Global Plain Bearings Market - Comprehensive Data-Driven Market Analysis & Strategic Outlook

The global plain bearings market and its industry were born out of some of the most basic engineering problems of the early industrial era. In the late 1800s, factories were in a hurry to manufacture speedier machines, but the rotating parts were still suffering from quick wear and tear because of friction and bad lubrication. The first inventors experimented with bronze, wood, and even animal fat just to keep the shafts rotating. These rough experiments were very much needed because heavy machinery would come to a halt if there was no reliable sliding support. Slowly, when engineers found that the life of machines could be increased by putting soft metals like babbitt between the moving parts, a silent breakthrough occurred. It allowed the factories to take their production to the next level without the need for constant repairs.

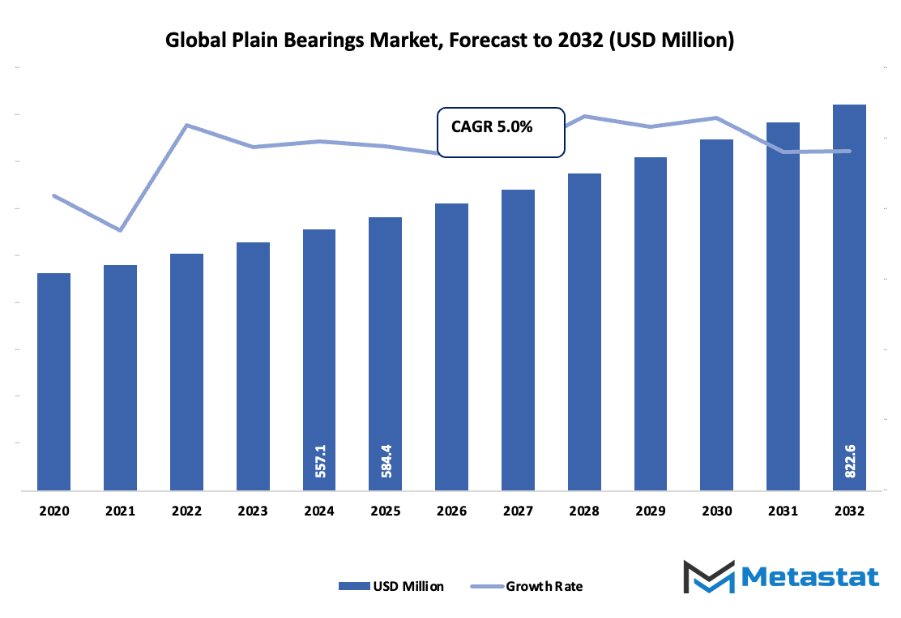

- The global plain bearings market was valued at about USD 12.8 million in 2025 and is expected to grow at a CAGR of around 5.5% until 2032, thereby exceeding USD 18.6 million

- The journal paper accounts for almost 32.7% of the market share, where the company focuses on innovation and applying high-tech research.

- The key trends are: the compact and low-maintenance machinery demand in industrial applications is rising, and the trend of using more and more of these products in automotive and heavy equipment for load-carrying and motion control is on the rise as well.

- One of the opportunities is seen in the area of developing advanced materials (for instance, self-lubricating composites, polymers) for high-performance applications.

- The market insight is that it is going to skyrocket in value over the next decade, henceforth, it is a good time to invest.

By the very beginning of the 20th century, rail and steam turbine technologies necessitated the creation of bearings that were not only capable of bearing the heaviest loads but also able to resist heat and vibration to a certain extent. Material Science, however, was the ultimate solution. The process of making bronze alloys was further improved and thus engineers could start working on shaping the surfaces of bearings with the utmost precision. The coming of automobiles was the one that changed the industry forever. The car engines relied on plain bearings for the smooth rotation of crankshafts, and the volume of production forced the suppliers to continuously improve the factors of consistency and durability. The war caused the allocation of the research funds to the development of the aluminum alloys, which the latter made possible to produce bearings that could bear the high-speed process.

With the turn of the century towards the late twentieth century polymeric and composite materials started dominating the markets plastics and composites were the new materials on the playing field. The new designs provided bearings with very low or no lubrication. Thus maintenance and running times were not any longer the issues with machines as the new products corresponded exactly to the growing factor of maintenance-free machines and longer operation times. Computer technology had then entered the manufacturing process allowing the engineers to simulate the friction and the wear before even producing the prototype. Thus development cycle time was shortened and waste was reduced.

