MARKET OVERVIEW

The Global Powder Metallurgy market will have the manufacturing industry focusing on the processing and use of metal powders. This entire line of powder metallurgy processes will include powder formation, compaction, and sintering in the development of high-performance components. These processes would be spread across a wide range of sectors such as automobiles, aircraft, electronics, and medical devices that would indicate a wide range of applications and a myriad of customers.

With time, the powder metallurgy techniques will be advanced, and the manufacturing industry will take on a trend of producing powder in more efficiency and sustainability. One innovation shall be the powder production method, either in gas atomization, water atomization, or mechanical milling; these will have been used to produce powder for exact usage with regard to increased performance and minimum waste. The choice of methods will depend on the requirements of particle size, shape, and material properties in order to satisfy ever-growing demands of various sectors.

The powder metallurgy market globally will also feature a broad array of materials, more conventional ones like iron and copper to advanced alloys, as well as composite powders. High-performance application specialty powders will be more common. These specialty powders will allow components that have improved mechanical properties, thermal stability, and corrosion resistance. This is one of the areas of the market that will go a long way to impact sectors such as aerospace and defense, where material performance is paramount.

The increasing integration of digital technologies within powder metallurgy processes forms another significant component of this market. Now, automation and smart manufacturing will transform every production line: more precise and efficient performance. On the basis of principles of Industry 4.0, the whole process of powder metallurgy would be monitored and optimized in real time to reduce production time as well as enhance product quality. This would help cater to the changing needs of all those industries that require high volumes of precision-engineered components.

Beyond technology, sustainability will prove to be the new theme for the Global Powder Metallurgy market. The industry is witnessing more and more awareness regarding the implementation of eco-friendly practices-such as recycling metal powders and renewable sources of energy in the production process-so that sustainability can become the driver of consumption and policy for the industry.

Geography of the Global Powder Metallurgy market is going to be sharply diverse, and it would feature players from North America, Europe, Asia-Pacific, and Latin America. All these regions would come forward with unique benefits based on the presence of leading manufacturers, robust supply chains, and demand levels by customers in those markets. China and India will be important countries.

The Global Powder Metallurgy market will encompass the following and will involve dynamic ranges of processes, materials, and technologies aimed at the production of high-quality metal components for the broadest range of applications. Production technology innovations and new materials, digital transformation, and sustainability initiatives will define the development and evolution of the market. This will generally provide a much larger scope and enable the market to play an important role in the wider manufacturing world, paving the path toward future growth and opportunities.

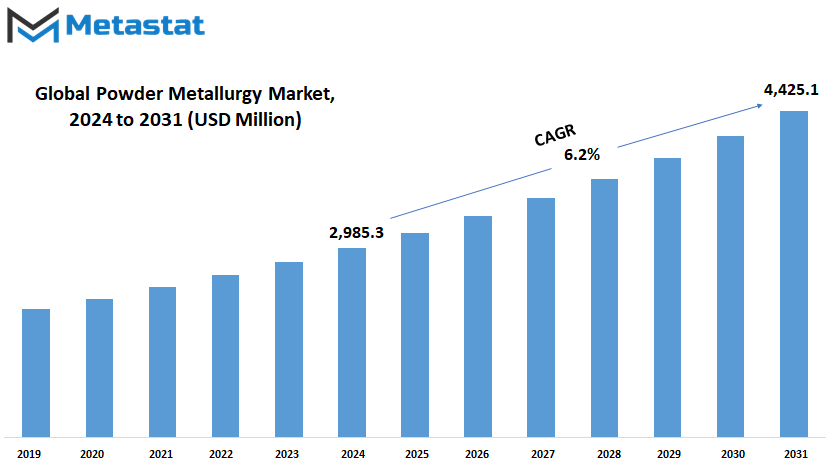

Global Powder Metallurgy market is estimated to reach $4,425.1 Million by 2031; growing at a CAGR of 6.2% from 2024 to 2031.

GROWTH FACTORS

There is rapid growth in the global powder metallurgy market with several factors changing its face. Growth in demand for lightweight and high-strength components in the automotive and aerospace sectors is one of the primary drivers for growth in this regard. These industries are continually under pressure to improve fuel efficiency and performance while also lowering emissions. This, therefore, has taken the manufacturers to power metallurgy as a way of developing parts that not only have a reduced weight but also possess enhanced strength value in comparison to the traditional materials used. The trend is therefore bound to continue as vehicle manufacturers and aerospace engineers pursue innovative solutions in their sectors to meet increasingly stringent regulatory standards and consumer expectations.

An upsurge in market growth comes from increasing usage of additive manufacturing and 3D printing technologies that use metal powders. Advanced manufacturing techniques allow for more design freedom and the production of complex geometries previously difficult or impossible to achieve with other methods. Various industries-attracting interests in healthcare, electronics, and consumer goods are attracted because they can print customized components on demand. Increased investment and usage in the global powder metallurgy market will follow when more companies realize the benefits of the technologies.

