability, and affordable building solutions that will continue to shape the future of construction methods worldwide.

The market is broad-based and widespread across various geographies. Expansion of infrastructure along with rapid urbanization, improved steel processing technology, and evolving demand patterns characterizes the infrastructure market. Such countries that enjoy high construction activity will form major contributors to this market's trends. Since steels are most preferred materials regarding strength and solidity, prefabrication provides them with an efficient edge through increased speed in erecting construction on-site while still reducing waste disposal. It simply means that significant projects can reach completion faster under the same security and structural reliability.

This market encompasses different kinds of prefabricated steel structures, including modular buildings, pre-engineered warehouses, steel bridges, and even multi-story commercial spaces. These categories of products meet particular industry needs for applicability and suitability in any given environment. More digital tools like BIMs and automation of manufacturing processes will just mean there's more momentum for this industry, improving the efficiency and handling options for end customers.

The construction industry has witnessed an increasing reliance on prefabricated steel systems due to their ability to streamline operations. Contractors and developers favor these solutions for their reduced labor requirements, faster assembly times, and minimal environmental impact compared to traditional construction methods. Steel’s recyclability further strengthens its appeal, aligning with global sustainability initiatives.

Technological innovations, changes in architecture preference, and favorable regulatory frameworks that encourage efficient building processes will drive demand in prefabricated steel structures. Smart cities and infrastructure modernization projects in different economies will also fuel the growth of the market. Assuredly, increased collaboration between producers of the material and construction companies will drive designs that are more advanced than currently available in terms of prefabrication.

In the future, developments in Global Prefabricated Steel Building Systems market would be expected with the onset of automation and artificial intelligence that makes production as well as assembling process efficient. Advanced steel alloys, new improved techniques of fabrication, and their incorporation with smart building technologies are set to further change the horizon of this industry. Increasing application of green building standards and energy-efficient designs is set to fine-tune market offerings in ways where prefabricated steel structures remain aligned to new goals in terms of sustainability.

The industry will need companies operating in this market to change with changing regulations, material innovations, and changing client demands as the industry moves forward. Increasing focus on reducing carbon footprints and improving energy efficiency will spur further research and development. Further investment in infrastructure projects, especially in developing nations, will create significant opportunities for market participants.

The Global Prefabricated Steel Building Systems market will be transformed in the coming years through digitalization, sustainability concerns, and innovations in the construction sector. As the systems become more advanced and are used more extensively, their role in shaping modern infrastructure will continue to be vital. With the continuous improvement in prefabrication techniques and steel production, this market will continue to provide solutions that address the challenges of modern construction while being efficient, durable, and cost-effective.

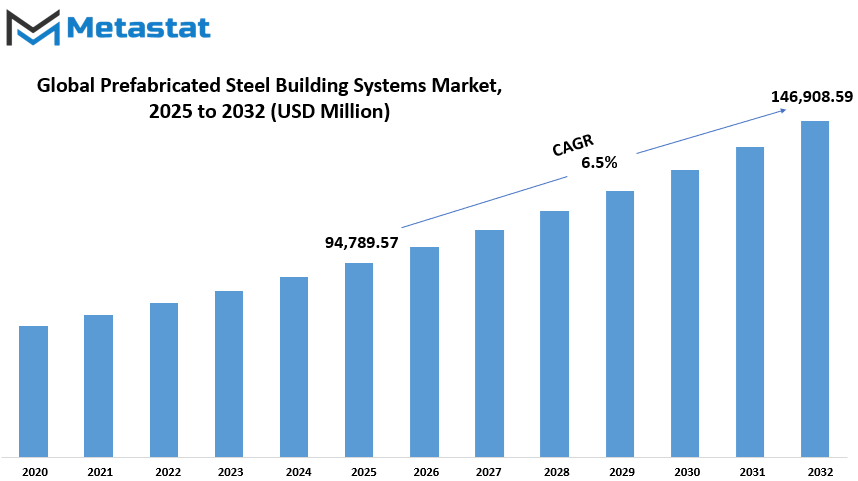

Global Prefabricated Steel Building Systems market is estimated to reach $146,908.59 Million by 2032; growing at a CAGR of 6.5% from 2025 to 2032.