The future of global plain bearings market will be determined today by such industries as renewable energy, electric cars, and automated factories. One of the things that modern customers look for in a component is its long life and quiet operation, plus the fact that the component facilitates the adoption of manufacturing cleaner processes. Regulatory bodies that control environment matters also contribute to the elimination of excess grease and oil from factories and this has resulted in promoting the materials that are capable of being run dry and the implementation of new surface treatments that are less sensitive to wear. It might not be long before sensors get integrated into the bearing housing thereby making it possible for the machinery to monitor its condition and plan maintenance activities even before a breakdown occurs.

This journey from the artisanal production of bronze sleeves to the high-tech composites formed using digital models is a good indication that the global plain bearings market will continue to reflect the way different industries cope with friction, durability, and efficiency in the machines that are responsible for technological advancement.

Market Segments

The global plain bearings market is mainly classified based on Type, End-use Industry.

By Type is further segmented into:

- Journal: Journal bearings provide support to a rotating shaft with a smooth surface that allows steady movement even under load. The bearing continues to perform its function while reducing friction owing to a lubricated contact surface that is formed between the bearing and the shaft during rotation. This reliability of performance is the reason for the use of such bearings in heavy-duty machines, where smooth motion and heat that is controlled are necessary for long operating cycles.

- Linear: Linear bearings allow motion only in one direction, and that is in a straight line. The bearing design permits the machine part that needs to travel forward or backward along a fixed track to do so in a clean and steady way. The design minimizes the force of friction and at the same time, the support for positioning is very precise, which enables the machine to obtain accurate locations during the production processes that involve repeated cycles.

- Thrust: Thrust bearings are able to resist axial loads that are directed in only one direction. The design of this type of bearing puts the contact surfaces in such a way that the load from a rotating part is gradually transferred over the bearing. The bearing is designed to provide support and reduce friction when machinery requires stable rotation under high forward force, thus contributing to the reliable performance of the entire equipment.

- Angular Contact: Angular contact bearings can bear both axial and radial loads at the same time. The shaping of the raceways is at a slope that enables the bearing to resist movement even when there is pressure coming from different directions. The design allows for strong support during high speeds or varying forces, which results in longevity and helps the machine to keep its alignment accurately in difficult conditions.

- Spherical Bearings: Spherical bearings permit turning and still tolerating slight misalignment between the machine parts that are connected. A matching outer ring has a curved inner surface that moves easily against it; thus, it is able to take the load from different directions. The letting go of the movement helps the machine to perform if the mounting surfaces are not perfectly aligned or when there is a slight vibration during the operation.

- Others: Other bearings in this group represent special-purpose designs that cater to certain movement needs or heavy-load applications. The use of customized shapes or materials helps to support uncommon motion patterns, reduce friction, and enhance the life of the machine. The choice of bearing is based on the machine's structure, desired motion type, and environmental factors like temperature, humidity, or constant vibration.

By End-use Industry the market is divided into:

- Automotive and Transportation: Automotive and transportation equipment depend on bearings for smooth movement of steering systems, engines, and suspension parts. Reduced friction helps create steady motion, longer part life, and quiet operation. Reliable movement allows strong performance in vehicles, rail systems, and transport machinery that demand predictable function and controlled wear.

- Manufacturing: Manufacturing facilities depend on bearings to guide machine parts through continuous cycles. Accurate movement supports cutting tools, conveyor systems, and automated stages that place materials in exact positions. Reduced friction lowers energy use and maintains consistent output, helping production lines maintain dependable timing during multiple shifts.

- Aerospace and Defense: Aerospace and defense machinery requires bearings that handle strong force, vibration, and extreme conditions. Precision movement improves safety and reliability during high-speed rotation or rapid direction change. Bearings with durable materials support strict performance demands and help keep advanced systems functioning during repeated missions or long-distance travel.

- Energy and Utilities: Energy and utility operations use bearings in turbines, pumps, and generators. Continuous rotation needs stable support, low friction, and safe heat control. Bearings help maintain steady output and reduce downtime by supporting heavy loads while limiting wear, which helps plants and utility stations reach expected performance targets.