Despite the optimistic trends outlined above, the market has its own battles that it faces in growth. Entry barriers to companies seeking to venture into this market may be created by the relatively high setup costs of powder metallurgy processes. The complexity of such processes also tends to require skilled labor and expensive equipment for the task, reducing access. There are also limited material options when using powder metallurgy; besides this, parts with high density may only be challenging to create, which creates even more challenges for manufacturers.

Looking forward, innovations in metal powder technologies and the design of new alloys are going to open more fields for the application of powder metallurgy in various sectors. This not only will enhance the capability of the materials available but will also create opportunities for entirely new designs and functions. These include, for instance, the realization of various alloys designed for their particular use, like realizing highly specialized components with extreme conditions-for example, at high temperatures or in corrosive environments.

The powder metallurgy market is on a scale towards growth, spurred by demand for advanced material in critical industries. High setup costs and limited material choices are challenges, but continuous technological development will bring in rewarding opportunities. The market will be ready for changes that are made due to adaptation, which will enable potential benefits from powder metallurgy to be exploited. Indeed, the near future is promising to be highly grown, as growth in the upcoming years for the market is expected.

MARKET SEGMENTATION

By Material

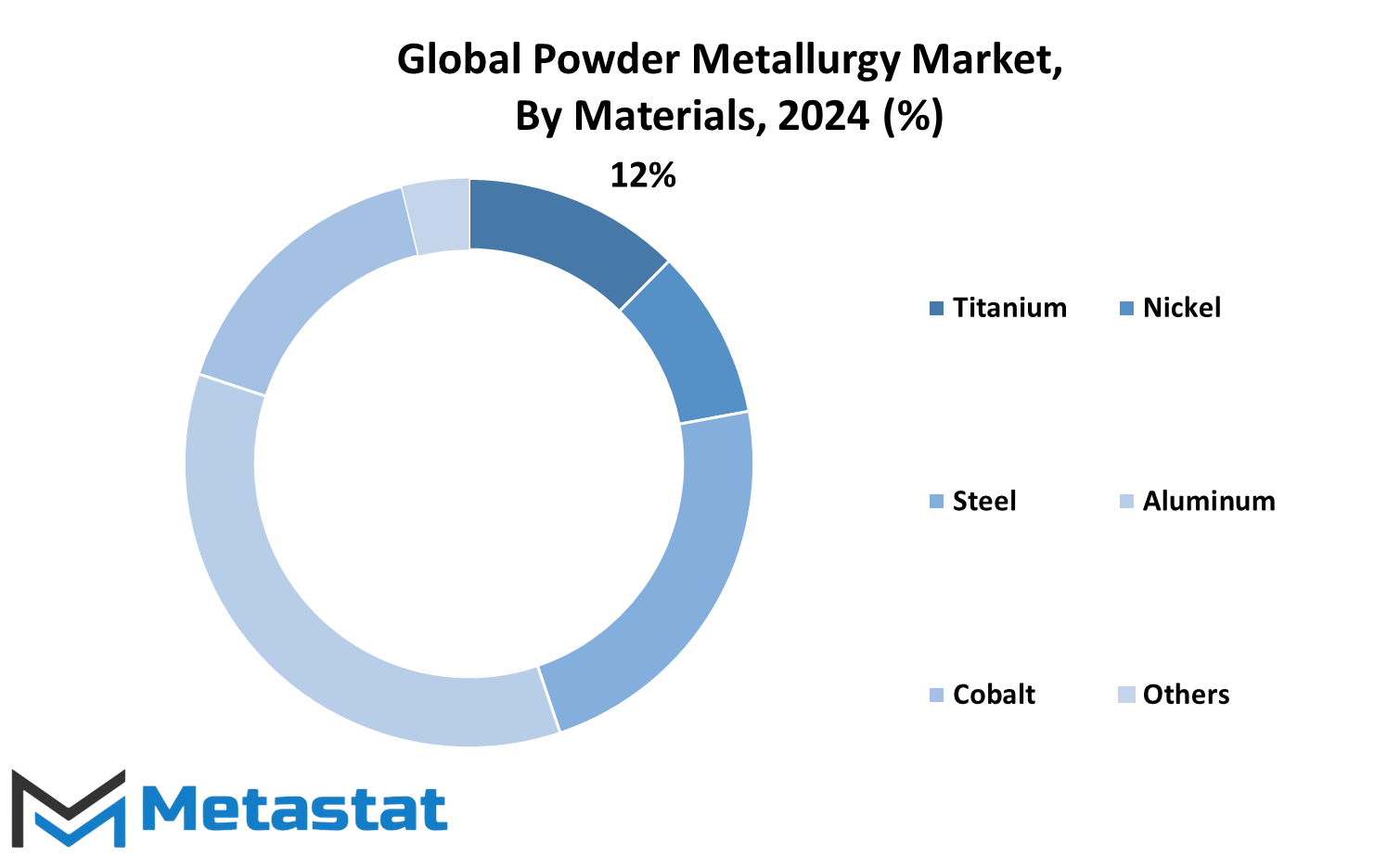

The worldwide powder metallurgy market is growing exponentially because the industries continue to seek the potentials of this manufacturing process. In this technique, the metal parts are made from powdered materials. These are compacted and then sintered together into a solid object. This technique has wide-ranging applications from autos to aerospace to electronics, and it exploits one-of-a-kind properties associated with powder metallurgy. Going forward, as the map of the market unfolds, segmentation into different types of materials would be key to a better understanding of what the future holds for the market.

Titanium is perhaps the most popular material in the global powder metallurgy market today. Its high strength-to-weight ratio over a broad range of strengths has enabled its increasing application in industries where either performance or durability is critical. Because of technology advancement and the introduction of newer classes of titanium materials, new applications for titanium powder should become available in aerospace, medical, and other high-performance areas. Moreover, titanium has inherent advantages toward reduced weight, which lend it to use by manufacturers to help save more fuel and reduce emissions.

Nickel is another critical material and is gaining significant attentions in this market. Its resistance towards corrosion and high temperatures make the material highly attractive for several applications that involve turbine blades and equipment used in chemical processing. High usage of nickel-based powders is likely to be found in advanced applications that require extreme condition-resistant material driven by the growing demand for energy-efficient technologies.

Steel will continue to dominate the global powder metallurgy market with a wide margin, primarily for its flexibility and economy. Process improvements will be at the top of most industries’ agendas, and the demand for steel powders would go up in both automotive and industrial applications. Steel powder production improvements would only mean the real ability of producers to add up weight to the components through increased strength without losing lightness.