GROWTH FACTORS

The global Prefabricated steel building systems market is therefore going to represent an important demand for growth among the industries as well as expanding urban areas, with the necessity for cost-effectiveness and timeliness in constructing the buildings in question. Cost-effectiveness with structural integrity seems to be key factors that led businesses and even governments to hasten the delivery of projects that still ensure building safety. These structures are manufactured off-site and assembled quickly, which reduces labor costs and minimizes construction delays.

This method is particularly beneficial in regions where skilled labor shortages and high on-site construction expenses pose challenges. This would be the main factor in increased market growth – rapid industrialization and urbanization. As a country’s economy grows, commercial, residential, and industrial constructions are needed, and prefabricated steel structures can be an ideal solution by allowing the faster construction of a warehouse, a factory, offices, or apartment complexes in contrast to traditional techniques. Such infrastructure systems are really attractive to the developers and investors because they offer an efficient approach to meeting increased infrastructure needs.

Despite these benefits, some potential challenges to market growth. The principal challenge is the heavy initial investment in establishing manufacturing facilities and logistics for transportation. Unlike conventional construction, which allows for site purchase of raw material and assemblage, prefabrication calls for specific manufacturing units along with infrastructure for transportation of large steel work. This further increases the cost incurred in the initial set-up, which could be a “big deterrent” in those companies or regions with insufficient funds.

Relative design inflexibility compared to conventional construction is also a limiting factor. Prefabrication enables standardization and efficiency, but projects sometimes require extremely customized architectural designs that may not be easily realized with pre-engineered steel components. This will limit adoption in certain segments where aesthetic or structural customization is considered paramount.

The market is likely to expand with ever-increasing green building initiatives supported by the increasing emphasis on sustainability and eco-friendly construction practices. Because industries and governments are increasingly focused on reducing carbon footprints, the trend of prefabricated steel structures is more aligned with the green construction trend. These structures produce less material waste, use fewer resources during construction, and can be designed for energy efficiency. Integration of solar panels, harvesting systems for rainwater, and the use of high insulation material further increases its sustainability and allows them to use these systems as their future choices.

The Global Prefabricated Steel Building Systems market is expected to experience significant growth in the near future, given the rapid progress of technology and further innovation in modular construction techniques. Economic and environmental factors are bound to shape the industry further, and these systems are expected to gain ground with long-term benefits for both developers and end users.

MARKET SEGMENTATION

By Component

The global prefabricated steel building systems market is witnessing rapid growth, mainly due to rapid urbanization and the demand for efficient construction solutions. Prefabricated steel structures are known for their durability, design flexibility, and ease of assembly, which makes them a popular choice in all sectors. As cities expand, the demand for quick and reliable construction methods has increased, making prefabricated steel buildings a viable solution.

Technological advancement is a primary driver in this market's growth. Robotic automation, computer-aided design, and building information modeling, amongst others, improve precision and effectiveness in the construction process. It decreases the labor cost and streamlines project timelines, an important factor that pushes up prefabricated steel building systems usage.

Sustainability is another prime driver of the market. Since steel is recycled and the prefabrication process produces less waste, this practice aligns with the increasing interest in environmentally friendly construction methods. Furthermore, such structures are more energy efficient and, therefore, cost less to operate, creating further incentive for their use across industries.

The market is divided into various segments, which include steel frames, steel panels, roofing systems, and others. Steel frames hold the most significant share, with an approximate value of $60,491.13 million. This is because steel frames offer strength and stability, which are necessary to construct strong buildings.

The prefabricated steel building systems market will witness further growth going forward. Its adoption will gain momentum as integration of advanced technologies and emphasis on sustainable practices pick up. Moreover, industries need cost-effective solutions for efficient construction, and, therefore, such prefabricated steel structures would be highly on the rise. This would reshape the future infrastructure development globally.

By Construction Method

The Global Prefabricated Steel Building Systems market is growing because of the developing methods of construction, which provide efficiency and sustainability. Amongst them are Modular Construction, Panelized Construction, Pre-Engineered Buildings, and Hybrid Systems, each holding benefits and designing the future for the industry.

Modular Construction refers to the manufacturing of entire building sections in a factory environment, which are then transported to the site for assembly. This means that the product can be made with much greater precision under controlled conditions, thereby allowing for a faster completion time and less waste. For example, a seven-story apartment block in Brisbane was constructed in only 11 days using such methods, and thus, there is a possibility for rapid urbanization.

Panelized construction involves the assembly of flat panels, such as walls and floors, off-site. These panels are then transported to the construction site and assembled to form the building’s structure. This method allows for flexibility in design and is particularly useful for residential projects, where customization can be achieved while maintaining efficiency.