- Construction: Construction machinery needs bearings that handle heavy loads and frequent movement over rough ground. Bearings help large equipment remain steady during lifting, digging, or pushing tasks. Strong surfaces and reduced friction support motion under pressure, improving durability and lowering the chance of mechanical failure during extended shifts.

- Marine: Marine equipment experiences moisture, salt, and vibration. Bearings chosen for marine use resist corrosion and maintain movement under unstable conditions. Steady rotation and strong support allow propulsion systems, winches, and steering parts to function smoothly, even when machinery faces constant movement from waves and shifting load.

- Agriculture: Agriculture machinery depends on bearings for smooth function in soil, dust, and frequent outdoor exposure. Bearings support rotation and sliding motion during planting, harvesting, and material handling. Strong materials and low friction extend machine life and allow steady operation through long days in changing field conditions.

- Others: Other industries adopt bearings for specialized equipment that requires consistent movement and reduced wear. Custom material choices or unique shapes support tasks that regular bearings cannot handle. The selection depends on environmental demands, load type, and movement style, helping machinery remain dependable during repeated cycles.

|

Forecast Period |

2025-2032 |

|

Market Size in 2025 |

$12.8 Million |

|

Market Size by 2032 |

$18.6 Million |

|

Growth Rate from 2025 to 2032 |

5.5% |

|

Base Year |

2024 |

|

Regions Covered |

North America, Europe, Asia-Pacific, South America, Middle East & Africa |

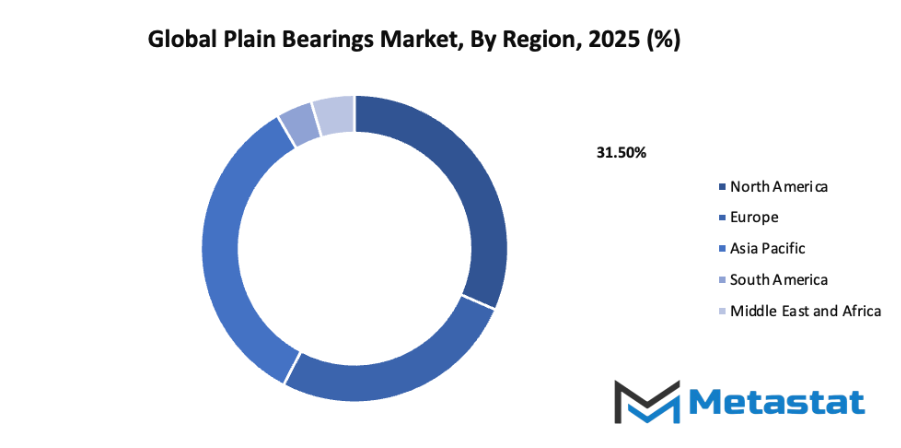

By Region:

- Based on geography, the global plain bearings market is divided into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

- North America is further divided into the U.S., Canada, and Mexico, whereas Europe consists of the UK, Germany, France, Italy, and the Rest of Europe.

- Asia-Pacific is segmented into India, China, Japan, South Korea, and the Rest of Asia-Pacific.

- The South America region includes Brazil, Argentina, and the Rest of South America, while the Middle East & Africa is categorized into GCC Countries, Egypt, South Africa, and the Rest of the Middle East & Africa.

Growth Drivers

Growing demand for compact and low-maintenance machinery in industrial applications: Growing focus on smaller, simpler machinery encourages greater use of plain bearings across factories and production facilities. Reduced maintenance needs support longer operating hours and lower downtime. As a result, many manufacturers choose this component to improve reliability. This trend strengthens demand across the global plain bearings market, especially where space and maintenance access are limited.

Increasing use in automotive and heavy equipment for load-bearing and motion control: Automotive, construction, and mining equipment require steady load support and smooth motion during continuous operation. Plain bearings offer strong load distribution and resistance to harsh working environments. Adoption in engines, suspension systems, and hydraulic setups continues to expand because steady performance helps maintain consistent movement and stable equipment function.

