Nov 07, 2025

The global plain bearings market, as illustrated by Metastat Insight, has gained new significance in an industrial world where efficiency, longevity, and dependability are the main traits of modern progress. The automotive sector along with energy and power transmission sectors are just a few examples where manufacturers keep using friction management to get the most out of their equipment and nothing less than a longer life expectancy. These friction reducing devices, at times not even noticed, but still very much needed, do play an important part in making all mechanical systems work smoothly and steadily. As technology gets more advanced, and a shift towards less maintenance and more efficient systems takes place, the role of plain bearings is gradually turning to be of strategic importance. The market is witnessing a shift in thinking that quality mechanical motion is the main element of productivity in every sector.

Industry context and mechanical necessity

The industrial world is grappling with the demands of high automation, heavy operating loads, and strict environmental standards. These challenges emphasize the necessity for parts that can reliably perform over long life cycles and at the same time require low maintenance. Conventional bearing solutions in these cases get more often the brunt of harsh conditions or contamination resulting to their quick deterioration or costly downtimes.

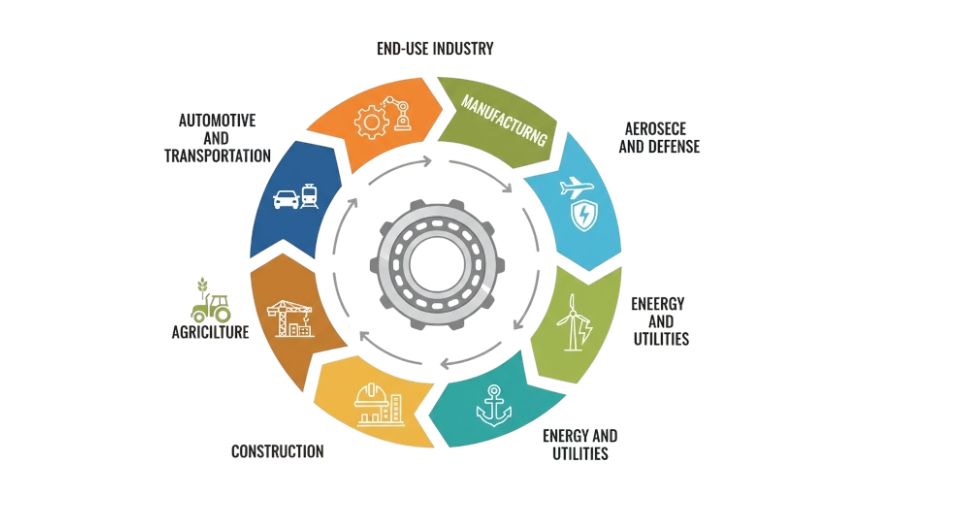

In this scenario, the global plain bearings market operates as a vital bridge linking mechanical reliability and operational continuity. Users are always on the watch for products that can carry heavy loads, do not get crushed, and perform even when the lubrication is very limited. The ability to change applications with no hassle has won them over in the areas of transportation, heavy machinery, and renewable energy making these products a must-have factor not only in design but manufacturing as well.

Operational principles and functional value

Plain bearings are based on a simple yet very effective principle smothly sliding of two surfaces with very little friction. The way they are made can be different depending on the type of materials they are made of, metallic, composite or polymer based materials, each of them selected for particular performance characteristics. The advantages are reduced complexity, long life and resistance to rust or misalignment.

These bearings in many industries are priced lower than the rolling types, particularly where high load or oscillatory movements are. Cutting-edge material science has made them more valuable by providing self-lubricating surfaces and eco-friendly designs which prolong usability without the need for frequent maintenance Interventions. Innovations have thus made these bearings go from industrial heavy-duty machines to precision systems that need quiet, stable motion.

Evolution and technological advancement

The journey of the global plain bearings market has paralleled the larger industrial movement towards efficiency and sustainability. The first generations of bearings were just simple metal sleeves; now, engineering has produced something like lightweight composites that have better load-carrying capacities and better wear resistance. Gradually the coating technologies have been improved and the advanced sintering methods have been developed which have resulted in the performance being more reliable.

Adoption rates have increased slowly but steadily as a result of the combination of high durability requirements and the tendency for operation to be done without lubrication, the so-called “clean” operation. This steady progress has allowed the technology to penetrate multiple industrial sectors, from the conventional power generation to the transportation and aerospace of the future. Manufacturers have slowly but surely refined p over time.

Geographical adoption and growth landscape

Adoption of plain bearings varies significantly across regions, reflecting industrial maturity and production intensity. Established manufacturing regions exhibit sustained demand due to expansive automotive and machinery sectors. Advanced engineering standards and established supply networks reinforce their continued presence in these areas. Meanwhile, emerging industrial economies demonstrate accelerated adoption as investments in infrastructure, manufacturing, and transportation systems rise.

Growth momentum in these regions often aligns with localized initiatives to improve domestic component production, reducing import reliance while enhancing machinery resilience. The balance between mature and expanding regions underscores the market’s global resilience and the universal importance of mechanical reliability.

Barriers and emerging prospects

While progress continues, challenges persist in material costs, manufacturing precision, and competition from alternative bearing technologies. Fluctuations in raw material availability can affect production economics, while regulatory expectations related to sustainability drive the search for greener alternatives. Manufacturers continue to address these pressures through research into bio-based materials, adaptive lubrication methods, and design standardization.

Opportunities remain abundant as new technologies create synergies across sectors particularly with electric mobility, automation, and renewable energy systems. Integration with digital monitoring platforms and condition-based maintenance frameworks could further elevate their role in predictive performance management.

Relevance in the current industrial shift

The importance of the global plain bearings market presented by Metastat Insight now extends beyond mechanical motion to strategic alignment with global industrial transformation. As sustainability, energy efficiency, and circular design principles reshape manufacturing philosophies, reliable friction control components become vital contributors.

Their role in minimizing energy loss, extending machinery lifespan, and supporting eco-friendly operations places them at the intersection of technological responsibility and performance optimization. With industries seeking cost stability and operational resilience, the bearing sector serves as a reminder that incremental mechanical improvements can yield substantial systemic gains.

In a world striving for cleaner processes and longer-lasting machinery, the global plain bearings market presented by Metastat Insight represents more than a supply chain category it symbolizes the foundation of efficient movement. Its continued evolution, grounded in material science and practical engineering, reinforces its position as a quiet enabler of industrial progress and a key influence on the direction of mechanical design in the years ahead.

Drop us an email at:

Call us on:

+1 214 613 5758

+91 73850 57479