Pre-Engineered Buildings include components that are designed and manufactured in advance with standardized measurements, which can then be assembled at the site for cost savings and reduced construction times. This technique is usually adopted for industrial and commercial buildings as it allows them to provide open large spaces.

Hybrid Systems combine elements of the aforementioned methods to leverage their respective advantages. By integrating modular units with panelized components or pre-engineered elements, builders can optimize both design flexibility and construction efficiency. This approach allows for tailored solutions that meet specific project needs.

In the future, these construction methods are expected to gain more acceptance, as people seek sustainable and efficient building practices. Technological advancements, such as robotic automation and computer-aided design, are further enhancing the precision and speed of prefabricated construction. As urbanization continues and the demand for quick, cost-effective building solutions grows, the Global Prefabricated Steel Building Systems market is poised for substantial expansion.

In a nutshell, the development trends of construction procedures in the prefab steel building construction industry are signs of a universal change towards an innovative and ecological way of delivering. Modular construction, panelized construction, Pre-Engineered Buildings, as well as the hybrid systems could meet the standards set by present-day urban requirements.

By End-Use Sector

Growth in the Global Prefabricated Steel Building Systems market is also fuelled by the development in construction techniques and increase demand for efficient building solutions. Prefabricated structures of steel are manufactured off-site within a controlled environment which then gets assembled at the site; it has much more benefits than conventional methods of construction. The benefits include decreased construction time, cost saved, and quality control.

The residential sector is increasingly turning to prefabricated steel buildings because of their durability and design flexibility. People are finding the speed with which construction can take place and their ability to customize designs according to their preferences attractive. With continued urbanization, there is a growing need for affordable and rapidly deployable housing solutions. The problem is being addressed by this form of prefabricated steel structure- sturdy and adaptable homes that can be constructed rapidly.

The institutional sector, encompassing educational and healthcare facilities, is also recognizing the benefits of prefabricated steel building systems. Schools and universities often require rapid expansion to accommodate growing student populations. Prefabricated solutions allow for the quick addition of classrooms and other facilities with minimal disruption. Similarly, in the healthcare industry, the ability to rapidly construct hospitals and clinics is crucial, especially in response to emergencies. For such emergency demands, prefabricated steel buildings provide the required speed and flexibility.

Prefabricated steel structures are being adopted in the commercial sector for construction. Retailers and office developers appreciate the fact that construction is faster in these systems, resulting in early operations. Prefabricated systems can design aesthetically beautiful and functional commercial spaces. Because such construction methods are cost-effective, businesses looking to maximize investments find this an ideal option.

This will lead to continued growth in the global prefabricated steel building systems market. Further, the technology evolving more complex and personalized prefabricated solutions opens the markets even broader for their adaptation through various sectors. In the main aspect of construction sustainability, prefabricated steel buildings are positioned at a very good position that can come into prominence in those demands. Steel is recyclable, thus the conception of off-site fabrication naturally contributes to a more sustainable construction process.

In conclusion, the Global Prefabricated Steel Building Systems market is evolving to meet the diverse needs of the residential, institutional, and commercial sectors. The inherent advantages of prefabricated steel structures, such as speed, cost efficiency, and design flexibility, make them a compelling choice for modern construction projects. As the industry continues to innovate, prefabricated steel building systems are set to play a pivotal role in shaping the future of construction worldwide.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$94,789.57 million |