Challenges and Opportunities

Higher friction and heat generation compared to rolling-element bearings: Plain bearings may create greater friction during rotation, leading to heat buildup that can shorten service life. Extra cooling solutions or lubrication procedures may be required, raising overall operating costs. This factor can influence purchasing decisions, especially when engineers compare multiple bearing technologies for efficiency and long-term performance.

Limited speed and motion efficiency in high-speed applications: Plain bearings deliver strong support during heavy loads, yet performance often declines under extreme rotation speeds. Reduced efficiency under rapid movement can lead to energy loss and uneven wear. Engineers sometimes select other bearing options for systems that require continuous rapid rotation and constant high-speed precision.

Opportunities

Development of advanced materials (self-lubricating composites, polymers) for high-performance applications: Material technology progress opens new possibilities for longer service life and reduced wear. Self-lubricating polymers and composite materials lower friction, reduce maintenance needs, and support heavier workloads. These advancements encourage broader adoption across new industrial designs, allowing manufacturers to meet demanding performance targets while minimizing frequent maintenance procedures.

Competitive Landscape & Strategic Insights

The global plain bearings market demonstrates a balanced mix of major international corporations and rapidly developing regional participants. Competition remains strong, with both established companies and new entrants working to expand their share through innovation, quality, and performance. Prominent companies influencing this sector include SKF Group, Timken Company, NTN Corporation, Schaeffler AG, SGL Carbon, THK Co., Ltd., RBC Bearings Incorporated, ElringKlinger AG, Bearing Boys Ltd., AST Bearings LLC, igus, Thomson Industries, Inc., GGB Bearing Technology, PBC Linear, Barden Corporation, AEC, IKO International, HepcoMotion, Alloy Bearings, and Emerson Bearing. Each of these companies contributes to shaping the direction of the market through continued improvements in design and manufacturing techniques.

The market’s growth is largely driven by rising industrial automation, increased demand in automotive applications, and the ongoing need for durable and efficient mechanical components. Companies continue to invest in advanced materials and precision engineering to improve performance and reduce maintenance costs. Global competition encourages constant innovation, ensuring that product quality and reliability remain top priorities. Regional manufacturers often focus on cost-effective solutions, while larger international firms emphasize technological development and expansion into emerging markets.

Sustainability also plays an increasing role in market development. Many companies are focusing on energy-efficient designs and eco-friendly production processes. The use of advanced composite materials helps enhance durability and reduce friction, resulting in longer product lifespans and lower operational costs. Partnerships and collaborations among key market players help accelerate technological progress and support wider availability of customized solutions.

Market size is forecast to rise from USD 12.8 million in 2025 to over USD 18.6 million by 2032. Plain Bearings will maintain dominance but face growing competition from emerging formats.

Overall, the global plain bearings market continues to grow through innovation, collaboration, and attention to quality. The presence of both leading corporations and strong regional competitors ensures a dynamic environment where efficiency, performance, and sustainability will guide future advancements.

Report Coverage

This research report categorizes the global plain bearings market based on various segments and regions, forecasts revenue growth, and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the global plain bearings market. Recent market developments and competitive strategies such as expansion, type launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the global plain bearings market.

Plain Bearings Market Key Segments:

By Type

- Journal

- Linear

- Thrust

- Angular Contact

- Spherical Bearings

- Others

By End-use Industry

- Automotive and Transportation

- Manufacturing

- Aerospace and Defense

- Energy and Utilities

- Construction

- Marine

- Agriculture

- Others

Key Global Plain Bearings Industry Players

- SKF Group

- Timken Company

- NTN Corporation

- Schaeffler AG

- SGL Carbon

- THK Co., Ltd.

- RBC Bearings Incorporated

- ElringKlinger AG

- Bearing Boys Ltd.

- AST Bearings LLC

- igus

- Thomson Industries, Inc.

- GGB Bearing Technology

- PBC Linear

- Barden Corporation

- AEC

- IKO International

- HepcoMotion

- Alloy Bearings

- Emerson Bearing

WHAT REPORT PROVIDES

- Full in-depth analysis of the parent Industry

- Important changes in market and its dynamics

- Segmentation details of the market

- Former, on-going, and projected market analysis in terms of volume and value

- Assessment of niche industry developments

- Market share analysis

- Key strategies of major players

- Emerging segments and regional growth potential

US: +1 3023308252

US: +1 3023308252