Light in weight and with better machinability, aluminum is another material that also has been demanded in this market. Automobile industries are increasingly focusing on the reduction of vehicle weights to make them fuel efficient. Aluminum powders would be in great demand for such applications. The aluminum powder will thus be further engineered by manufacturers to be in tune with the demands of these new applications.

Cobalt is the least used of the metals listed but remarkable in its properties that make it essential in selected applications. Because of excellent hardness and wear resistance, cobalt shall be a material of choice in the production of cutting tools and high performance parts. Led by demand for performance and reliability, cobalt powders will find a sizeable market share.

Its development will also be driven by new products in the global powder metallurgy market. These will come in new powders that manufacturers will keep inventing to produce unique solutions for changing industry needs. In general, this is how the industry will approach segmentation by material in the global powder metallurgy market and drive innovation and growth as it helps industries develop advanced materials and products so well suited for a fast-changing world.

By Process

The Global Powder Metallurgy market is likely to grow strongly, driven by the increased uptake of advanced manufacturing processes in industries. Powder metallurgy stands out as, over time, it becomes technologically possible to make higher-quality components with superior precision. Innovations in the techniques used during the manufacturing process combined with an increase in demand for more efficient methods of production in all these sectors, like automotive, aerospace, and electronics, shape the market.

One of the main processes in this market is Additive Manufacturing, which lately has become a red-hot topic of interest. This technology builds parts layer by layer, thus it gives the designer freedom of designing geometries that have, to a large extent in past, been impossible to achieve with traditional manufacturing techniques. Additive manufacturing proves to be especially useful because it minimizes waste and could potentially shorten production times significantly. Most probably, efforts toward efficiency and sustainability will increase additive manufacturing demand in powder metallurgy and push these processes into many other diverse industries.

The second major process is Powder Metal Hot Isostatic Pressing, a process that increases the density and mechanical strengths of metal powders. This technique is used to expose the powder to high temperature in a controlled pressure environment, thereby creating extraordinary strength and durability components. It will heavily rely on this technique for those industries that require extreme conditions for the components, such as aerospace and defense. Improved material sciences will continue to promote new applications, which promises to make this process provide lightweight components with strength, meeting the biggest tasks involved in modern engineering.

Another vital segment of the Global Powder Metallurgy market is Metal Injection Molding (MIM). This process combines the benefits of plastic injection molding with that of powder metallurgy for enabling the mass production of complex shapes with tight tolerances. MIM is very valuable for the production of small, more complex parts that demand a high degree of precision and, therefore, is ideal in medical and electronic sectors. As manufacturers continue to look for ways to streamline operations and cut expenses, MIM will continue to grow in the powder metallurgy landscape.