|

Market Size by 2032 |

$146,908.59 Million |

|

Growth Rate from 2024 to 2031 |

6.5% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

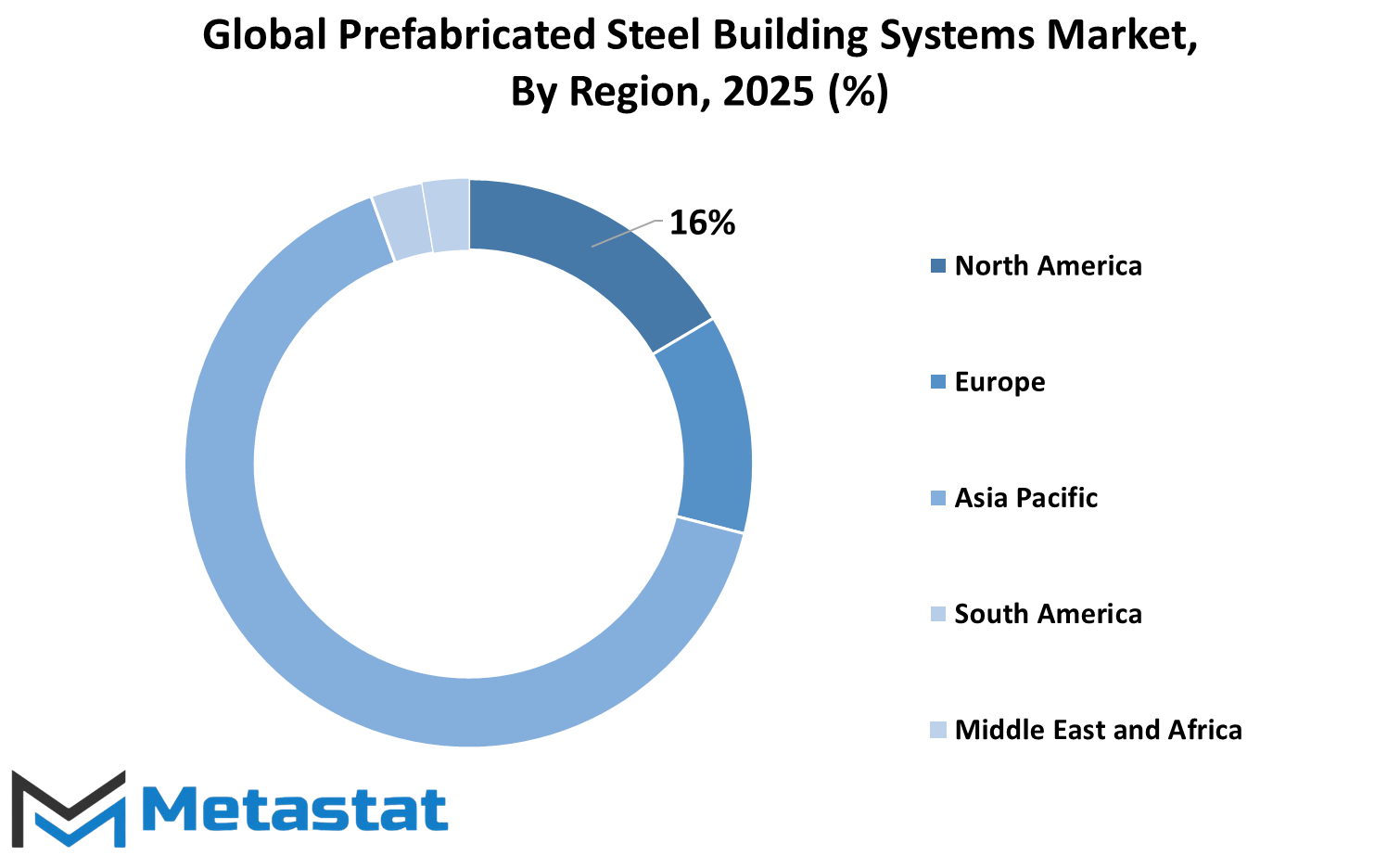

REGIONAL ANALYSIS

The Global Prefabricated Steel Building Systems market is shaping the future of construction across different regions, with each area contributing uniquely to its growth. As industries seek faster, more cost-effective, and sustainable building solutions, the demand for these structures is expected to rise. The advancement of technology and the push for eco-friendly practices are also influencing how steel building systems are developed and used worldwide.

The North American market is expanding with increasing urbanization, rising construction projects, and adoption of modern building techniques. This shift towards more prefabricated solutions is paramount for companies that emphasize efficiency and durability. In the U.S., it leads since commercial and industrial infrastructure investments are relatively high; however, such adoption patterns and spending can be increasingly seen in Canada and Mexico as well. Future innovations in smart construction methods and automation are going to further spur this growth. Europe is changing too, and countries such as the UK, Germany, France, and Italy are turning towards prefabricated steel structures.

Strict environmental regulations as well as increased energy-efficient buildings keep driving the demand. In Europe, innovation will continue to grow, particularly in modular construction where the sections of buildings are manufactured off-site and can be assembled quickly. This method results in minimal construction waste and faster completion of the projects, making developers opt for it. Asia-Pacific is expected to grow even faster with the rapid growth in industrialization and urbanization. China and India are heavily investing in infrastructure projects, which are surging offsite prefabricated steel buildings.