In short, the Global Powder Metallurgy market continues down the trajectory of significant change. Additive Manufacturing, Powder Metal Hot Isostatic Pressing, and Metal Injection Molding process advances will unlock tens of thousands of opportunities for innovative, efficiency-centric solutions. As these techniques are embraced by industries, the market grows to offer solutions capable of serving very wide changing industry needs. Future of Powder Metallurgy: Bright is the future-a future where better, faster, and greener manufacturing techniques become more and more in our future horizon.

By End-use

The Global Metal Processing Machines market will undergo huge changes in the near future, mainly because of the latest innovation in the technology sector and the growing demand for the product across various industries. Automation and smart manufacturing constitute the most important primary driver for the market. Firms are now increasingly implementing advanced metal processing machines with higher precision, speed, and efficiencies. They will reduce the need for human intervention and increase productivity, thereby resulting in cost savings and better quality goods. As industries continue to mature, demand will be placed on machines that can accomplish complex tasks with minimal error, so as to smooth the production processes.

In the end, the global Powder Metallurgy market-one of the important segments of this larger category of metal processing machines-appears to consist almost entirely of Original Equipment Manufacturers (OEMs) and Additive Manufacturing (AM) operators. Given the kind of complex machinery required to produce metal parts for such applications as automotive, aerospace, and industrial machinery, OEMs will probably be of primary importance in that market. Along with these industries growing, the demand for specialized metal processing machines that suit their needs increases.

On the other hand, additive manufacturing operators will critically shape the emerging additive manufacturing technology, also called 3D printing. The operators need a machine to process metal powder into high-quality parts with an excellent level of detail and durability. This is one of the trends going on in customized production as industries adjust towards more highly specialized lots produced in smaller batches. The increased ability of metal processing machines to facilitate this trend will make them all the more valuable in the future.

Future sustainability will turn out to be a key driver in the Global Metal Processing Machines industry too. On the way to greener practices, companies want machines that consume less energy while having the capability of using greener materials. This transition will send manufacturers into more investment in R&D to make machines not only deliver in performance but also to reduce damage caused by metal processing in the environment.

Thus, the Global Metal Processing Machines market seems to have a bright future ahead in the form of innovative product development and growth driven by advancement in technology, rise in automation, and more recent focus on sustainability. Even though OEMs continue to play their role in shaping the market, there would still be opportunities for manufacturers, who can offer very customized and concentrated needs, to supply the necessary equipment to the AM operators. The market will either move forward in terms of being responsive to change and ready with answers that fit the sort of needs that will evolve over time or will be defined by the trajectory it takes in response to these changes.

|

Report Coverage |

Details |

|

Forecast Period |

2024-2031 |

|

Market Size in 2024 |

$2,985.3 million |

|

Market Size by 2031 |

$4,425.1 Million |

|

Growth Rate from 2024 to 2031 |

6.2% |

|

Base Year |

2022 |

|

Regions Covered |

North America, Europe, Asia-Pacific Green, South America, Middle East & Africa |

REGIONAL ANALYSIS

Based on geography, the global Powder Metallurgy market is divided into North America, Europe, Asia-Pacific, South America, and Middle East & Africa. North America is further divided in the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and Rest of Europe. Asia-Pacific is segmented into India, China, Japan, South Korea, and Rest of Asia-Pacific. The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and Rest of Middle East & Africa.

COMPETITIVE PLAYERS

Key players operating in the Powder Metallurgy industry include Molyworks Materials Corporation, Advanced Technology & Materials Co., Ltd. (AT&M), JSC POLEMA, Sandvik AB, Höganäs AB, GKN PLC, Rio Tinto Metal Powders, Rusal, CRS Holdings Inc., Liberty House Group, AP&C (Advanced Powders & Coatings), ATI Powder Metals, Aubert & Duval, Fine Sinter Co., Ltd., Kennametal Inc., Hitachi Chemical Co., Ltd.

Powder Metallurgy Market Key Segments:

By Material

- Titanium

- Nickel

- Steel

- Aluminum

- Cobalt

- Others

By Process

- Additive Manufacturing

- Powder Metal Hot Isostatic Pressing

- Metal Injection Molding

By Application

- Aerospace & Defense

- Automotive

- Oil & Gas

- Industrial

- Medical & Dental

By End-use

- OEMs

- AM Operators

Key Global Powder Metallurgy Industry Players

- Molyworks Materials Corporation

- Advanced Technology & Materials Co., Ltd. (AT&M)

- JSC POLEMA

- Sandvik AB

- Höganäs AB

- GKN PLC

- Rio Tinto Metal Powders

- Rusal

- CRS Holdings Inc.

- Liberty House Group

- AP&C (Advanced Powders & Coatings)

- ATI Powder Metals

- Aubert & Duval

- Fine Sinter Co., Ltd.

- Kennametal Inc.

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252