Japan and South Korea mainly take on advanced technologies, such as 3D printing, and AI-driven design processes, further optimizing the construction sector. As smart cities and large housing projects are coming up in these countries, the market will keep growing. The focus on cheap but long-lasting construction solutions from Brazil and Argentina in South America would have started dominating the market. Economic fluctuations were somewhat of an obstacle, but prefabricated steel buildings stand out as an alternative for steady long-term growth. The government initiatives to upgrade dwelling and commercial infrastructures will help boost this region.

The second most important is the Middle East & Africa, with prefabricated steel buildings becoming increasingly popular. GCC countries, Egypt, and South Africa are rolling out large infrastructure projects in commercial and industrial sectors. The growing need for sustainable and efficient construction will see this region call for more use of prefabricated systems. Future developments, such as the incorporation of renewable energy solutions into these buildings, will further increase their attractiveness. With technology advancing and sustainability remaining a priority, the Global Prefabricated Steel Building Systems market will continue to grow in all regions and shape the future of modern construction.

COMPETITIVE PLAYERS

The Global Prefabricated Steel Building Systems market is growing rapidly due to the demand for efficient and sustainable construction. Since prefabricated steel buildings have advantages in terms of less construction time, cost savings, and durability, they are preferred in various sectors, such as residential, commercial, and industrial application areas.

Some strong players are emerging in this competitive arena. Tata BlueScope Steel is known for innovation in steel products as well as solutions for different building needs. Kirby Building Systems specializes in pre-engineered steel buildings, wherein they develop customized designs that tend to suit the specific needs of a client. PEB Steel Buildings Co. Ltd. offers a wide range of prefabricated steel structures within the focus areas of quality and timely delivery. Pennar Industries Limited deals with design, manufacture as well as installation of steel buildings aimed at servicing multiple industries. ATAD Steel Structure Corporation offers a comprehensive solution in steel building, which focuses on excellence in engineering and customer satisfaction.

Norsteel Buildings is a leading provider of prefabricated steel building systems with adaptability and strength. Allied Steel Buildings is a turnkey solution provider for projects from conceptualization to completion. Faisal Roofing Solution (I) Pvt. Ltd. specializes in roofing solutions under the prefabricated steel building industry. SML Group provides a variety of steel building products, catering to different market segments. PERFECT METAL STRUCTURE PRIVATE LIMITED specializes in manufacturing and supplying steel structures for various applications. Riddhima Building System Private Limited offers prefabricated steel buildings with a focus on innovation and quality. Primex Building Systems Pvt. Ltd. provides customized steel building solutions, ensuring compliance with international standards. The Indian Roofing Industries Pvt. Ltd. delivers roofing and cladding solutions, contributing to the prefabricated steel building industry.

Looking ahead, the market is poised for further expansion. Technological advancements are expected to play a crucial role, with companies investing in research and development to enhance product offerings and meet evolving customer expectations. The integration of smart technologies into prefabricated steel building systems is anticipated to improve energy efficiency and sustainability, aligning with global environmental goals. Adopting modular construction methods will be much easier, as this will increase flexibility and reduce the time taken to construct on-site.

In conclusion, the Global Prefabricated Steel Building Systems market is looking up, backed by the initiatives of major players and the relentless quest for innovation. As one would expect from the growth of the construction industry, prefabricated steel building systems will soon be part of modern building practices that deliver efficiency, sustainability, and flexibility in solutions.

Prefabricated Steel Building Systems Market Key Segments:

By Component

- Steel Frames

- Steel Panels

- Roofing Systems

- Other

By Construction Method

- Modular Construction

- Panelized Construction

- Pre-Engineered Buildings

- Hybrid Systems

By End-Use Sector

- Residential

- Institutional

- Commercial

Key Global Prefabricated Steel Building Systems Industry Players

- Tata BlueScope Steel

- Kirby Building Systems

- PEB Steel Buildings Co. Ltd.

- Pennar Industries Limited

- ATAD Steel Structure Corporation

- Norsteel Buildings

- Allied Steel Buildings

- Faisal Roofing Solution (I) Pvt. Ltd.

- SML Group

- PERFECT METAL STRUCTURE PRIVATE LIMITED.

- Riddhima Building System Private limited

- Primex Building Systems Pvt. Ltd.

- The Indian Roofing Industries Pvt. Ltd .

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1-(714)-364-8383

US: +1-(714)-364-8383